Reciprocating compressor, driving unit and control method for the same

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

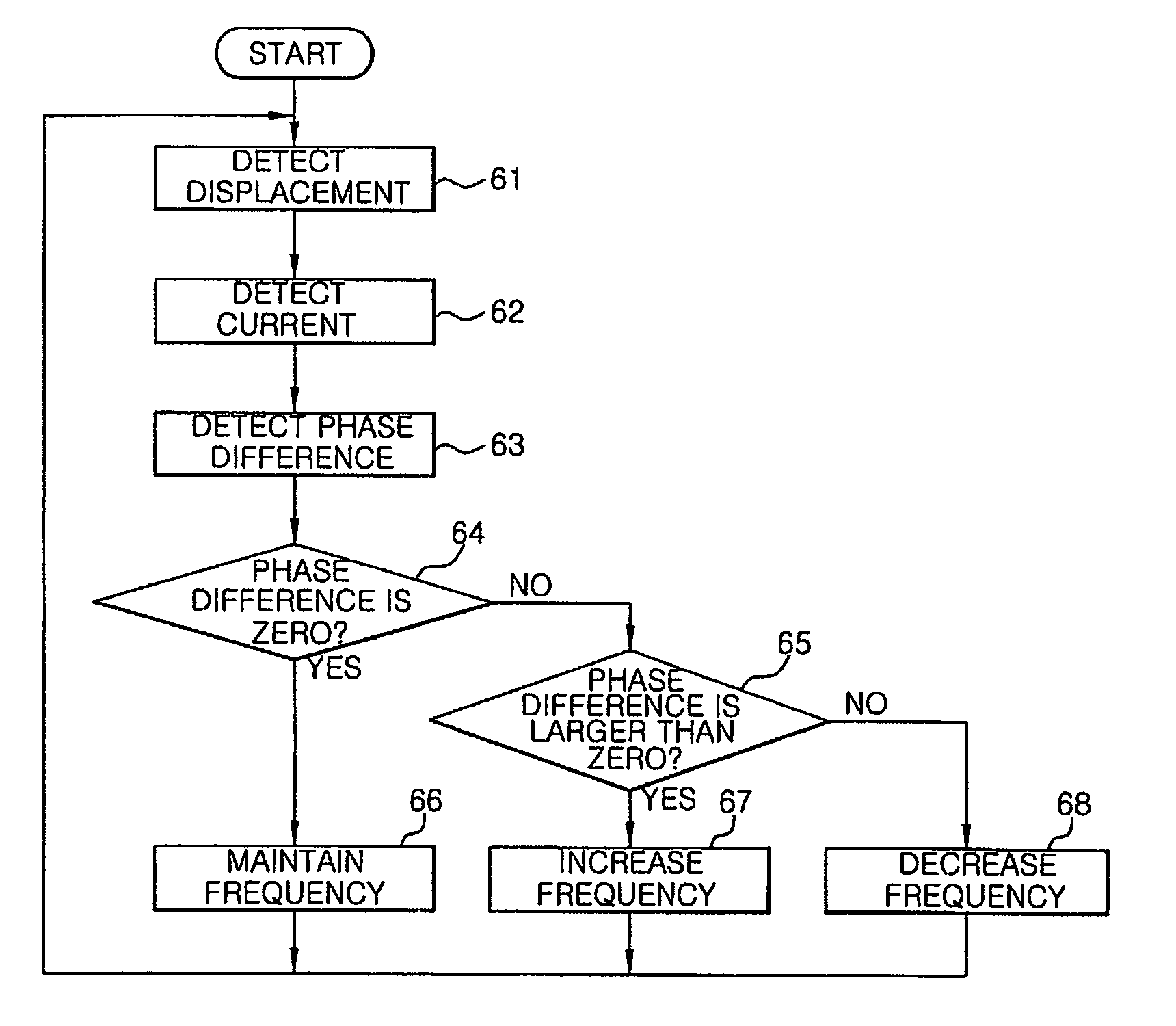

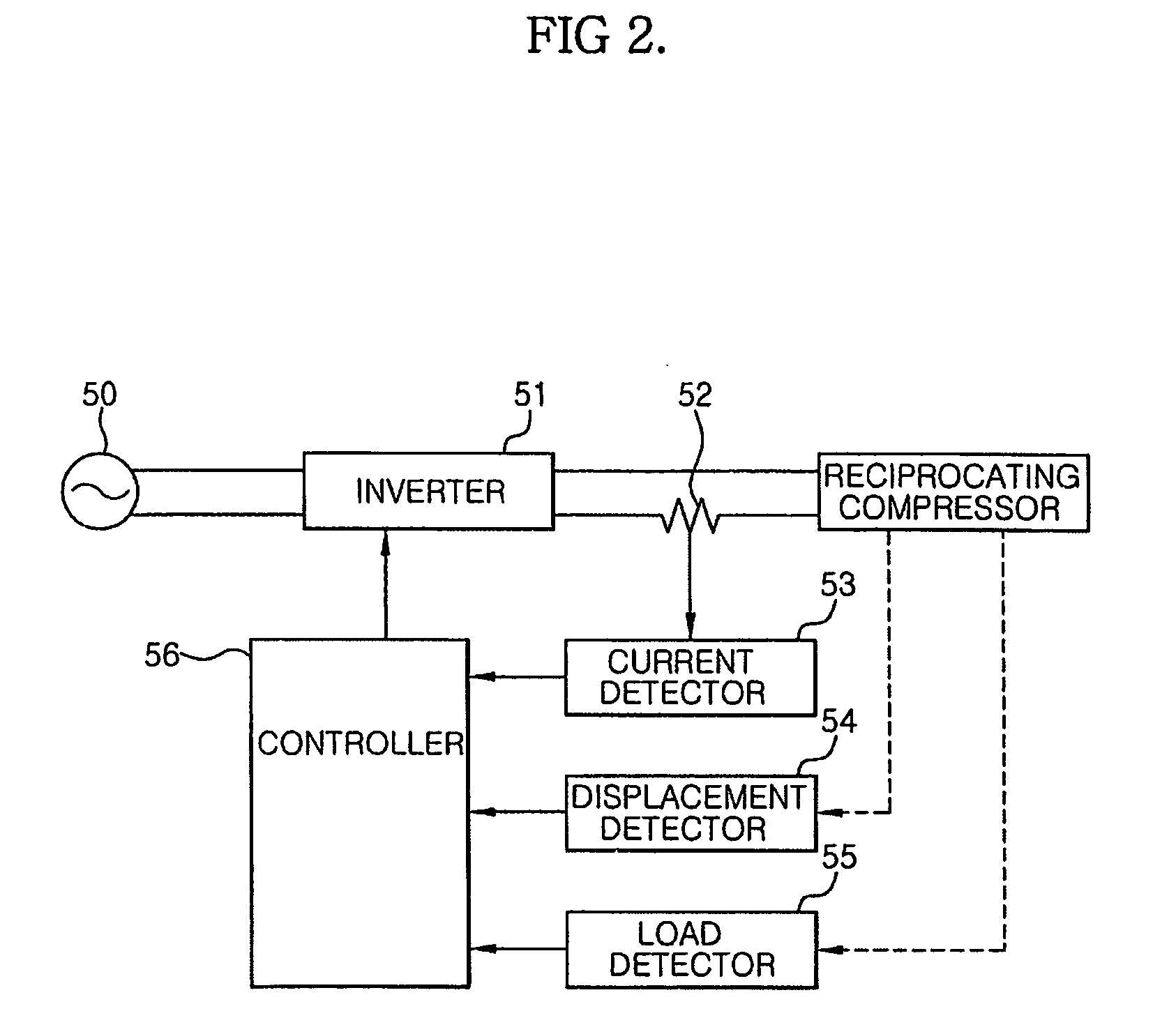

[0028] Reference will now be made in detail to the embodiment of the present invention, an example of which is illustrated in the accompanying drawings, wherein like reference numerals refer to like elements throughout. The embodiment is described below to explain the present invention by referring to the figures.

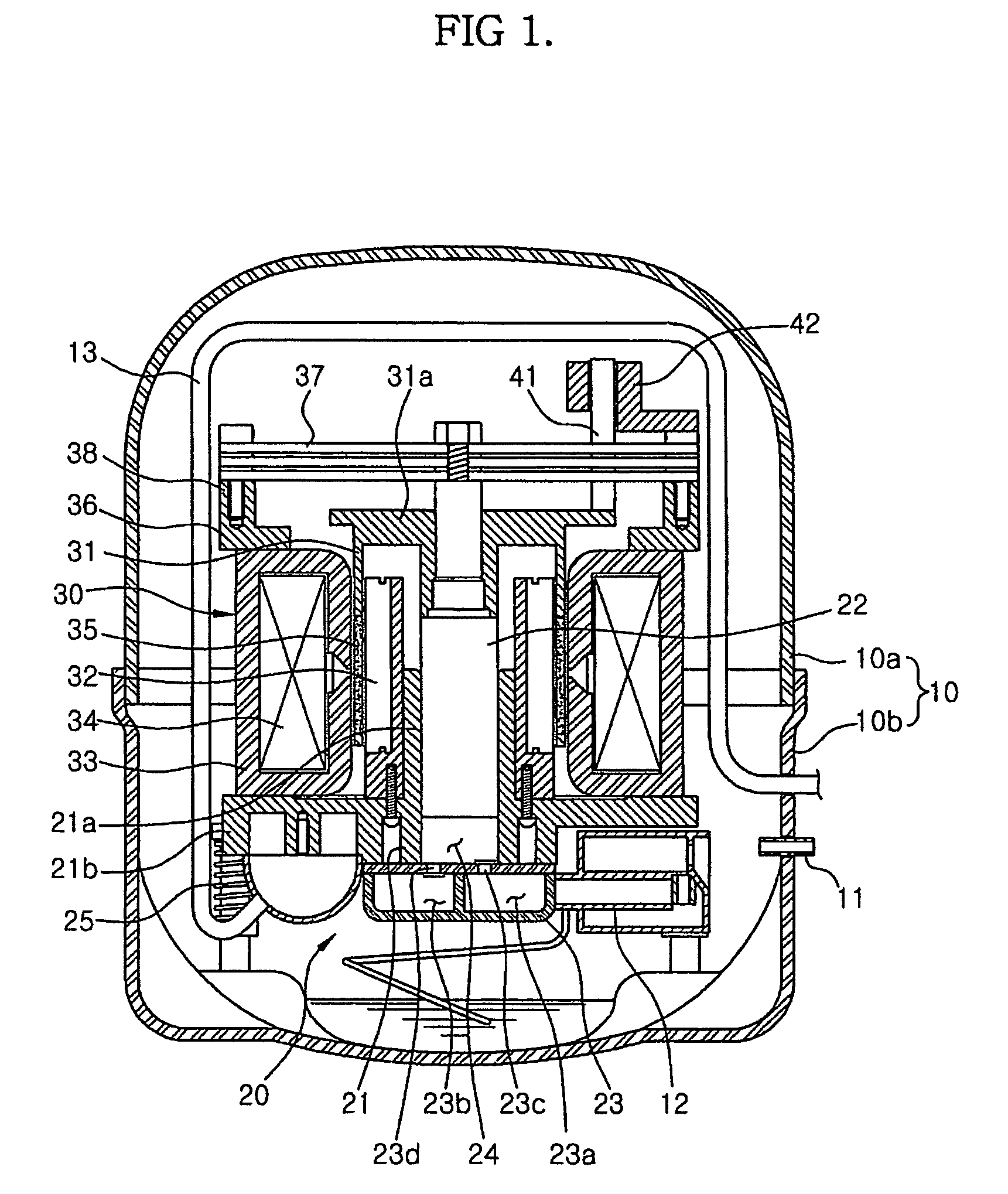

[0029]FIG. 1 is a sectional view of a reciprocating compressor in accordance with an embodiment of the present invention. As shown in FIG. 1, the reciprocating compressor includes a hermetically sealed container 10 formed by coupling an upper container 10a and a lower container 10b. The reciprocating compressor further includes: a compression unit 20 having a cylinder block 21, a piston 22 and a cylinder head 23; and a linear motor 30. The linear motor 30 drives the compression unit 20 and has a mover 31 and inner and outer stators 32 and 33. The compression unit 20 and the linear motor 30 are mounted as a set in the hermetically sealed container 10.

[0030] The cylinder bl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com