Multifunctional workover rig

A multi-functional, operating machine technology, applied to the chassis of agricultural machinery, agricultural machinery and implements, agriculture, etc., can solve the problems of complex process, inability to realize fast assembly of external tools, high production cost, etc., to achieve simple processing technology, Improved early wear and reduced weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

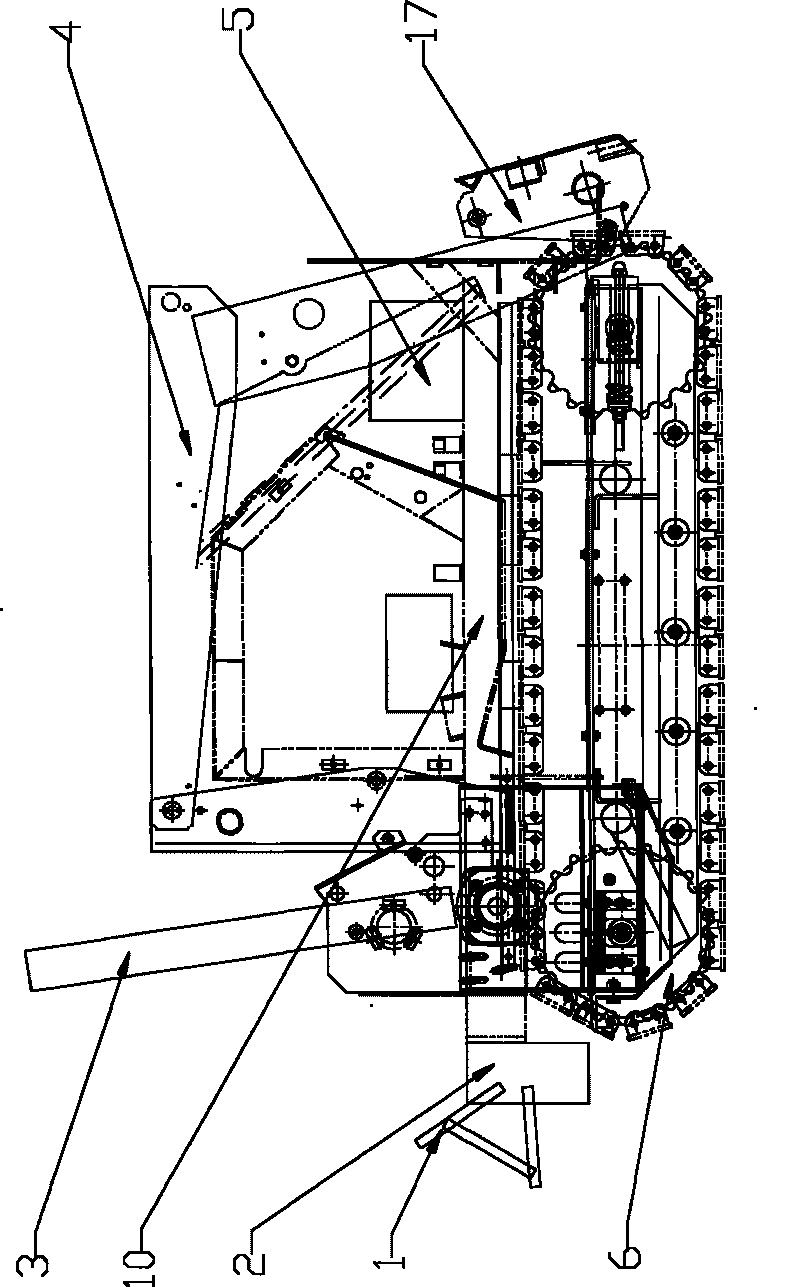

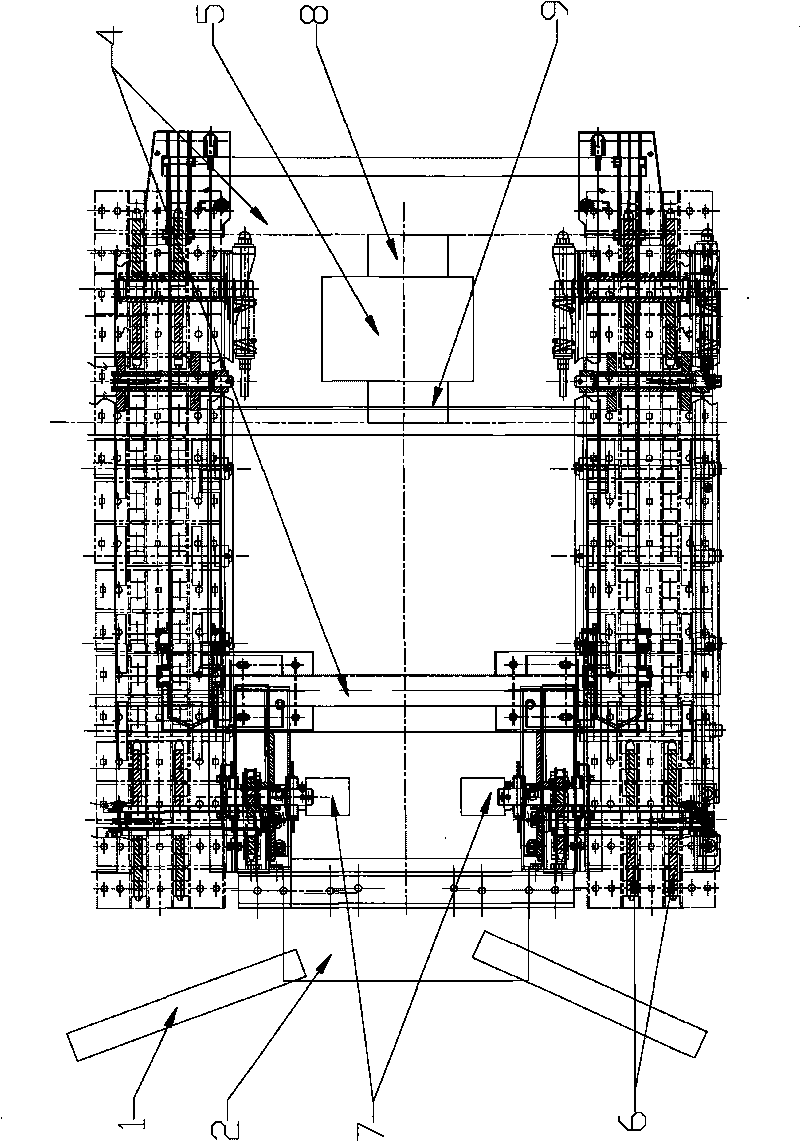

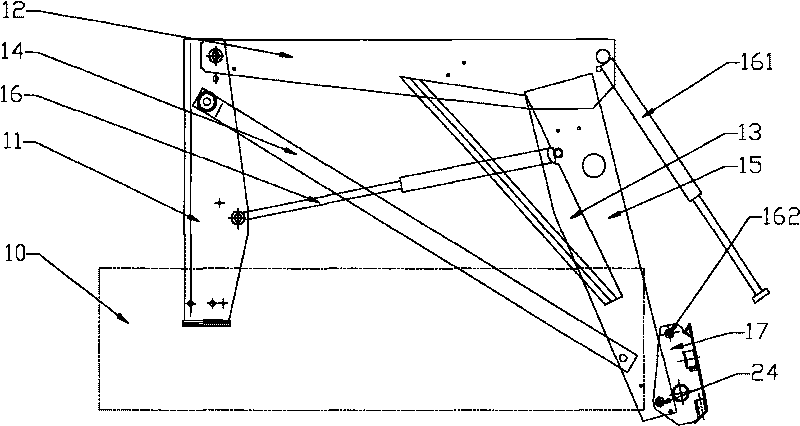

[0064] Such as figure 1 , 2 As shown, the quick-loading connection mechanism assembly 17, the multifunctional power arm 4, the anti-roll frame 3, and the engine 5 of the hydraulic system are installed on the top of the frame 10, and the power output device 2 and the three-point hydraulic suspension assembly 1 are installed on the machine frame. Frame 10 rear portions, engine 5, walking pump 9, working pump 8 are installed in frame 10 front portions. Walking pump 9, valve, hydraulic motor 7, two-stage chain wheel side decelerate to drive track driving wheel 6, wherein track driving wheel 6 adopts a double wheel disc structure to realize crawler walking. The power output shaft of the power output device 2 is driven by the hydraulic pump through the operating valve to drive the hydraulic motor with low speed and high torque, and the power is transmitted to the power output shaft. The speed of the engine 5 is used to control the speed of the hydraulic motor and the power output s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com