Safe valve group for pump

A technology for safety valves and pumps, applied in the field of hydraulic components, can solve the problems of high bypass pressure of safety valves, inconvenient disassembly and maintenance, unstable system pressure, etc., achieving small compression capacity, convenient assembly, disassembly and maintenance, Reduce the effect of connecting pipes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

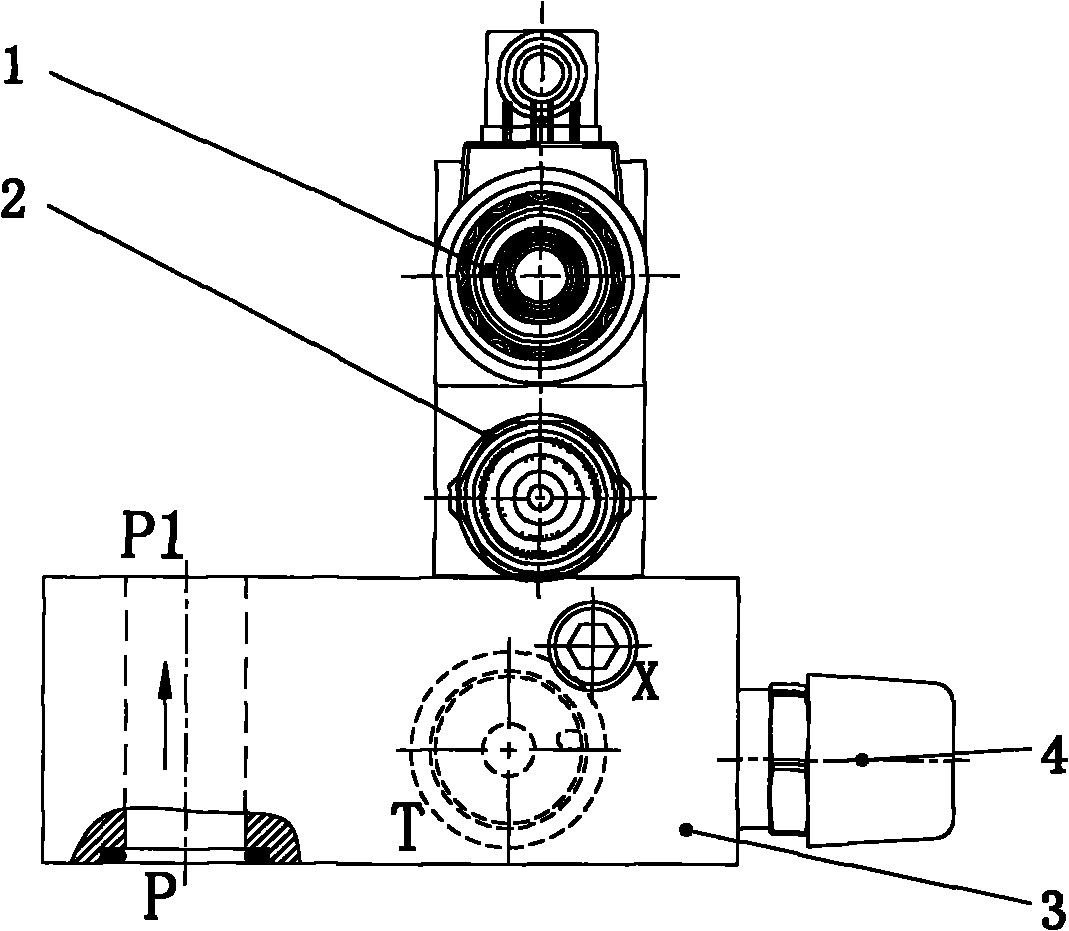

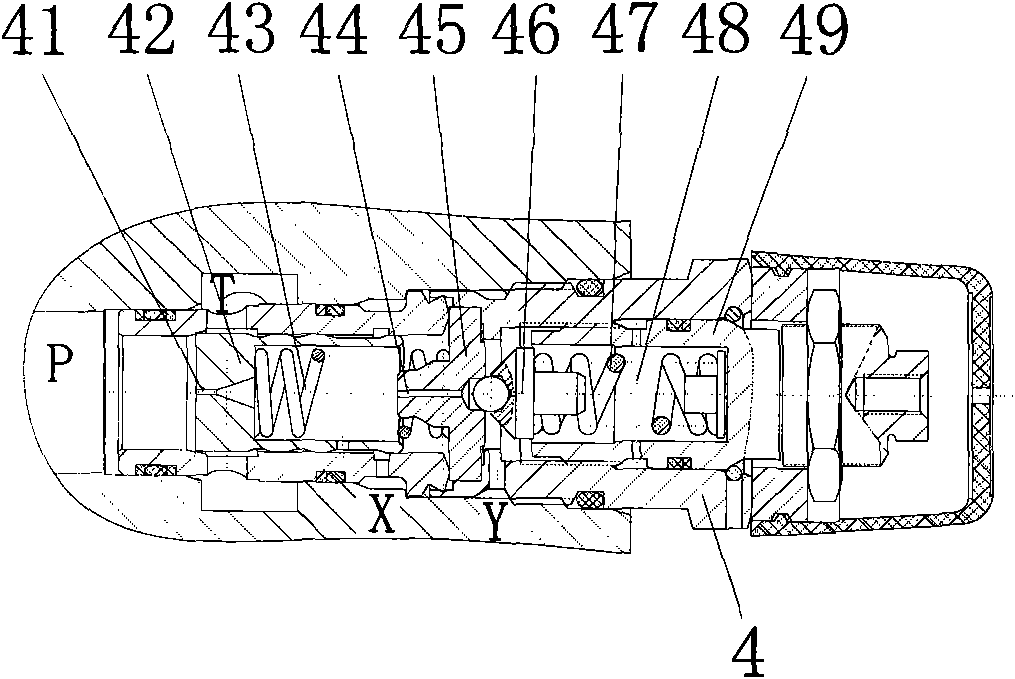

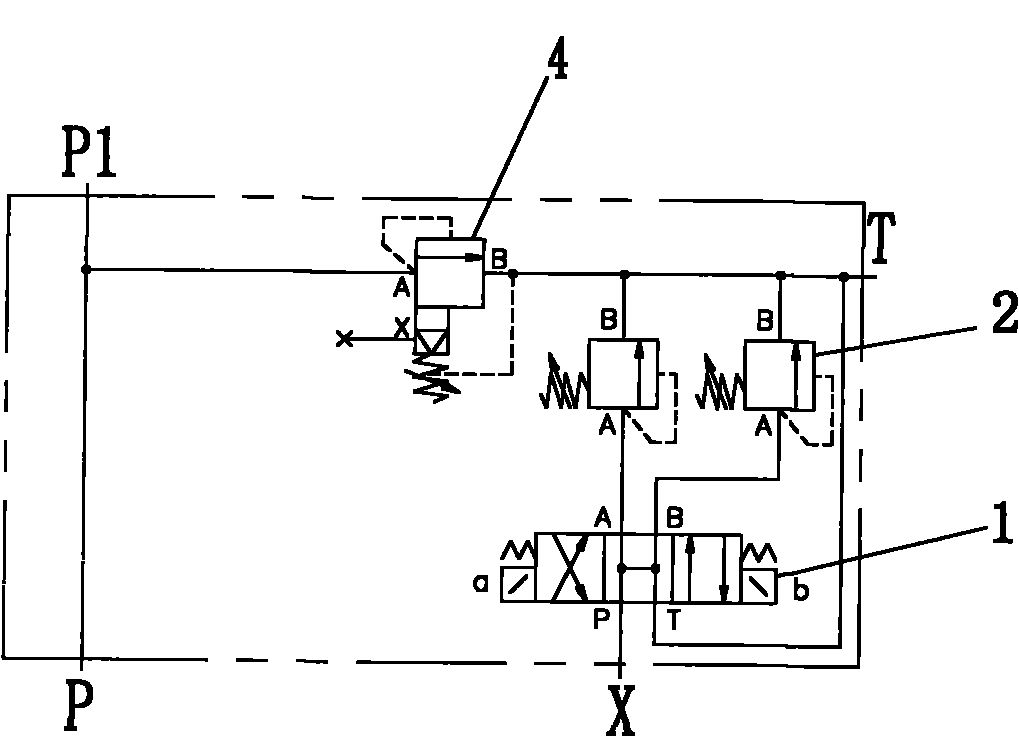

[0020] see figure 1 , 2 , and 3, the pump safety valve group, including a valve body 3, an electromagnetic reversing valve 1, a superposition relief valve 2 and a cartridge relief valve 4.

[0021] An oil inlet P, an oil outlet P1, an oil return port T and a control port X are processed on the valve body 3 to communicate with the main oil circuit. The upper surface of the valve body 3 is also provided with a through hole for connecting the main oil circuit of the valve body and the control oil circuit of the superposition relief valve 2 . A mounting hole is machined on the left end of the valve body for mounting a cartridge relief valve 4 .

[0022] The superimposed relief valve 2 is installed on the upper surface of the valve body 3 through bolts, and the superimposed relief valve communicates with the oil inlet P, the oil outlet P1, the oil return port T and the control port X of the valve body. The electromagnetic reversing valve 1 is fixedly mounted on the superimposed ...

Embodiment 2

[0033] Such as Figure 4 The shown pump safety valve group includes a valve body 3 , an electromagnetic reversing valve 1 , a stacked relief valve 2 and a cartridge relief valve 4 .

[0034] Oil inlet P, oil outlet P1, oil return port T, control port X, throttling port 6 and pressure measuring port M are processed on the valve body 3 to communicate with the main oil circuit. A damper 7 is arranged in the control channel of the valve body 3 . The upper surface of the valve body 3 is also provided with a through hole for connecting the main oil circuit of the valve body and the control oil circuit of the superposition relief valve 2 . A mounting hole is machined on the left end of the valve body for mounting a cartridge overflow valve 4 .

[0035] The superimposed overflow valve 2 is installed on the upper surface of the valve body 3 through bolts, and the electromagnetic reversing valve 1 is fixed on the superimposed overflow valve 2 through bolts. The left end surface of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com