Frequency variable compressor and control method thereof

a compressor and variable speed technology, applied in the direction of machines/engines, liquid fuel engines, lighting and heating apparatus, etc., can solve the problem that the variable speed dc inverter compressor has the longest yearly operating time in the low to mid speed range, and achieves the effect of reducing over-compression loss, small compression capacity and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

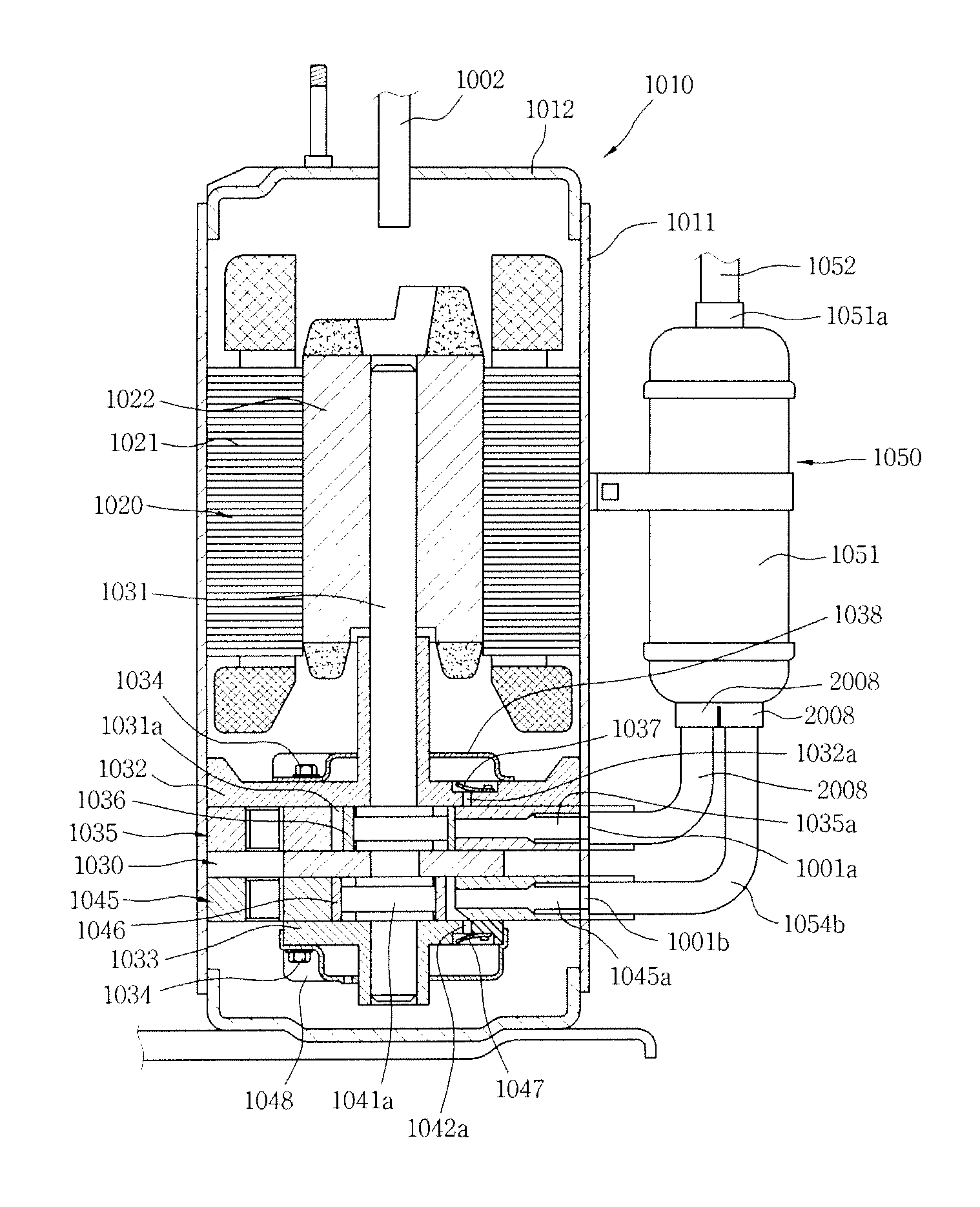

[0092]The frequency variable compressor includes a shell 100 forming the external appearance of the compressor, a DC variable speed frequency variable motor 200 (hereinafter, referred to as ‘frequency variable motor’) is installed in the shell 100 as a motor unit, and a rotating shaft 300 transferring a rotational force of the frequency variable motor 200 is connected to the frequency variable motor 200. According to the present invention, the frequency variable motor 200 is positioned on the upper side in the shell 100, and the rotating shaft 300 is downwardly extended from the frequency variable motor 200. A compression mechanism unit 400 is installed below the frequency variable motor 200, receives power from the frequency variable motor 200 through the rotating shaft 300, and compresses the refrigerant. The compression mechanism unit 400 includes a first compression mechanism unit 410 and a second compression mechanism unit 420 which are rotary compression mechanisms. That is, t...

second embodiment

[0102]According to the present invention, a mid-pressure passage 830′ penetrates an upper portion of the shell 100. This can significantly reduce piping vibration generated in the mid-pressure passage 830′. Moreover, in the drawings, a discharge passage 820 and a first discharge port 610 are formed in the opposite direction to a mid-pressure discharge valve 510 and a second discharge port 620 such that the discharge passage 820 and the first discharge port 610 do not overlap with the mid-pressure discharge valve 510 and the second discharge port 620. However, actually, the discharge passage 820 and the first discharge port 610 are very close to the mid-pressure discharge valve 510 and the second discharge port 620. If the discharge passage 820 is distant from the mid-pressure discharge valve 510, i.e., if the discharge passage 820 is distant from a discharge hole 410d of a first compression mechanism unit 410, when the refrigerant flows, its pressure loss is generated in the lower b...

third embodiment

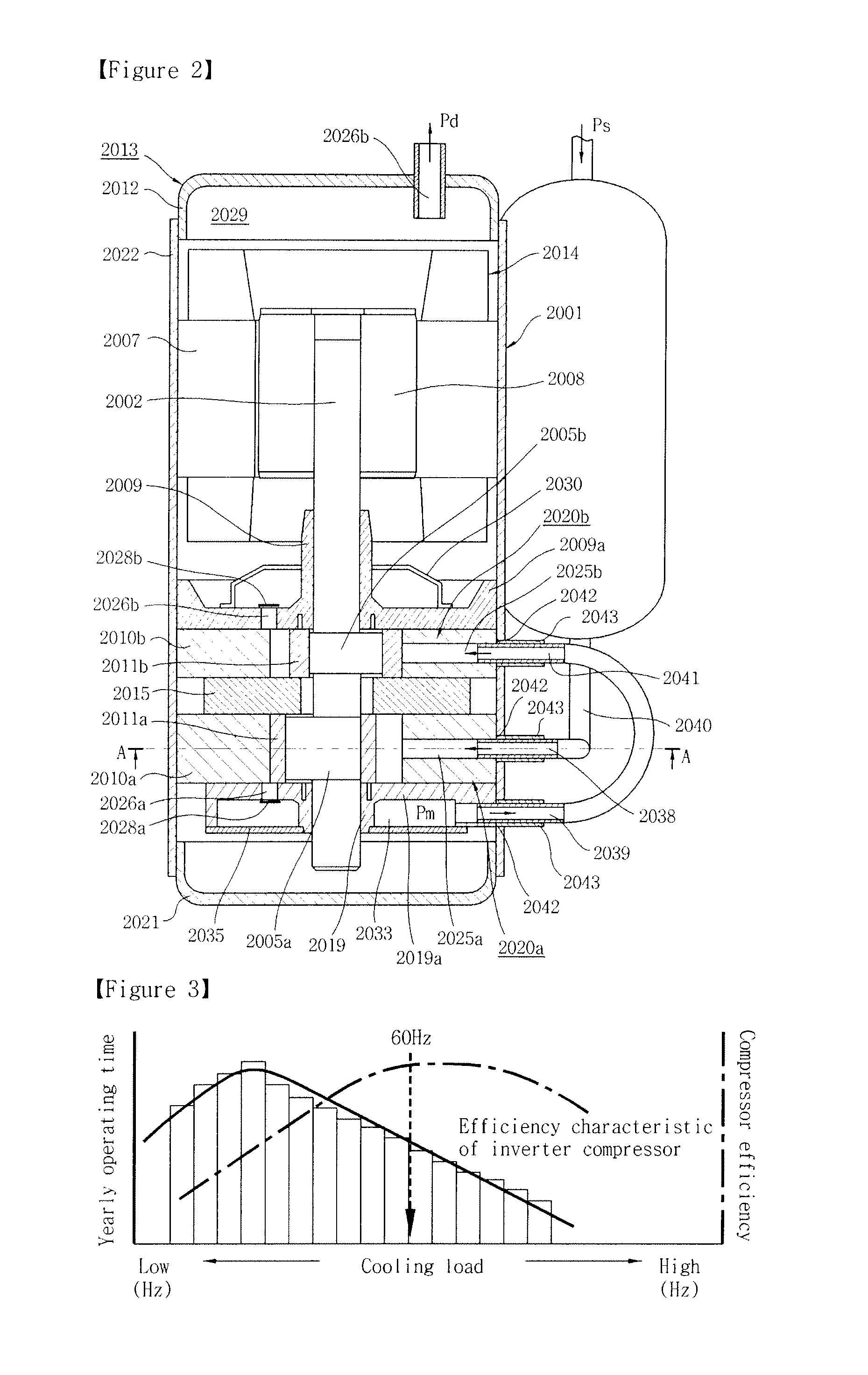

[0105]FIGS. 10 and 11 are views of a frequency variable compressor according to the present invention. FIG. 10 illustrates a state where the compressor compresses refrigerant by a twin compression method, and FIG. 11 illustrates a state where the compressor compresses refrigerant by a 2-stage compression method.

[0106]Like the first and second embodiments, the frequency variable compressor according to the third embodiment of the present invention includes a shell 100, a frequency variable motor 200, a rotating shaft 300, a compression mechanism unit 400, a lower bearing 500, an upper bearing 600, a valve 700 and an accumulator 900. The third embodiment is the same as the first and second embodiments except the construction of suction passages and discharge passages.

[0107]First, the driving by the twin compression method will be described with reference to FIG. 10. The refrigerant is sucked into a first compression mechanism unit 410 through a first suction passage 810, compressed th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com