Rotary compressor with air injection enthalpy-increasing function

A technology of rotary compressor and air injection to increase enthalpy, applied in the direction of rotary piston machinery, rotary piston pump, mechanical equipment, etc., to achieve the effect of improving structure, increasing heating capacity, and increasing suction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

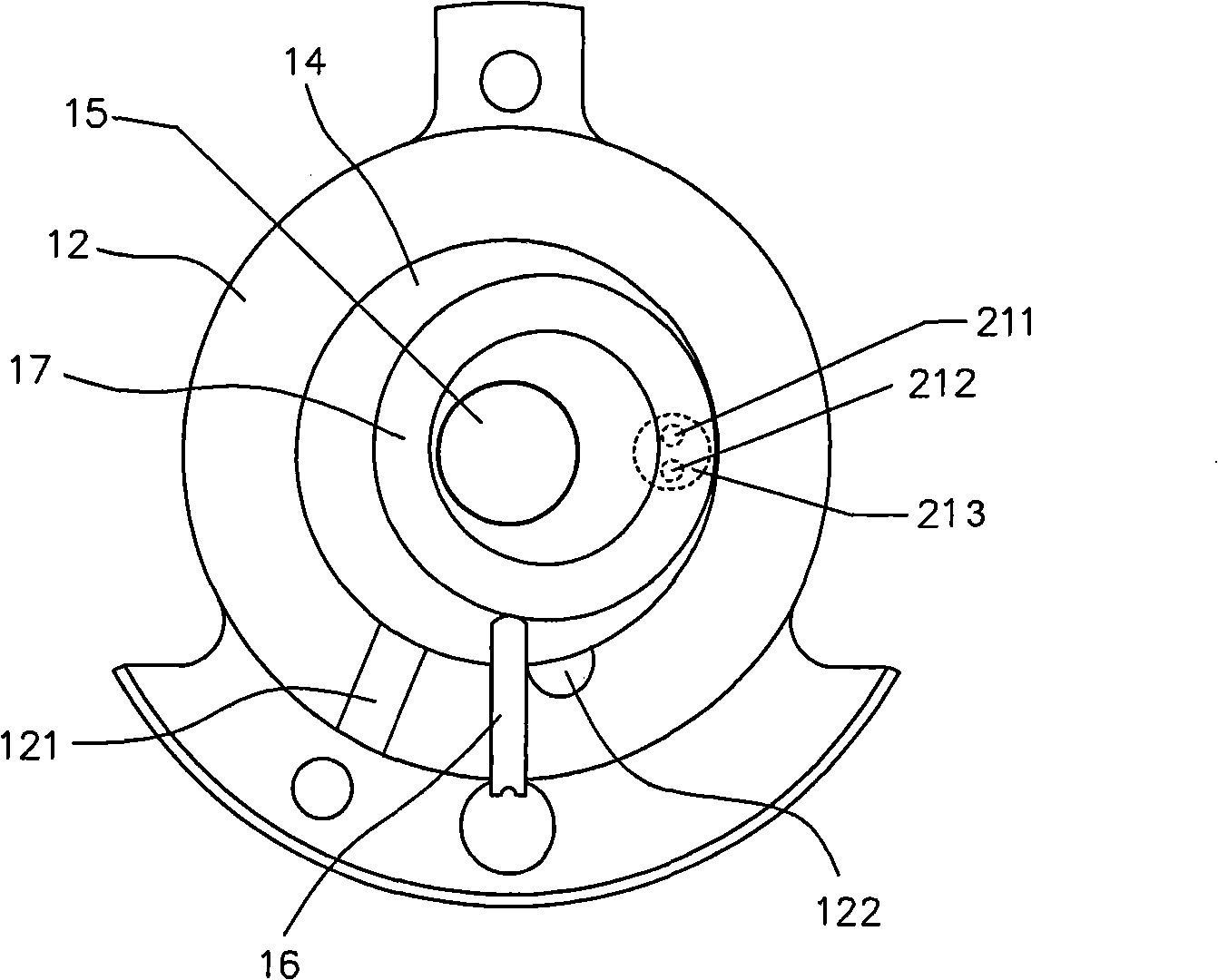

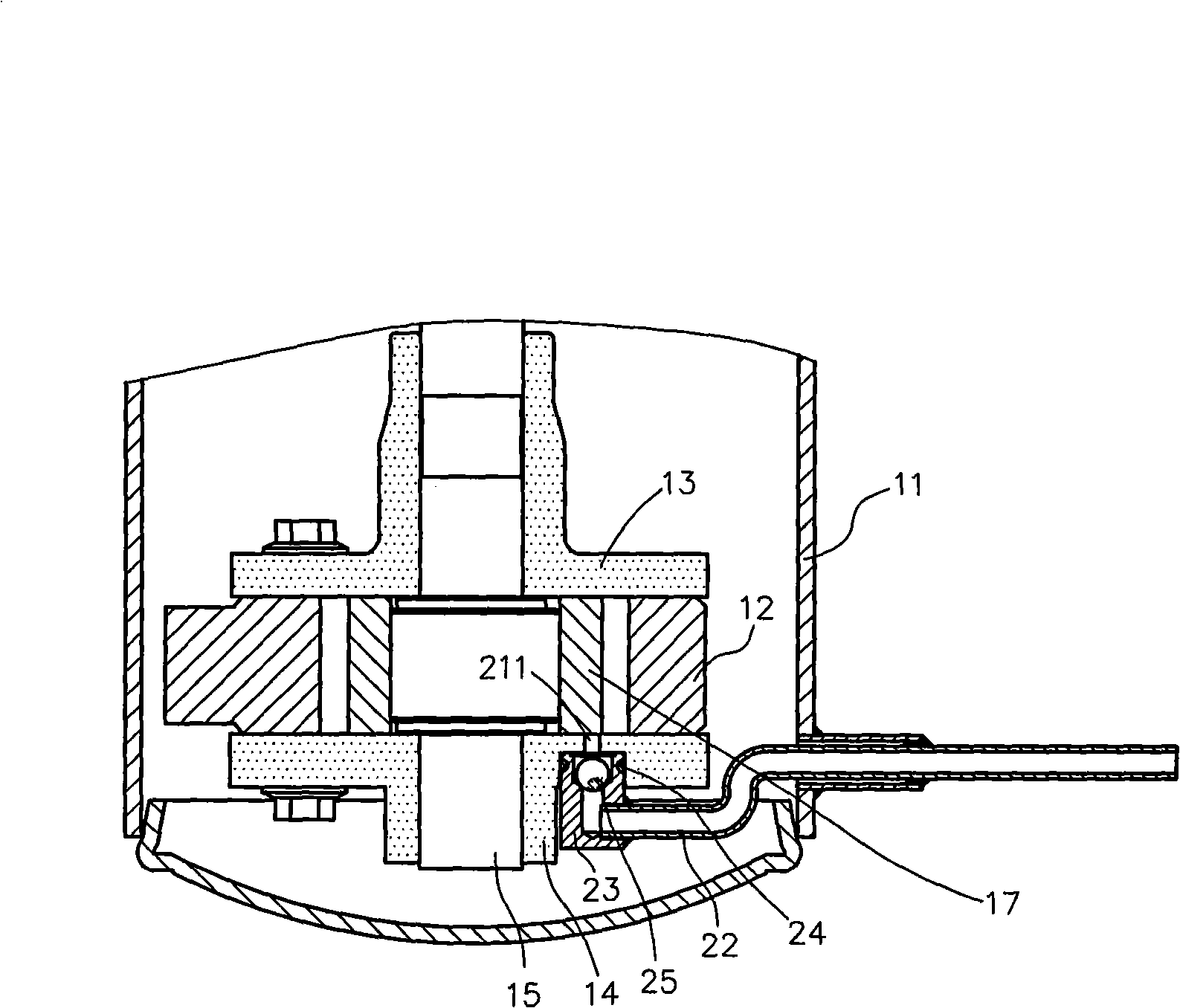

[0016] Please refer to figure 1 and figure 2 , The rotary compressor provided in this embodiment includes: a housing 11 , a cylinder 12 , an upper bearing 13 , a lower bearing 14 , a crankshaft 15 , a motor (not shown in the figure), sliding vanes 16 , and rollers 17 . The radial direction of the cylinder 12 is provided with a suction port 121 without a suction valve and an exhaust port 122 with an exhaust valve. The roller 17 is mounted on the eccentric crankshaft 15. A crescent-shaped working chamber is formed. The end of the slide 16 is in close contact with the roller 17 by the force of the spring, and the crescent-shaped working chamber is divided into two parts. The slide 16 and the roller 17 roll along the slide groove. When doing rotary motion, the upper and lower bearings 13 and 14 are placed at both ends of the cylinder 12, and form a closed cylinder volume with the inner wall of the cylinder 12, the outer wall of the roller 17, the tangent point, and the sliding p...

Embodiment 2

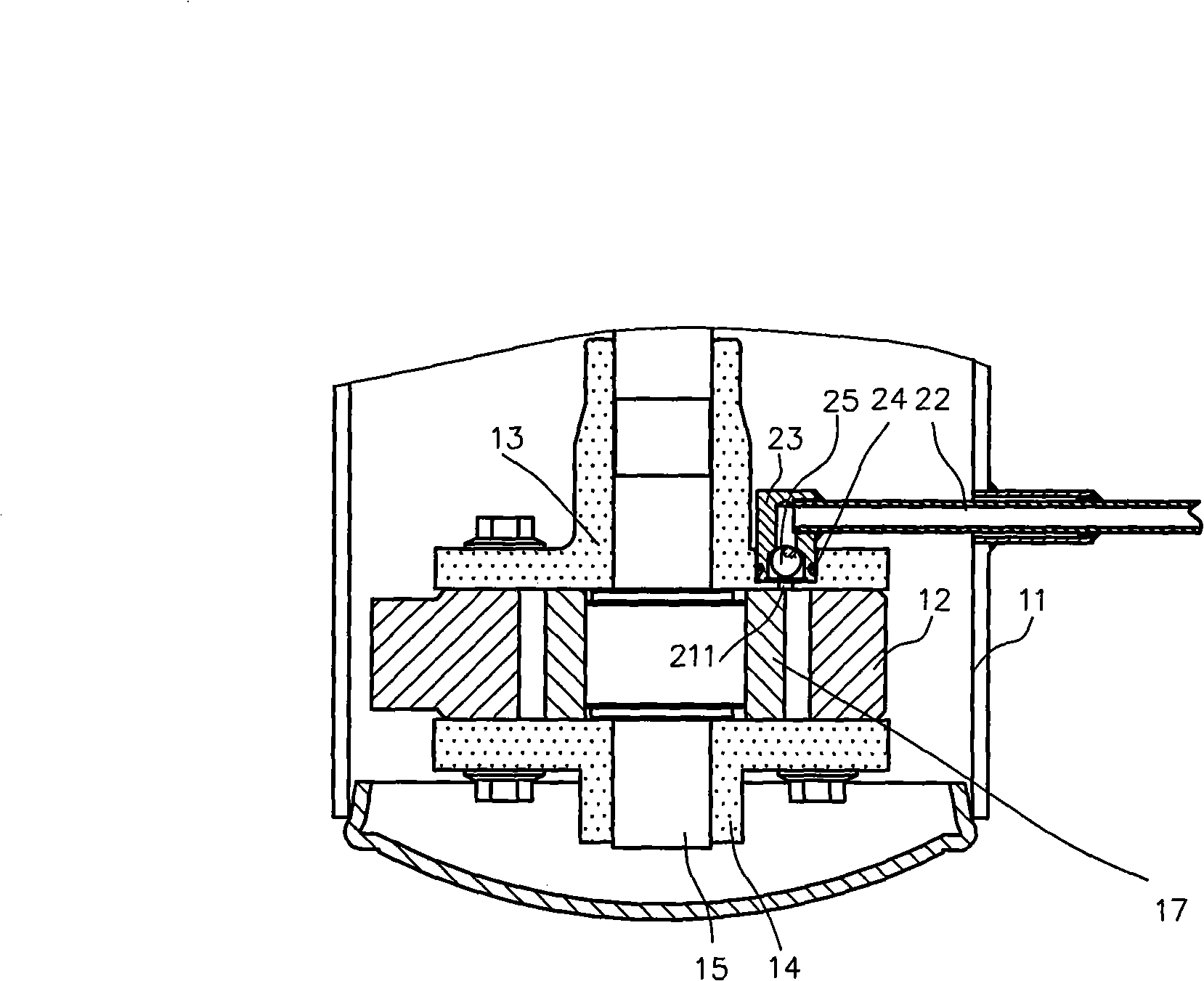

[0021] Please refer to image 3 , the difference from Embodiment 1 is that in the rotary compressor provided by Embodiment 2 with the function of increasing enthalpy by gas injection, the gas injection holes 211, 212 are provided on the upper bearing 13, and the upper bearing is provided with the gas injection holes 211, 212 An assembly hole is arranged above the 212 place, and the assembly hole communicates with the compressor cylinder 12 downwards through the air injection holes 211, 212. distance setting. The pipeline 22 cooperates with the air injection holes 211 and 212 provided on the upper bearing 13 through the connecting piece 23 and the sealing ring 24, so as to connect the cylinder of the compressor with the outside.

[0022] Figure 4 A schematic diagram of the use of the rotary compressor with the function of increasing enthalpy by air injection used in the air conditioning system provided by the present invention. The air-conditioning system shown in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com