Airfoil and corresponding guide vane, blade, gas turbine and turbomachine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

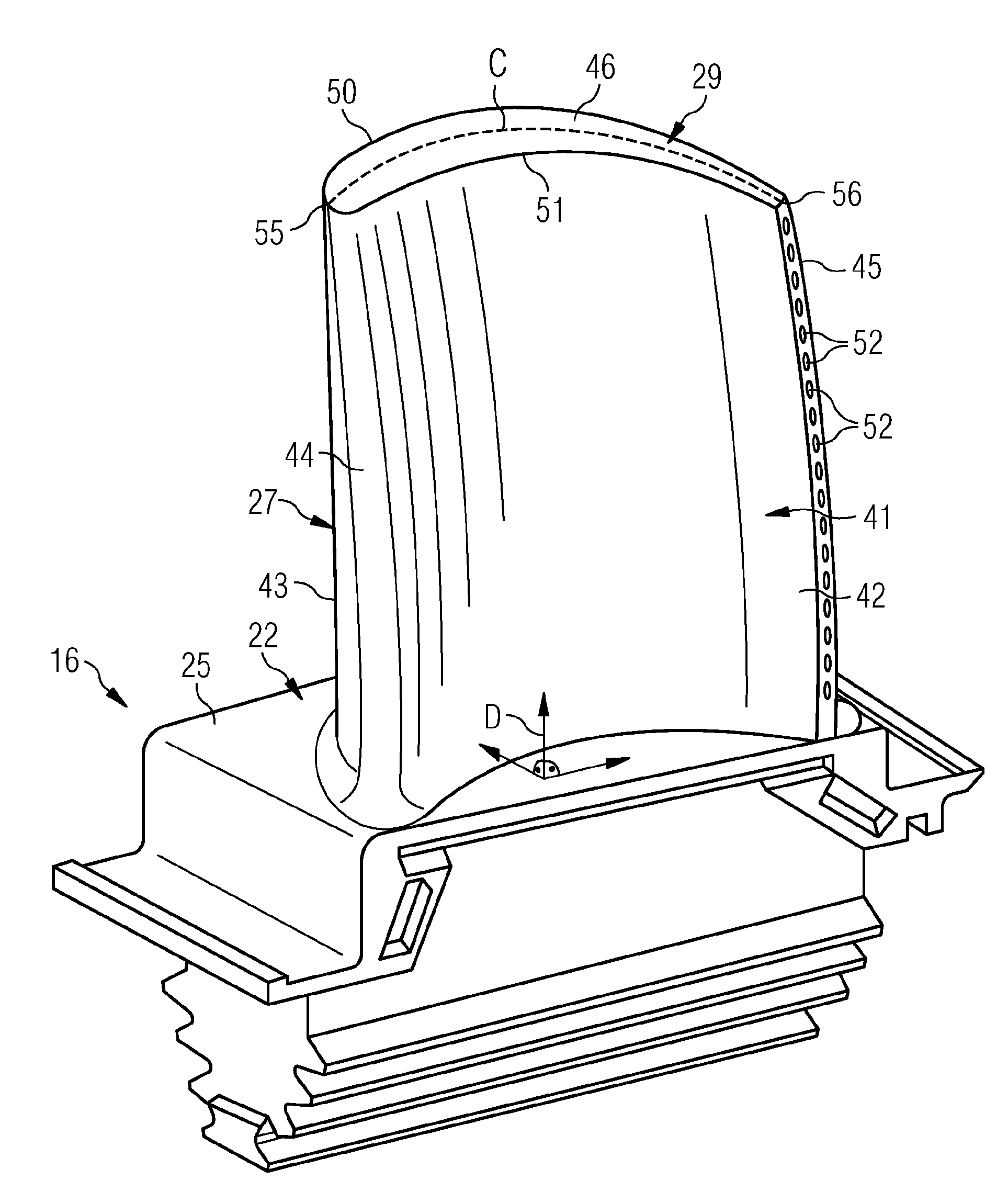

[0069]FIG. 4A specifies a first embodiment, in which the ribs extend in parallel between the leading tip edge 55 and the trailing tip edge 56. The ribs, defined by alternating first surfaces 70 and second surfaces 71, may be completely straight, or may follow the curved form of the airfoil along the pressure surface 42 and / or the suction surface 43. Alternatively the ribs may be arranged perpendicular to the direction of rotation of the airfoil 27 or may be arranged at a specific angle in respect of the direction of rotation.

second embodiment

[0070]In a second embodiment according to FIG. 4B, again parallel ribs of alternating first surfaces 70 and second surfaces 71 are shown. The direction of the ribs is substantially perpendicular to at least one area of the suction surface 43 and / or pressure surface 42. In FIG. 4B each partial surface of the first surface 70 is substantially rectangular. Alternatively first surfaces 70 may be in form of a trapezium if the grooves between the ribs are not perfectly parallel.

[0071]Not shown in the figures, the embodiments of FIG. 4A and FIG. 4B may be combined to gain a grid pattern with a set of parallel grooves extending between the leading tip edge 55 and the trailing tip edge 56 and a set of parallel grooves extending between the suction surface 43 and the pressure surface 42.

[0072]Further variants of grid patterns are shown in FIGS. 4C and 4D. In both variants a first plurality of ribs or grooves are arranged diagonally in direction of the trailing tip edge 56 of the airfoil 27 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com