Rotary compressor and heat pump system

a compressor and heat pump technology, applied in the field of rotary compressors, can solve the problems of increasing the temperature of the compressor, reducing the capacity and efficiency of the compressor, and reducing the volume of intake refrigerant, so as to achieve the effect of ensuring the reliability of the compressor, improving the efficiency of the compressor, and low cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

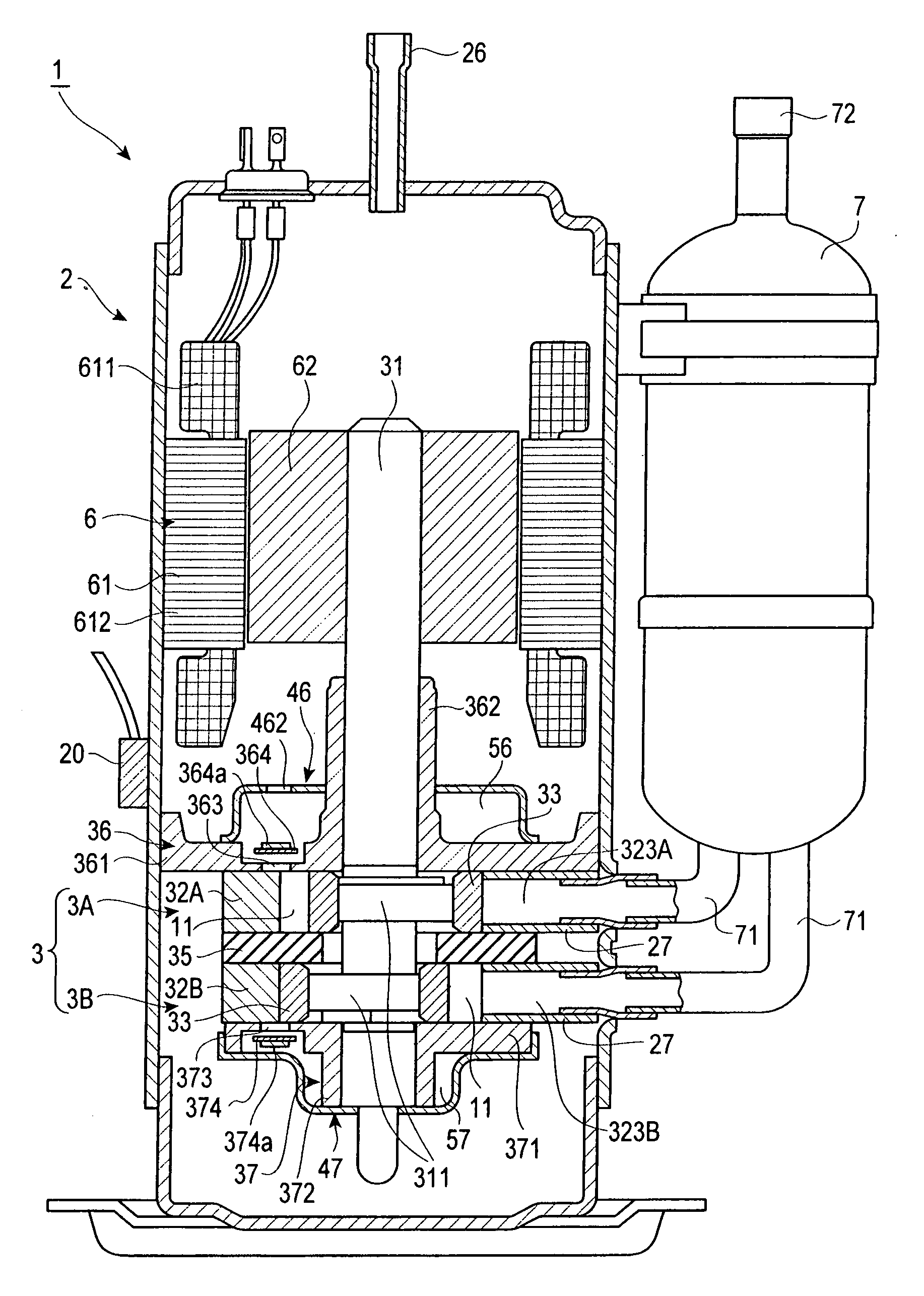

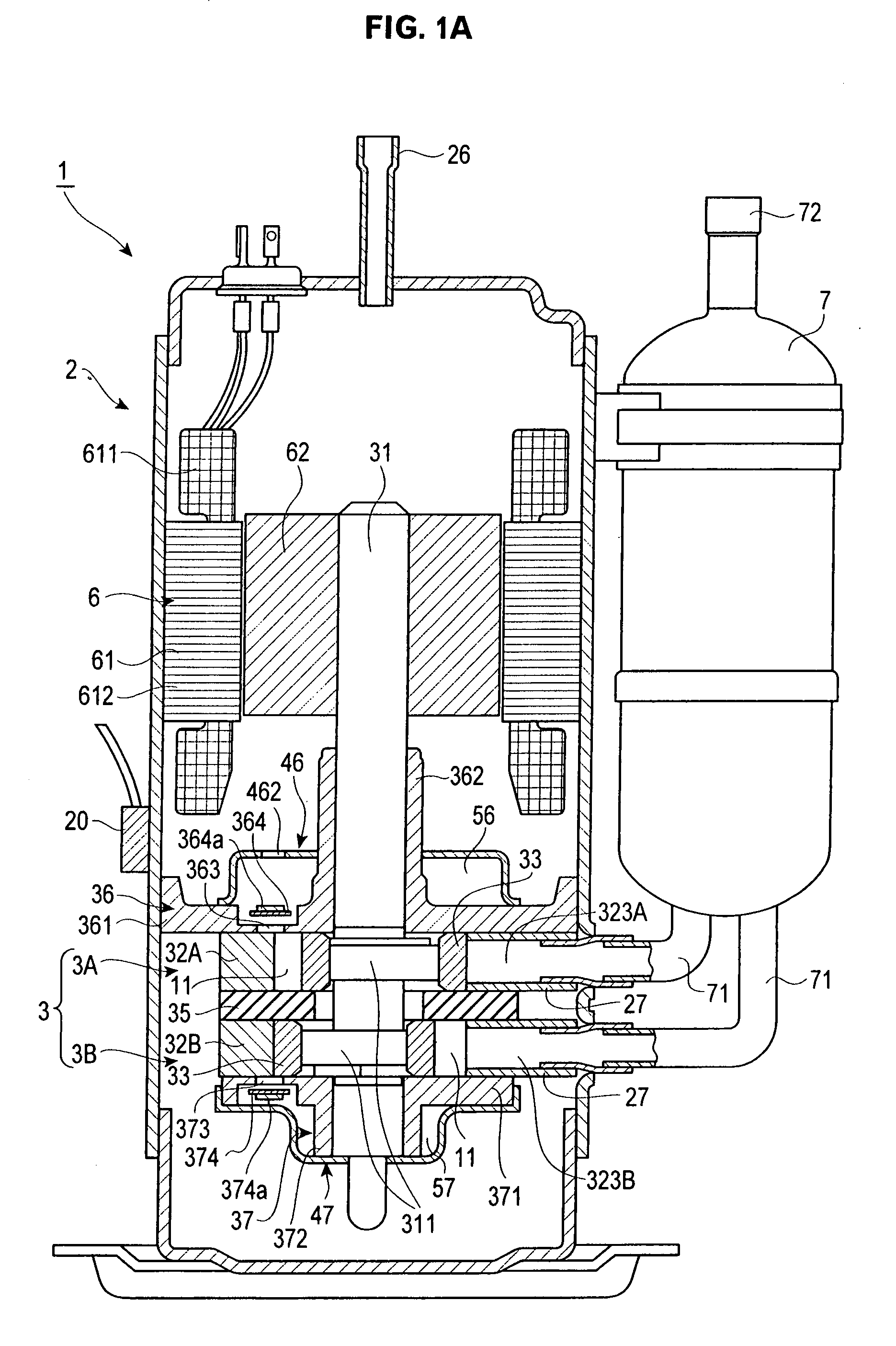

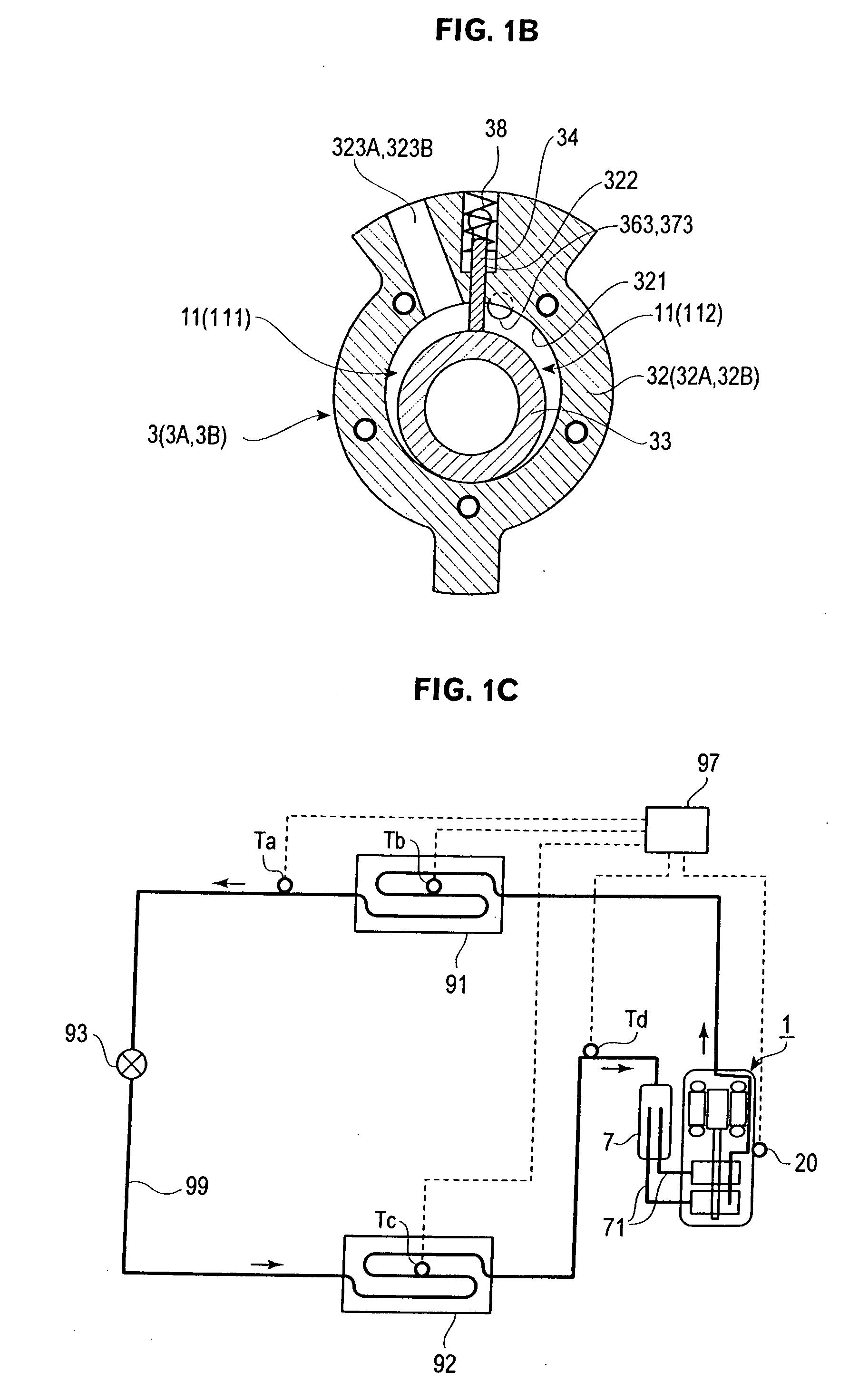

first embodiment

[0081]Thereby, the difference between the closed container temperature in the portion in which the discharge temperature sensor 20 is mounted and the refrigerant temperature immediately after the discharge from the compression section can be made small as compared with the first embodiment, so that the degree of superheat of intake refrigerant can be kept proper with higher accuracy.

[0082]Next, a third embodiment of the present invention is explained with reference to FIGS. 3A and 3B. FIG. 3A is a perspective view of the upper muffler cover of a rotary compressor in accordance with the third embodiment of the present invention, and FIG. 3B is a partial sectional view of a lower part of the rotary compressor in accordance with the third embodiment of the present invention. In FIGS. 3A and 3B, the same reference symbols are applied to elements that are the same as those in FIG. 1A showing the first embodiment, and the detailed explanation thereof is omitted. The refrigeration cycle is...

third embodiment

[0083]As shown in FIG. 3A, in the third embodiment, a cut and raised part 465 capable of being pressed simultaneously with the pressing of the whole of the upper muffler cover is provided in the end plate part 463 of the upper muffler cover 46.

[0084]As shown in FIG. 3B, the cut and raised part 465 is open toward the inner peripheral surface of the closed container 2 as the upper muffler discharge hole 462 so that the refrigerant discharged from the upper muffler chamber 56 is sprayed directly onto the inner peripheral surface of the closed container 2. Further, the discharge temperature sensor 20 is mounted on the outer peripheral surface of the closed container 2 opposed to the sprayed portion.

second embodiment

[0085]Thereby, the upper muffler discharge hole 462 that is open toward the inner surface of the closed container can be formed without separately fabricating the side plate part 464 of the upper muffler cover 46 as compared with the second embodiment, so that the degree of superheat of intake refrigerant can be kept proper with high accuracy at a lower cost.

[0086]Next, a fourth embodiment of the present invention is explained with reference to FIG. 4. FIG. 4 is a partial sectional view of the lower part of a rotary compressor in accordance with the fourth embodiment of the present invention. In FIG. 4, the same reference symbols are applied to elements that are the same as those in FIG. 1A showing the first embodiment, and the detailed explanation thereof is omitted. The refrigeration cycle is the same as that in the first embodiment shown in FIG. 1C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com