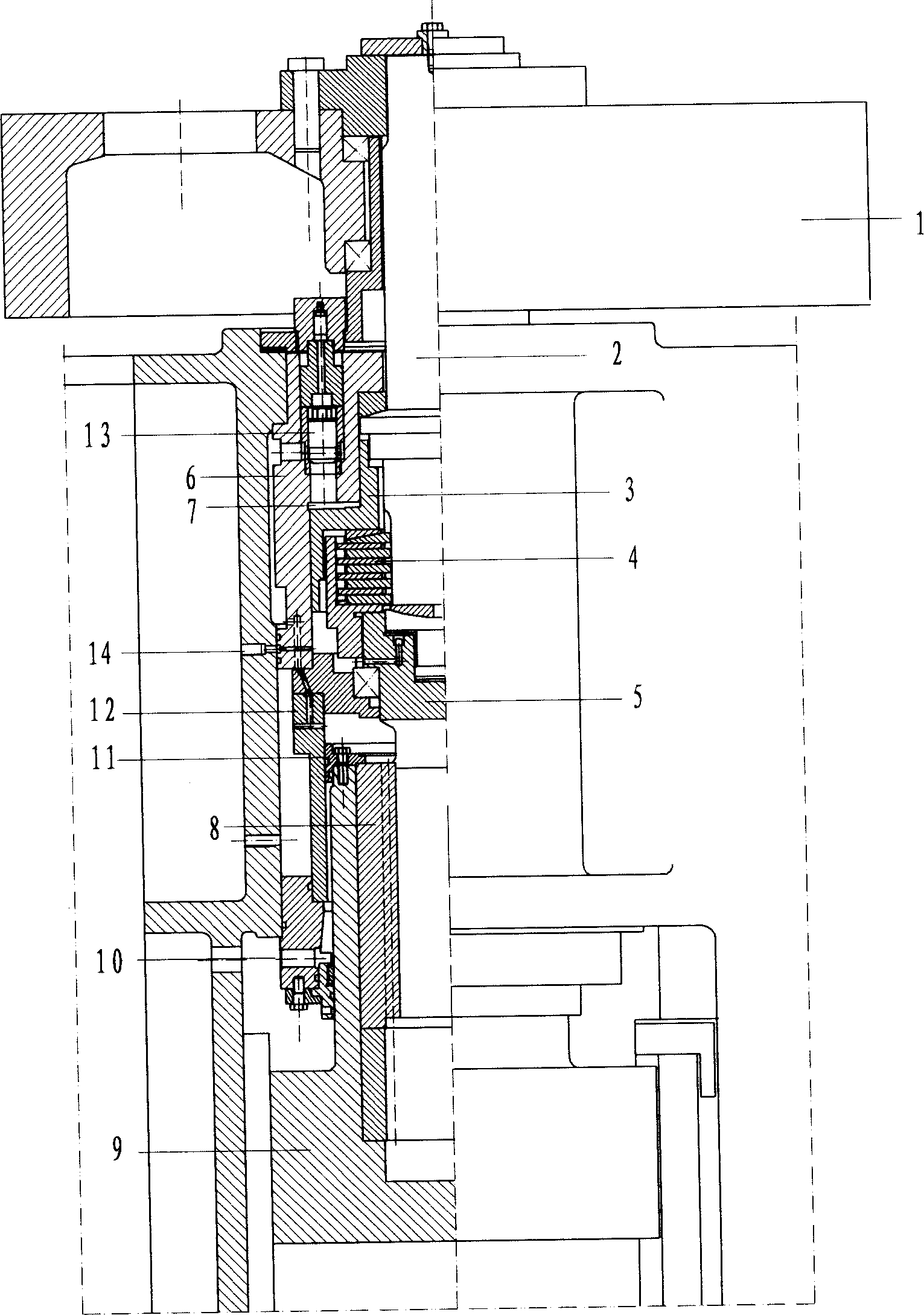

High energy screw press

A screw press, high-energy technology, applied to presses, stamping machines, forging presses, etc., can solve problems such as poor guidance, noise of air pumps, and difficulty in tight contact, so as to improve guidance and sealing performance and reduce installation accuracy requirements , Good effect of processing technology performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

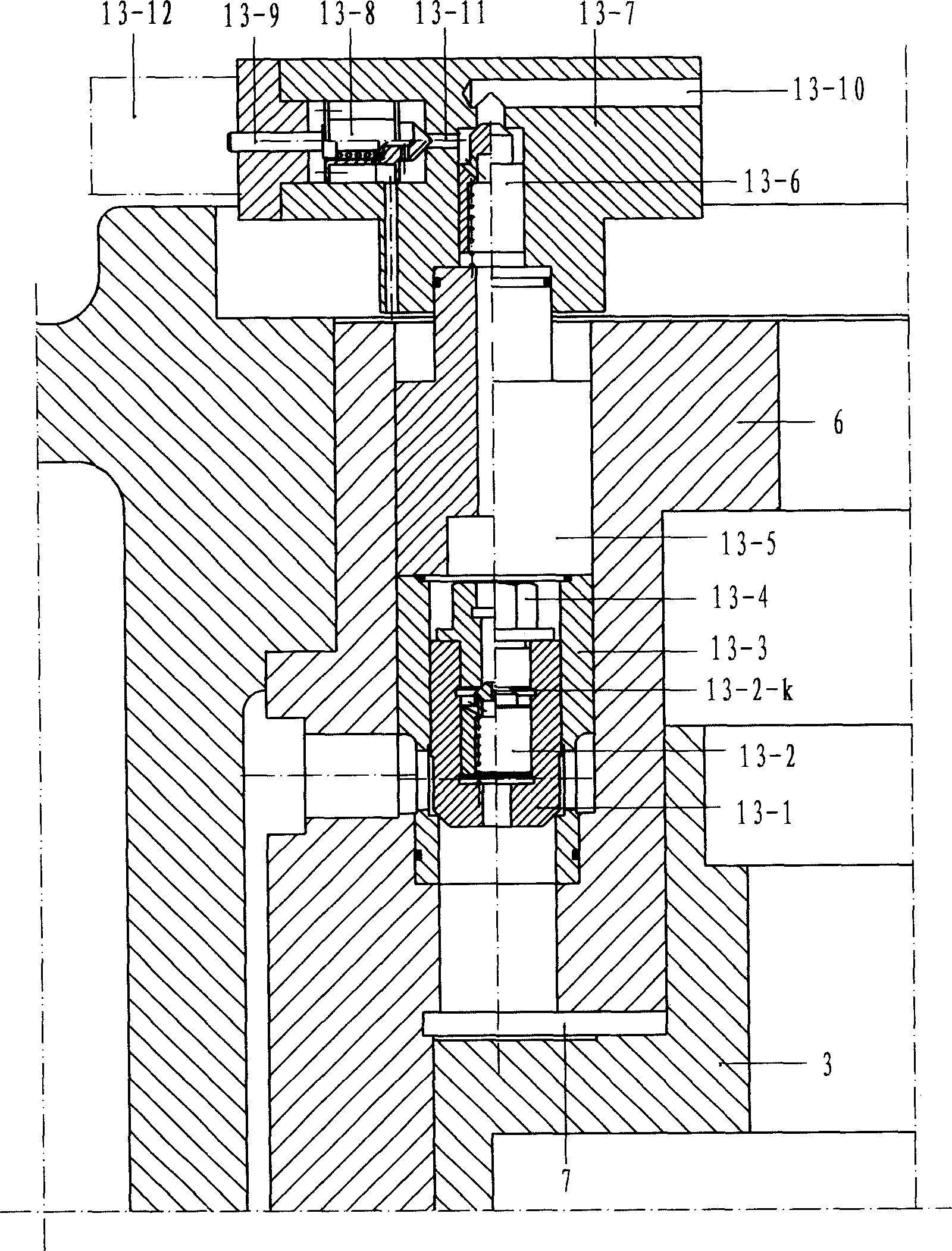

[0017] Embodiments of the present invention are as follows:

[0018] When the present invention is in a static state, the slider stays at the uppermost position by the hydraulic oil sealed in the annular return cylinder. The compression piston 3 is under the action of the 0.2MPa low-pressure oil at the bottom of the compression cylinder, so that the clutch driving plate and the driven plate are in a loose state. When starting, the electromagnet 13-12 is energized, and the electromagnetic suction presses the pilot spool 13-8 tightly on the aperture 13-11 through the control valve 13-9. At the same time, the return cylinder 12 discharges oil to the oil tank of the hydraulic oil supply system through the oil inlet and outlet ports 10, the slide block 9 falls freely under the action of gravity, and the screw rod 5 is driven by the nut 8 to rotate forward and accelerate. After a certain time delay, the hydraulic system enters the oil through the oil inlet 13-10 of the valve seat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com