Hermetic two-stage rotary compressor

A technology of rotary compressors and compressors, which is applied in the direction of rotary piston machinery, mechanical equipment, machines/engines, etc., can solve the problems of complex structure and cost increase, and achieve the effect of simple structure and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

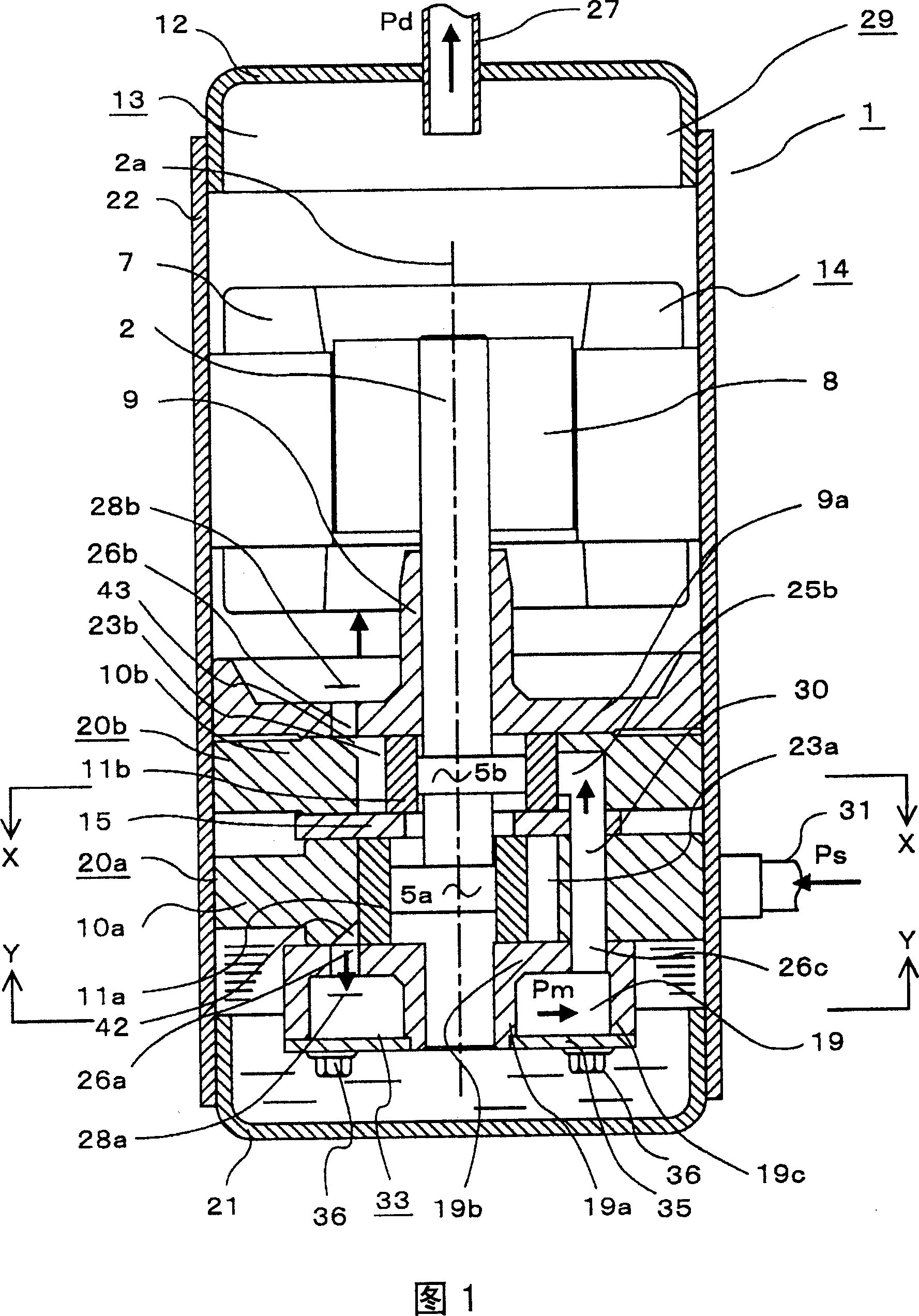

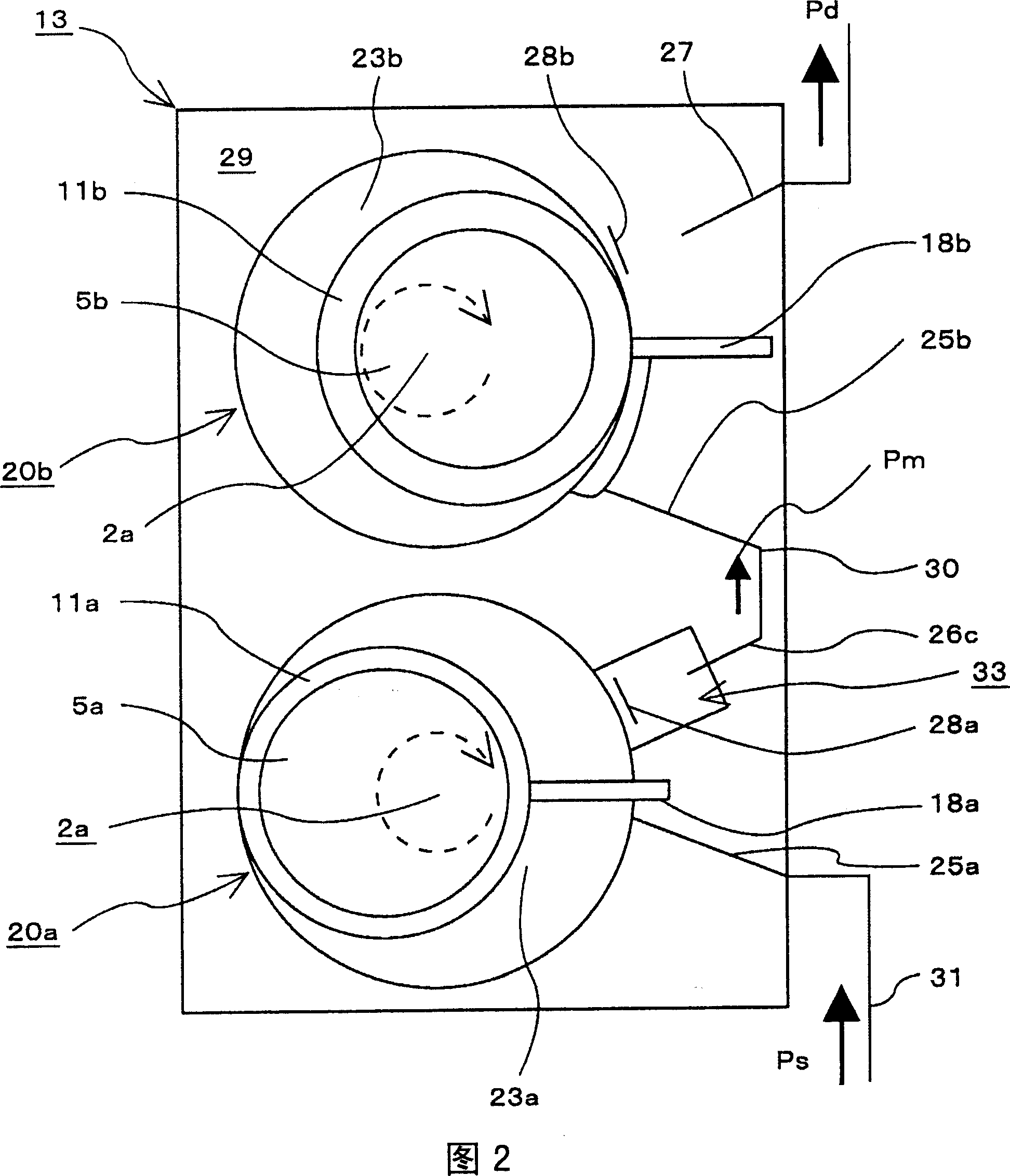

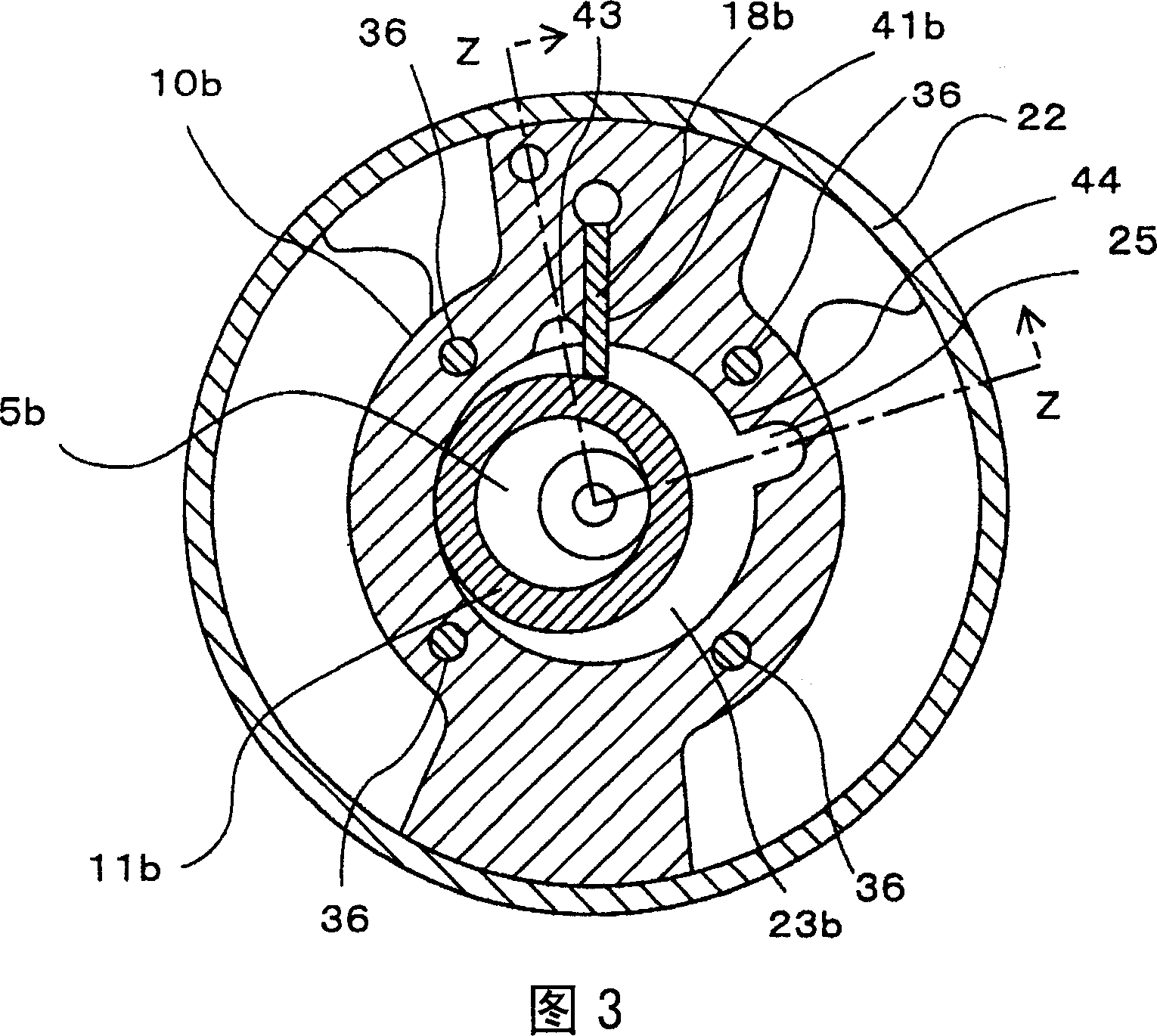

[0032] A hermetic two-stage rotary compressor according to a first embodiment of the present invention will be described with reference to FIGS. 1 to 4 . Fig. 1 is a longitudinal sectional view of a hermetic two-stage rotary compressor according to a first embodiment, and Fig. 2 is a schematic diagram showing a planar arrangement of a low stage compressor part and a high stage compressor part of a compression mechanism part according to the first embodiment , Fig. 3 is the X-X sectional view of Fig. 1, and Fig. 4 is the Y-Y sectional view of Fig. 1 . In addition, FIG. 1 is a Z-Z sectional view of FIG. 3 .

[0033] As shown in FIG. 1 , a hermetic two-stage rotary compressor 1 has a hermetic container 13 composed of a bottom 21 , a cover 12 , and a body 22 . An electric motor 14 having a stator 7 and a rotor 8 is provided in the upper part of the airtight container 13 . The outer periphery of the stator 7 is fixed to the airtight container 13 , and the rotor 8 is fixedly coupl...

no. 2 Embodiment approach

[0056] Next, a second embodiment of the present invention will be described with reference to FIGS. 5 to 7 . 5 is a longitudinal sectional view of a hermetic two-stage rotary compressor according to a second embodiment of the present invention, FIG. 6 is a X-X sectional view of FIG. 5 , and FIG. 7 is a Y-Y sectional view of FIG. 5 . In addition, FIG. 5 is a Z-Z sectional view of FIG. 6 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com