Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

182results about How to "Improve compressor efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

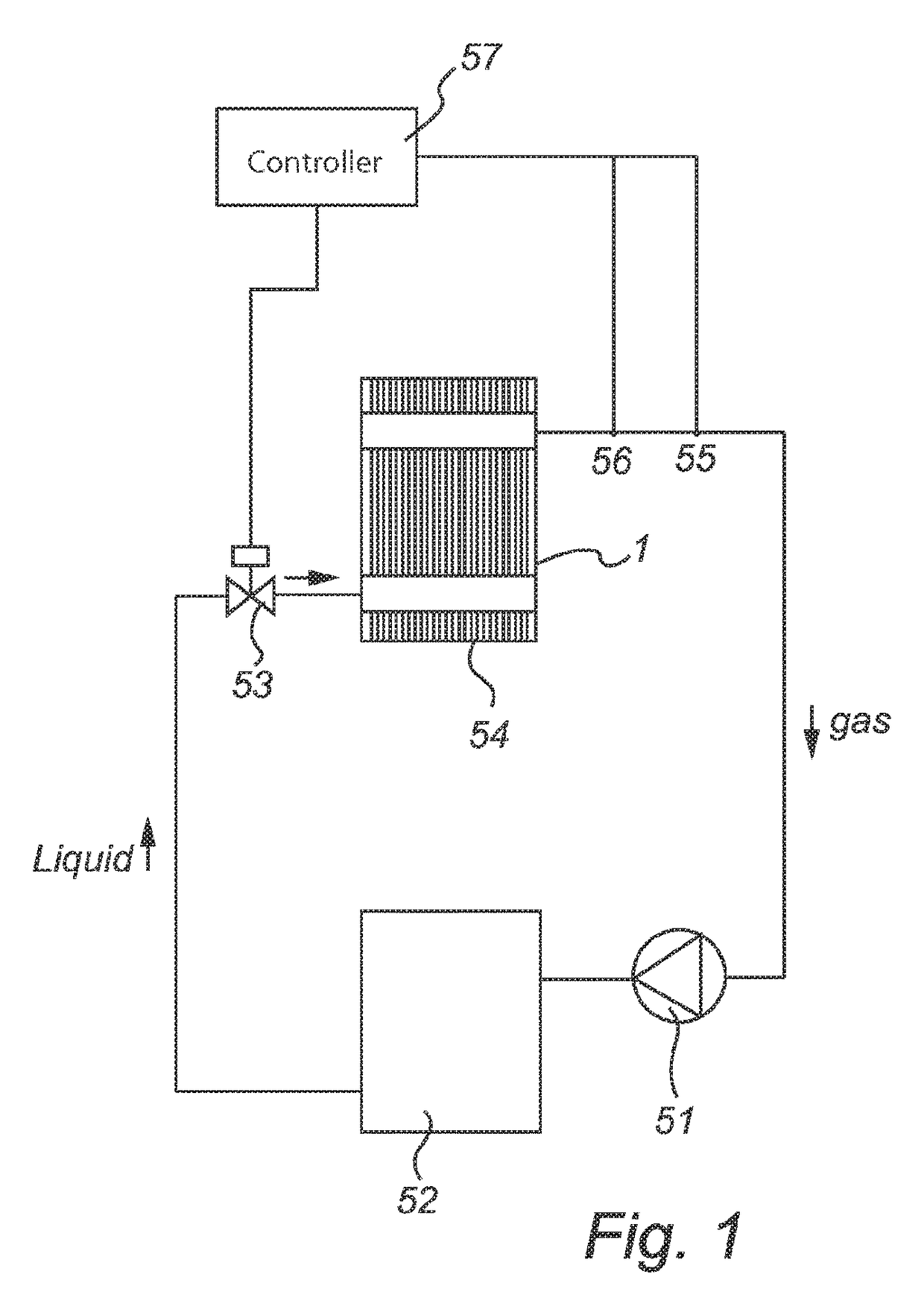

System and method for dynamic control of a heat exchanger

InactiveUS20170167810A1Easy to controlImprove plating efficiencyMechanical apparatusEvaporators/condensersProcess engineeringFluid supply

The present application relates to a system for dynamic control of the operation of a heat exchanger, the system comprising a heat exchanger, a plurality of injector arrangements, a local sensor arrangement, and a controller, wherein the local sensor arrangement comprises a plurality of local temperature sensors being arranged to measure temperature values; and wherein the controller is arranged to determine a difference between the measured temperature values and is further arranged to communicate with the valves of the plurality of injector arrangements to adjust the local amount of first fluid supplied by at least one of the injector arrangements in order to even out the determined difference. The application also relates to a method for the dynamic control of the operation of a heat exchanger in such a system.

Owner:ALFA LAVAL CORP AB

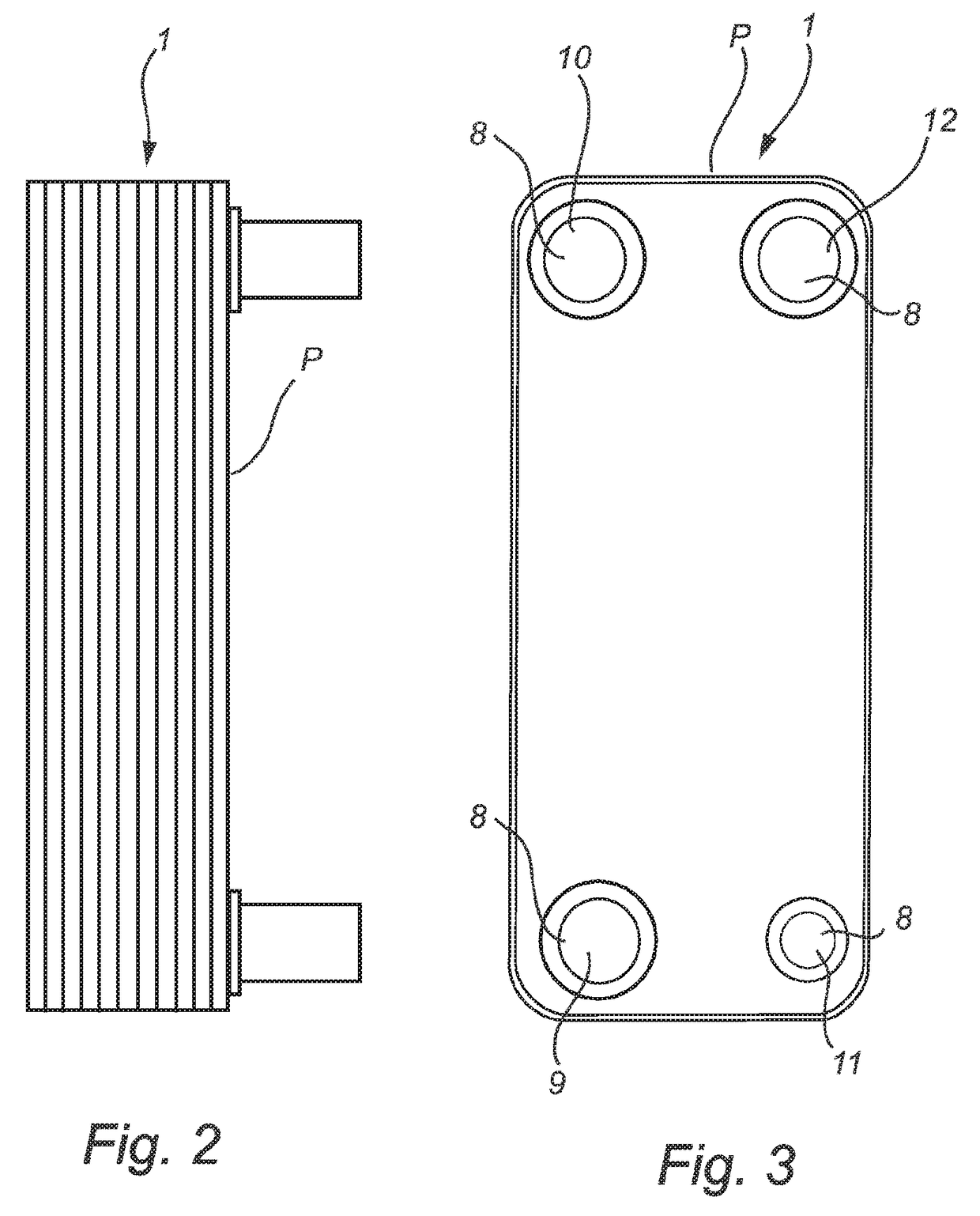

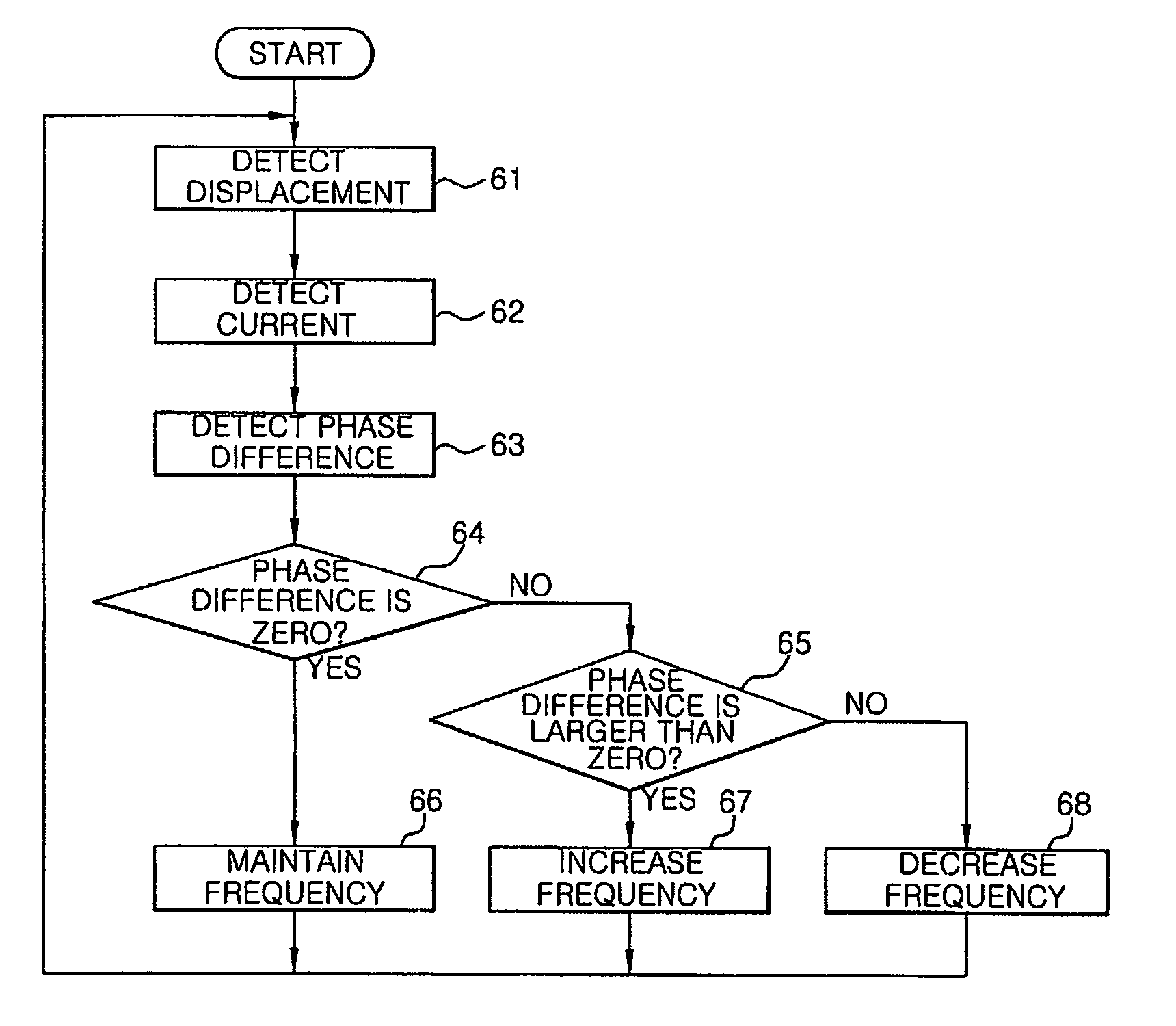

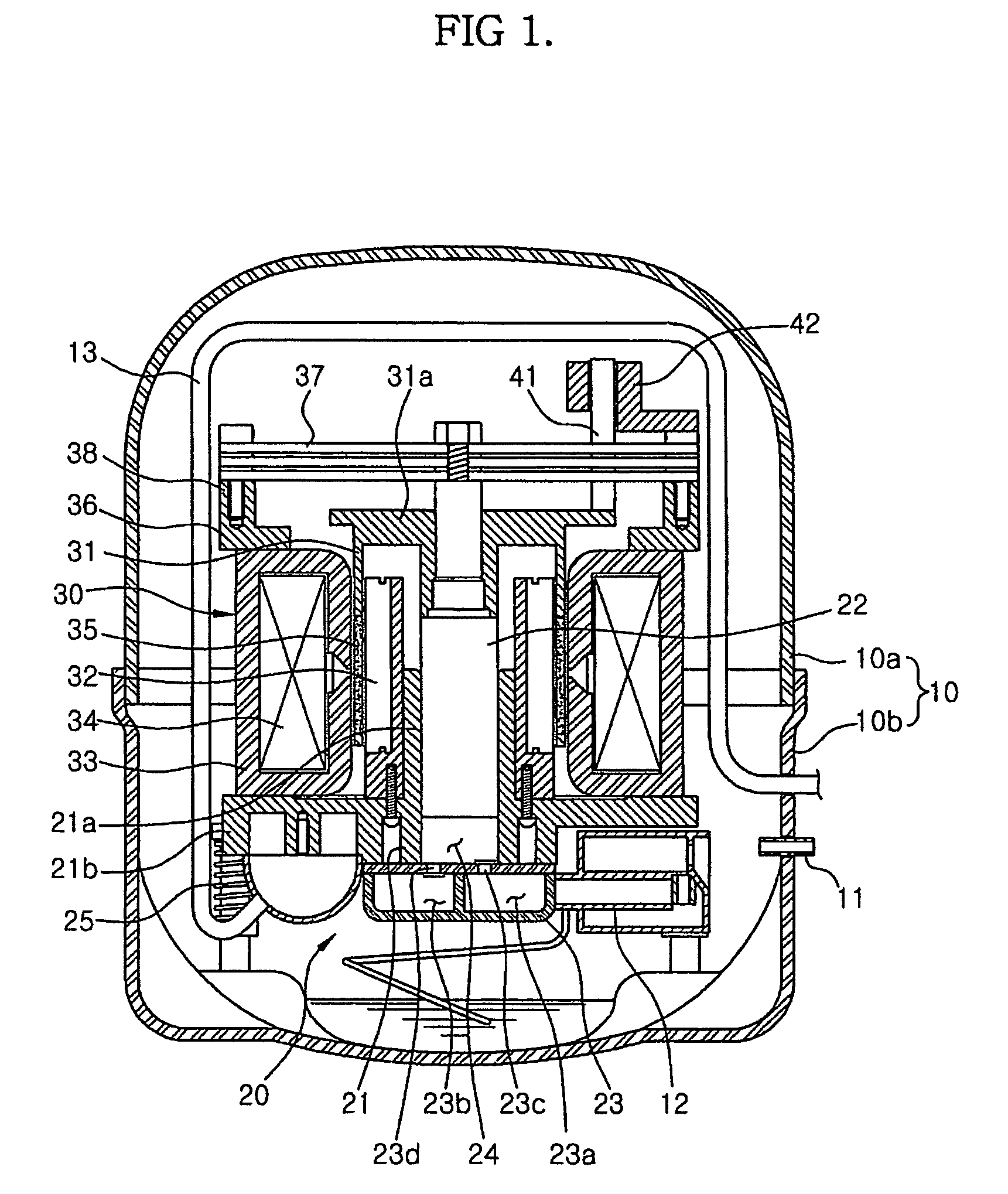

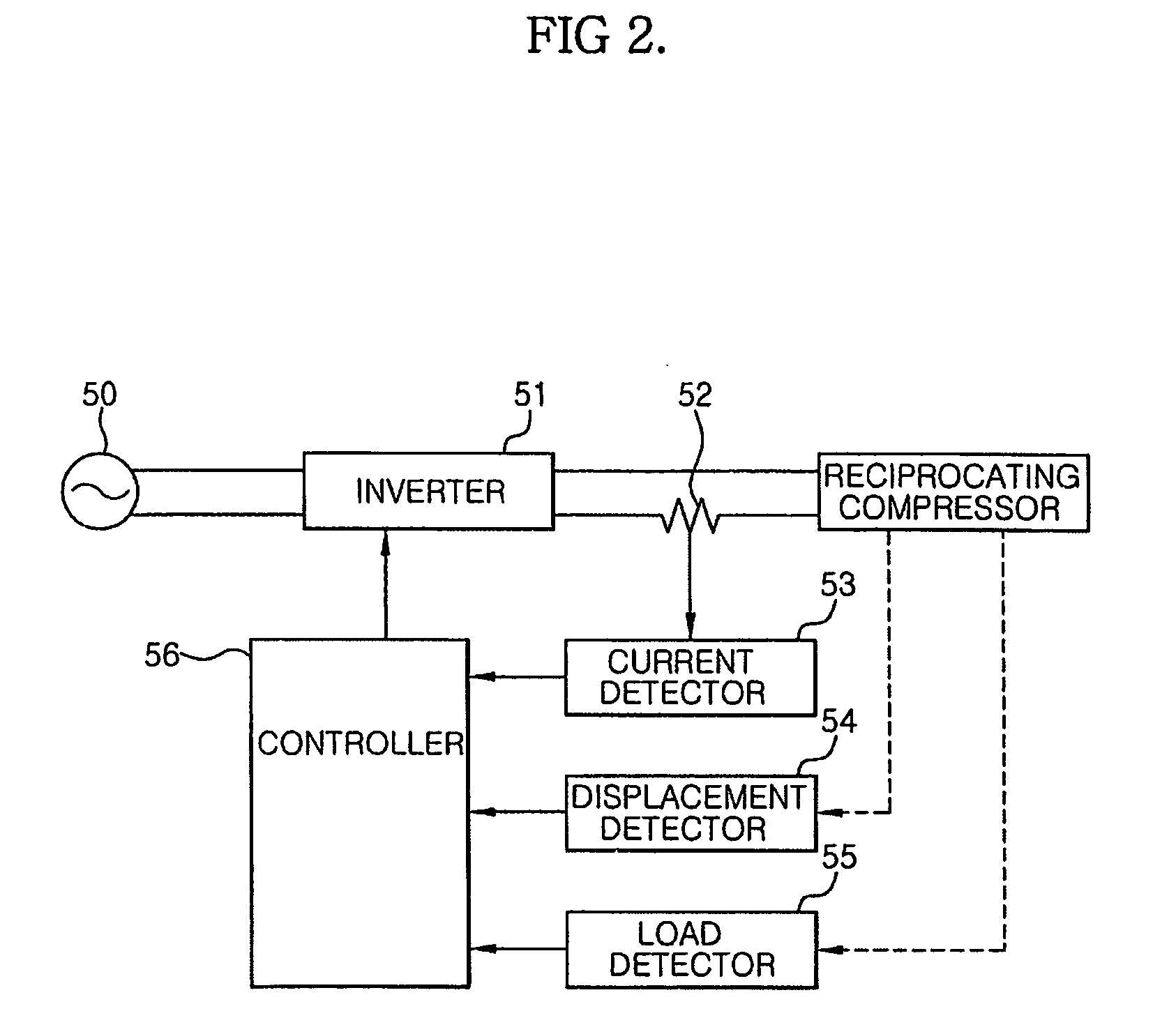

Reciprocating compressor, driving unit and control method for the same

InactiveUS20050271526A1Improve efficiencyImprove compressor efficiencyMotor parameterPump parameterEngineeringReciprocating compressor

A driving unit and control method for a reciprocating compressor for controlling a frequency of input power so that an operational frequency of the compressor follows a resonant frequency, which varies depending on a variation of the load applied to the compressor. The reciprocating compressor includes an inverter to adjust the frequency of the input power, so that the frequency of the input power is set at a value corresponding to the resonant frequency by the inverter. The resonant frequency is set in a range of 60% to 90% of the normal power frequency. The compressor further includes a controller to control the frequency of the input power so that the operational frequency of the compressor follows the resonant frequency, which varies depending on the operation of the compressor.

Owner:SAMSUNG ELECTRONICS CO LTD

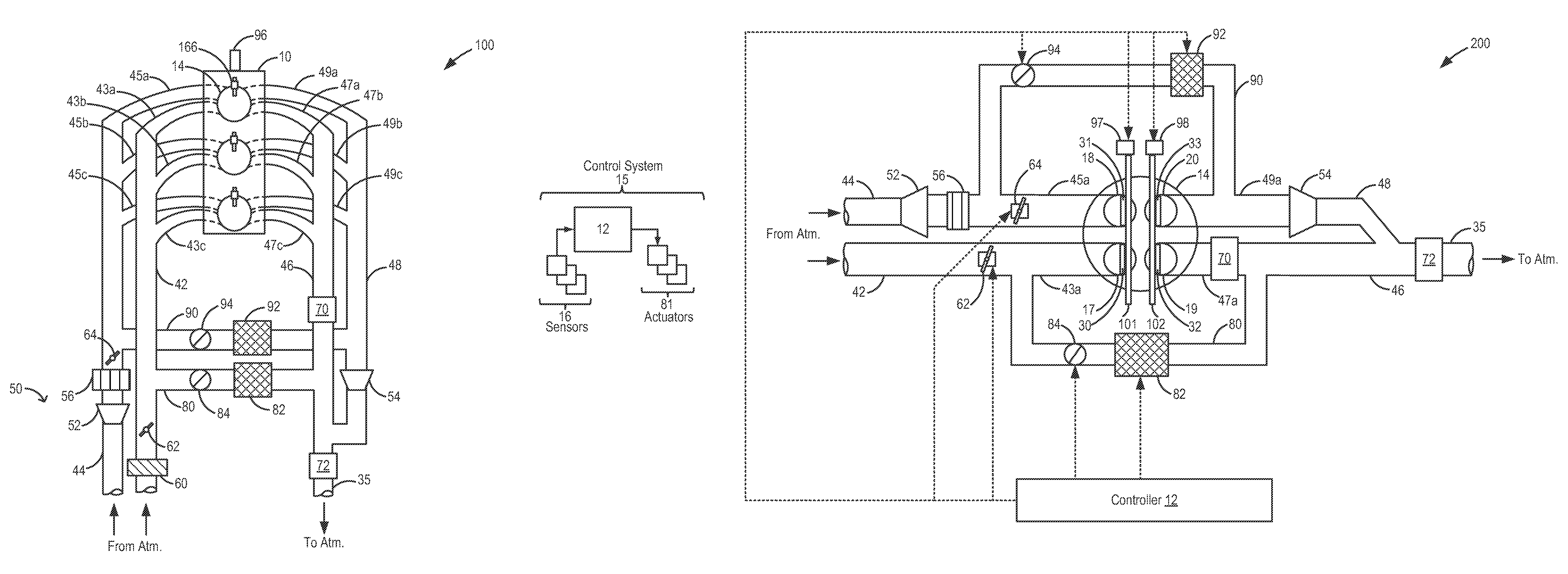

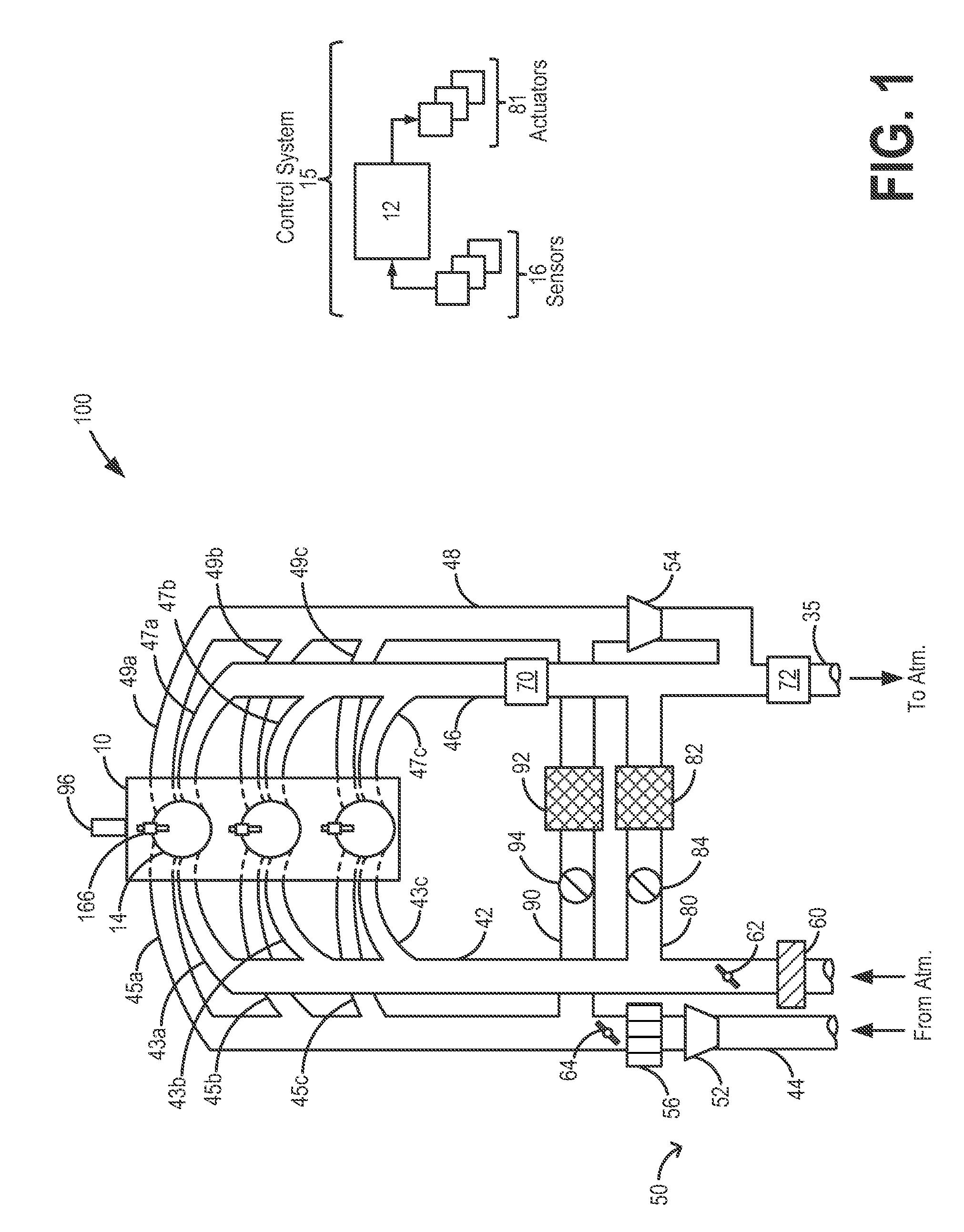

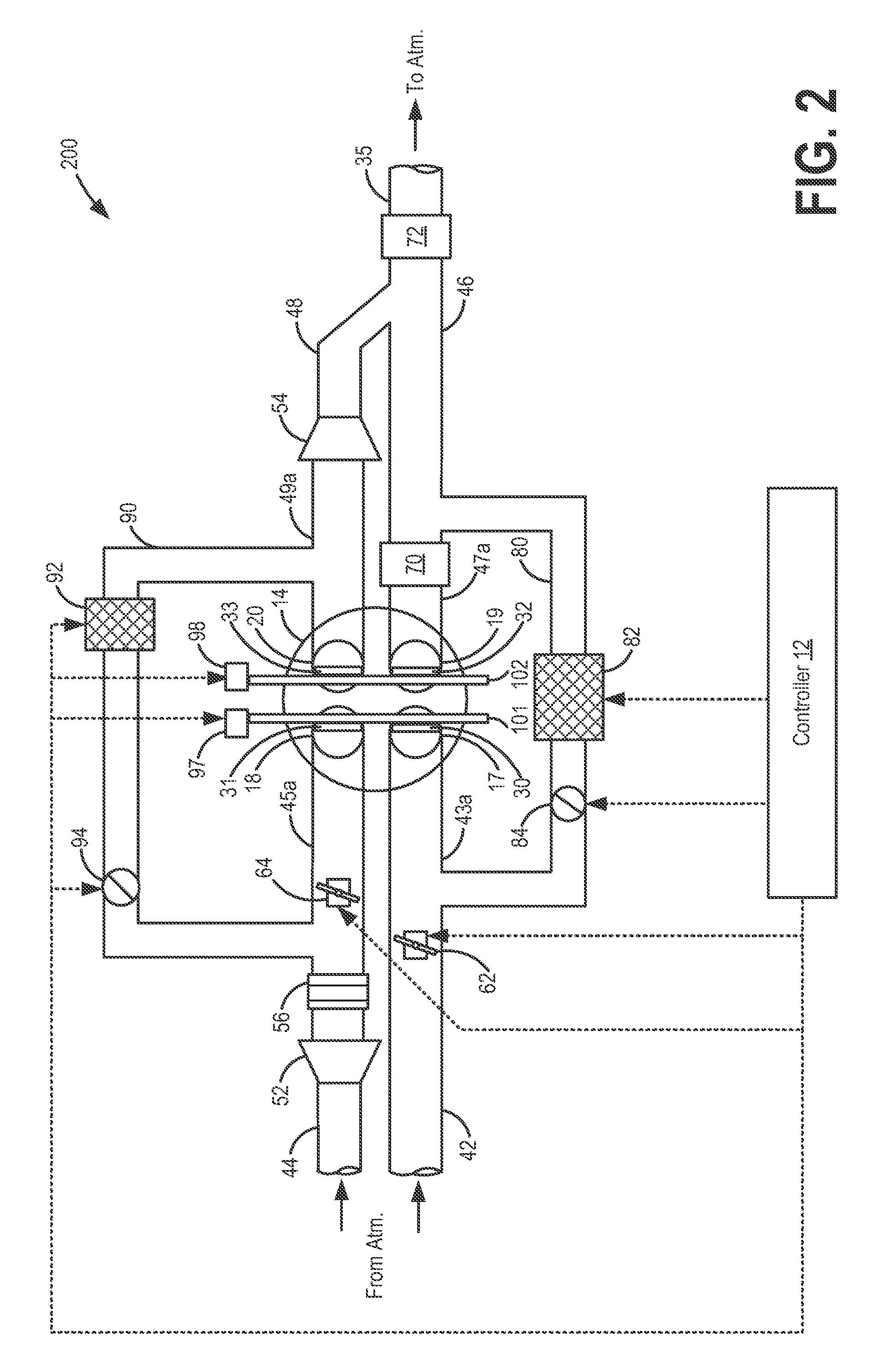

Method and system for a turbocharged engine

ActiveUS8479511B2Without compromising boost performanceBoosted airchargeValve arrangementsElectrical controlEngine cycleAutomotive engineering

Methods and systems are provided for a boosted engine having a split intake system coupled to a split exhaust system. Aircharges of differing composition, pressure, and temperature may be delivered to the engine through the split intake system at different points of an engine cycle. In this way, boost and EGR benefits may be extended.

Owner:FORD GLOBAL TECH LLC

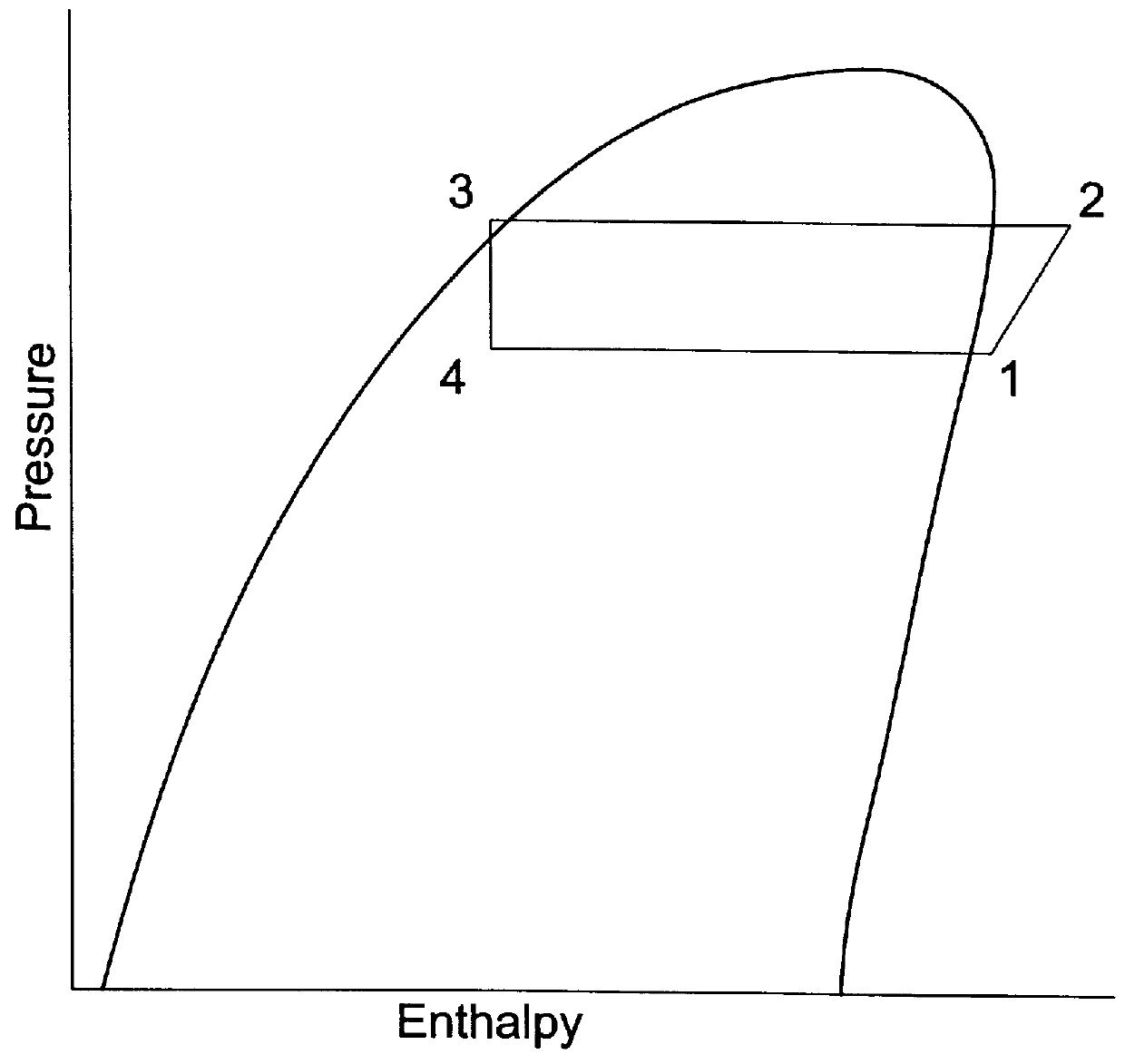

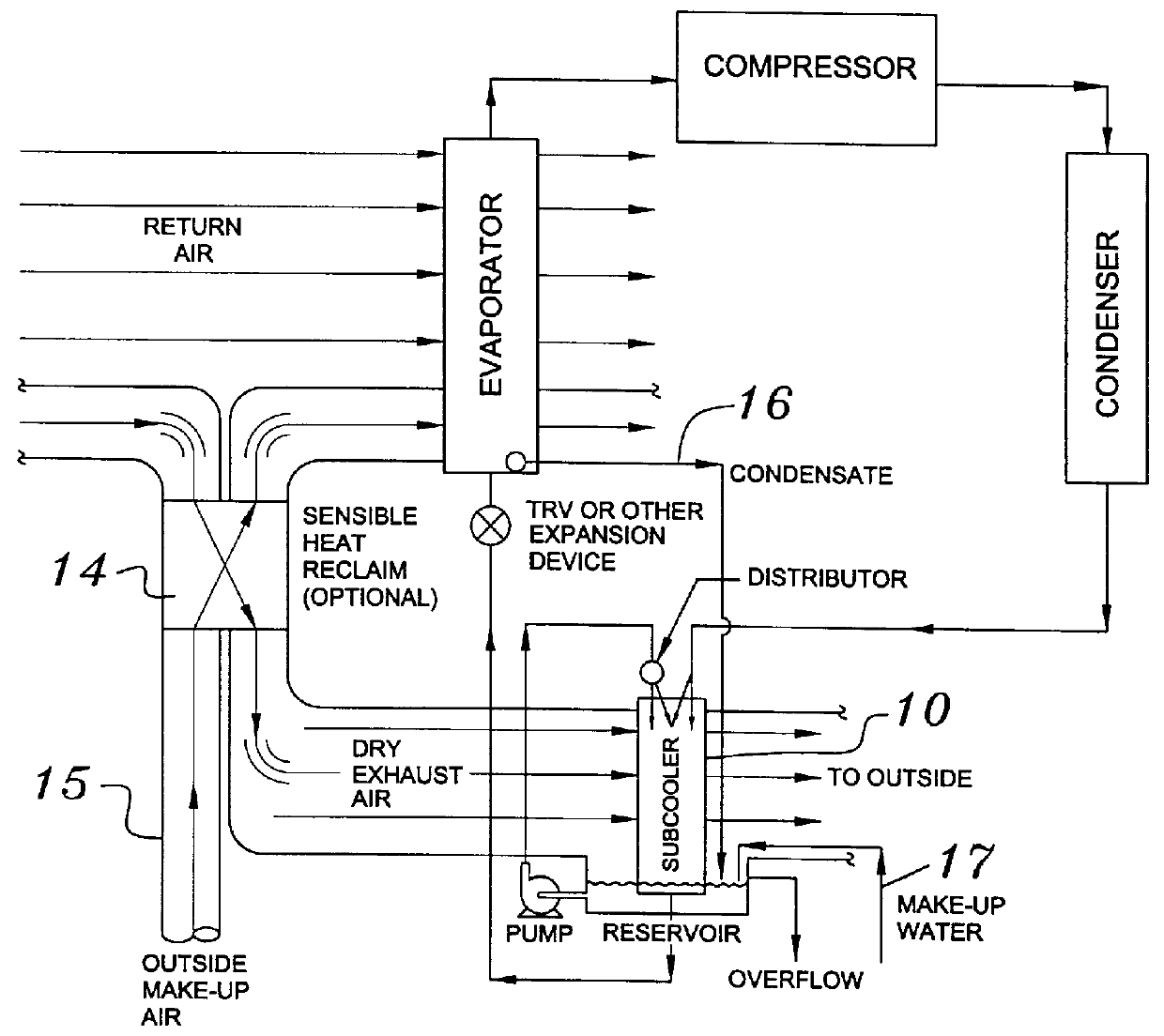

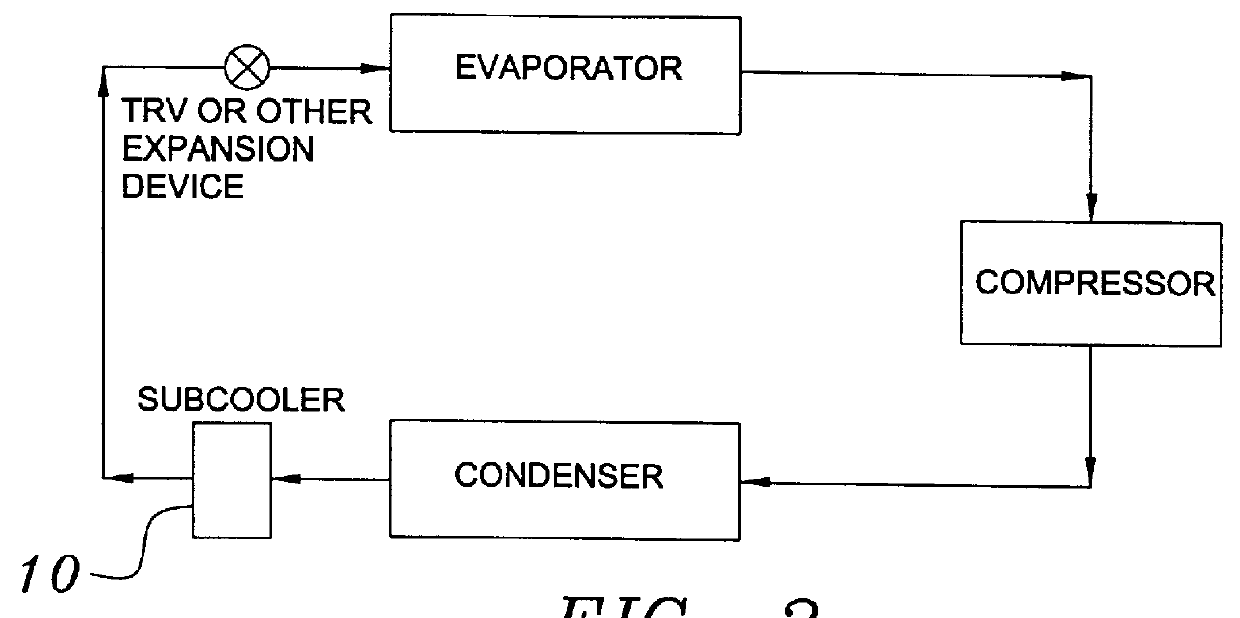

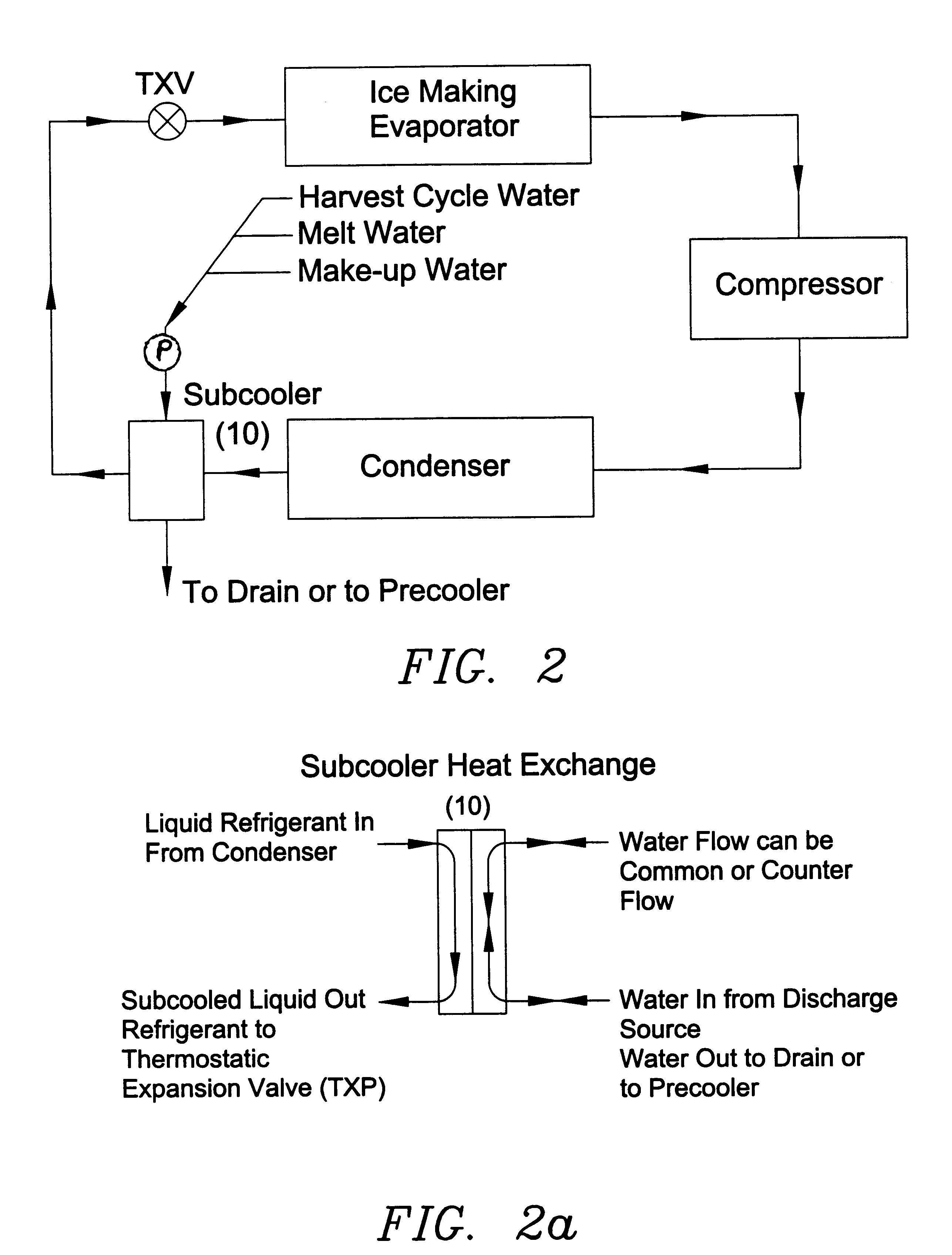

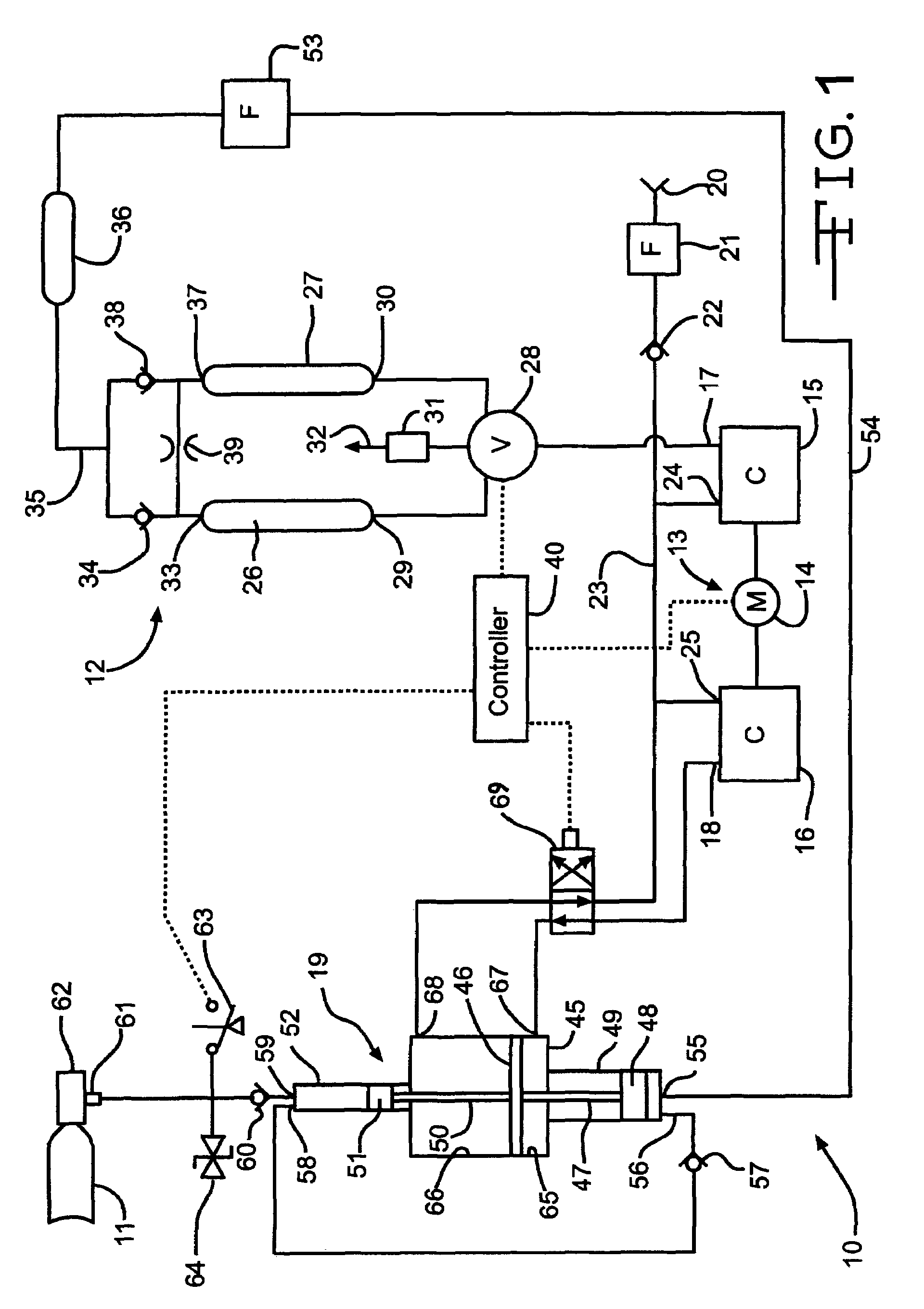

Building exhaust and air conditioner condenstate (and/or other water source) evaporative refrigerant subcool/precool system and method therefor

InactiveUS6070423AComprehensive understandingReduce the temperatureEnergy recovery in ventilation and heatingHeat recovery systemsWater wetIndoor air quality

First, a system for providing liquid refrigerant subcooling, subsequent to that subcooling accomplished by the primary condenser of an air conditioner or heat pump, by means of evaporative cooling utilizing the condensate water of said air conditioner or heat pump system and / or some other water supply to wet the surface of the subcool heat exchanger and then passing the cold, dry building exhaust air required for good indoor air quality across the wetted surface of the subcool heat exchanger. Said exhaust air could be used after first undergoing a sensible heat exchange with the incoming make up air. Said subcooling providing for an increased refrigeration capacity, and efficiency of the system. Secondly, a system for providing hot gas discharge refrigerant precooling before said hot gas passes into the primary condenser of an air conditioner or heat pump, by means of evaporative cooling utilizing the condensate water of said air conditioner or heat pump system and / or some other water supply to wet the surface of the precool heat exchanger and then passing the cold, dry building exhaust air required for good indoor air quality across the wetted surface of the precool heat exchanger. Said precooler providing lower power consumption of the compressor, lower head pressure, increased mass flow of the refrigerant and improved efficiency of the primary condenser of the air conditioning or heat pump system. Said exhaust air could be used after first undergoing a sensible heat exchange with the incoming make up air on either the subcooler or precooler. Finally, a combination subcooler and precooler system where the cold dry exhaust air is first used to evaporatively subcool the liquid refrigerant in the water wetted subcooler and then subsequently used to conductively cool the hot gas refrigerant passing through a dry surface precooler or alternately used to evaporatively cool the wetted surface of the precooler thereby evaporatively precooling the hot gas refrigerant passing through the precooler.

Owner:GLOBAL ENERGY & ENVIRONMENT RES INC +1

Impeller for centrifugal compressors

InactiveUS6905310B2Interference minimizationMinimizes separationPropellersRotary propellersSuction stressAerodynamic load

In an impeller for centrifugal compressors comprising a plurality of blades each having a base end attached to a central hub, each of the blades is given with a thickness which increases progressively toward a hub end thereof, and a suction surface side of the blade is given with a greater thickness increase rate with respect to a neutral plane than a pressure surface side of the blade. Thereby, the inter-blade channel is narrowed locally in the region near the hub end of the suction surface of each blade, and this locally reduces the aerodynamic loading on the blade. In particular, the surge property is improved, and the generation of radially outwardly directed secondary flows can be minimized. This allows the distribution of aerodynamic loading in the radial direction or from the tip end to the hub end of each blade to be controlled at will, and enables the optimum design of the impeller.

Owner:HONDA MOTOR CO LTD

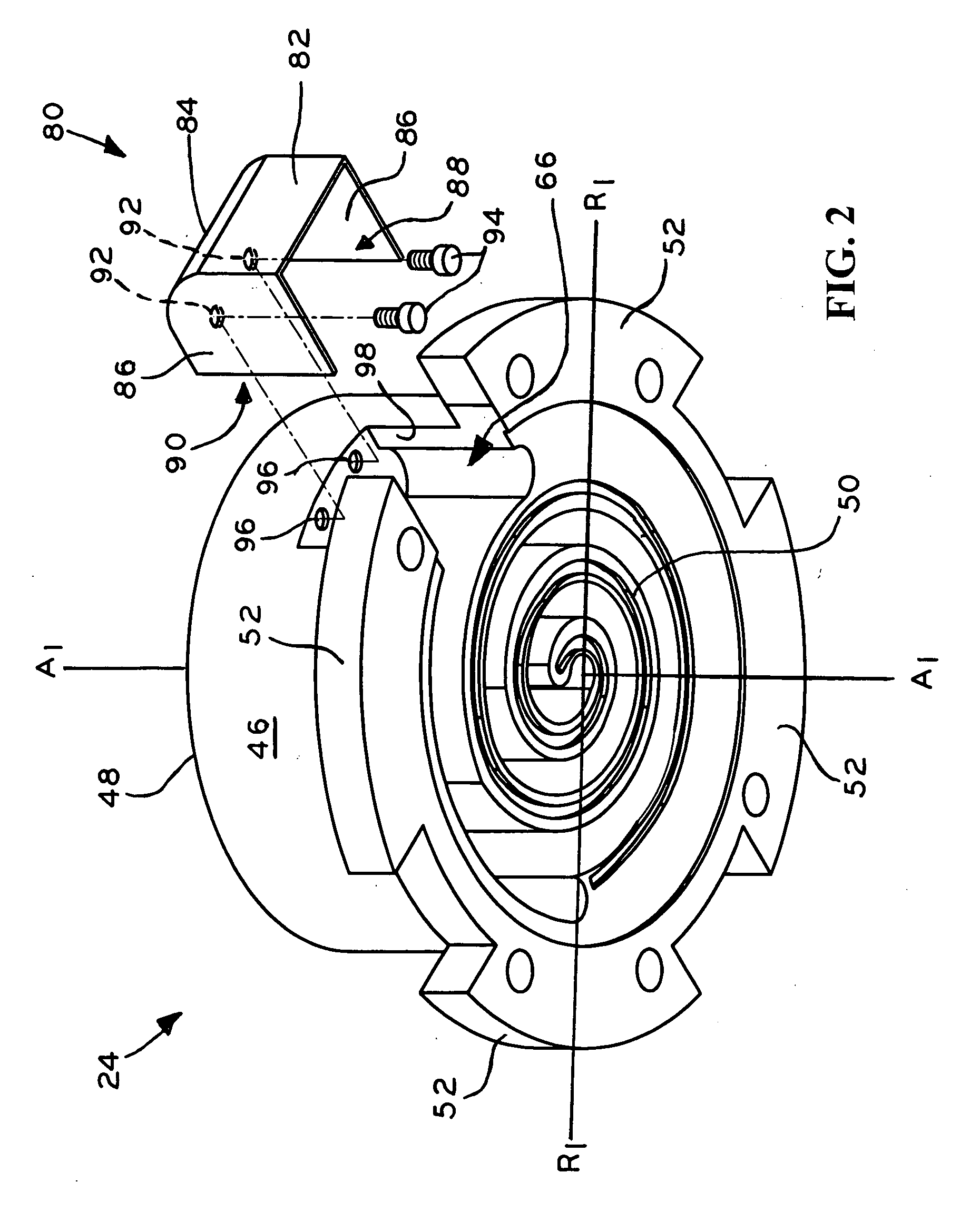

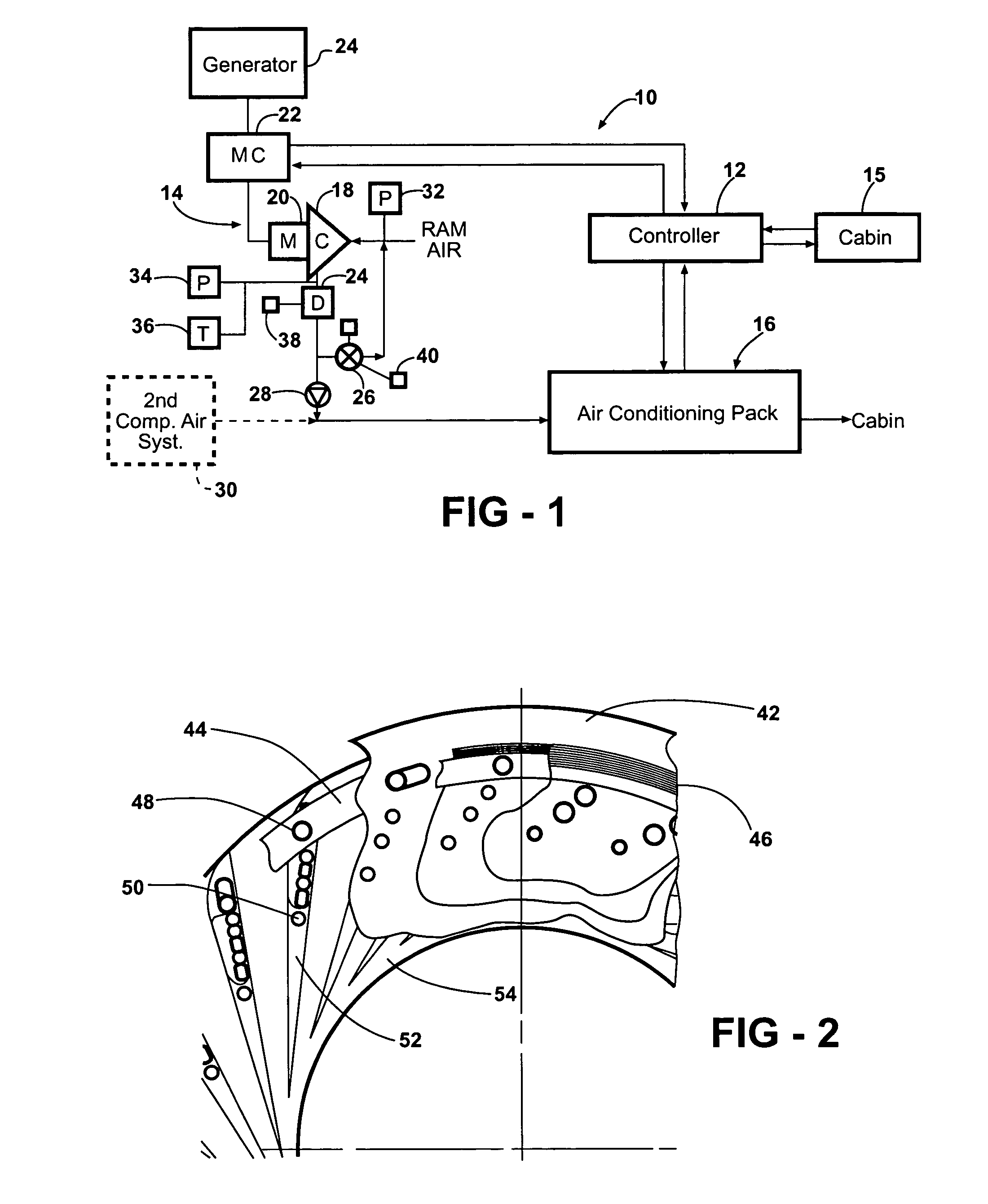

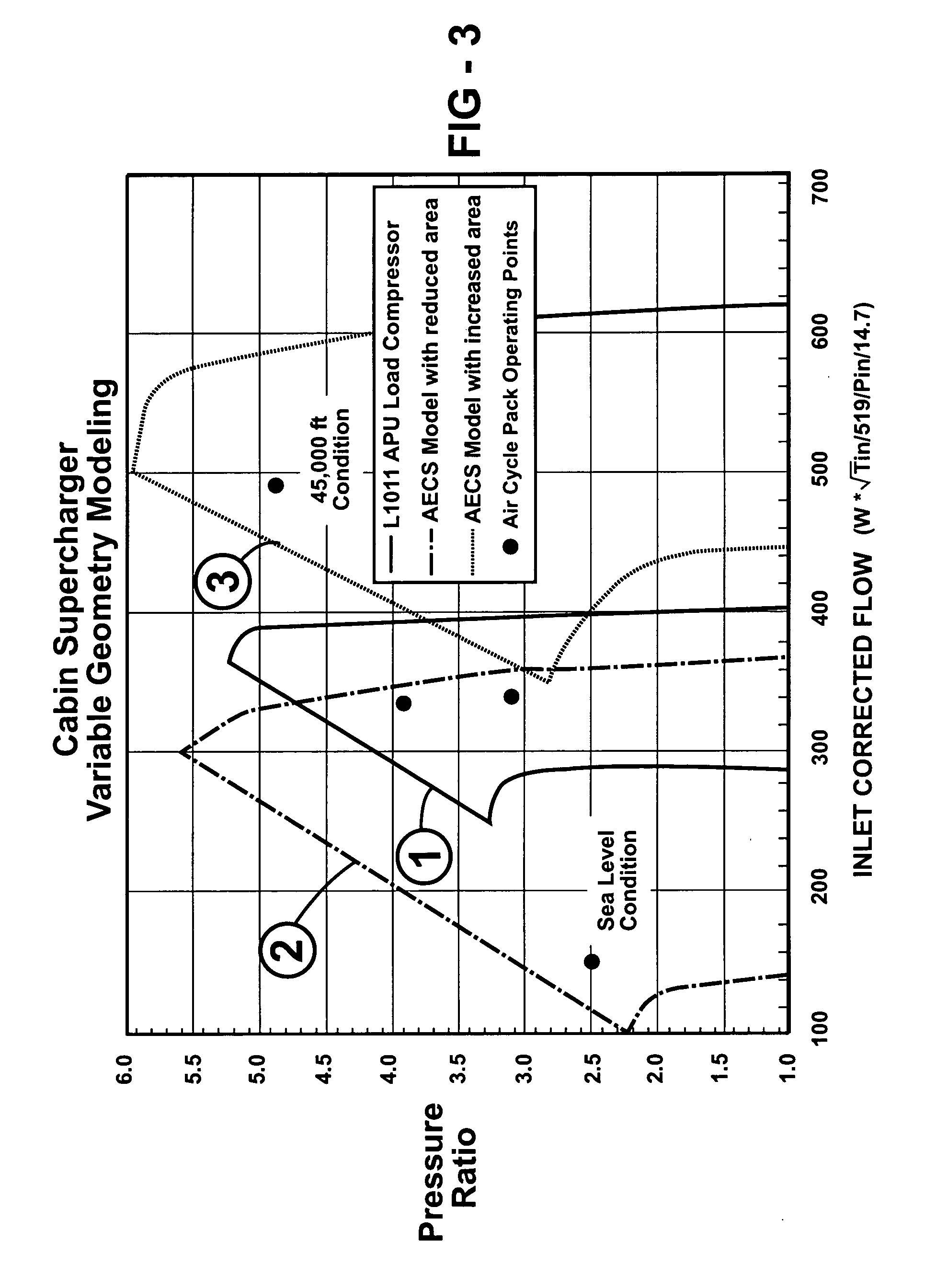

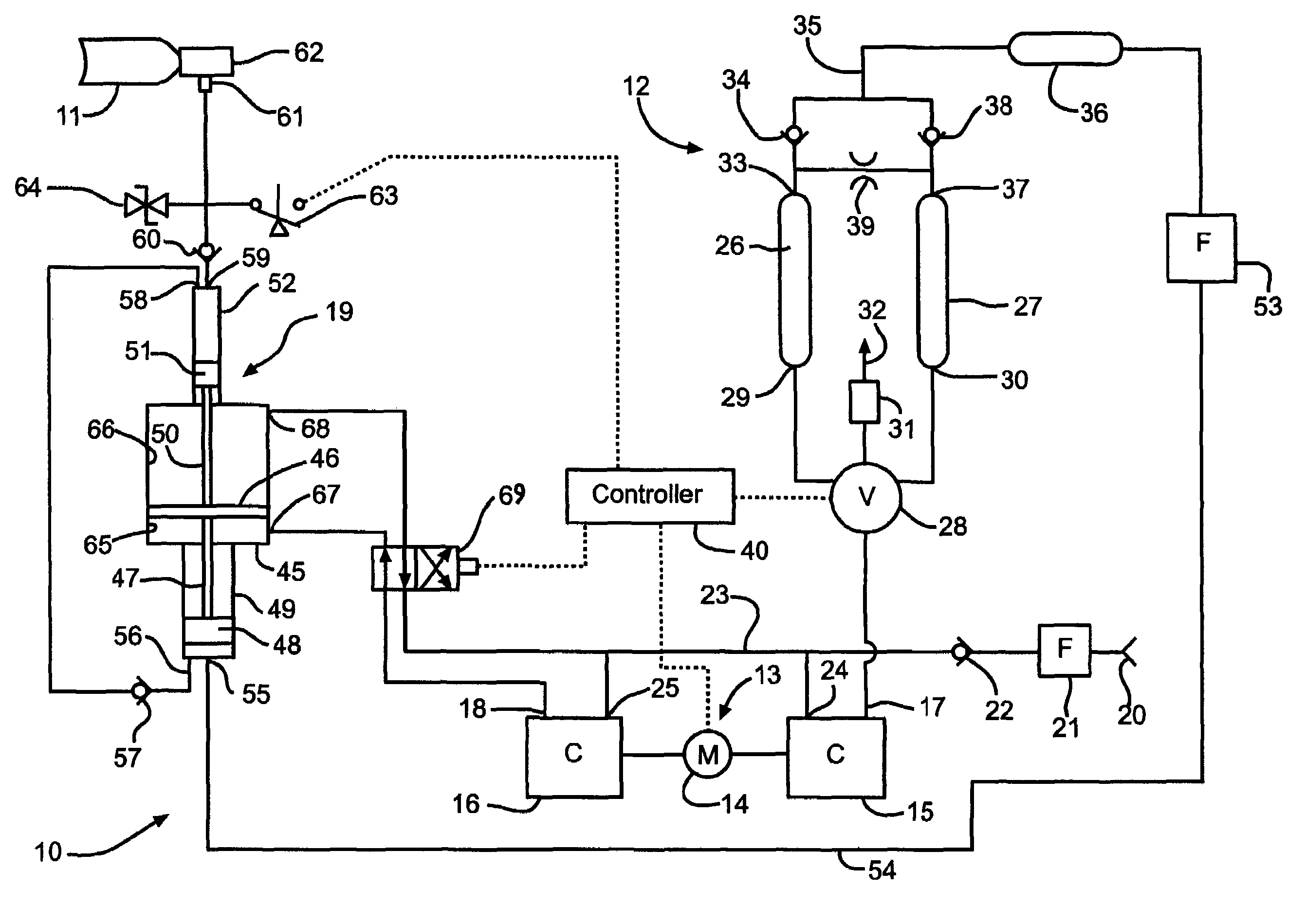

Electric motor driven supercharger with air cycle air conditioning system

ActiveUS7322202B2Improve compressor efficiencyReduce energy wasteDomestic cooling apparatusAir-treatment apparatus arrangementsAir cycleAir conditioning

Owner:HAMILTON SUNDSTRAND CORP

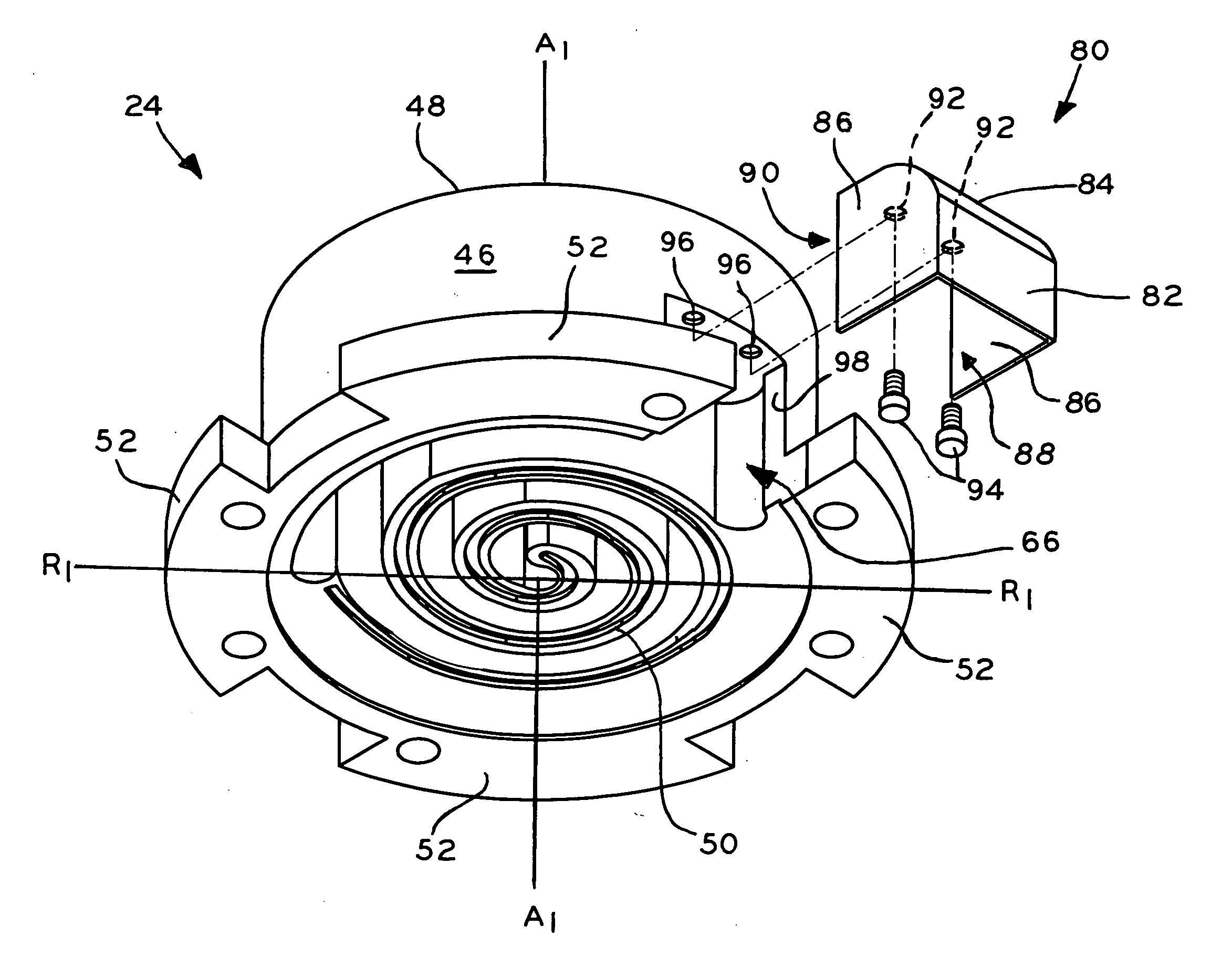

Advanced scroll compressor, vacuum pump, and expander

ActiveUS7942655B2Improve compressor efficiencyEngine of arcuate-engagement typeOscillating piston enginesEngineeringVacuum pump

Modifications of a scroll compressor provide a bellows suitable for liquid cooling and a plunger actuated seal for the scroll tips of various equipment. A bellows spans the fixed and the orbiting scrolls and hermetically seals the scroll device. Using two bellows, the present invention allows for liquid cooling of a compressor with an inlet and an outlet to exhaust heated coolant to a heat exchanger. Then the scrolls have a spiral upon a plate that ends in a tip. A seal upon the tip that abuts the fixed scroll upon a biased plunger modifies existing scroll designs to maintain the seal in contact with the fixed scroll. The modifications also provide an improved coating that seals the fixed and orbiting scrolls to each other without the use of epoxy, disassembly, and cleaning.

Owner:AIR SQUARED

Baffle member for scroll compressors

InactiveUS20100021330A1Improve compressor efficiencyAvoid normal workRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeCrankcaseLubricant

A baffle member for use in scroll compressors. In one exemplary embodiment, the baffle member is attached to a portion of the crankcase and, in use, deflects lubricant that may be thrown from the thrust surface of the crankcase during operation of the compressor away from the flow of working fluid, and also aids in directing the flow of working fluid away from the thrust surface of the crankcase and toward a suction inlet in the compression mechanism.

Owner:TECUMSEH PROD CO

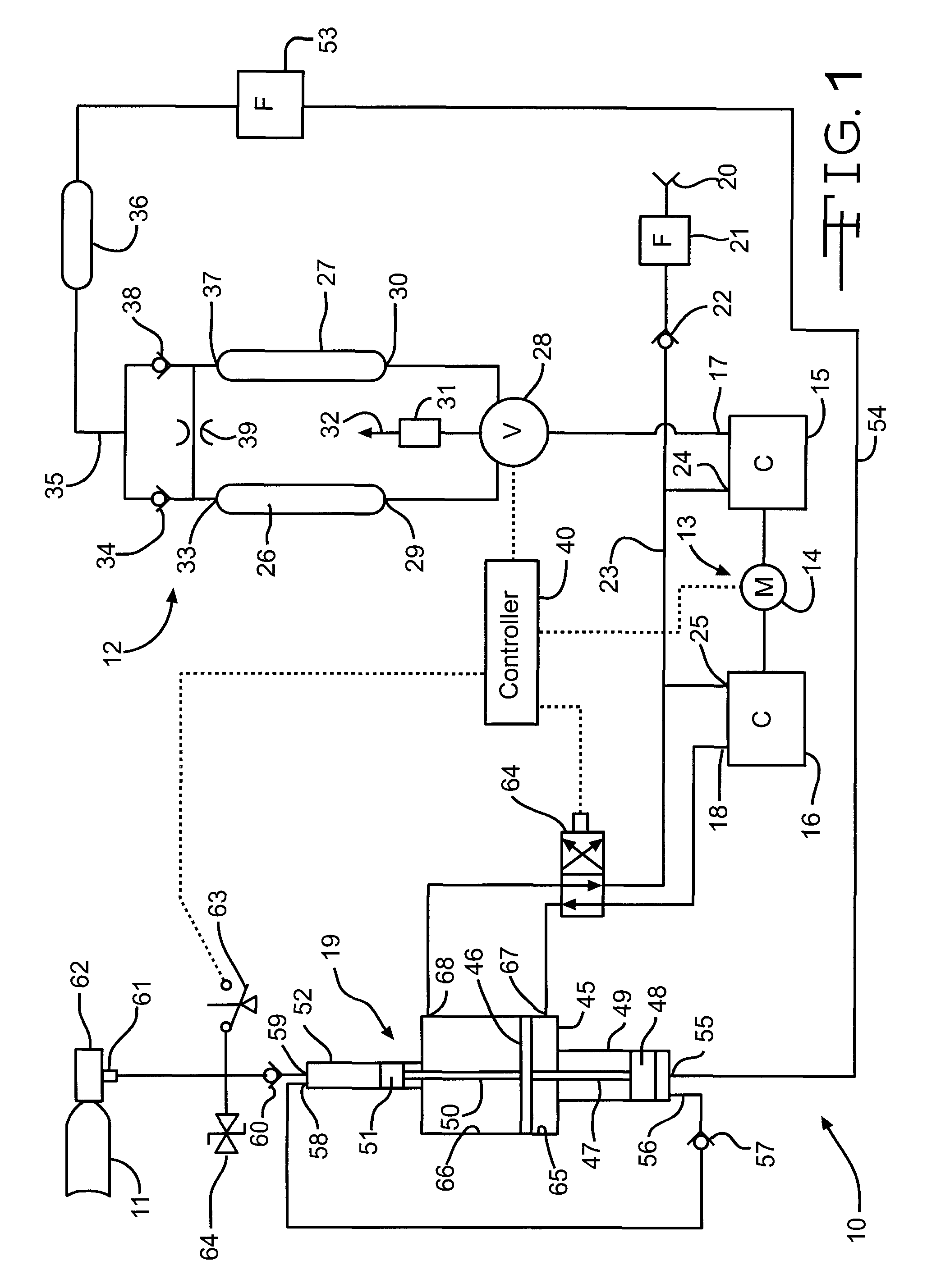

Compact Heat Pump Using Water as Refrigerant

InactiveUS20090100857A1Improve efficiencyAvoid residueHeat pumpsDomestic cooling apparatusEvaporationEngineering

According to the present invention there is provided a compact heat pump using water as refrigerant, comprising an evaporator (20) located at a first end section of the heat pump casing (12), adapted to allow evaporation of water therefrom, One or more compressors (40) located at a second end section of the heat pump casing adapted to induce said evaporation by maintaining vacuum, provided with an intake conduit (32) extending from the evaporator (20) to the compressor (40) leading vapor thereto. A condenser (30) is located in the intermediate section of the casing (12) wherein the intake conduit (32) passes therethrough, adapted for condensing the vapor. The heat pump also comprises vacuum means (39) allowing creating and maintaining vacuum in the casing. There is also provided a snow dome allowing skiing and snow related activities in above zero conditions using the heat pump for creation of snow or ice slurry.

Owner:IDE TECHNOLOGIES

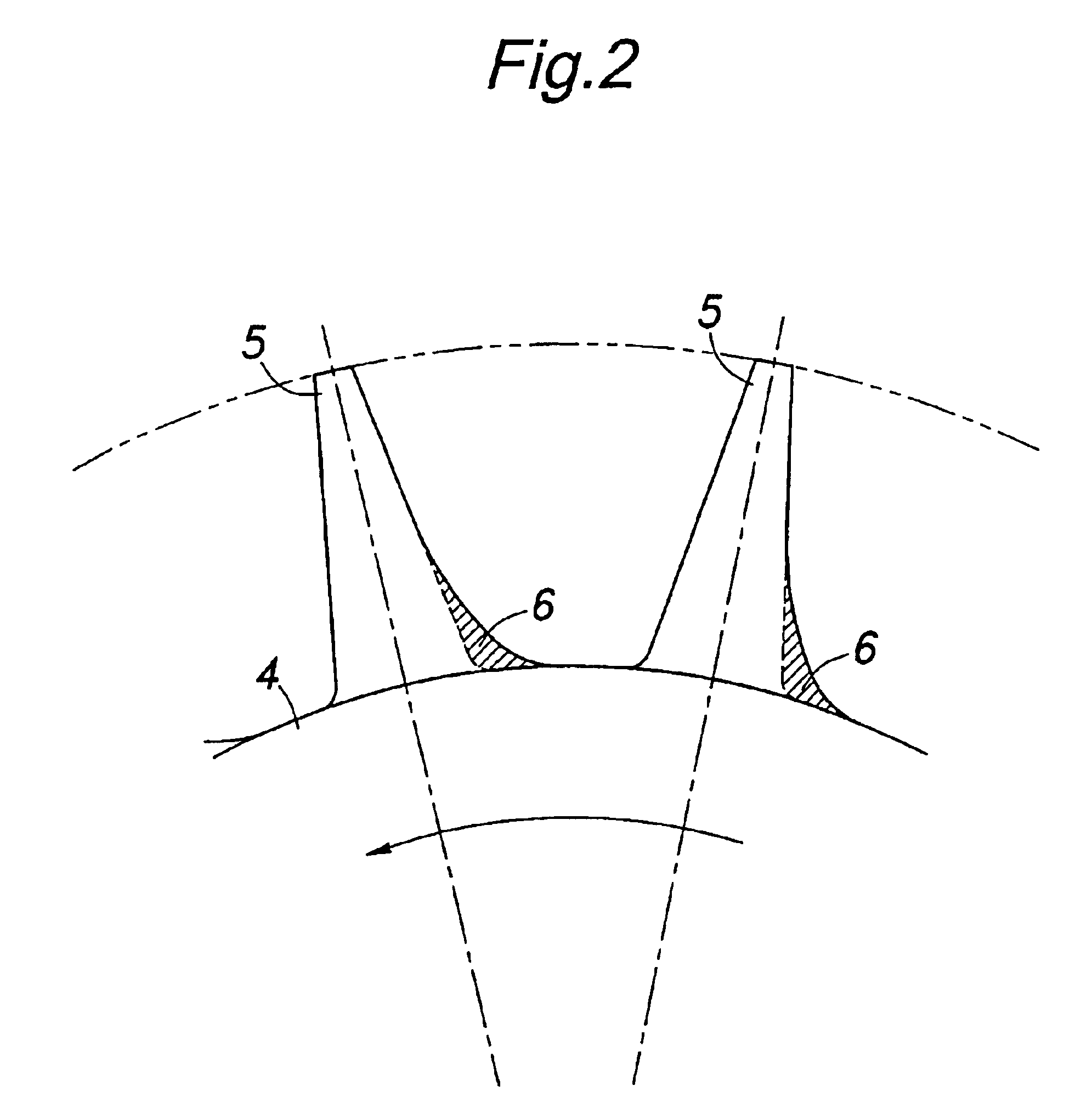

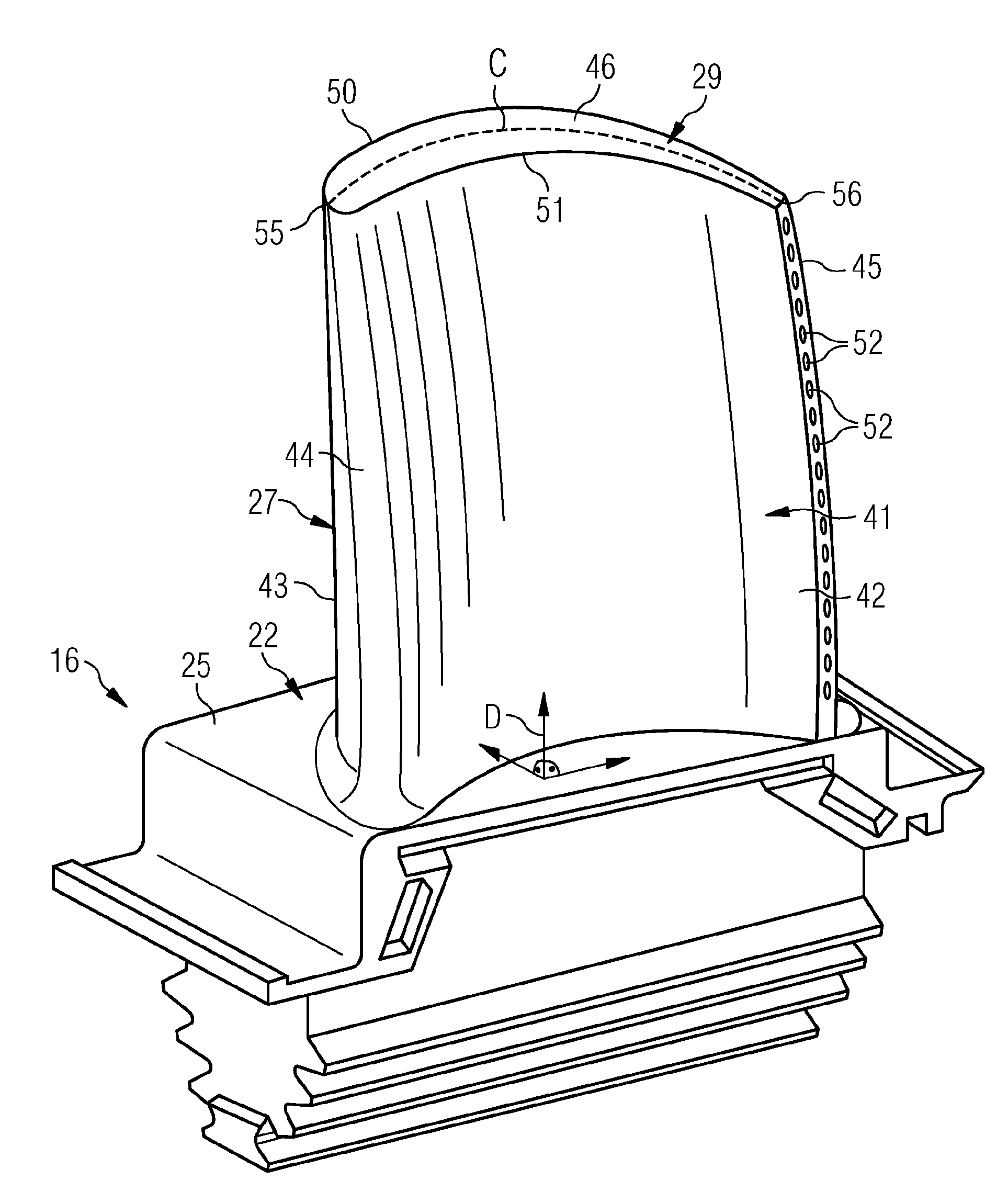

Airfoil and corresponding guide vane, blade, gas turbine and turbomachine

InactiveUS20120230818A1Reduce leakageMitigate such drawbackPropellersPump componentsAbnormal shapedGas turbines

An airfoil suitable for being arranged in a compressor section of the gas turbine includes a platform, a pressure surface and a suction surface, and a tip region. The tip region is located between the pressure and the suction surface opposite to the platform in respect of the pressure and the suction surfaces, being a distant end of the airfoil in direction along the first direction perpendicular to the platform. The tip region includes a first surface with a first distance to the platform along the first direction, and a second surface with a second distance to the platform along the first direction. The first distance is greater than the second distance and the first surface and the second surface together build a profiled surface. The profiled surface is a ribbed surface. The material of the first surface is deformable to bend away from the rotation direction of the airfoil.

Owner:SIEMENS AG

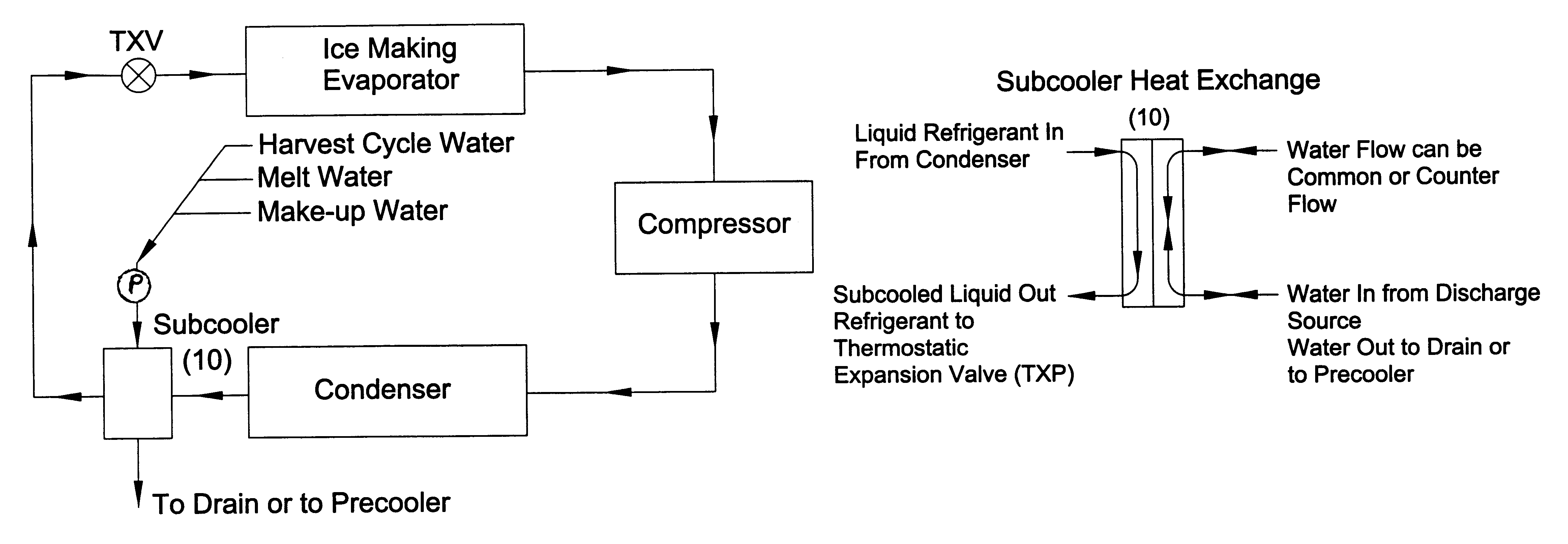

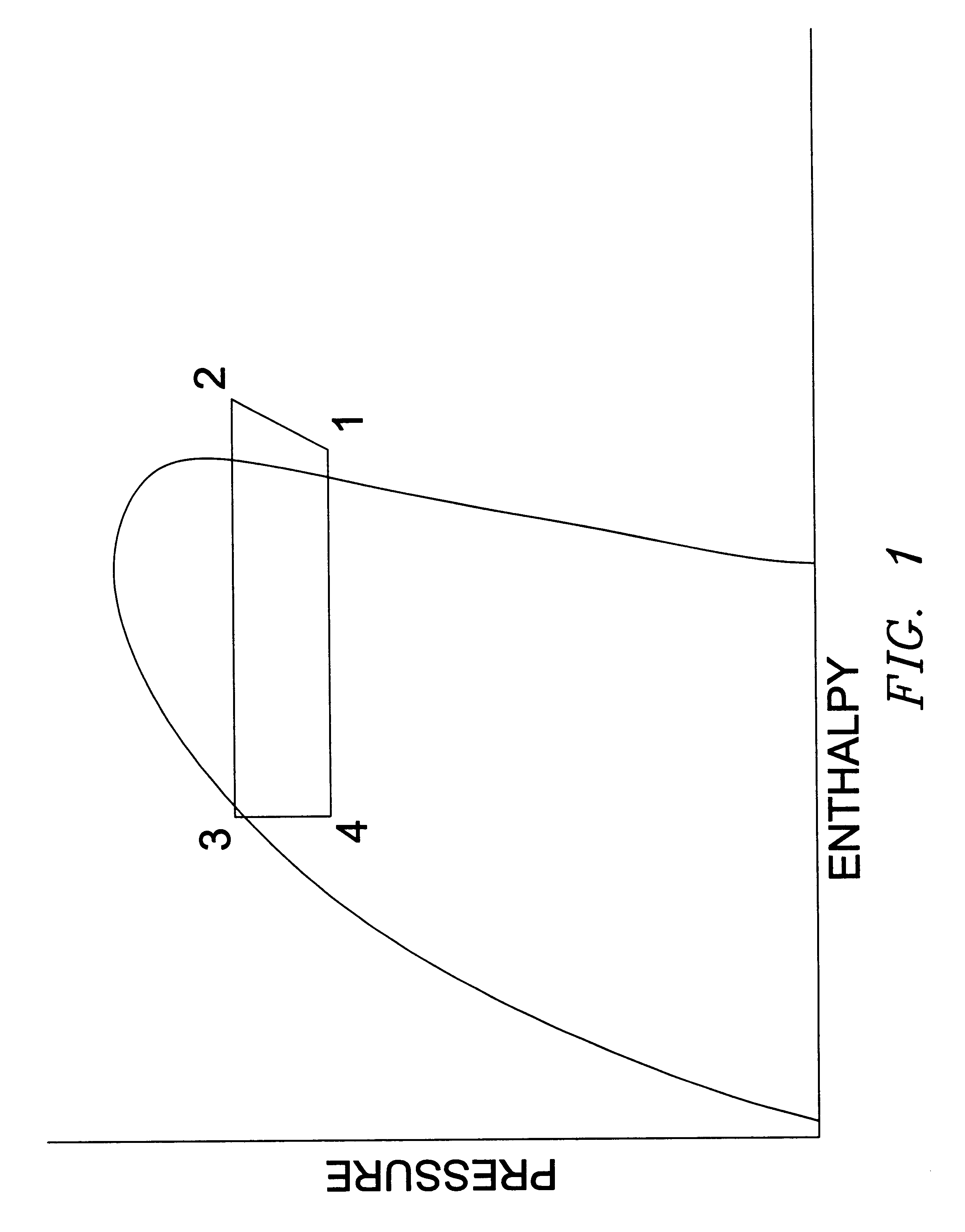

Utilization of harvest and/or melt water from an ice machine for a refrigerant subcool/precool system and method therefor

InactiveUS6237359B1Comprehensive understandingReduce heat dissipationSkin implantsFood processingCounter flowWater discharge

A system for providing liquid refrigerant subcooling, subsequent to that subcooling accomplished by the primary condenser of an ice machine, by means of utilizing cold harvest and / or melt water discharge from said ice machine. The subcooler is connected in fluid communication with the output of a pump that pumps stored ice machine discharge water to directly flow through the subcooler from a bottom portion to a top portion in a counter-flow direction and then to discharge such that the subcooler utilizes the pumped and flowing cold discharge water from the ice machine for providing maximum available subcooling to the liquid refrigerant of said ice machine

Owner:OLIVE TREE PATENTS 1 +1

Rotary compressor

InactiveUS6077058AReduce total powerImprove compressor efficiencyEngine of arcuate-engagement typeOscillating piston enginesDrive shaftEngineering

PCT No. PCT / JP96 / 02658 Sec. 371 Date Dec. 31, 1997 Sec. 102(e) Date Dec. 31, 1997 PCT Filed Sep. 13, 1996 PCT Pub. No. WO97 / 12148 PCT Pub. Date Apr. 3, 1997When a driving shaft rotates, a piston (9) revolves around the driving shaft in a cylinder room (6a) with supported by a swing bush (32) as a supporting point through a blade (31). Discharge ports (22) are formed in a front head (7) and a rear head (8) respectively and are disposed to be located in the proximity of the blade (31) and to communicate with a high pressure room. A semicircular portion of the discharge port (22) overlaps with the swing bush (32) and the cylinder (6). A pair of upper and lower cut parts (41) are each formed by cutting away an outer peripheral edge of the swing bush (32) and an inner peripheral edge of the cylinder (6) which are overlapped with the discharge port (22).

Owner:DAIKIN IND LTD

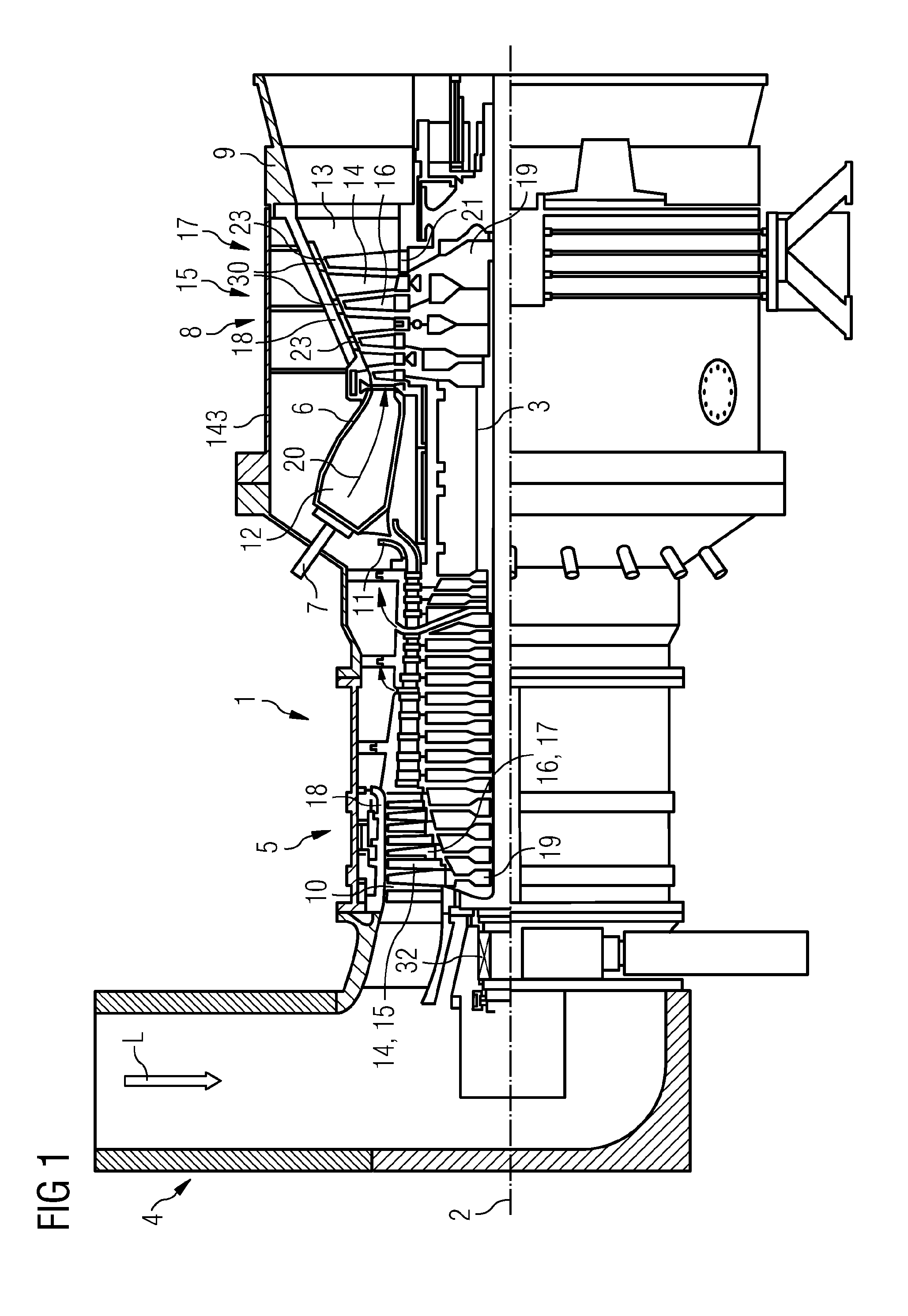

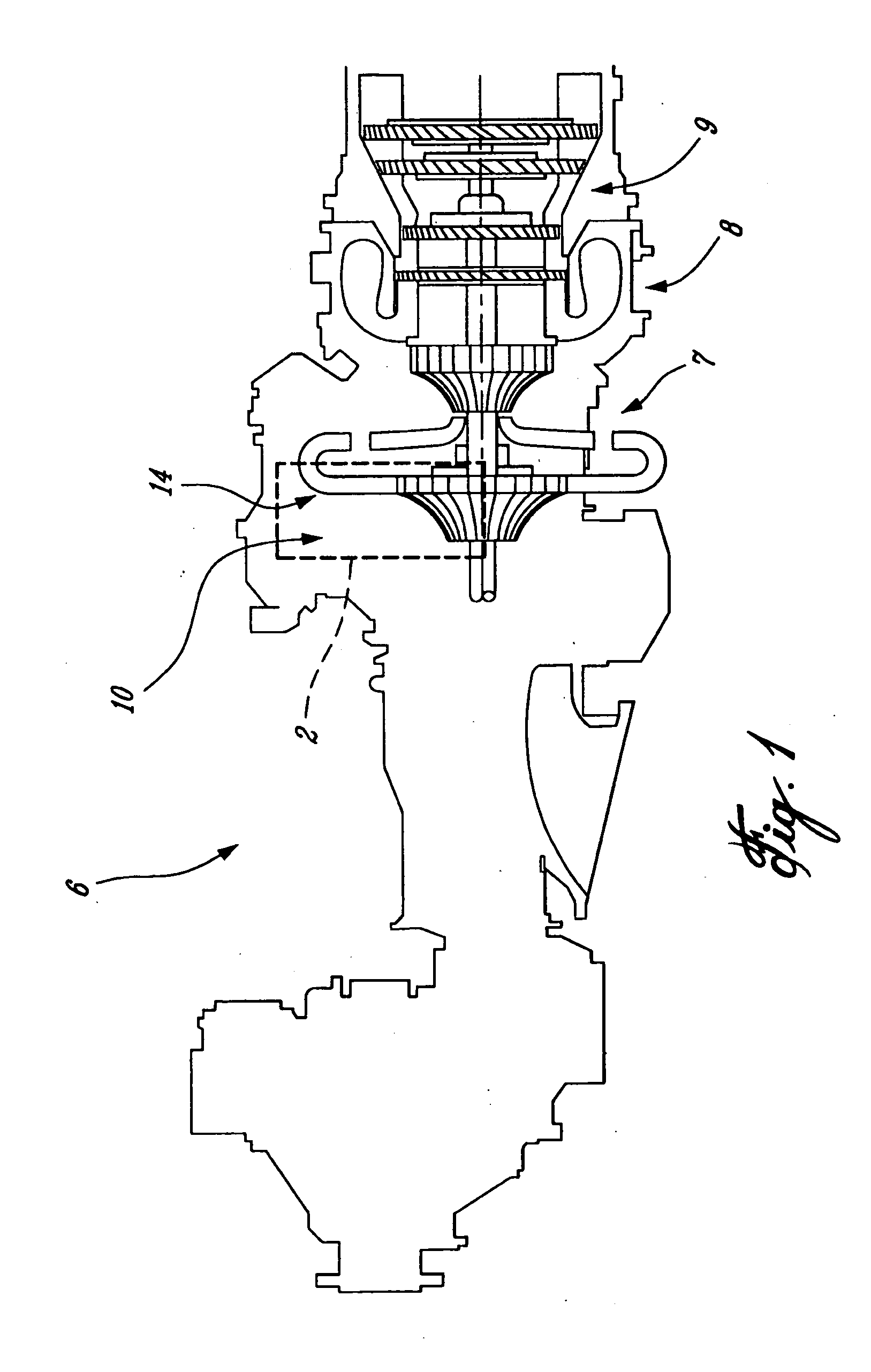

Axial flow machine having an asymmetrical compressor inlet guide baffle

InactiveUS20110164967A1Avoid disadvantagesImprove stabilityPump componentsStatorsAngle of incidenceEngineering

An axial flow machine having an asymmetrical air inlet and, downstream therefrom, a compressor having an inlet guide baffle composed of guide vanes is characterized in that at least some of the guide vanes of the inlet guide baffle have a vane profile and / or an angle of attack that deviate(s) from the remaining guide vanes. The inlet flow angle of the first compressor stage is hereby evened out circumferentially symmetrically. This is accomplished in that the different inlet angles resulting at various circumferential positions of the inlet guide baffle due to the asymmetry of the air inlet, are influenced by selective profiling and / or by selectively modifying the angle of incidence of individual guide vanes in such a way that a circumferentially symmetrical outflow angle from the inlet vane ring results. In this way, the circumferential distortions caused by the asymmetrical air inlet are minimized and, thus, circumferentially symmetrical inlet conditions are passed onto the first compressor stage, which results in an improved stability and an enhanced efficiency of the compressor.

Owner:MTU AERO ENGINES GMBH

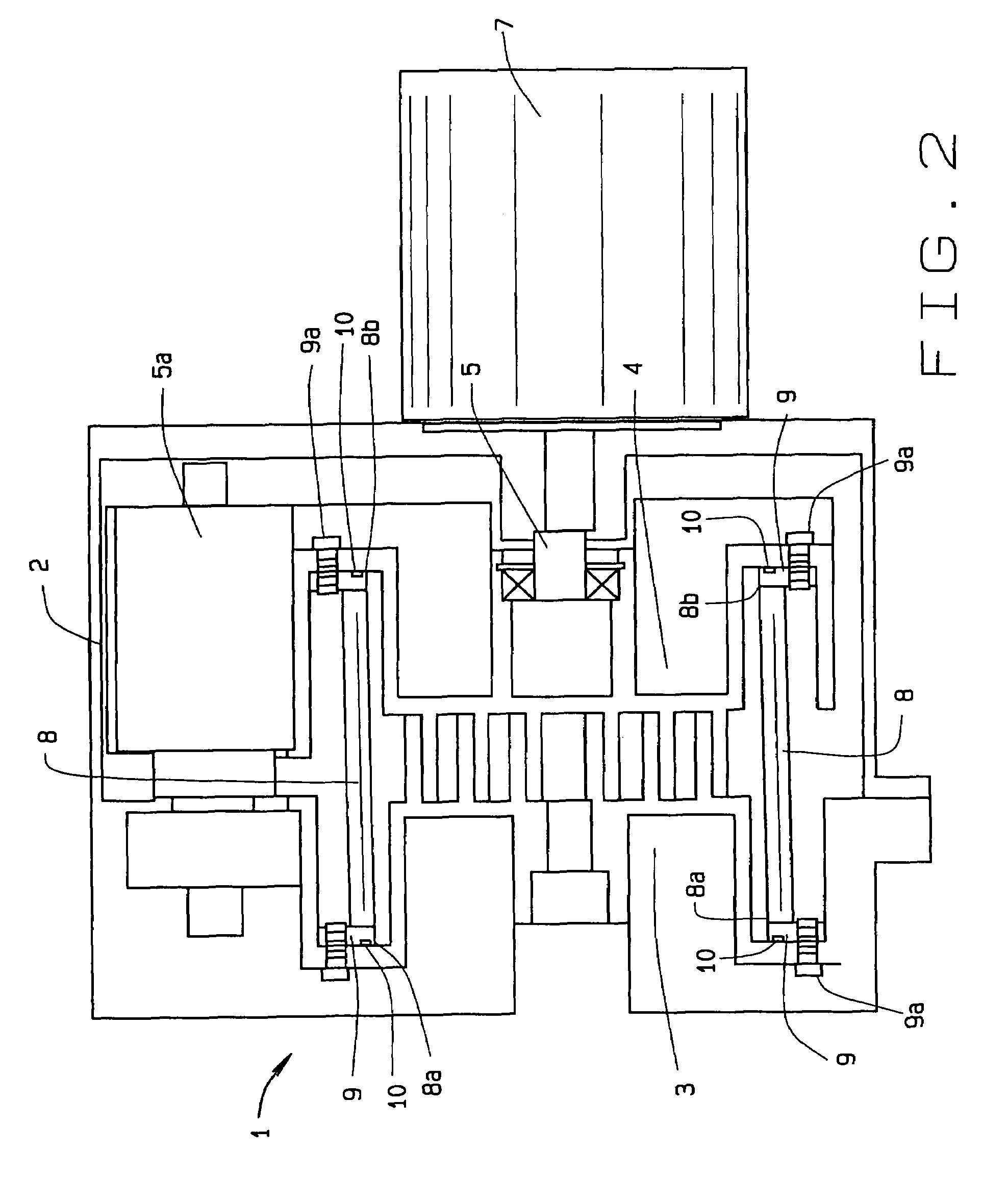

Cylinder Filling Oxygen Concentrator

InactiveUS20070084342A1Improve efficiencyImprove compressor efficiencyRespiratorsGas treatmentMotor driveGas cylinder

An energy efficient oxygen concentrator for filling high pressure portable cylinders with medical oxygen for use by ambulatory patients. Two compressors provide two pressurized air sources, one for operating an oxygen concentrator to provide a stream of oxygen enriched gas, and the other for driving a pressure intensifier for filling portable oxygen cylinders. Pressurized exhaust from the pressure intensifier is returned to the inlet side of at least one of the compressors for reducing the energy required to drive the compressor. Preferably, each compressor has a single reciprocating piston, a single motor drives both pistons and the pressurized exhaust from pressure intensifier is provided to the inlets for both compressors.

Owner:DEVILBISS HEALTHCARE

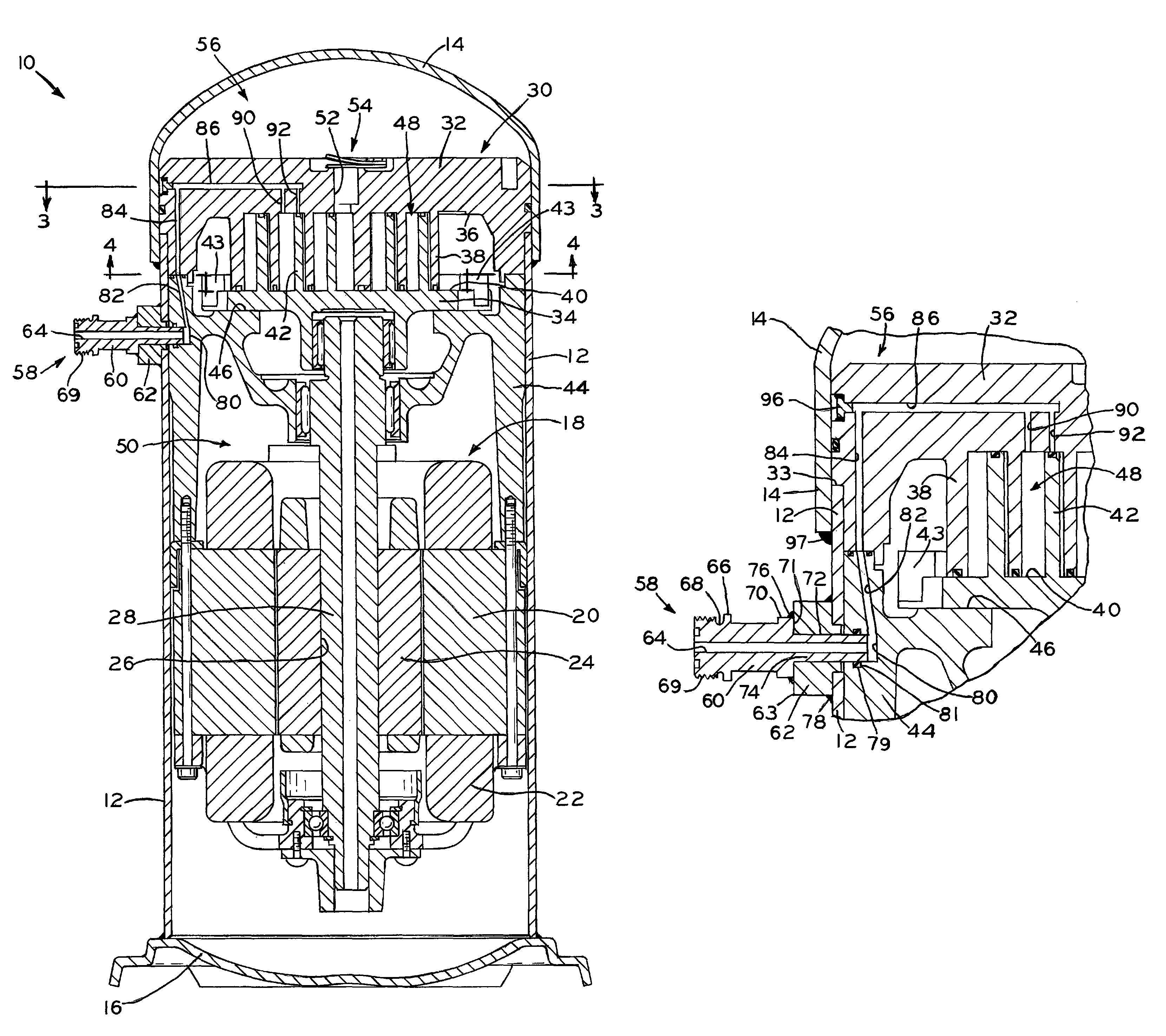

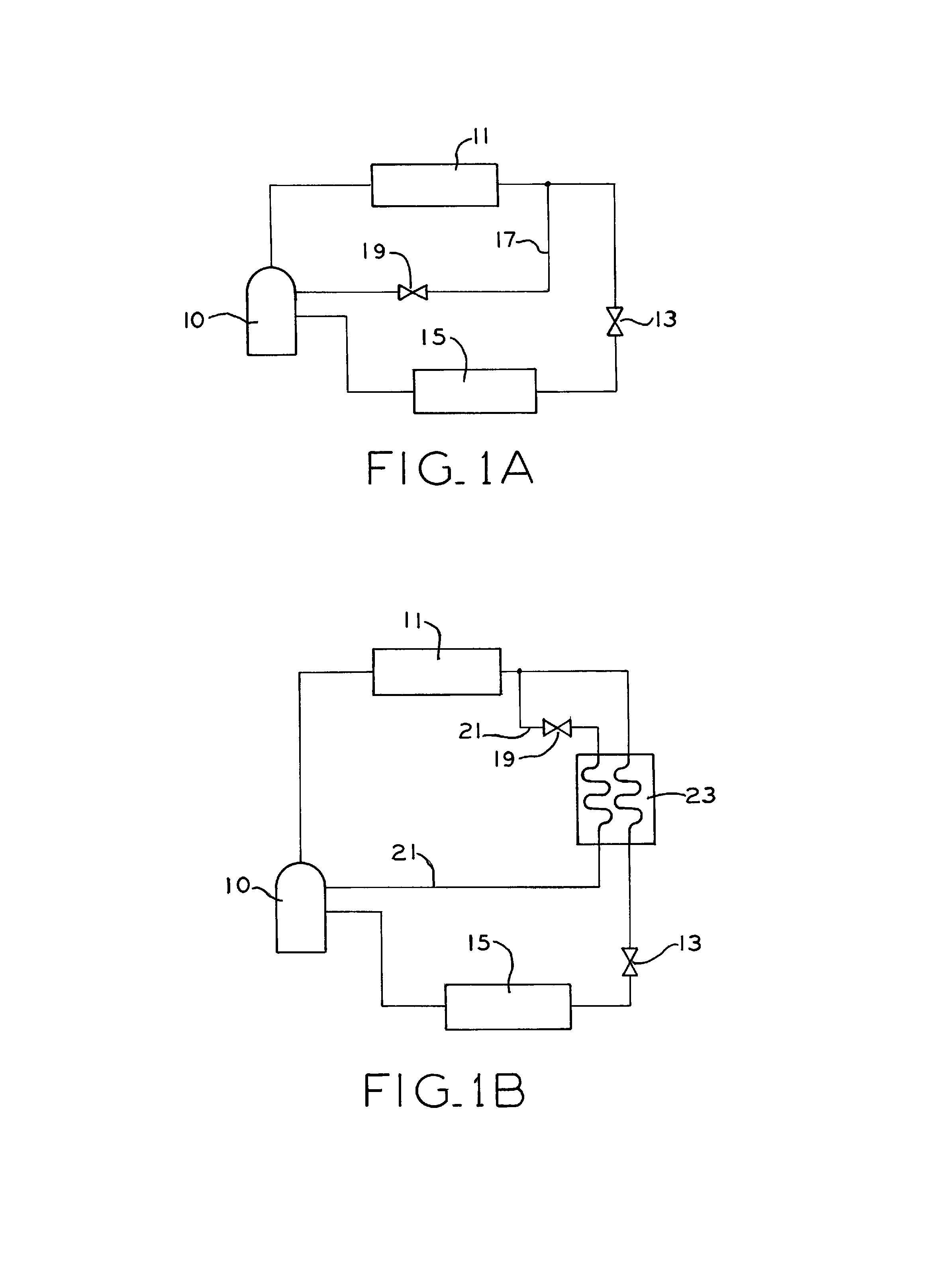

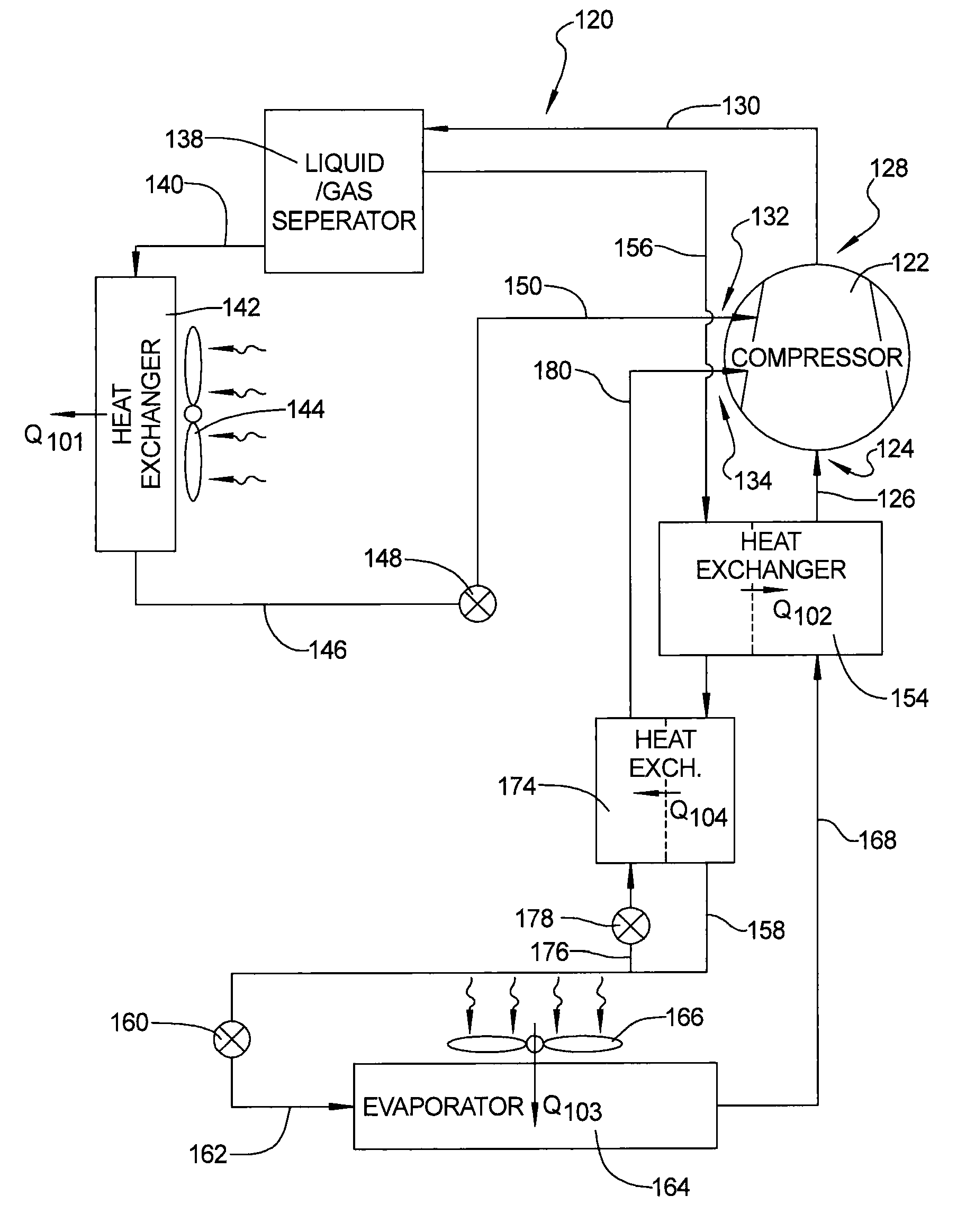

Refrigeration system

ActiveUS20080078204A1Improve cooling effectImprove compressor efficiencyCompressorCompression machines with non-reversible cycleRefrigerantRefrigeration

A refrigeration system can incorporate a liquid-injection system that can provide a cooling liquid to an intermediate-pressure location of the compressor. The cooling liquid can absorb the heat of compression during the compression of the refrigerant flowing therethrough. The refrigeration system can include an economizer circuit that injects a refrigerant vapor into an intermediate-pressure location of the compressor in conjunction with the injection of the cooling liquid. The incorporation of the vapor injection in conjunction with the cooling-liquid injection can advantageously increase the cooling capacity and / or efficiency of the refrigeration system and the performance of the compressor.

Owner:COPELAND LP

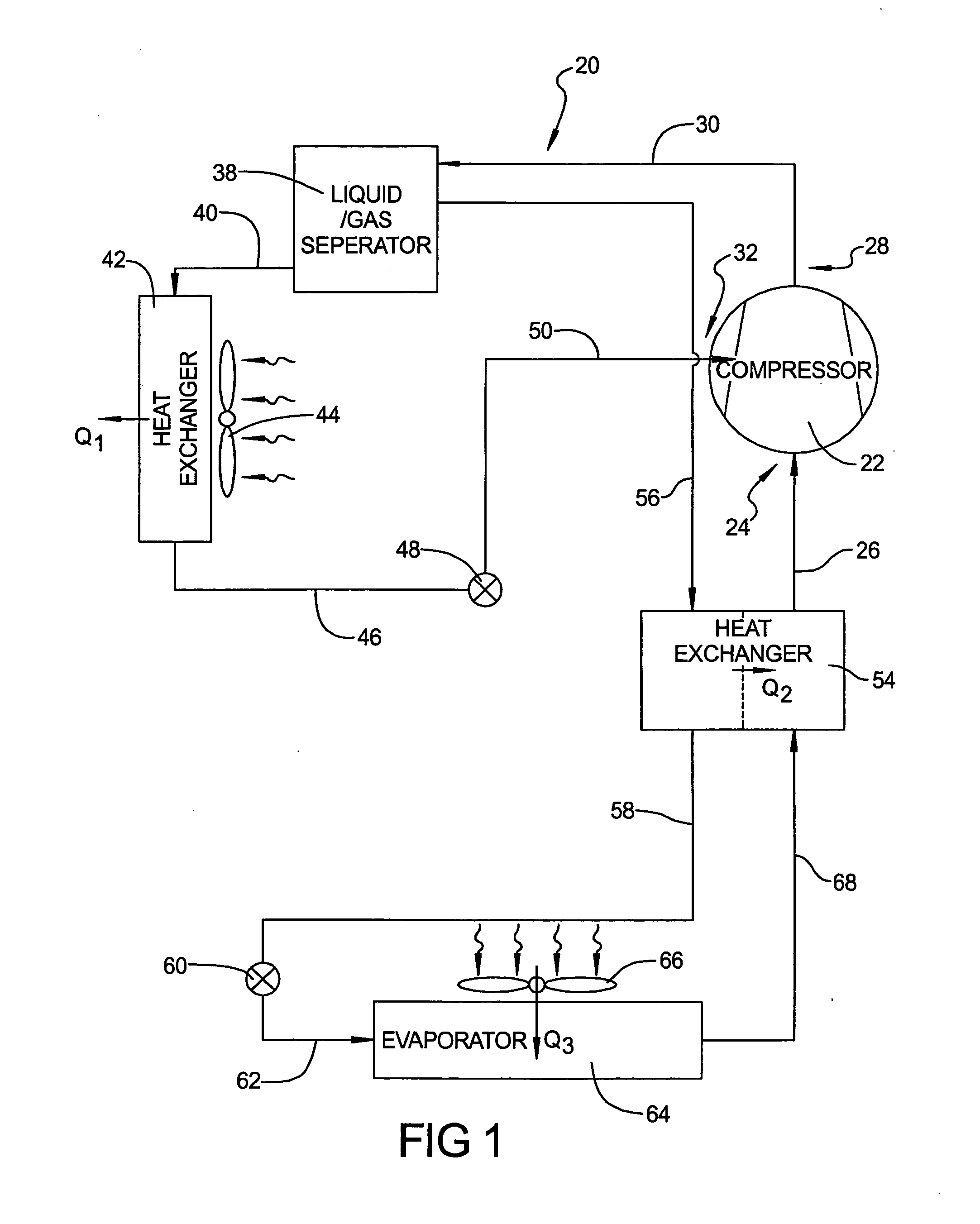

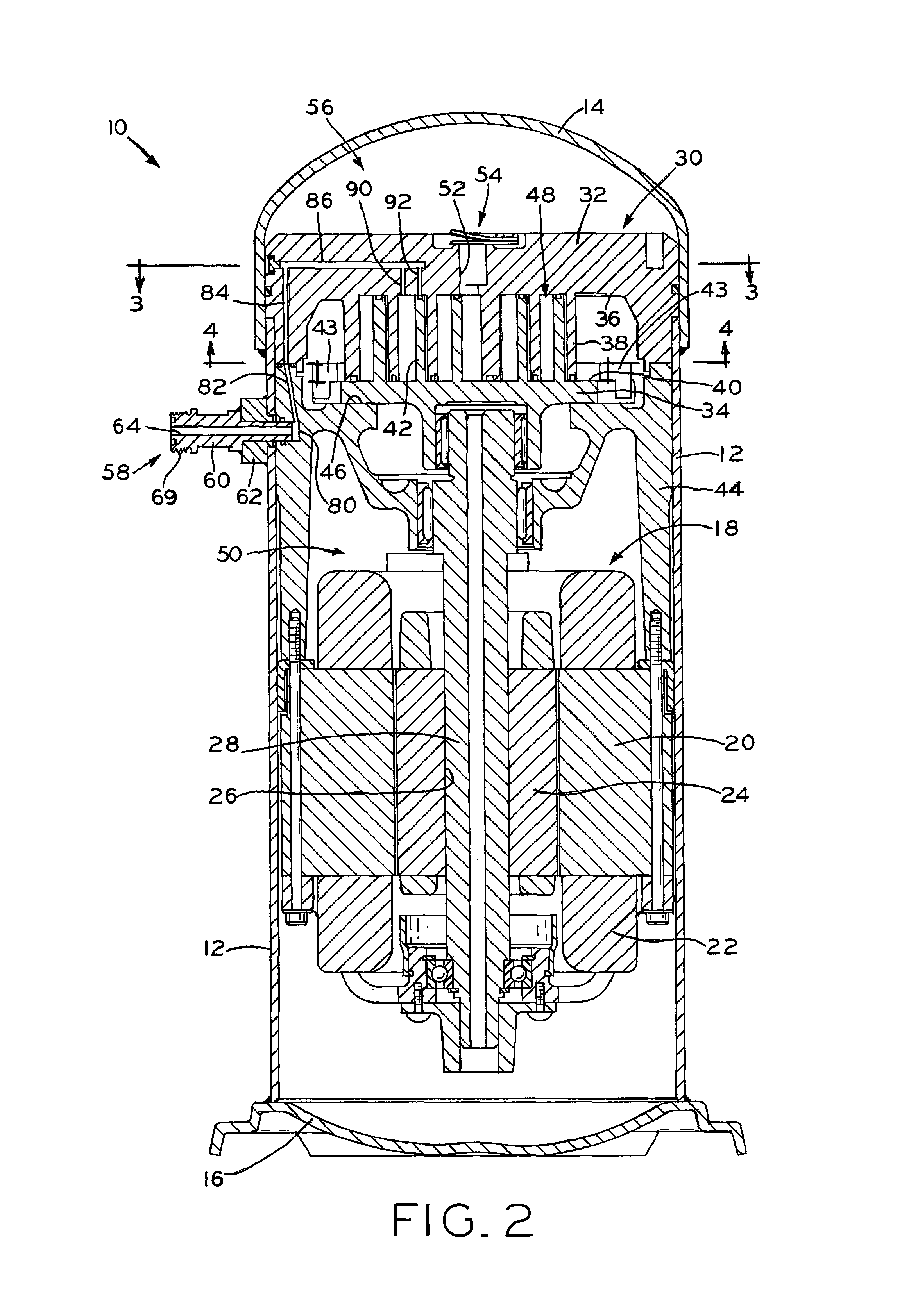

Scroll compressor utilizing liquid or vapor injection

ActiveUS8303278B2Improve compressor efficiencyRobust sealRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeWorking fluidCrankcase

A scroll compressor that utilizes liquid or vapor injection to cool a working fluid being compressed by an orbiting scroll member and a non-orbiting scroll member, and / or to increase the efficiency of the compressor. An injection fitting is secured to, and extends through, the compressor housing and receives liquid or vapor working fluid from a source external to the compressor. The non-orbiting scroll member may be fixedly mounted with respect to the crankcase of the compressor, and internal passages formed within the crankcase and the non-orbiting scroll member, which are substantially isolated from the suction pressure and discharge pressure chambers of the compressor, are used to convey liquid or vapor working fluid from the injection fitting into intermediate pressure working pockets defined between the scroll members. The compressor may include an end cap fitted over an open end of its housing which overlaps an end of the passage provided in the non-orbiting scroll member to provide a robust sealing of the passage.

Owner:TECUMSEH PROD CO

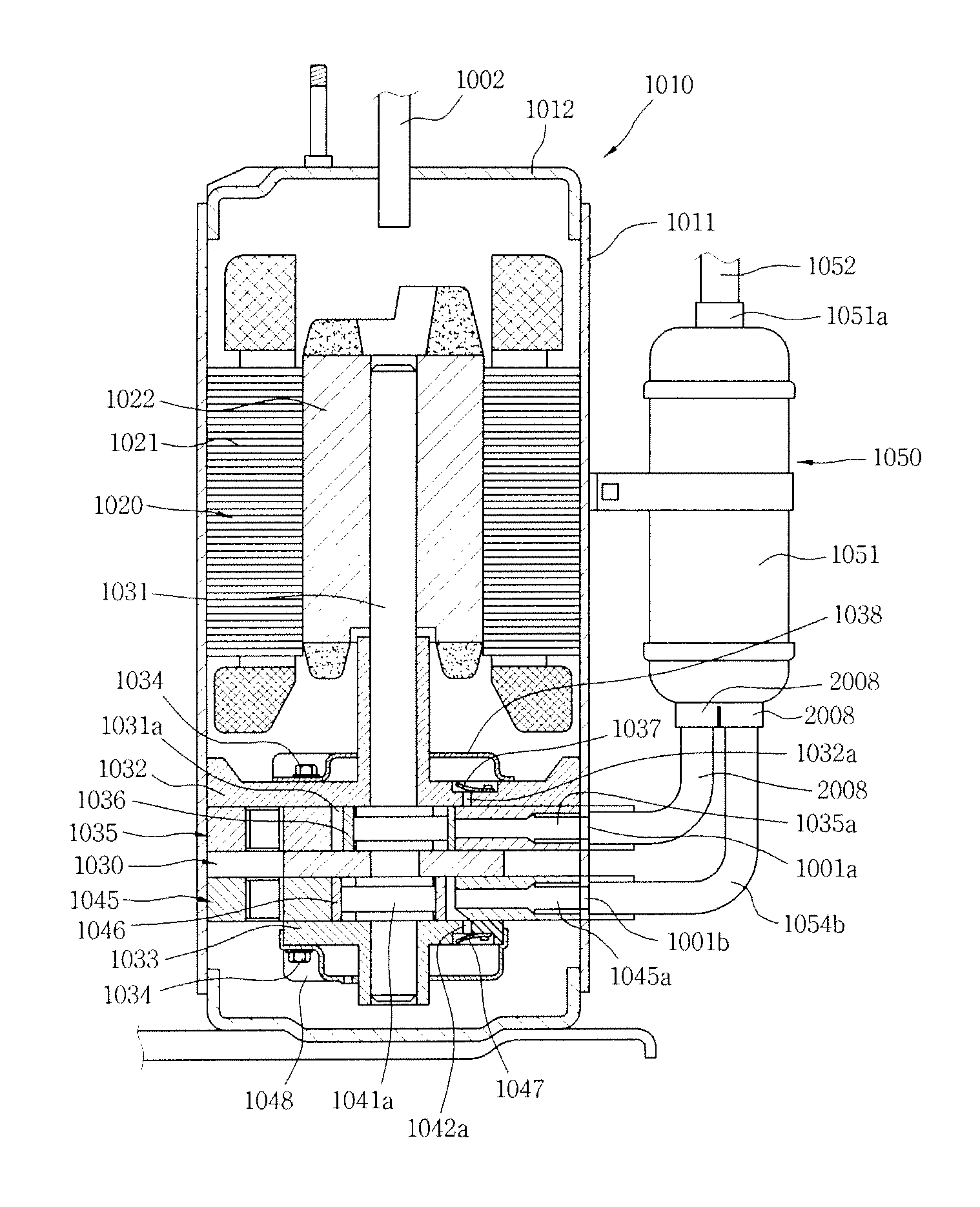

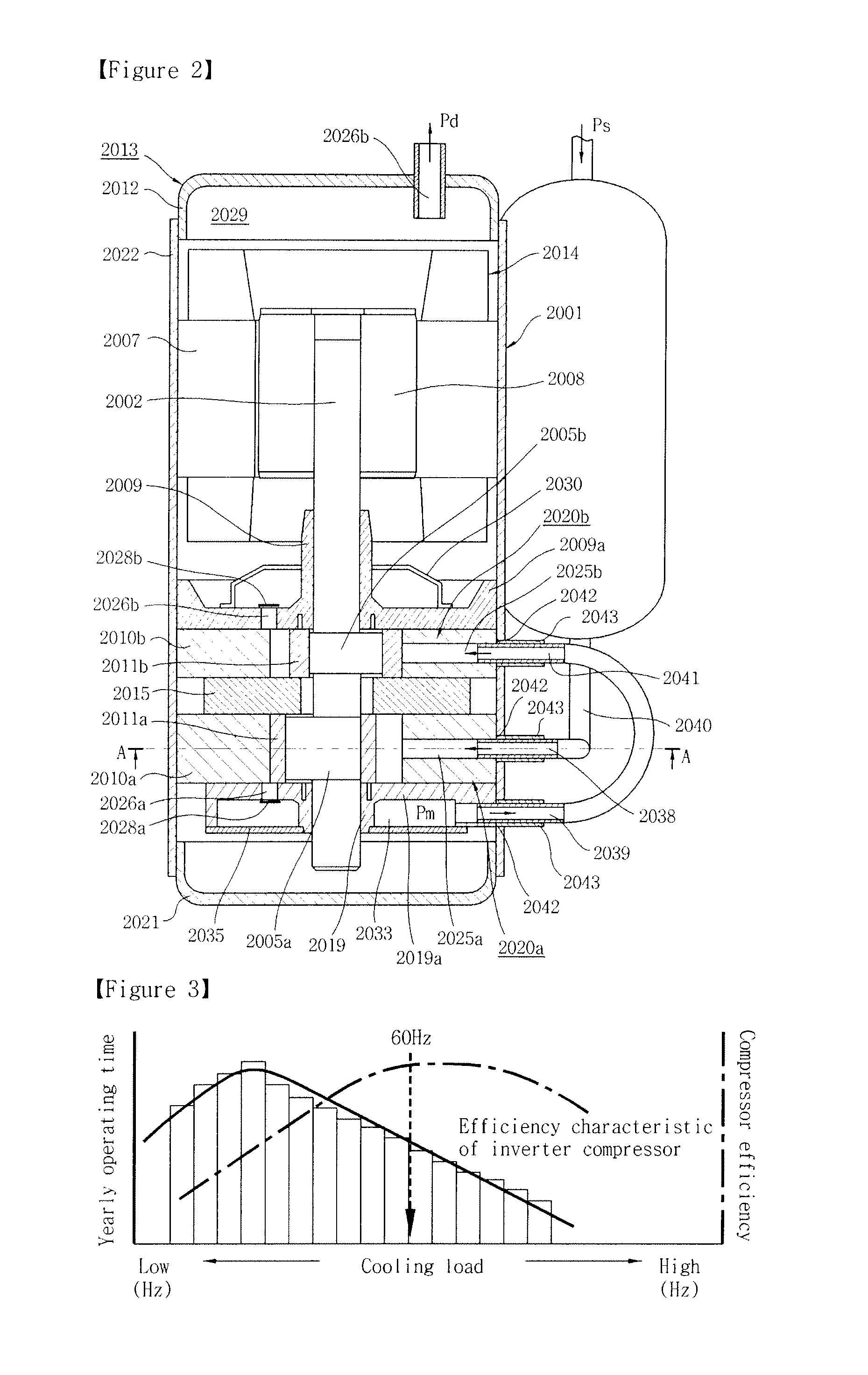

Frequency variable compressor and control method thereof

InactiveUS20110271699A1Small compression capacityImprove efficiencyRotary/oscillating piston combinations for elastic fluidsCompression machines with non-reversible cycleRefrigerantInverter compressor

The present invention discloses a frequency variable compressor, including a shell defining an airtight space, an accumulator temporarily storing refrigerant before introducing the refrigerant into the shell, a first compression mechanism unit positioned in the shell, including a rolling piston, a cylinder, a refrigerant suction hole, a refrigerant discharge hole and a vane, and compressing refrigerant, a second compression mechanism unit positioned in the shell, including a rolling piston, a cylinder, a refrigerant suction hole, a refrigerant discharge hole and a vane, and compressing refrigerant, a frequency variable motor positioned in the shell and transferring power to the rolling pistons of the first and second compression mechanism units through a rotating shaft, and a valve controlling the flow of the refrigerant such that the first and second compression mechanism units compress the refrigerant by a twin rotary compressor type or a 2-stage rotary compressor type.

Owner:LG ELECTRONICS INC

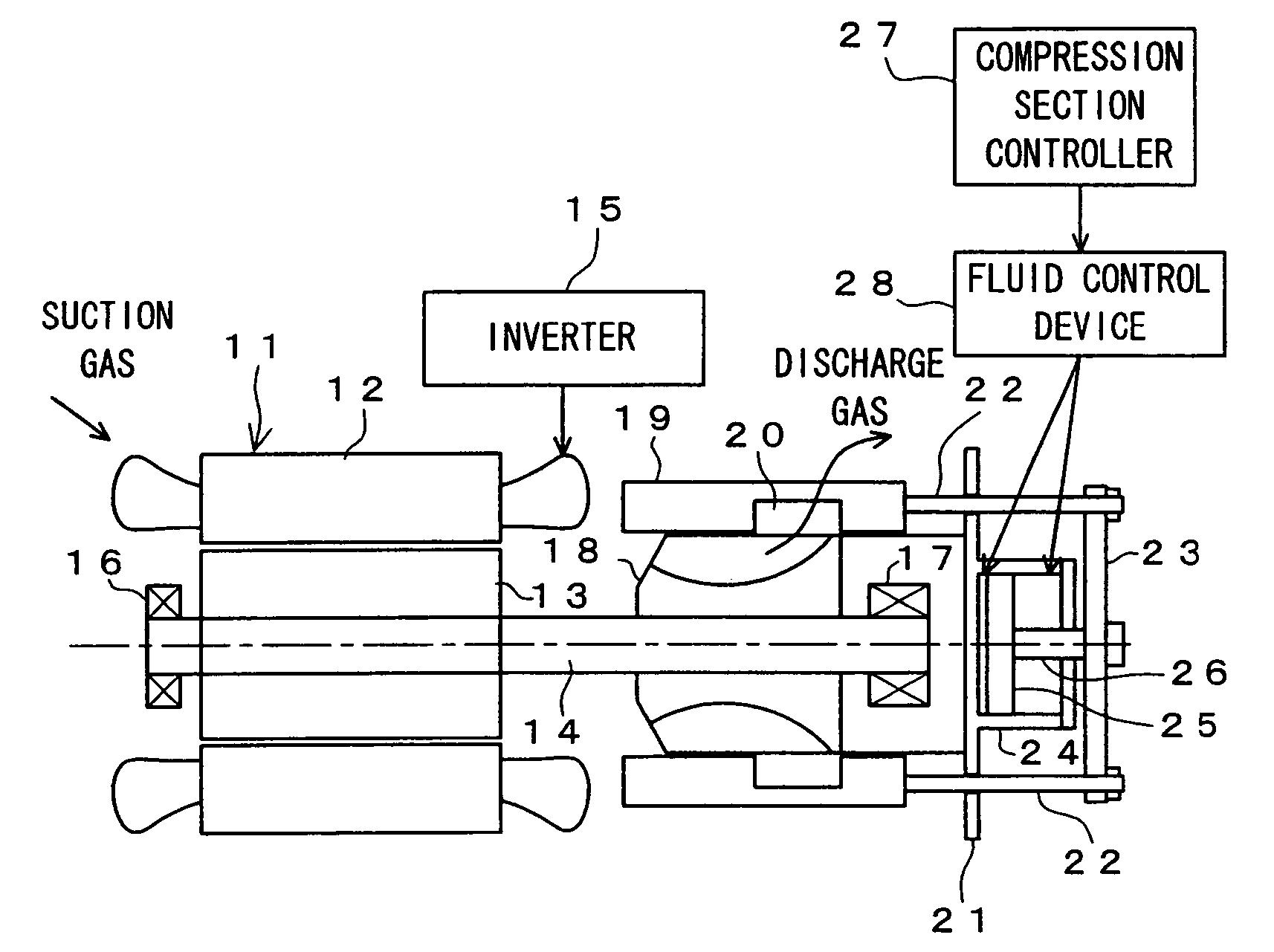

Variable inner volume ratio-type inverter screw compressor

InactiveUS20060039805A1Improve compressor efficiencyEasy to controlCompression machines with non-reversible cycleRotary piston pumpsPistonDelayed time

Regulating compression capability to a load is performed by an inverter (15) that regulates revolution number of an electric motor (11). This makes unload control in capability regulation unnecessary, preventing operational efficiency from lowering. Further, a capacity control valve for capacity control is eliminated for a simplified valve control mechanism. Regulating a variable inner volume ratio achieves the highest compressor efficiency corresponding to operating condition (capability). When a low inner volume ratio command is issued, a slide valve (19) is moved by a compression section controller (27) in an axial direction toward the electric motor (11). This advances completion time of a compression step to advance discharge of a compressed gas. When a high inner volume ratio command is issued, the slide valve (19) is moved in an axial direction toward a piston (25), which delays time of completion of compression step to delay discharge of a compressed gas.

Owner:DAIKIN IND LTD

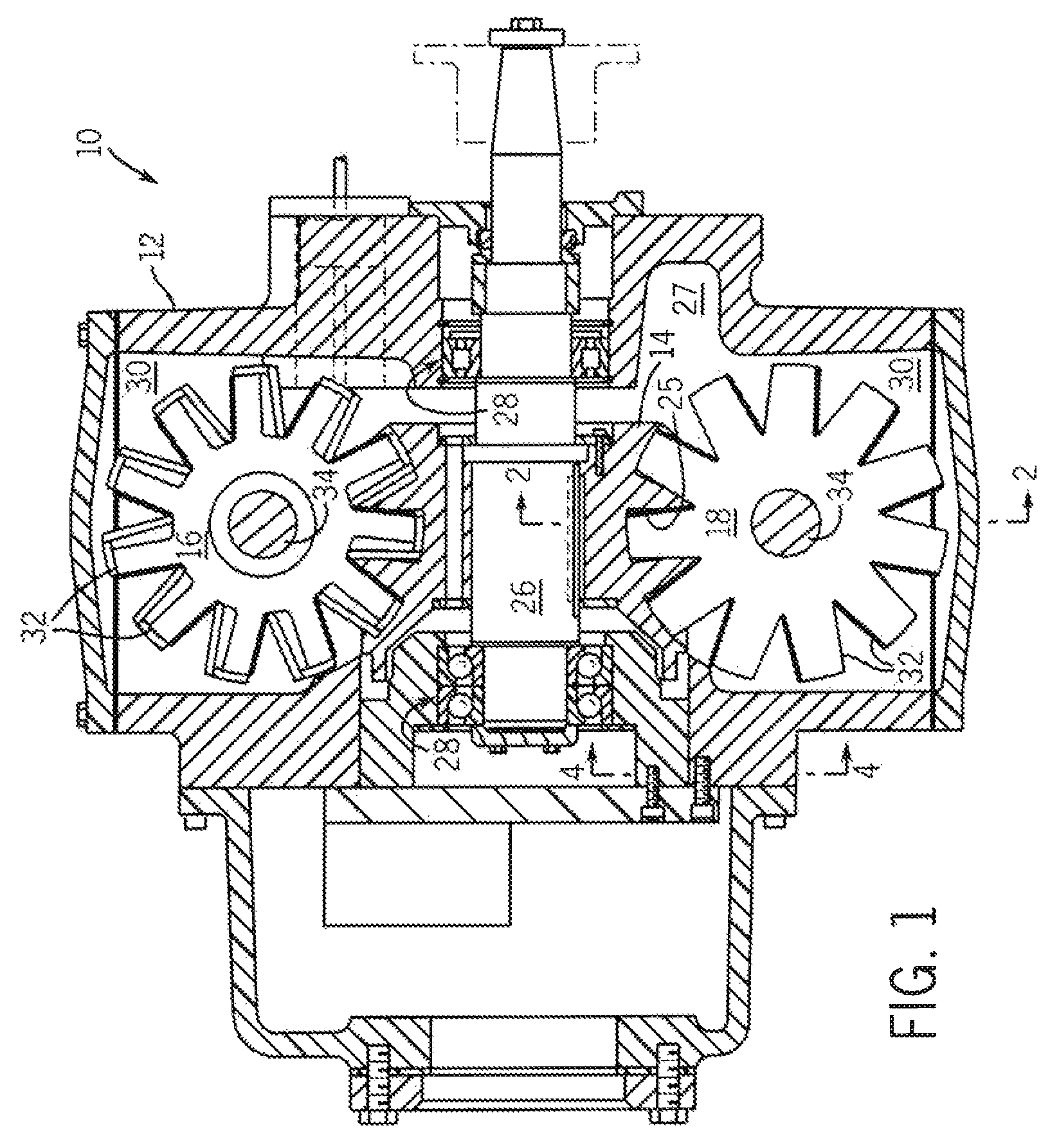

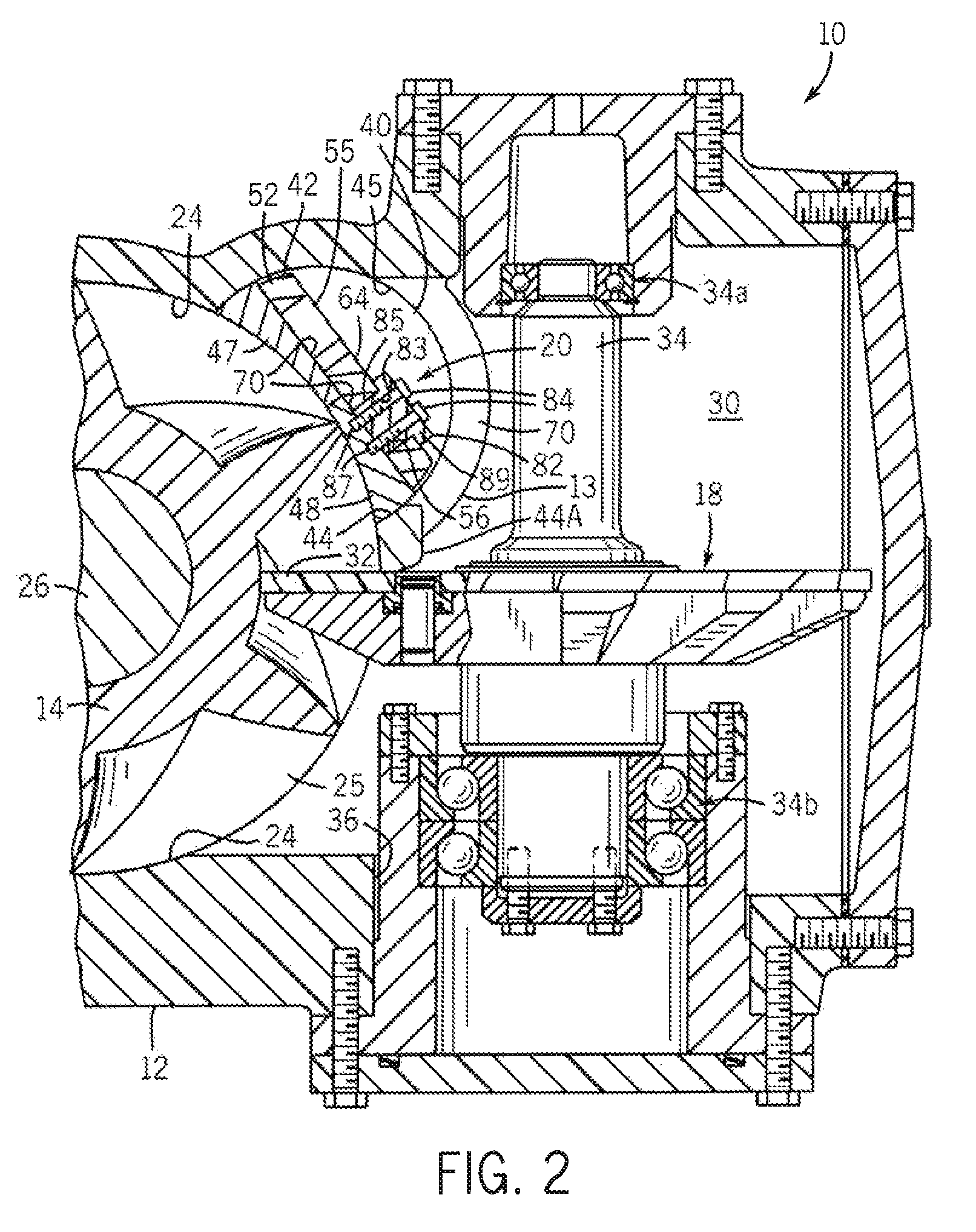

Compressor having a dual slide valve assembly

ActiveUS7891955B2Improve compressor efficiencyOscillating piston enginesEngine of counter-engagement typeGas compressorVolume load

A compressor having a dual slide valve assembly is disclosed. The slide valve assembly includes: i) a volume slide valve mechanism that is slidably movable to control compressor volume ratio and power input to the compressor; and ii) a capacity and volume slide valve mechanism that is in operational association with the volume slide valve mechanism, and the capacity and volume slide valve mechanism is slidably movable to control compressor capacity and to control volume ratio and power input to the compressor. In at least some embodiments, the compressor is a rotary gas compressor for a compression (e.g., refrigeration) system. A method of increasing compressor efficiency using the dual slide valve assembly is also disclosed. Compressor volume load and / or volume ratio and / or compressor power input can be simultaneously controlled by both the volume slide mechanism and the capacity and volume slide mechanism. Advantageously, compressor efficiency is increased.

Owner:COPELAND IND LP

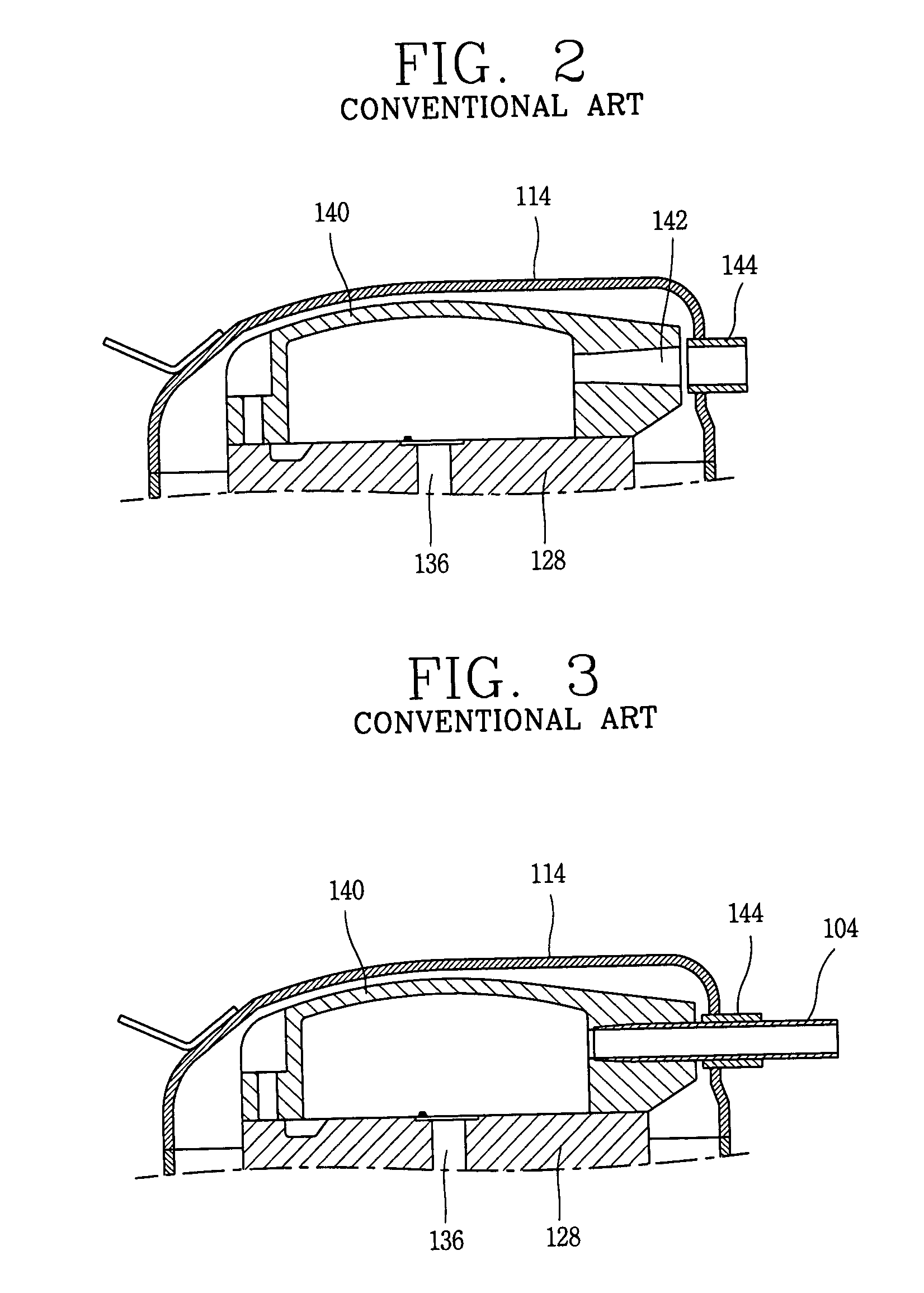

Assembling mechanism of discharge pipe for hermetic compressor and method thereof

InactiveUS7147444B2Improve compressor performanceAvoid deformationRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsEngineeringMuffler

An assembling mechanism of a discharge pipe and a method thereof, capable of preventing deformation of an upper cover and a compression unit generated in assembling the discharge pipe by improving assembling mechanism of the discharge pipe, thus to improve performance of the compressor. The assembling mechanism includes an upper cover on which a guide member having a discharge pipe inserted therein is mounted, a muffler in which an insertion hole having the discharge pipe inserted therein is formed, a first connection portion for welding / combining the discharge pipe and the muffler after inserting the discharge pipe in the insertion hole and a second connection portion for welding / combining the upper cover and discharge pipe.

Owner:LG ELECTRONICS INC

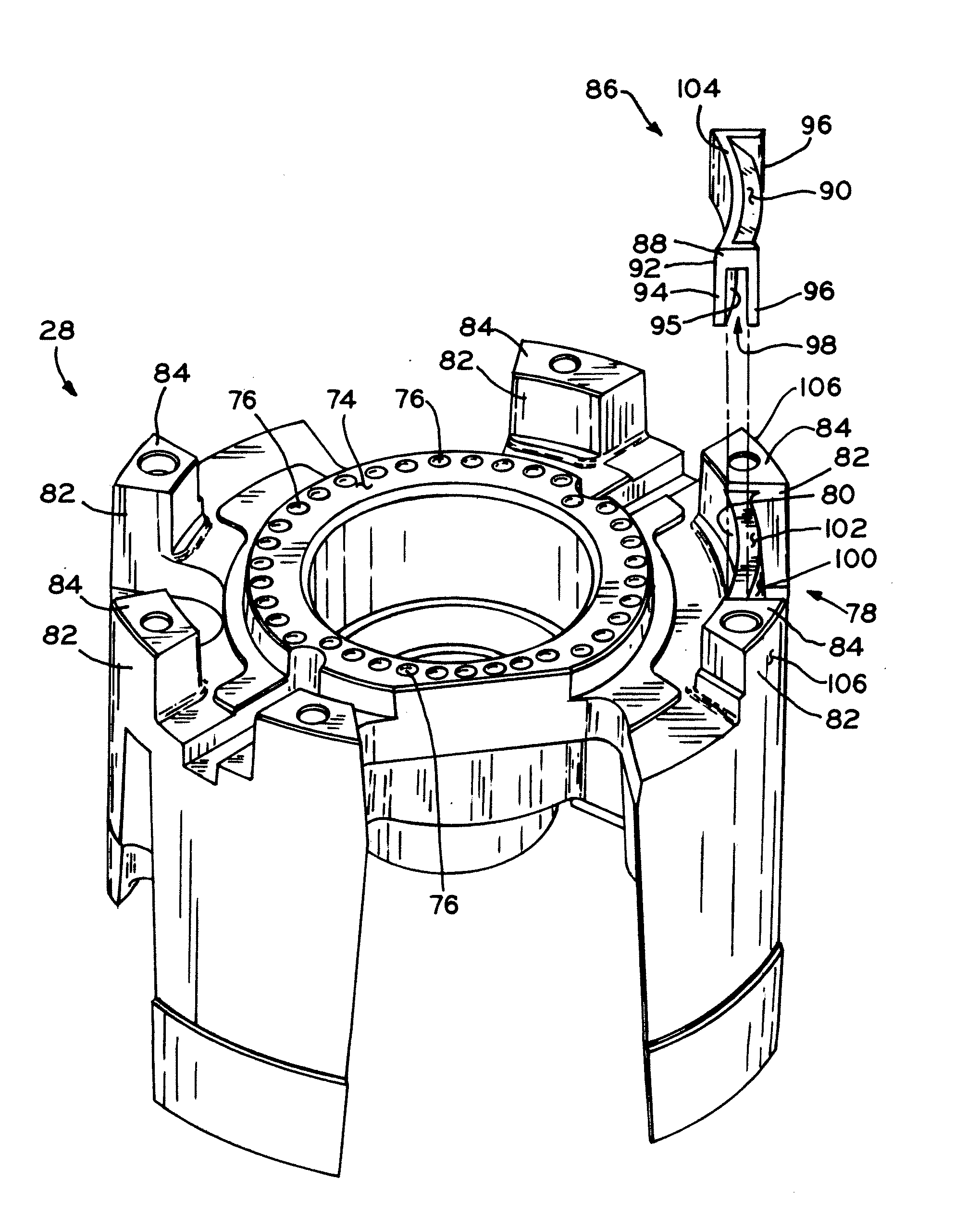

Discrete passage diffuser

InactiveUS20050118019A1Improve compressor efficiencyImproved incidence matchEngine manufacturePump componentsLeading edgeExit angle

A centrifugal compressor includes an impeller and a diffuser. The impeller has an inner integral hub with vanes thereon, is adapted to rotate within an outer shroud about a central longitudinal axis, and has a defined hub-to-shroud distribution of fluid exit angles. The diffuser, downstream from the impeller, comprises a plurality of circumferentially spaced discrete passages at least partially defining fluid paths through the diffuser, and angled such that adjacent discrete passages intersect each other to form an annular semi-vaneless diffuser inlet space. The discrete passages downstream of the semi-vaneless space each have an inlet therefrom and an outlet with a greater cross-sectional area than the inlet. The intersection of the annular semi-vaneless space and each discrete passage defines a leading edge thereof. Each discrete passage is defined by a wall bounding a cross-sectional area, the wall comprising at least a first substantially rectilinear portion and a second opposed convexly curved portion; the first substantially rectilinear portion is adjacent the hub of the impeller and the second opposed convexly curved portion is adjacent the outer shroud. The leading edge of each discrete diffuser passage provides a close incidence angle match with the fluid exit angles of the impeller.

Owner:PRATT & WHITNEY CANADA CORP

Refrigeration system

ActiveUS8181478B2Improve cooling effectImprove compressor efficiencyCompressorCompression machines with non-reversible cycleRefrigerationRefrigerant

A refrigeration system can incorporate a liquid-injection system that can provide a cooling liquid to an intermediate-pressure location of the compressor. The cooling liquid can absorb the heat of compression during the compression of the refrigerant flowing therethrough. The refrigeration system can include an economizer circuit that injects a refrigerant vapor into an intermediate-pressure location of the compressor in conjunction with the injection of the cooling liquid. The incorporation of the vapor injection in conjunction with the cooling-liquid injection can advantageously increase the cooling capacity and / or efficiency of the refrigeration system and the performance of the compressor.

Owner:COPELAND LP

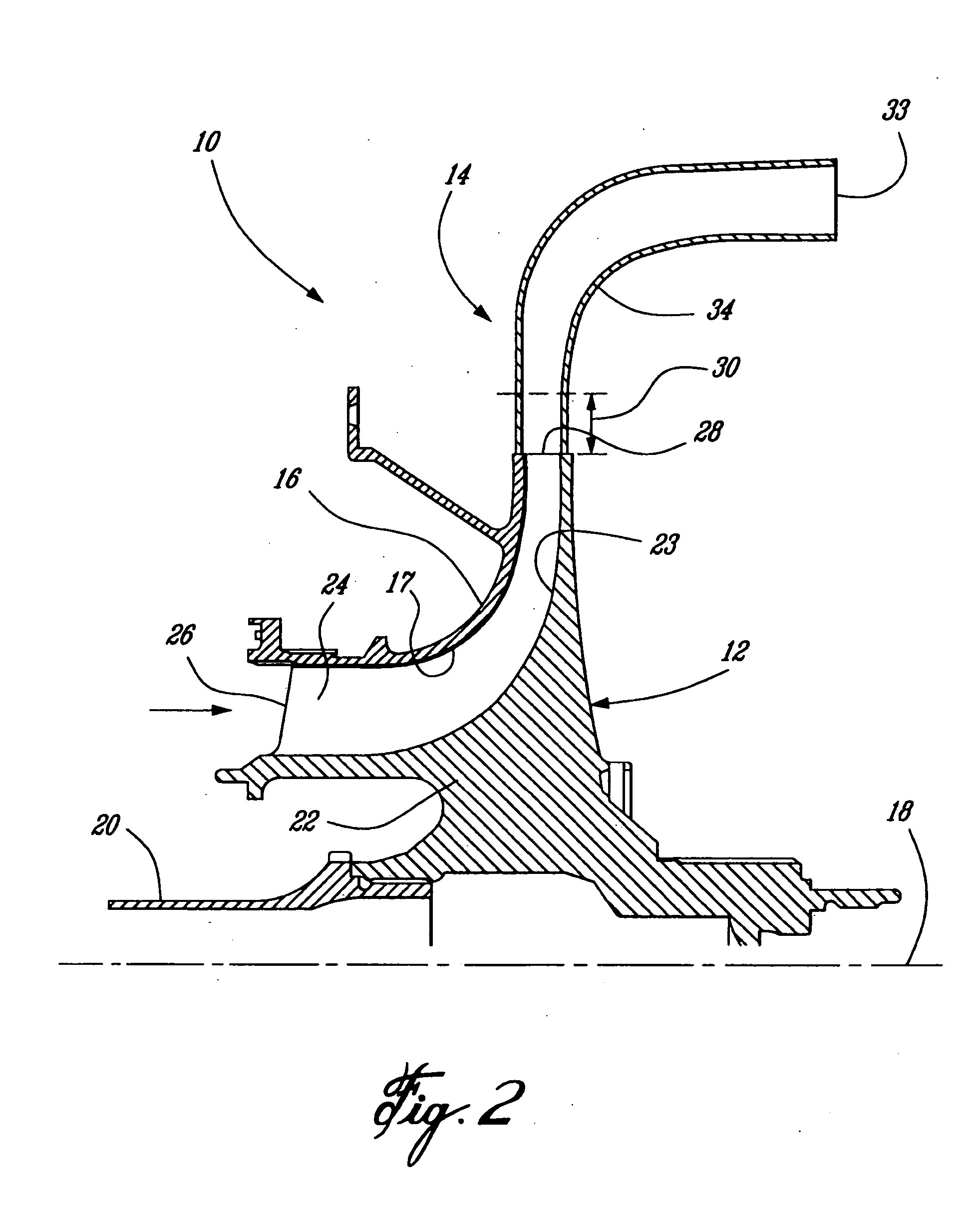

Suction baffle for scroll compressors

InactiveUS20060245967A1Reduce turbulent flowImprove compressor efficiencyRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeFastenerWorking fluid

A scroll compressor including a hermetic housing with a motor-compressor unit disposed therein, including fixed and orbiting scrolls. The fixed scroll defines perpendicular axial and radial directions, and includes an outer wall having a suction inlet facing substantially in the radial direction. A baffle member is associated with the suction inlet of the fixed scroll, and in one embodiment, is attached to the fixed scroll with fasteners. The baffle member includes a first open end facing in the axial direction toward a suction port of the compressor housing, and a second open end facing in the radial direction in fluid flow alignment with the suction inlet of the fixed scroll. The baffle member directs a portion of the working fluid which enters the compressor housing substantially directly into the suction inlet of the fixed scroll to reduce turbulent flow of the working fluid within the compressor housing, improving the operating efficiency of the compressor.

Owner:TECUMSEH PROD CO

Electric motor driven supercharger with air cycle air conditioning system

ActiveUS20060059927A1Improve compressor efficiencyReduce energy wasteDomestic cooling apparatusAir-treatment apparatus arrangementsAir cycleAir conditioning

An inventive air conditioning system includes an air conditioning pack for receiving pressurized air and converting the pressurized air into conditioned air for an aircraft. Pressurized air is provided by a compressed air supply system that is fluidly connected to the air conditioning pack for providing air to the air conditioning pack. The compressed air system includes a compressor driven by an electric motor. The electric motor is commanded by a controller to provide pressurized air when needed. In particular, the controller commands the electric motor based upon a desired conditioned airflow that is to be provided by the air conditioning pack. For high altitude aircraft, applications, a diffuser is used to increase the efficiency of the compressor within the compressed air supply system.

Owner:HAMILTON SUNDSTRAND CORP

Air conditioning system for vehicle

ActiveUS6973798B2Improve cooling effectImprove fuel economyAir-treating devicesCompression machines with non-reversible cycleMotor driveAir conditioning

An air conditioning system 1 includes a primary compressor (an engine-driven compressor 6) driven by a primary driving source (an engine 2) and a secondary compressor (a motor-driven compressor 7) driven by a secondary driving source (a motor 3). When a required cooling capability is equal to or greater than a predetermined value, the air conditioning system 1 causes the primary compressor (the engine-driven compressor 6) to be driven by the primary driving source (the engine 2) and adjusts the rotational speed of the secondary compressor (the motor-driven compressor 7), whereas when the required cooling capability is equal to or smaller than the predetermined value, the air conditioning system 1 causes the secondary compressor (the motor-driven compressor 7) to be driven by the secondary driving source (the motor 3) so as to control the rotational speed of the primary compressor (the engine-driven compressor 6).

Owner:SHAREINTEL +1

Cylinder filling oxygen concentrator

InactiveUS7550031B2Improve efficiencyImprove compressor efficiencyRespiratorsGas treatmentMotor driveOxygen tank

An energy efficient oxygen concentrator for filling high pressure portable cylinders with medical oxygen for use by ambulatory patients. Two compressors provide two pressurized air sources, one for operating an oxygen concentrator to provide a stream of oxygen enriched gas, and the other for driving a pressure intensifier for filling portable oxygen cylinders. Pressurized exhaust from the pressure intensifier is returned to the inlet side of at least one of the compressors for reducing the energy required to drive the compressor. Preferably, each compressor has a single reciprocating piston, a single motor drives both pistons and the pressurized exhaust from pressure intensifier is provided to the inlets for both compressors.

Owner:DEVILBISS HEALTHCARE

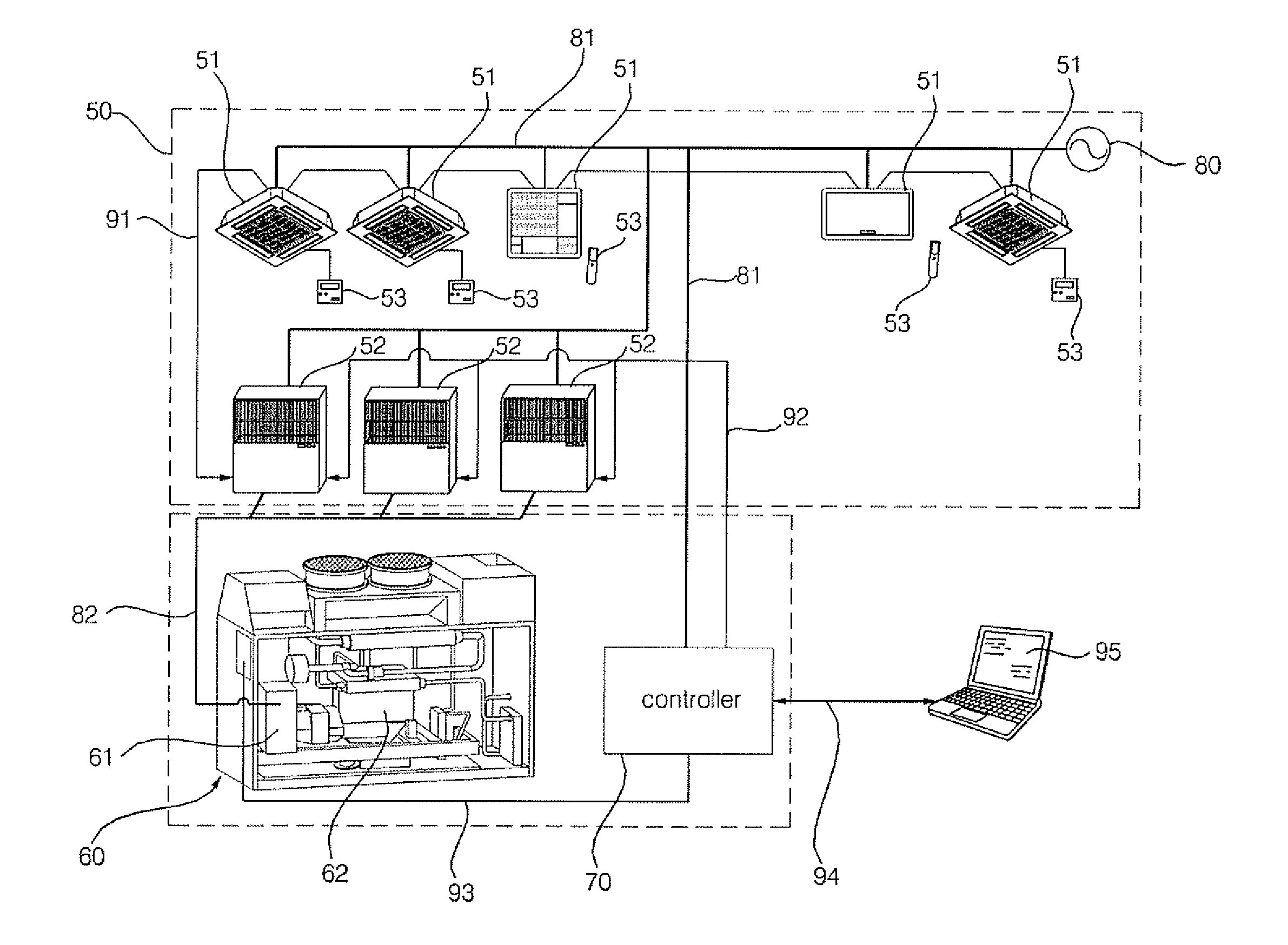

Cogeneration system and method for controlling the same

InactiveUS20070018009A1Easy to operateEasy to useMechanical apparatusEnergy industryElectricityCogeneration

A cogeneration system and a method for controlling the same have an advantage that it is easy to operate a cogeneration device because the operation of the cogeneration device can be controlled according to operation signals of an air conditioner, and have an effect that it is possible to make the best use of the generated electricity of the cogeneration device through an interconnection between the air conditioner and the cogeneration device.

Owner:LG ELECTRONICS INC

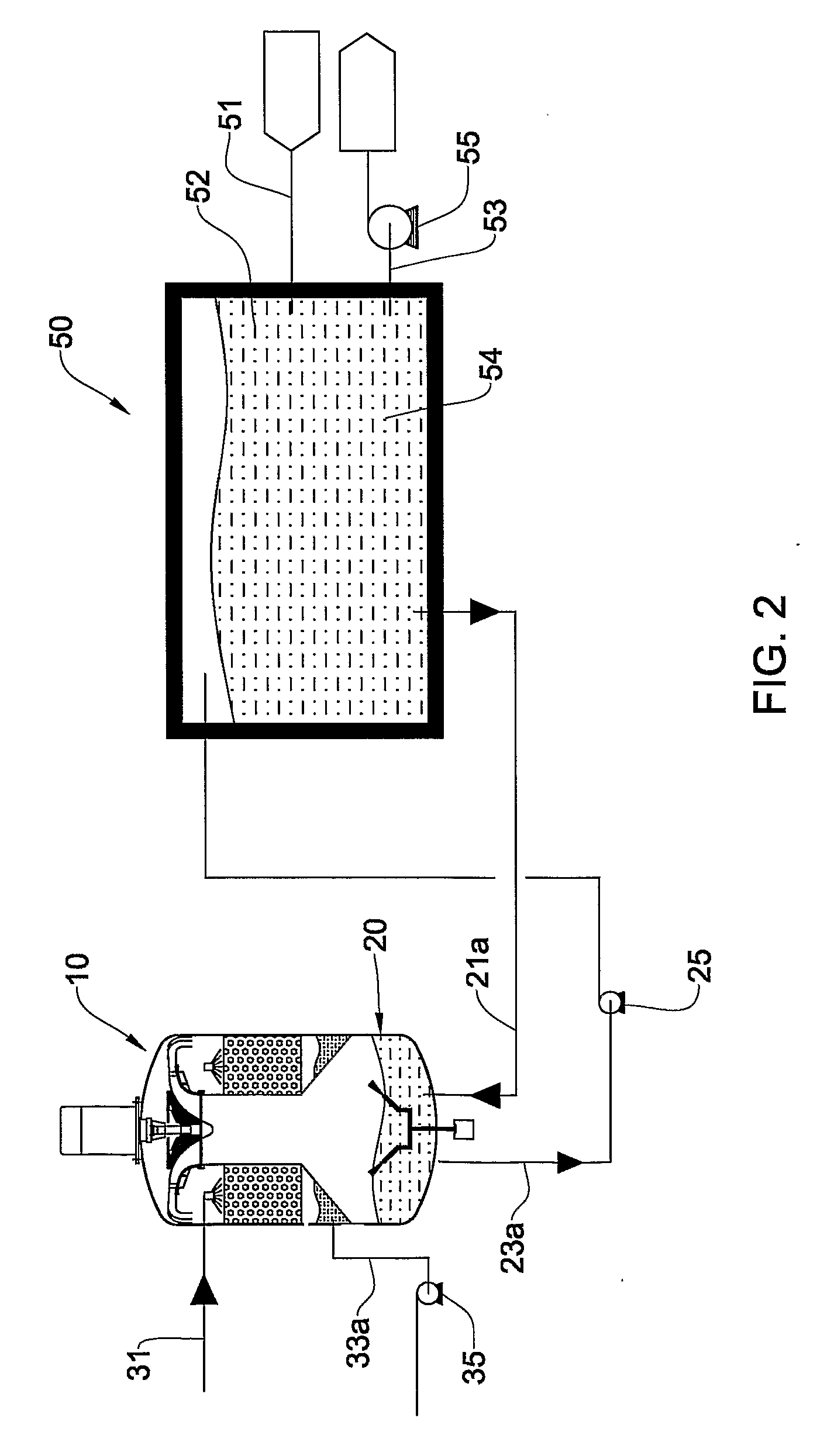

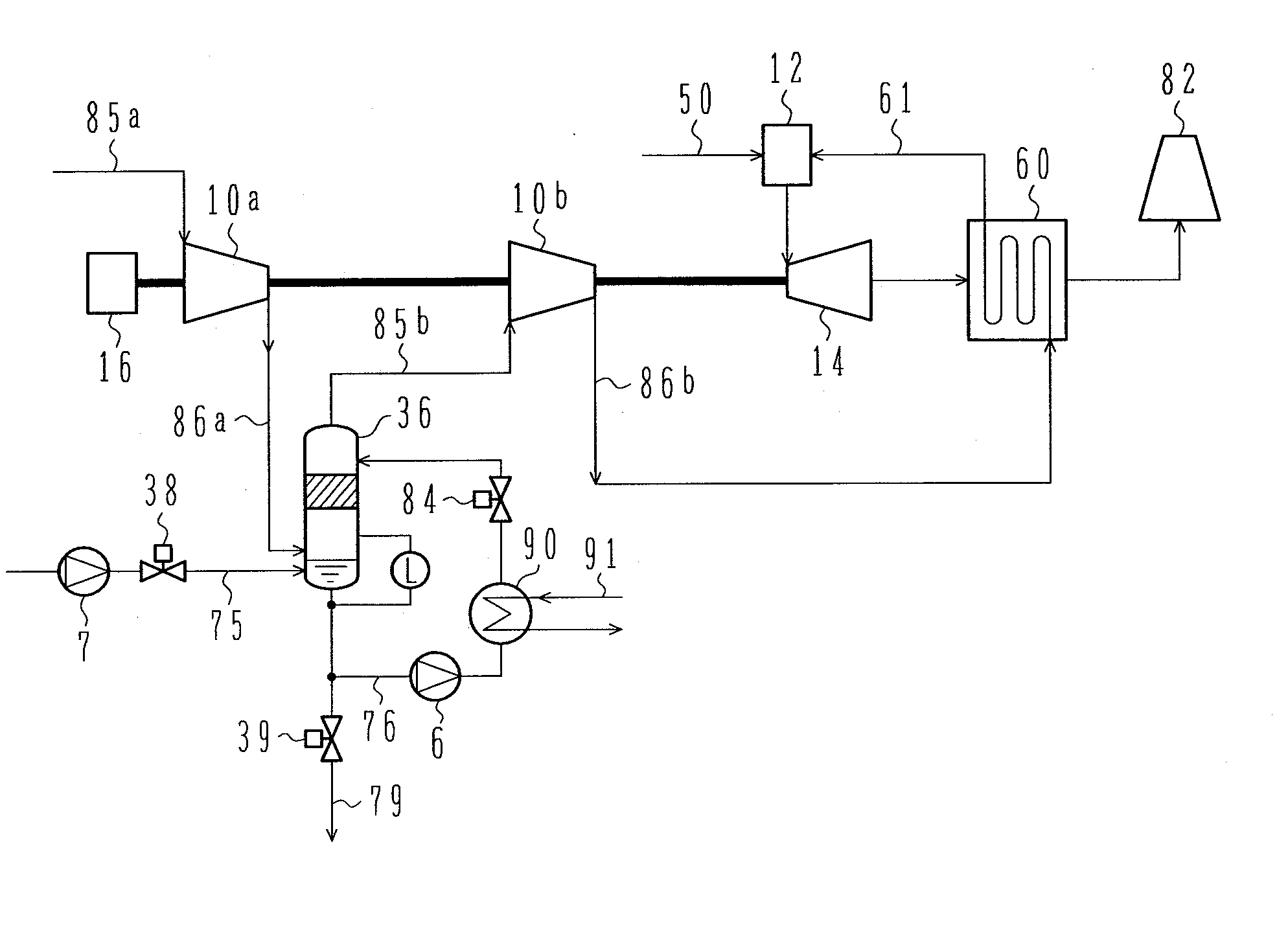

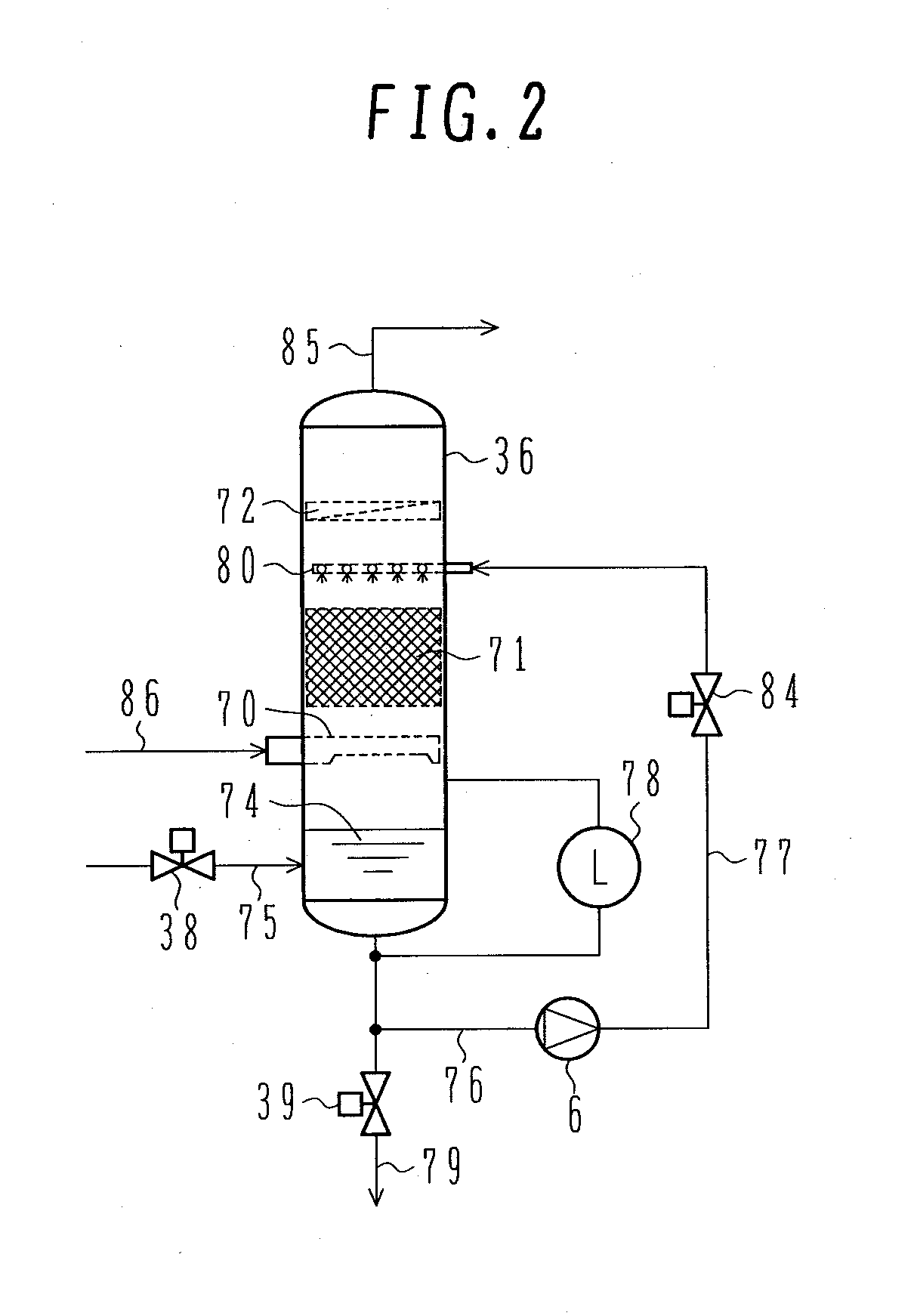

Cooling apparatus, gas turbine system using cooling apparatus, heat pump system using cooling system, cooling method, and method for operating cooling apparatus

InactiveUS20090056303A1Improve compressor efficiencyLow efficiencyPump componentsTurbine/propulsion engine coolingIntercoolerChiller

The amount of water to be injected in an intercooler is controlled to cool the compressed gas to the saturation temperature. It is difficult to adjust the amount of the water to be injected, however, since the temperature of the compressed gas at an intercooler outlet is actually higher than the saturation temperature. An intercooling system is configured so as to cool a gas to the saturation temperature without controlling the amount of water injection and thereby maintain the reliability of the compressor while improving the cooling efficiency.The intercooling system is located between a plurality of compression stages of a gas compressor to cool the gas that has been in the compressor. A desired amount of liquid is sprinkled to cool the compressed gas while restraining inflow of the liquid into the compression stages.

Owner:HITACHI LTD

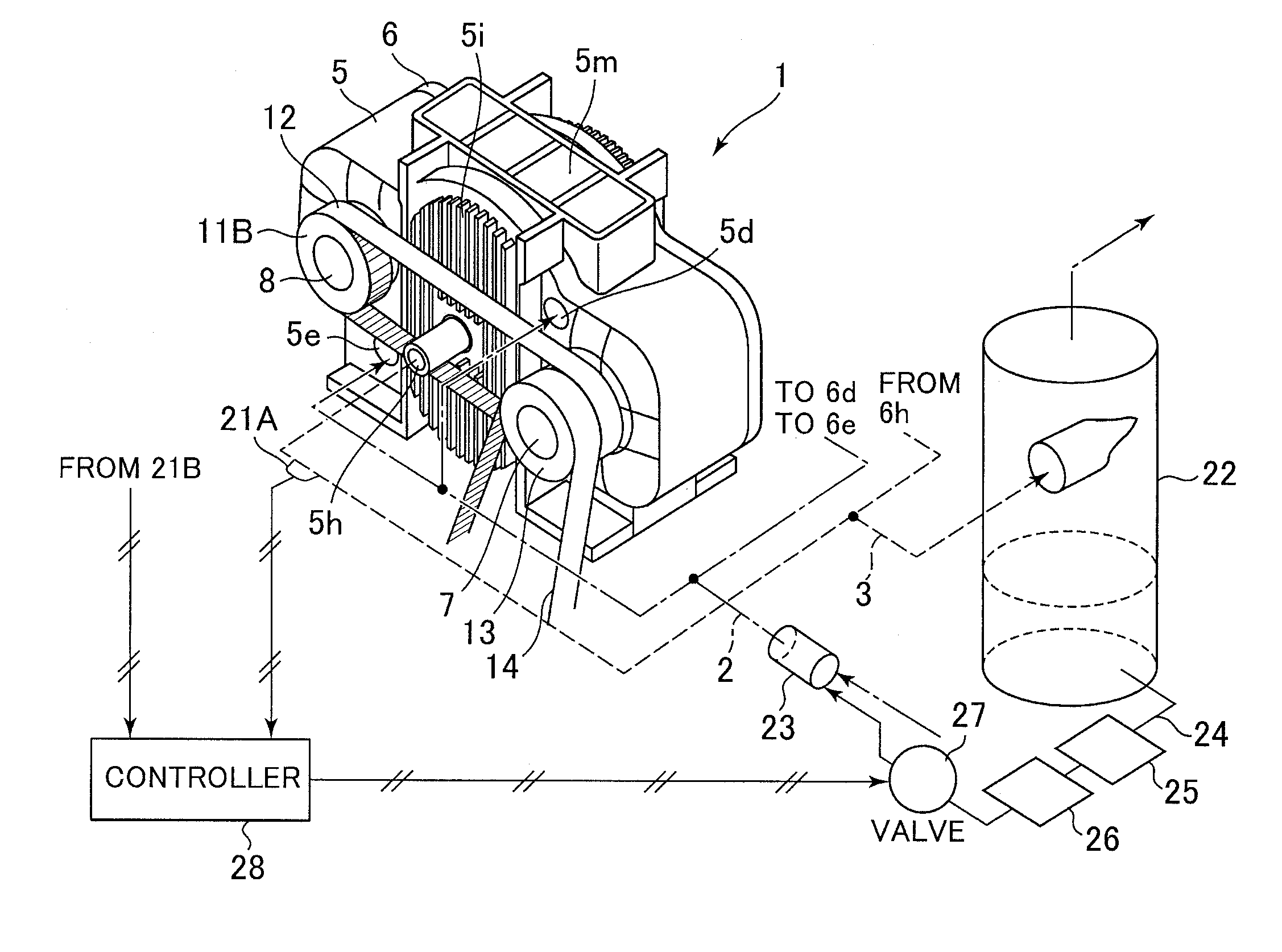

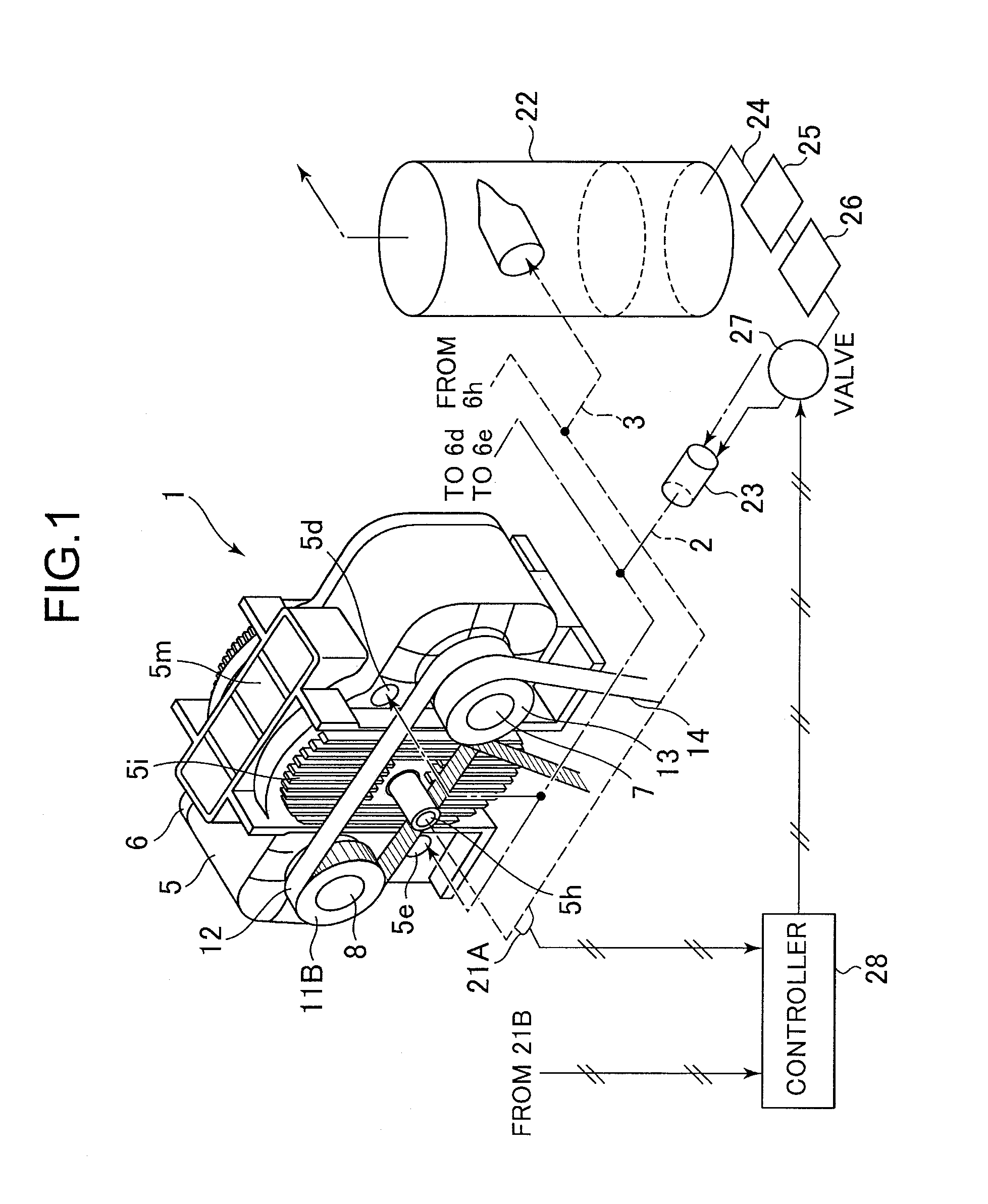

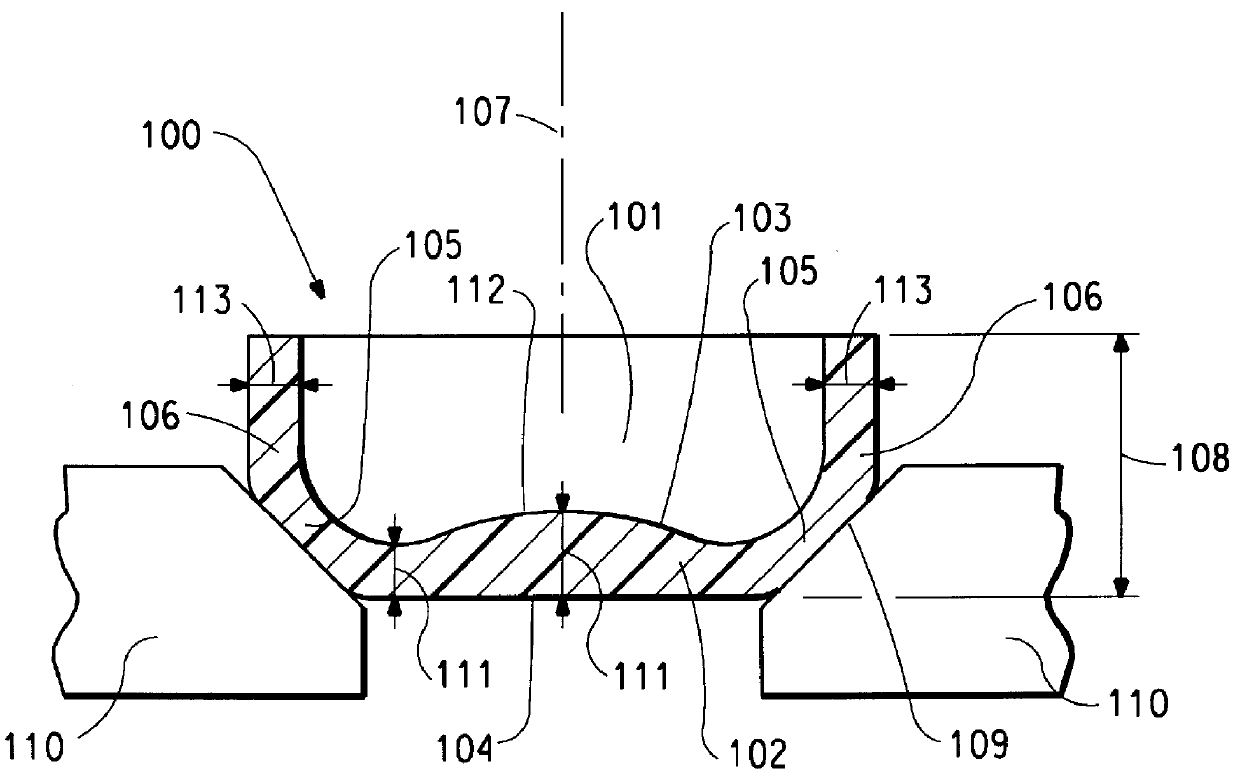

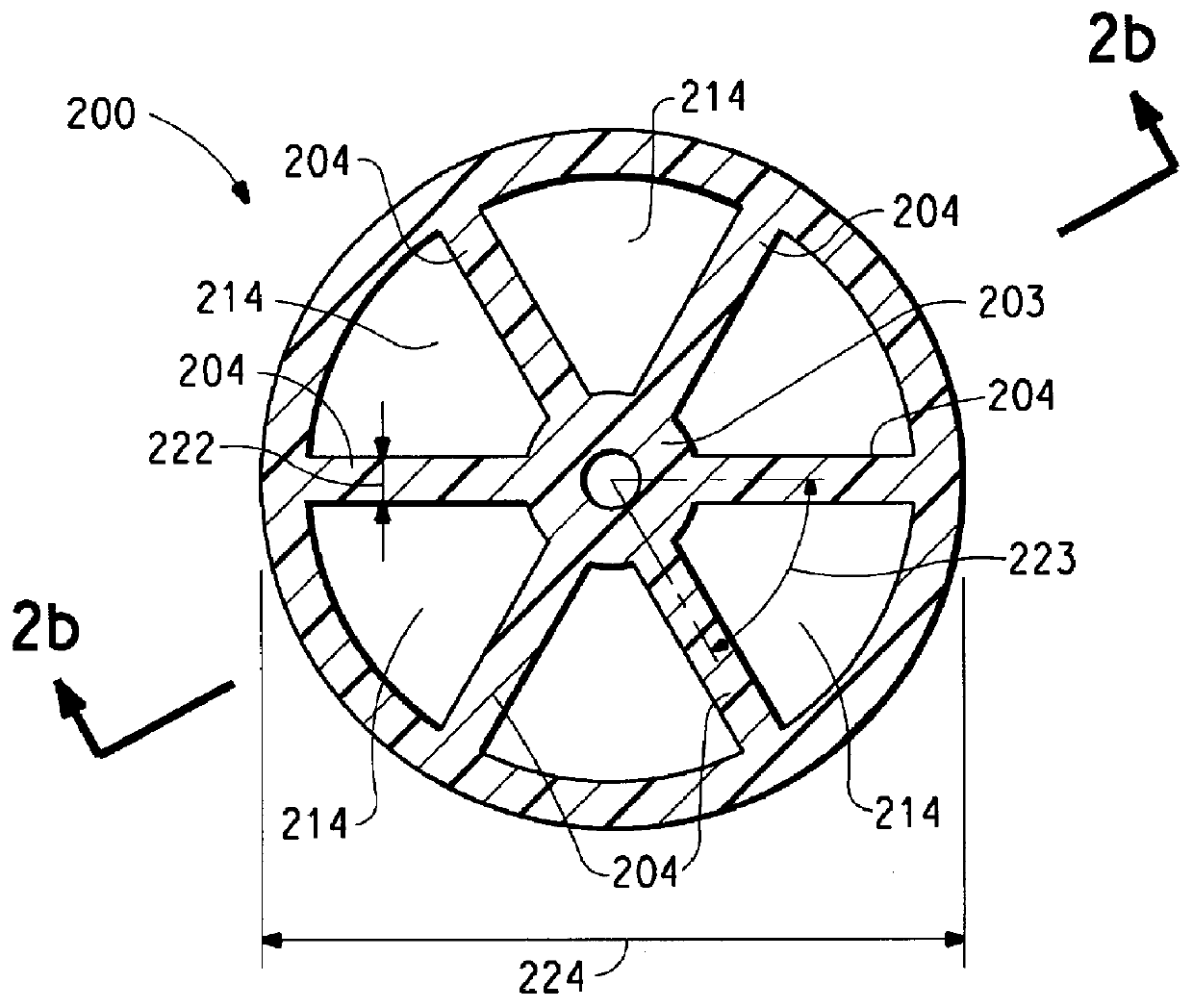

Water-injection type scroll air compressor

ActiveUS20110129362A1Quantity minimizationAccomplished more rapidlyEngine of arcuate-engagement typeGas turbine plantsWater volumeWater flow

Disclosed is a water-injection type scroll air compressor whose pre-stopping operation time for drying can be reduced while enhancing compressor efficiency. The compressor body 1 includes a water supply line 24 for supplying water to a water feeder 23 connected to an air suction line 2. The water supply line 24 is provided with a control valve 27 that can control a flow rate of the water. A controller 28 conducts driving control of the control valve 27 in a 5×10−5 to 40×10−5 range of an injected-water volume ratio (more specifically, a volume ratio between an intake air flow rate and injected-water flow rate in the water feeder 23 of the suction line 2) and at the same time, in an injected-water volume ratio range of the compressor characterized so that an increase rate of overall adiabatic efficiency of the compressor per 1×10−5 increase rate of the injected-water volume ratio stays less than 2% of an original or initial value.

Owner:HITACHI IND EQUIP SYST CO LTD

Uniform cross-section and ribbed thermoplastic compressor valve

InactiveUS6024126AReduce partIncreased dimensional tolerancesPositive displacement pump componentsCheck valvesEngineeringMechanical engineering

A uniform cross-section and ribbed thermoplastic compressor valve which can be used as a discharge valve for a compressor and has internal rib structure and uniform wall thickness. The valve member can be made of high-performance polymeric resin such as polyimide. The valve member comprises a base member, an annular wall member, a central member protruding from the base member, and a plurality of internal wall members. The internal wall members provide the internal rib structure which strengthens the valve member and allows for light-weight construction. Preferably, there are six internal wall members and the central member has a cavity.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com