Preparation method for high-speed rail brake powder metallurgy copper base friction material

A technology of powder metallurgy and friction materials, which is applied in the field of preparation of powder metallurgy copper-based friction materials for high-speed rail brakes, can solve problems such as unstable friction coefficient, poor high temperature stability, and increased wear, and achieve improved friction stability and enhanced friction Force, improve the effect of wear and tear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

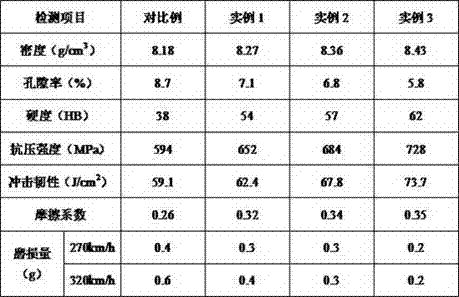

example 1

[0016] First, according to the mass ratio of 1:10, molybdenum trioxide and 1% potassium permanganate solution were stirred and mixed and placed in a beaker. After ultrasonic dispersion at 200W for 10 minutes, they were left to stand at room temperature for 45 minutes. After completion, dropwise add 20% glacial acetic acid solution of potassium permanganate solution quality in the beaker, control the time of dripping to be 25min, after the completion of the dropwise addition, stir and mix and leave it to stand for 3 days, after the completion of the standstill, add it at 170 Heating in an oil bath at ℃ for 20 hours, then standing to cool to room temperature, filtering to obtain a filter cake, washing with absolute ethanol and deionized water for 3 times, drying naturally, and grinding to prepare modified molybdenum trioxide particles, according to In terms of parts by weight, weigh 1 part of modified molybdenum trioxide particles, 10 parts of ferric nitrate and 75 parts of deion...

example 2

[0019] First, according to the mass ratio of 1:10, molybdenum trioxide and 1% potassium permanganate solution were stirred and mixed and placed in a beaker. After ultrasonic dispersion at 250W for 13 minutes, they were left at room temperature for 53 minutes. After completion, dropwise add potassium permanganate solution quality 20% glacial acetic acid solution in the beaker, control the time of dropping to be 28min, after the completion of the dropwise addition, stir and mix and leave it to stand for 4 days, after the completion of the standstill, add the solution at 175 Heating in an oil bath at ℃ for 22 hours, then standing to cool to room temperature, filtering to obtain a filter cake, washing with absolute ethanol and deionized water for 4 times, drying naturally, and grinding to prepare modified molybdenum trioxide particles, according to In terms of parts by weight, weigh 1 part of modified molybdenum trioxide particles, 13 parts of ferric nitrate and 78 parts of deioniz...

example 3

[0022]First, according to the mass ratio of 1:10, molybdenum trioxide and 1% potassium permanganate solution were stirred and mixed and placed in a beaker. After ultrasonic dispersion at 300W for 15 minutes, they were left at room temperature for 60 minutes. After completion, drip potassium permanganate solution quality 20% glacial acetic acid solution in the beaker, control the time of dripping to be 30min, after the completion of the dropwise addition, stir and mix and leave it to stand for 5 days, after the completion of the standstill, add it at 180 Heating in an oil bath at ℃ for 24 hours, then standing to cool to room temperature, filtering to obtain a filter cake, washing with absolute ethanol and deionized water for 5 times, drying naturally, and grinding to prepare modified molybdenum trioxide particles, according to In terms of parts by weight, weigh 2 parts of modified molybdenum trioxide particles, 15 parts of ferric nitrate and 80 parts of deionized water, put them...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com