Variable inner volume ratio-type inverter screw compressor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

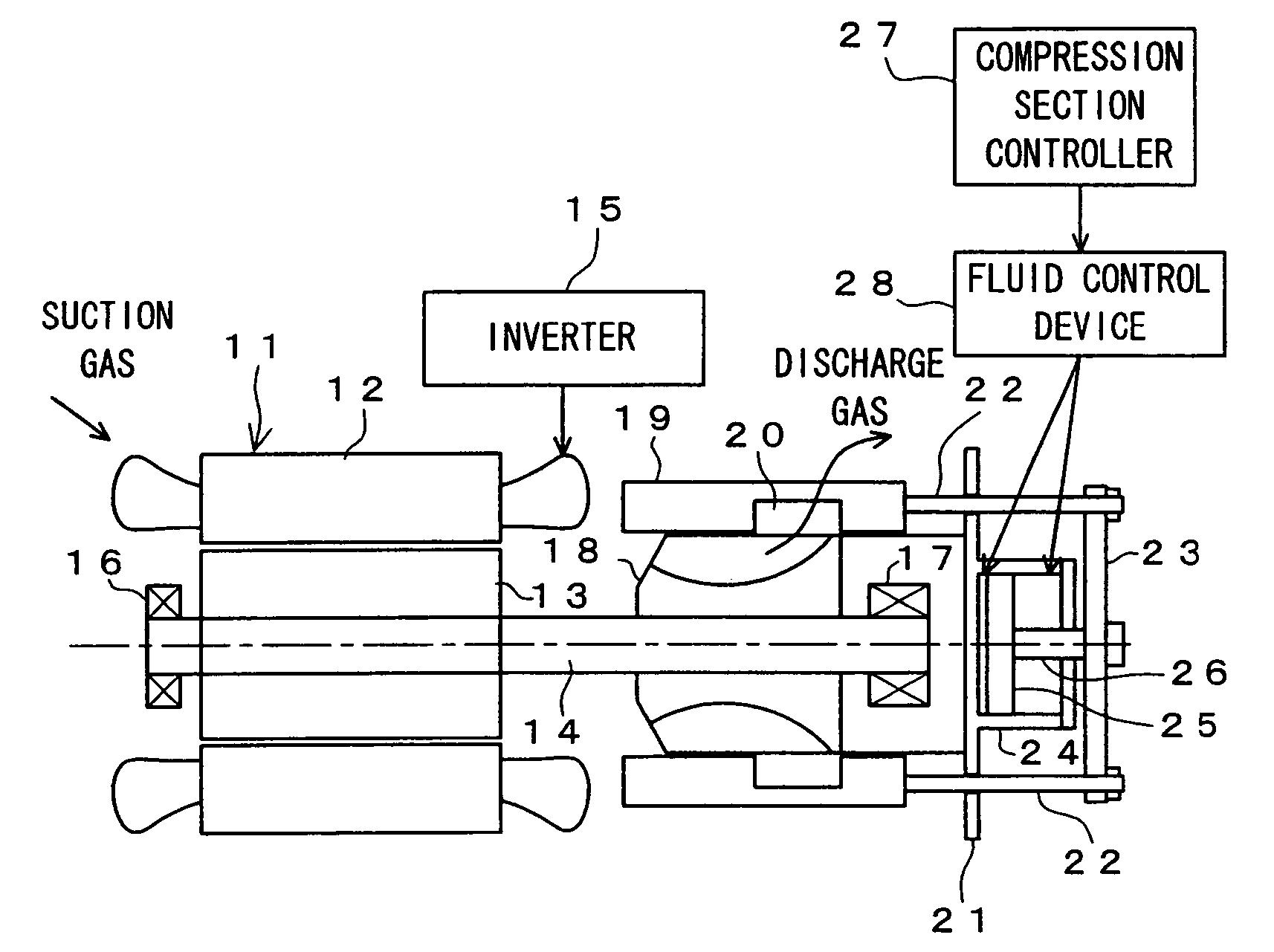

[0025] Hereinafter, this invention will be described in detail by way of preferred embodiments shown in the accompanying drawings. FIG. 1 is a schematic structural diagram showing a variable inner volume ratio-mode inverter screw compressor of this embodiment. It is to be noted that FIG. 1A shows the case when inner volume ratio is low and FIG. 1B shows the case when inner volume ratio is high.

[0026] In FIGS. 1A and 1B, reference numeral 11 denotes an electric motor, which has a stator 12 fixed on a casing (not shown) and a rotor 13 rotating and fixed on one edge side of a main shaft 14. The electric motor 11 is driven by an inverter 15. Both ends of the main shaft 14 are supported by bearings 16 and 17, and a screw rotor 18 is fixed on the other edge side of the main shaft 14. When the main shaft 14 is rotated by the electric motor 11, the screw rotor 18 rotates and suction gas is compressed by the screw groove (not shown) on the outer circumferential surface of the screw rotor. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com