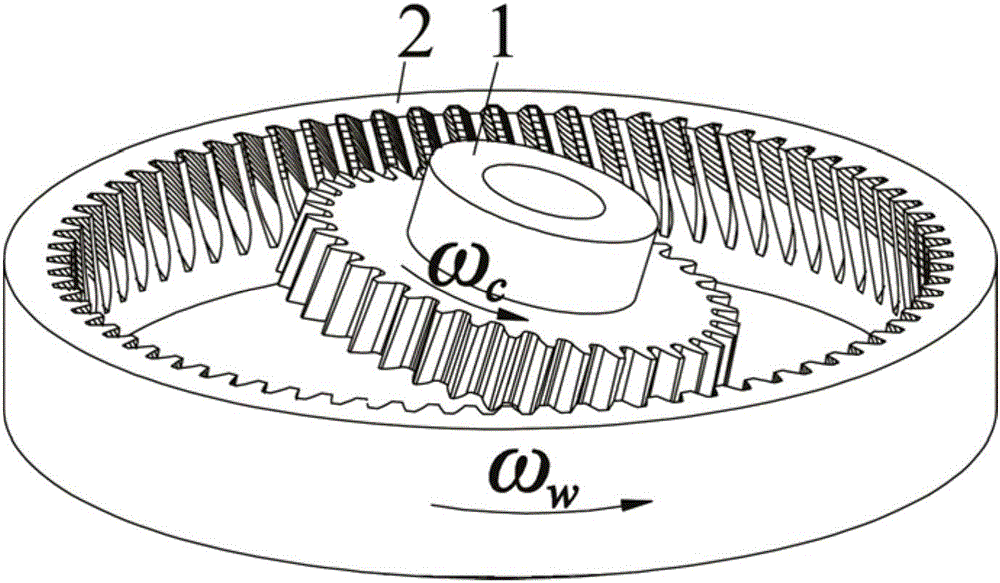

Skiving cutter feeding method realizing singe-edge cutter relieving radical cutter feeding

A tool-feeding, unilateral technology, applied in the direction of turning equipment, turning equipment, manufacturing tools, etc., to achieve the effect of ensuring machining accuracy, improving tool life, and improving wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

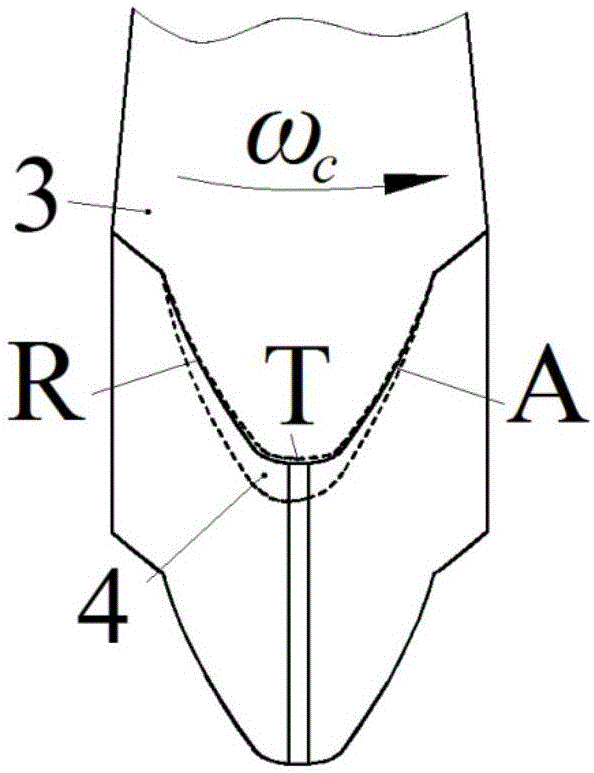

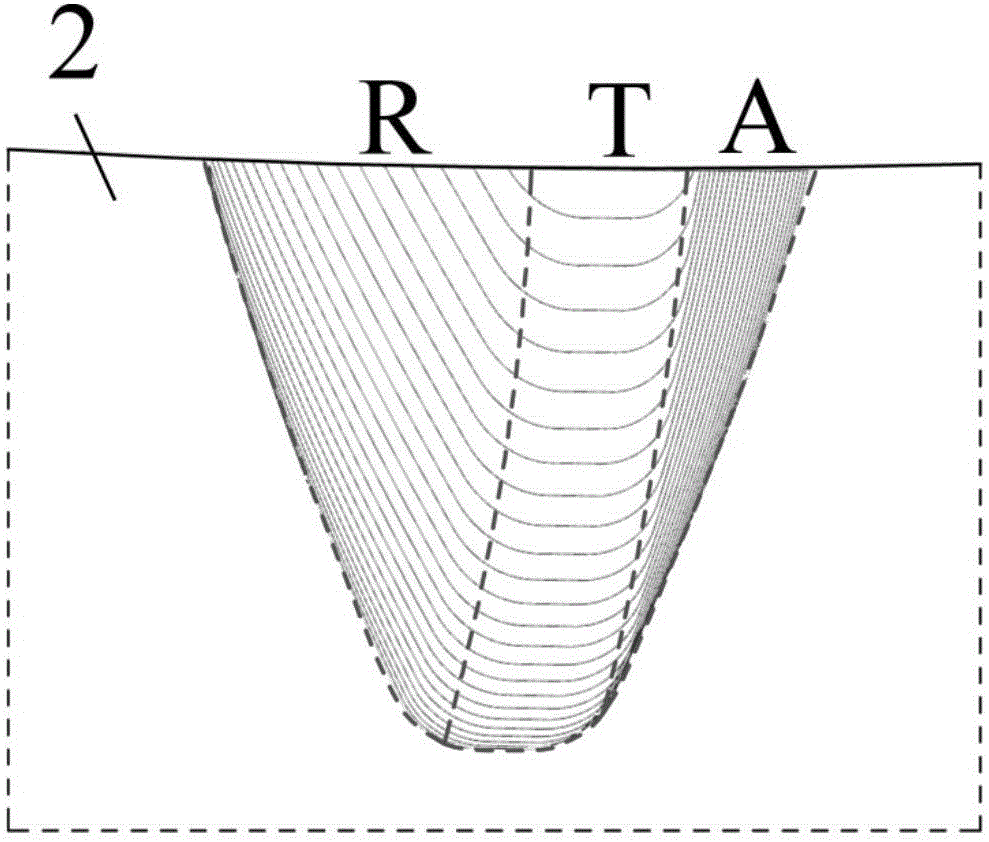

Method used

Image

Examples

Embodiment

[0031] According to the method mentioned above, the straight-tooth skiving cutter is designed, and the skiving knife-feeding method of unilaterally allowing the knife to feed radially is adopted. Select an internal helical gear as a specific example of processing, the workpiece parameters are shown in Table 1:

[0032] Table 1

[0033] Number of teeth z 1 Normal modulus m n Normal pressure angle α n tooth width B Helix angle β Rotation 80 1 20° 20 20° left-handed

[0034] The basic parameters of the gear cutter are shown in Table 2:

[0035] Table 2

[0036] Number of teeth z 2 Modulus m Top edge relief angle α Top edge rake angleγ Feed times 50 1 9° 5° 5

[0037] Workpiece circumferential compensation angle θ i and let-off angle ψ i See Table 3:

[0038] table 3

[0039] Number of feed knives 1 2 3 4 5 Cutting depth(mm) 0.45 0.90 1.35 1.80 2.25 θ i (°) 0.120 0.101 0.177 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com