Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

31results about How to "Enhanced hydrodynamic effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

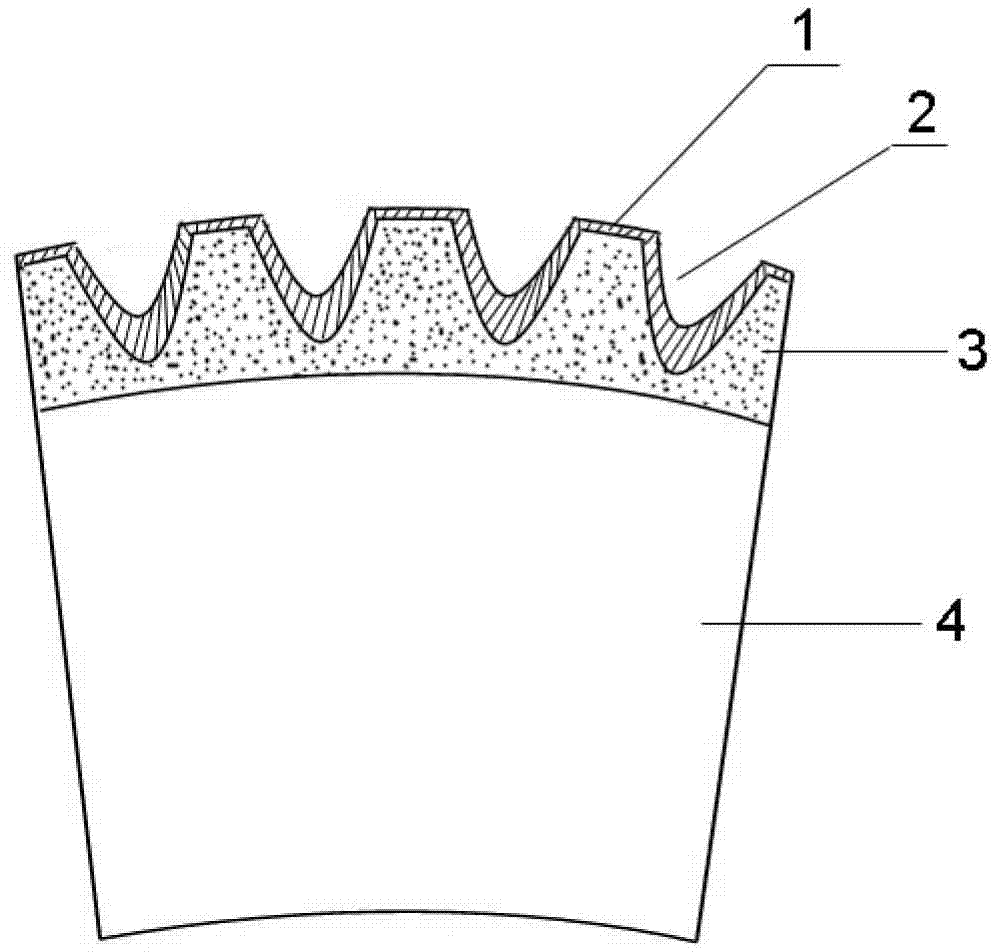

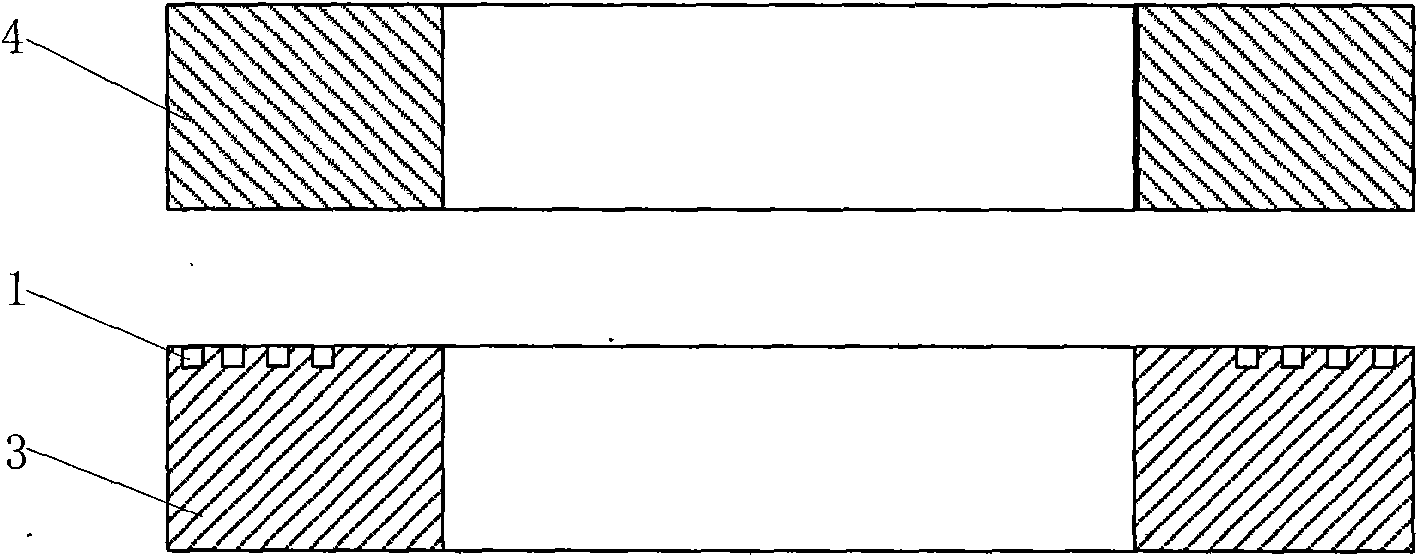

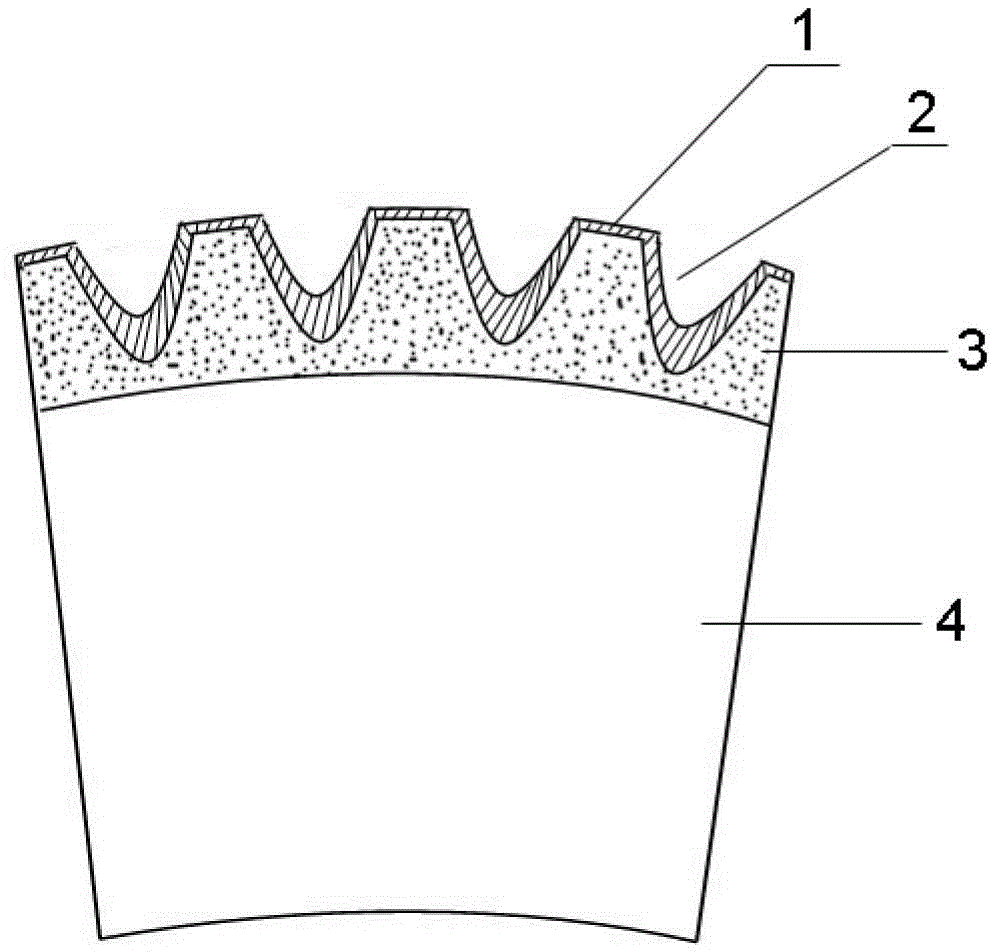

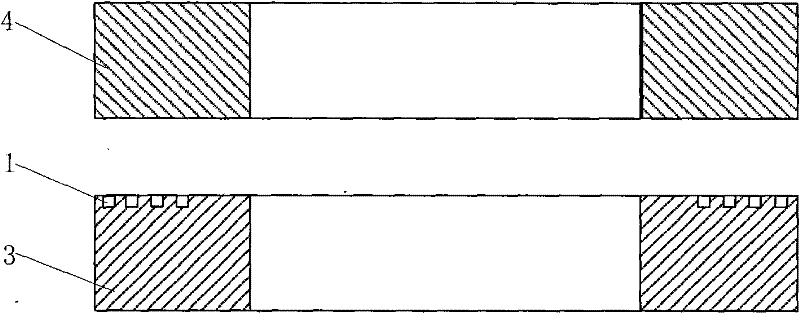

Wear-resisting piston ring with hard-soft composite coating and textured surface and wear-resisting piston ring manufacture method

InactiveCN103089479AImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingChromium coatingDust particles

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

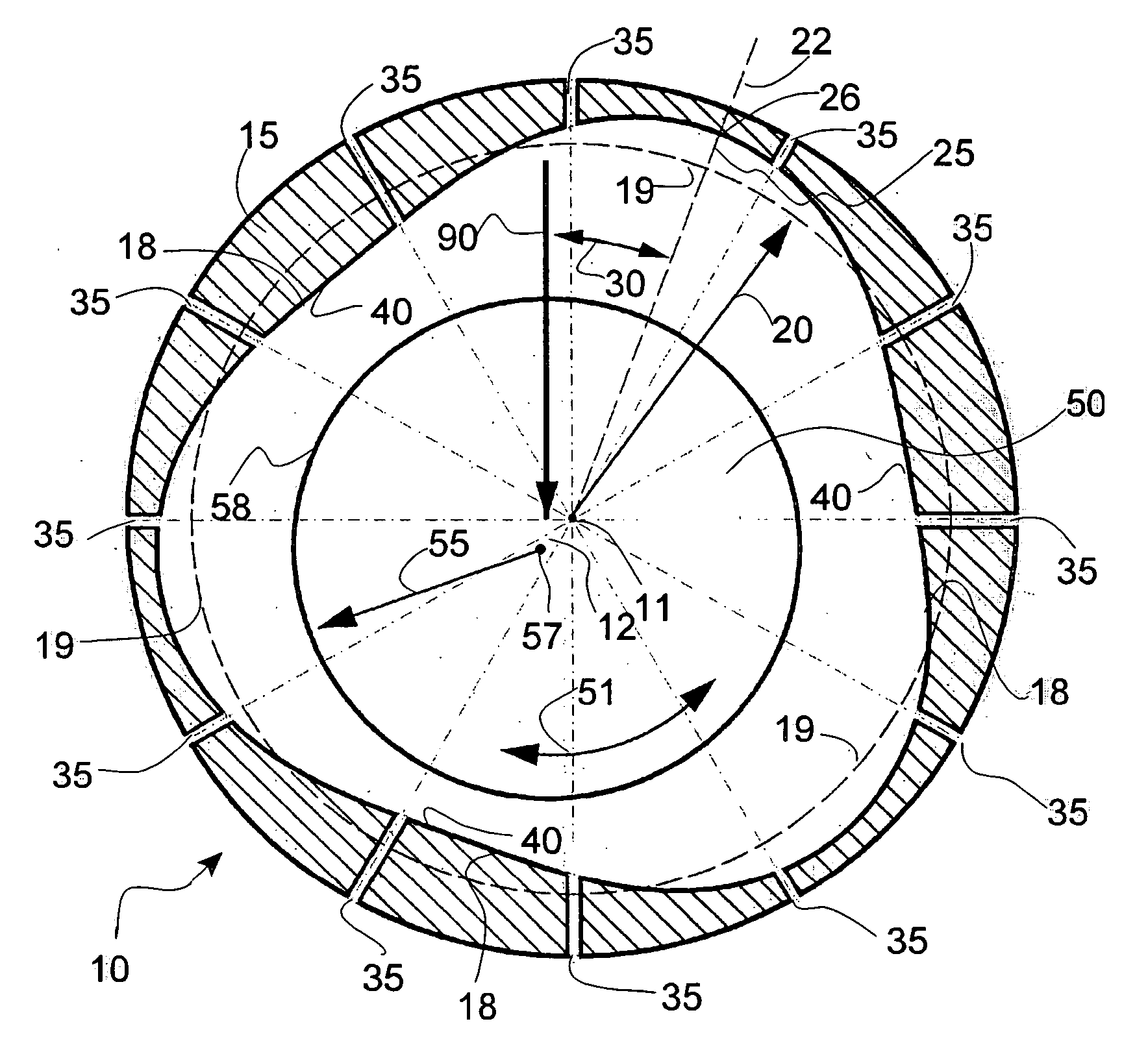

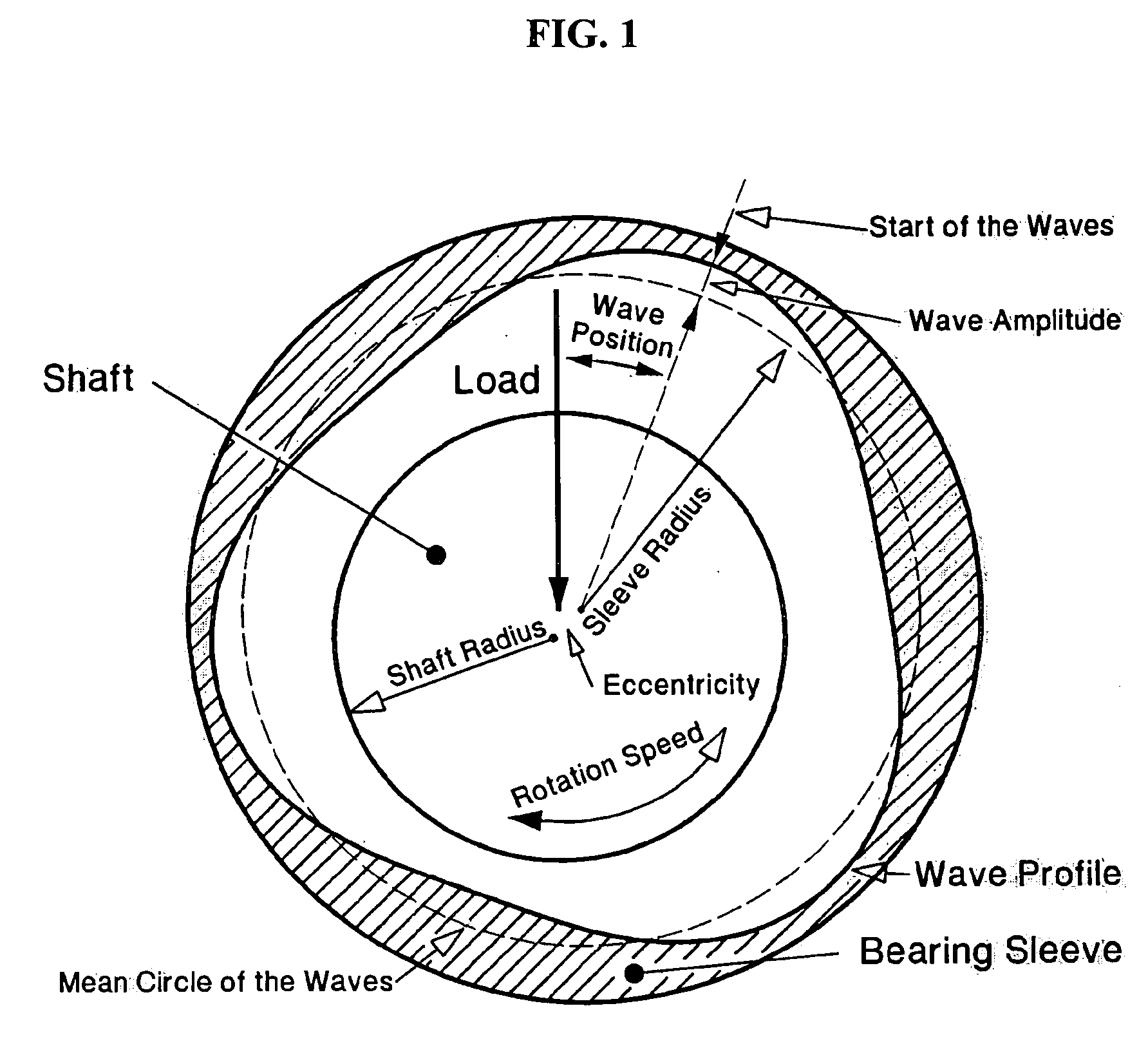

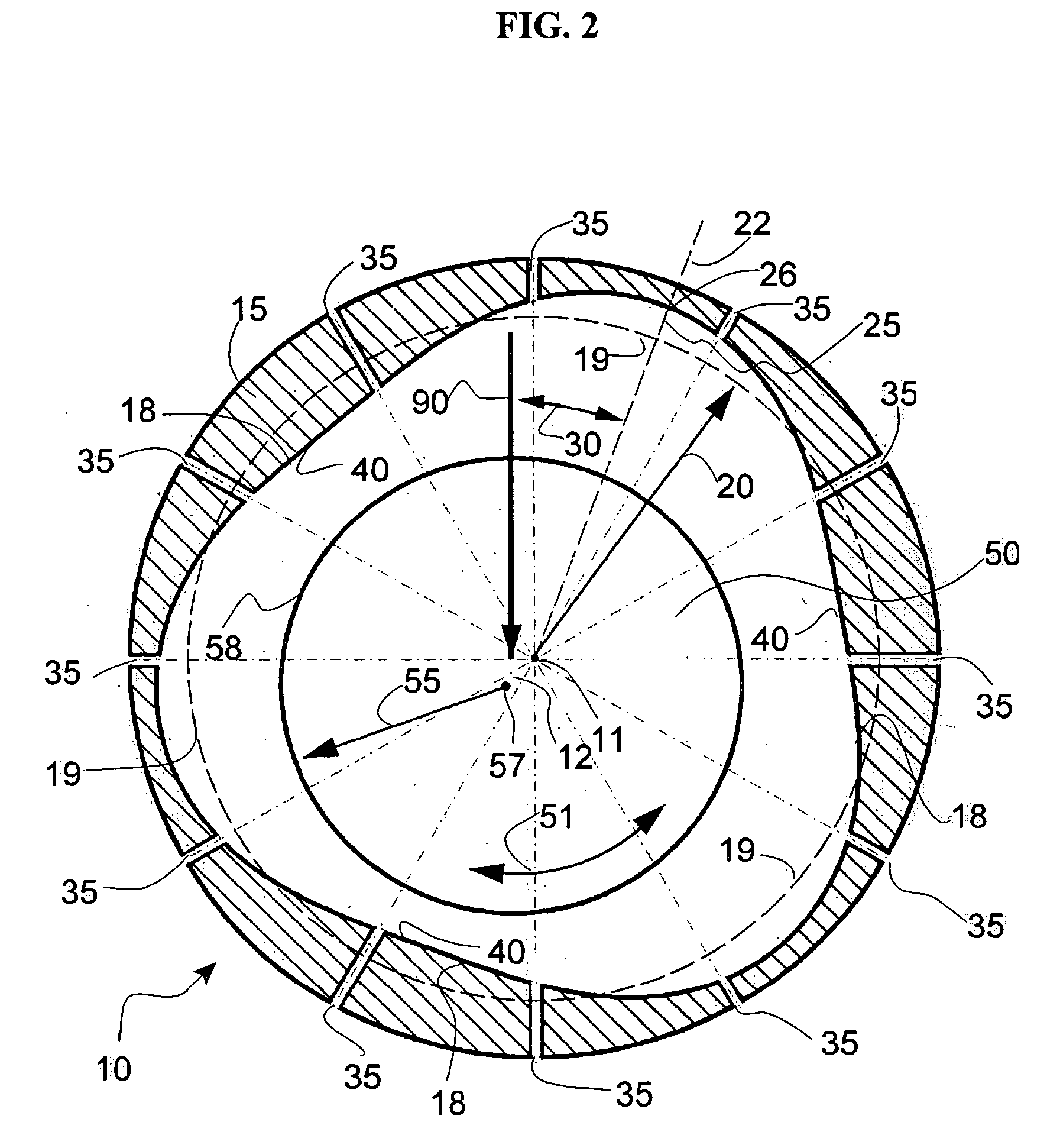

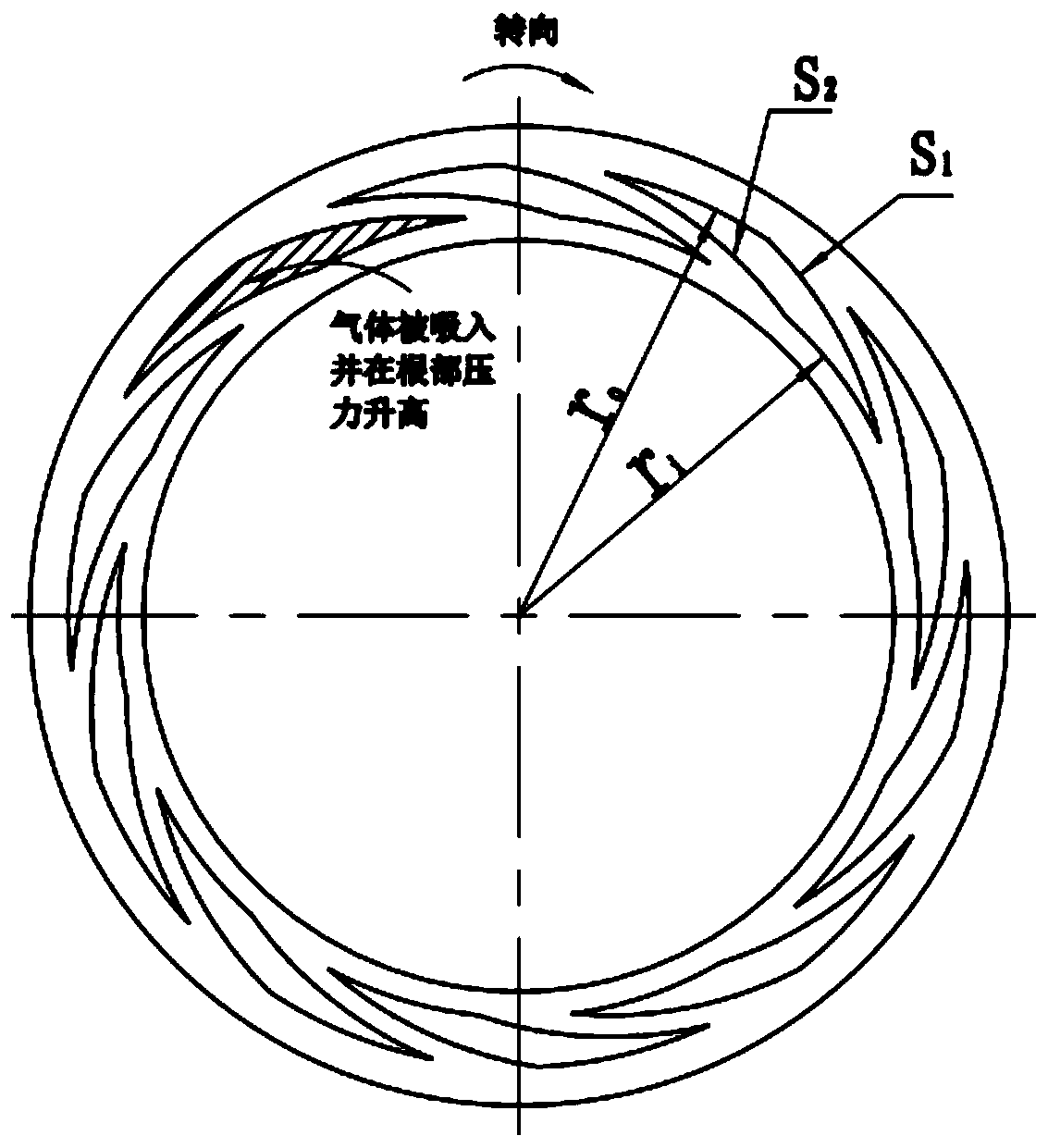

Wave bearings in high performance applications

InactiveUS20060078239A1Enhanced hydrodynamic effectSurface distortionBearing componentsSliding contact bearingsThrust bearingEngineering

The present disclosure concerns the application of the “Wave Bearing Concept” to journal and thrust fluid film bearings to increase performance and reliability. The wave surface is present on whichever member is stationary or non-rotating. Some applications are: pressurized gas journal wave bearings for increased load capacity and dynamic stability; journal wave bearings with liquid lubricants for extreme load capacity and excellent thermal and dynamic stability under any load; thrust wave bearings for axial positioning and axial loads; journal bearings with an elastic wave sleeve that can be activated via actuators (“active / passive control fluid film bearing”) or may change by itself (“smart bearings”) to adapt the bearing performance to the applied bearing load and speed. Journal and thrust bearings incorporating the present invention are appropriate for either mono-directional or bi-directional rotation.

Owner:DIMOFTE FLORIN

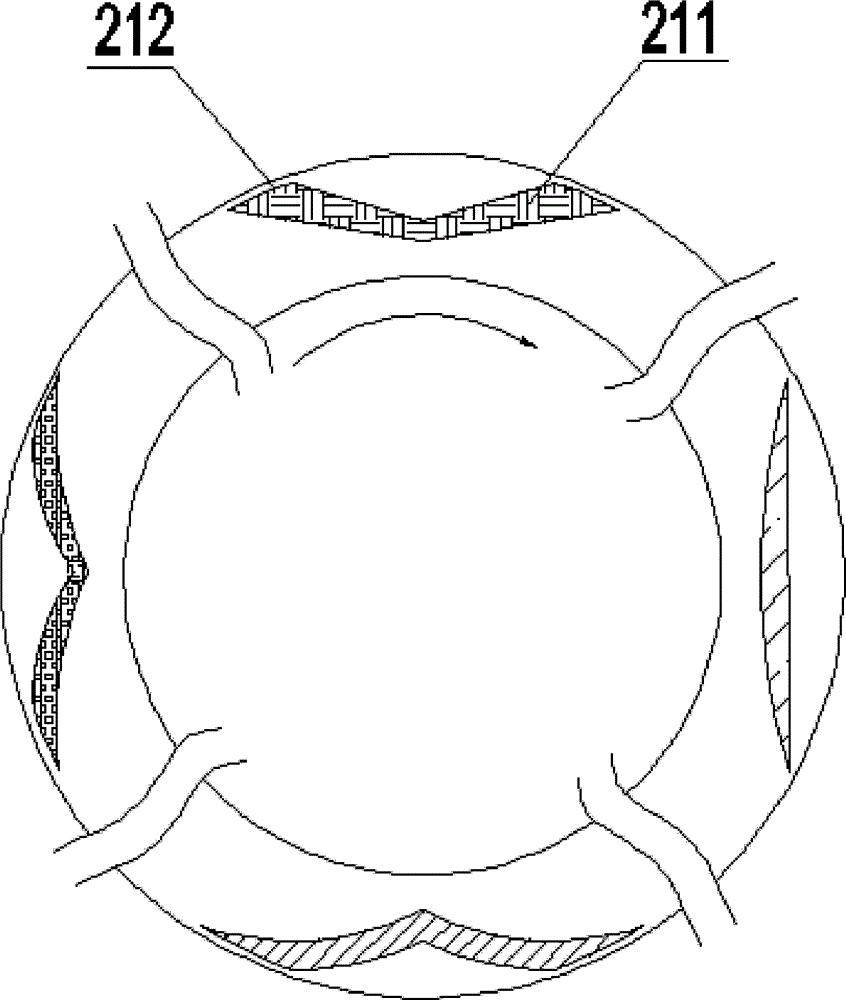

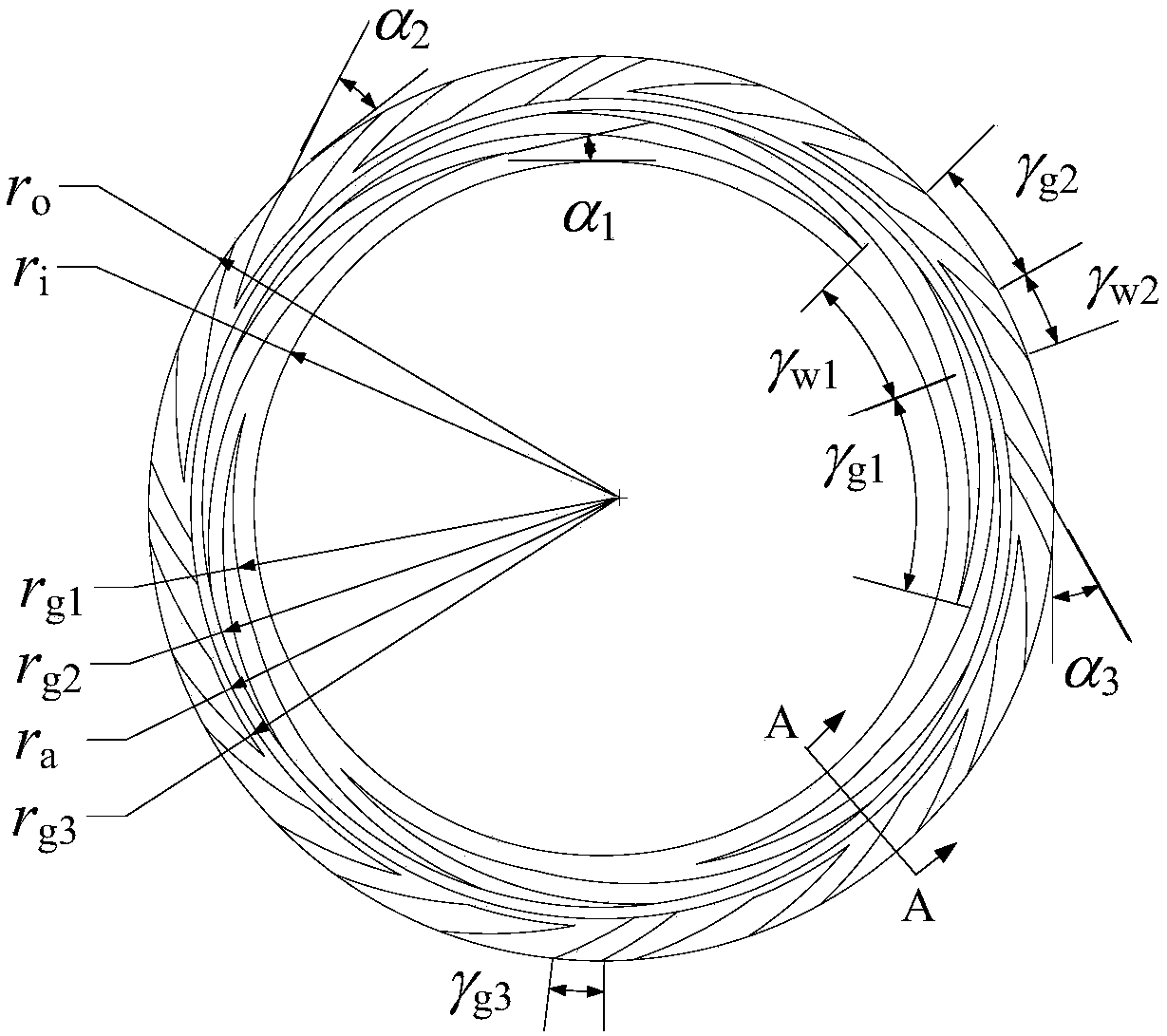

Non-contact mechanical end face sealing structure

InactiveCN1828098AImprove sealing abilityExtended service lifeEngine sealsCentre of rotationEngineering

The invention relates to a non-contact mechanical end surface sealing structure, which comprises mechanical sealed movable ring and stable ring. While the end surface of stable or movable ring has micro groove and porous zone that symmetry according to the rotational center. Wherein, said zone is at the ascending part of end surface and the micro groove is at the descending part, which has a circular sealing dam beside it. The invention can be used in variable mediums to increase the ability of solid particle, the static pressure property, fluid dynamic pressure property and the pump adsorption property, to attain better sealing effect, with long service life.

Owner:ZHEJIANG UNIV OF TECH

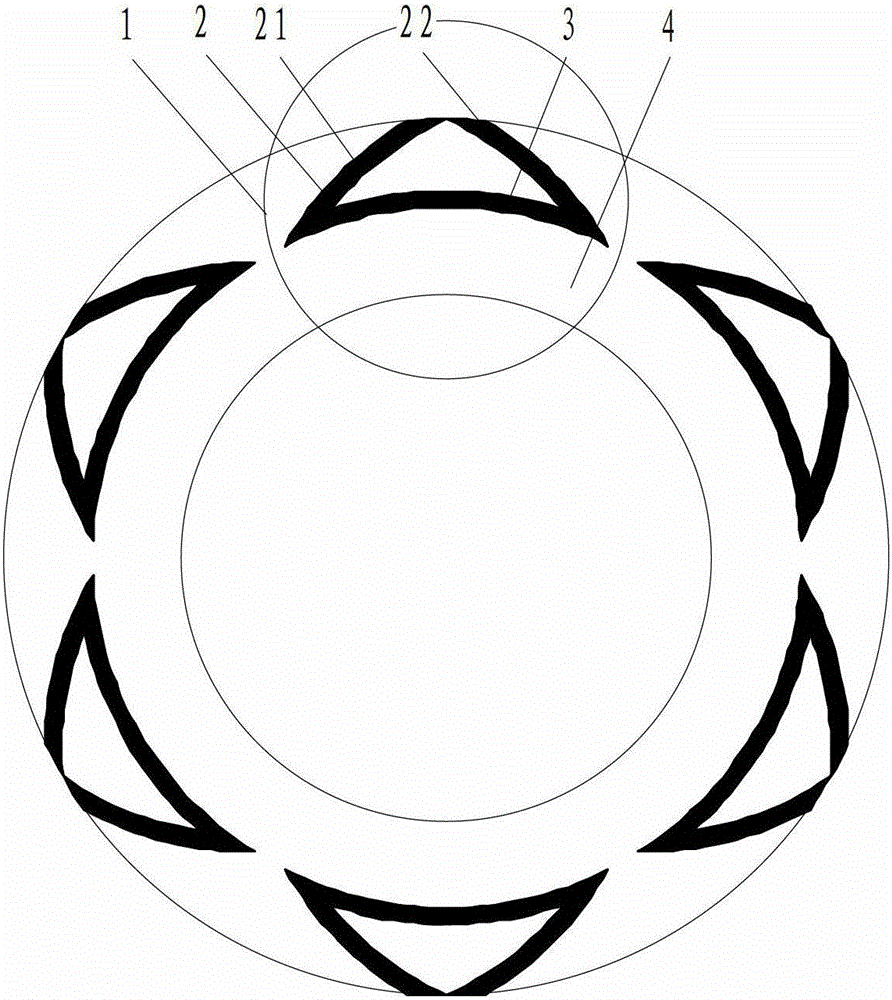

Bilaterally rotatable end surface mechanical sealing structure with dovetail grooves

ActiveCN103133697AImprove compression performanceImprove carrying capacityEngine sealsEngineeringHigh pressure

Owner:ZHEJIANG UNIV OF TECH

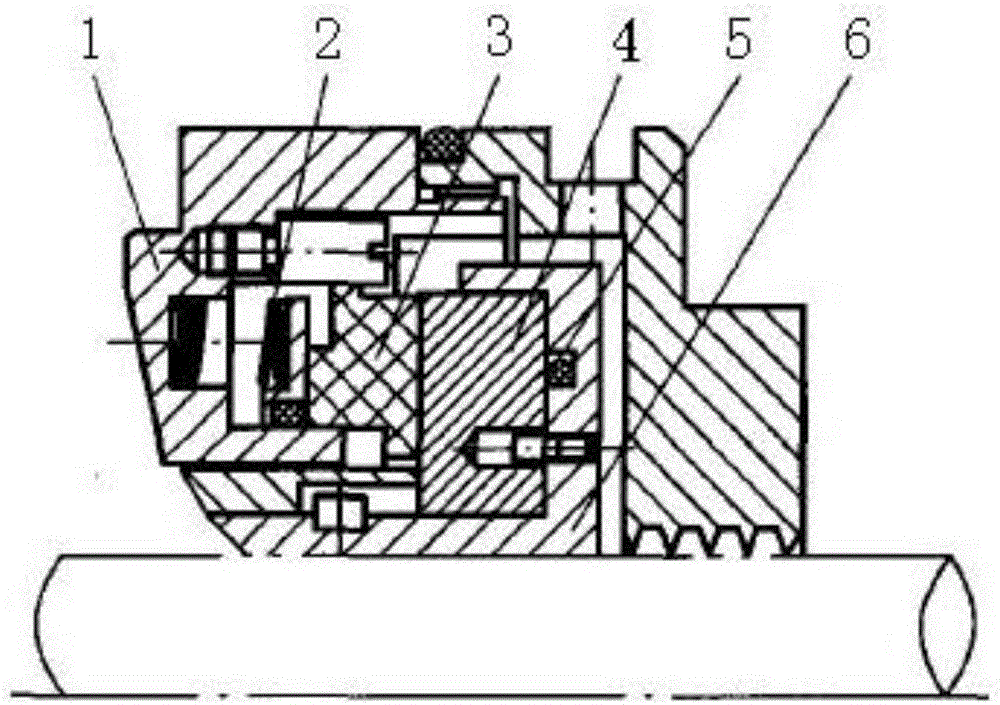

Dry gas seal device

InactiveCN105156687AEnhanced hydrodynamic effectImprove air film stiffnessEngine sealsDry gas sealEngineering

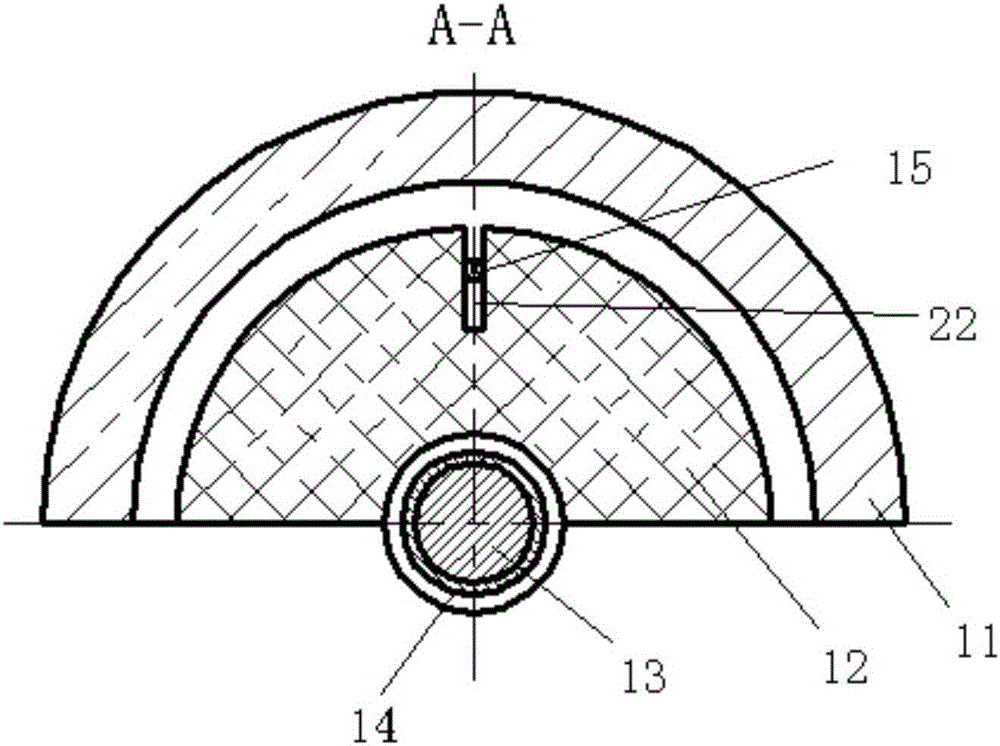

The invention belongs to the technical field of mechanical seals, and provides a dry gas seal device to solve the problems that when a current dry gas seal is applied to high-temperature large-amplitude vibration equipment, an auxiliary seal O-type ring of a compensation ring is likely to deform due to high temperature, and the compensation ring and an active ring are likely to rub. The dry gas seal device comprises a seal support, a pressure spring, a floating ring, a rotary shaft, a shaft sleeve and a locating pin. Bearings are arranged in the middle of the seal support, and the rotary shaft is assembled on the bearings. Spiral grooves, tables and dams are arranged on the outer wall of the shaft sleeve, and the shaft sleeve is arranged on the rotary shaft. The floating ring is located in the seal support and arranged on the shaft sleeve in a sleeving manner. One end of the floating ring and the seal support are circumferentially fixed through the locating pin, and the other end of the floating ring is connected with the pressure spring. The dry gas seal device is good in opening characteristic, high in gas film rigidity, stable in running and capable of adapting to shaft end seals of the high-temperature large-amplitude vibration equipment.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

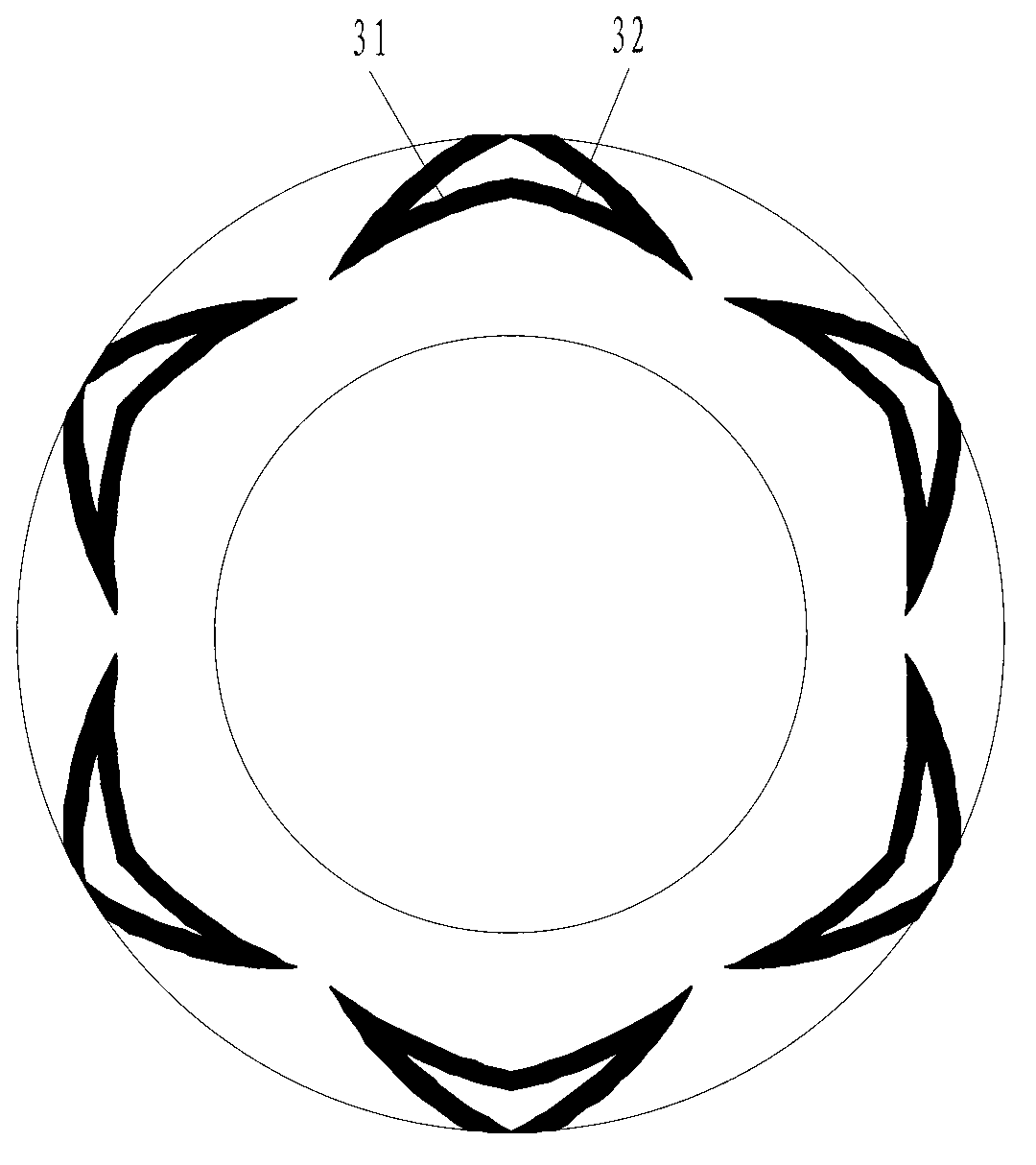

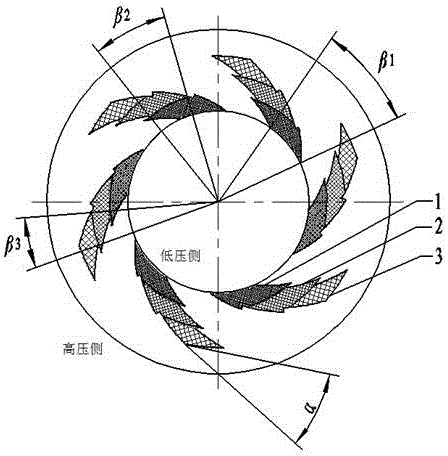

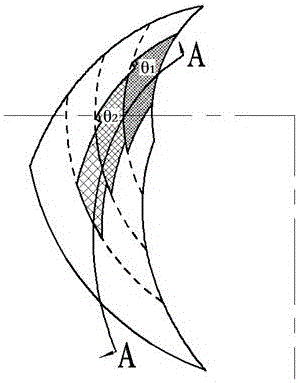

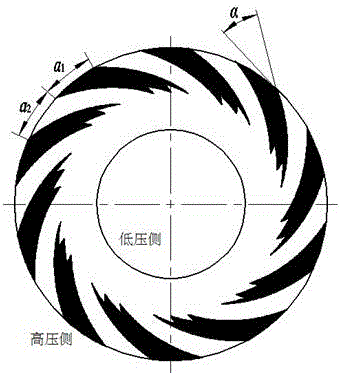

Profiled groove end surface non-contact mechanical seal with backflow function

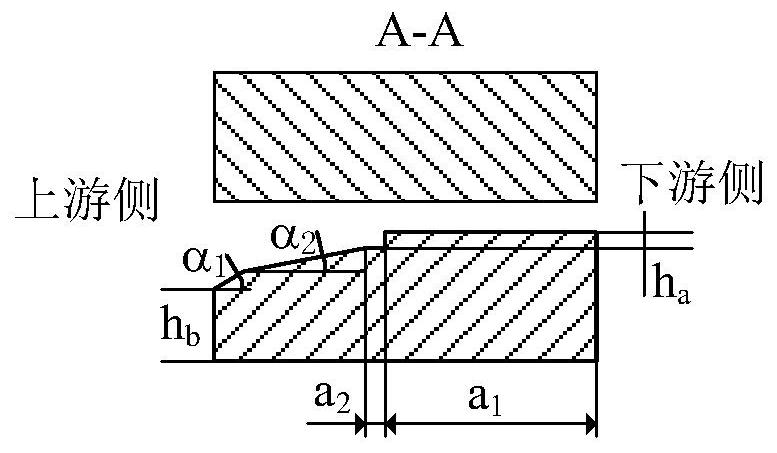

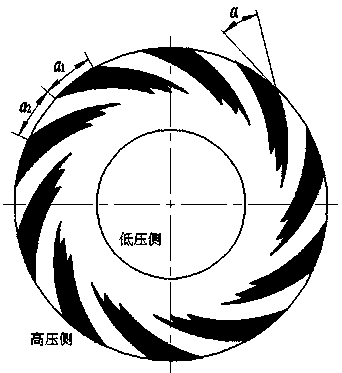

The invention discloses a profiled groove end surface non-contact mechanical seal with a backflow function. The profiled groove end surface non-contact mechanical seal comprises a mechanical seal moving ring and a mechanical seal static ring, wherein one side of the end surface of each of the moving ring and the static ring is a high-pressure side, i.e. an upstream; the other side of the end surface of each of the moving ring and the static ring is a low-pressure side, i.e. downstream; the downstream of the end surface is provided with an annular sealing dam of a smooth plane; and at least one sealing end surface in the moving ring and the static ring is provided with a plurality of groups of fluid profiled grooves. The profiled groove end surface non-contact mechanical seal with a backflow function is characterized in that the fluid profiled groove is formed by compounding the drainage groove and a pumping reflux groove, wherein the average groove depth of the drainage groove is more than the average groove depth of the pumping reflux groove; the drainage groove is arranged on the upstream of the end surface and is communicated with sealing medium; the pumping reflux groove is the profiled groove with the appearance structure characteristic of a flying bird wing; the groove depth is in the variation rule that the middle is deep and two sides are shallow; and the tail ends of two sides of the pumping reflux groove has a certain space with the upper stream of the end surface. The profiled groove end surface non-contact mechanical seal has dual actions of upstream pumping and downstream pumping to the sealing medium, the leakage amount is reduced, and the operation reliability of sealing is improved.

Owner:ZHEJIANG UNIV OF TECH

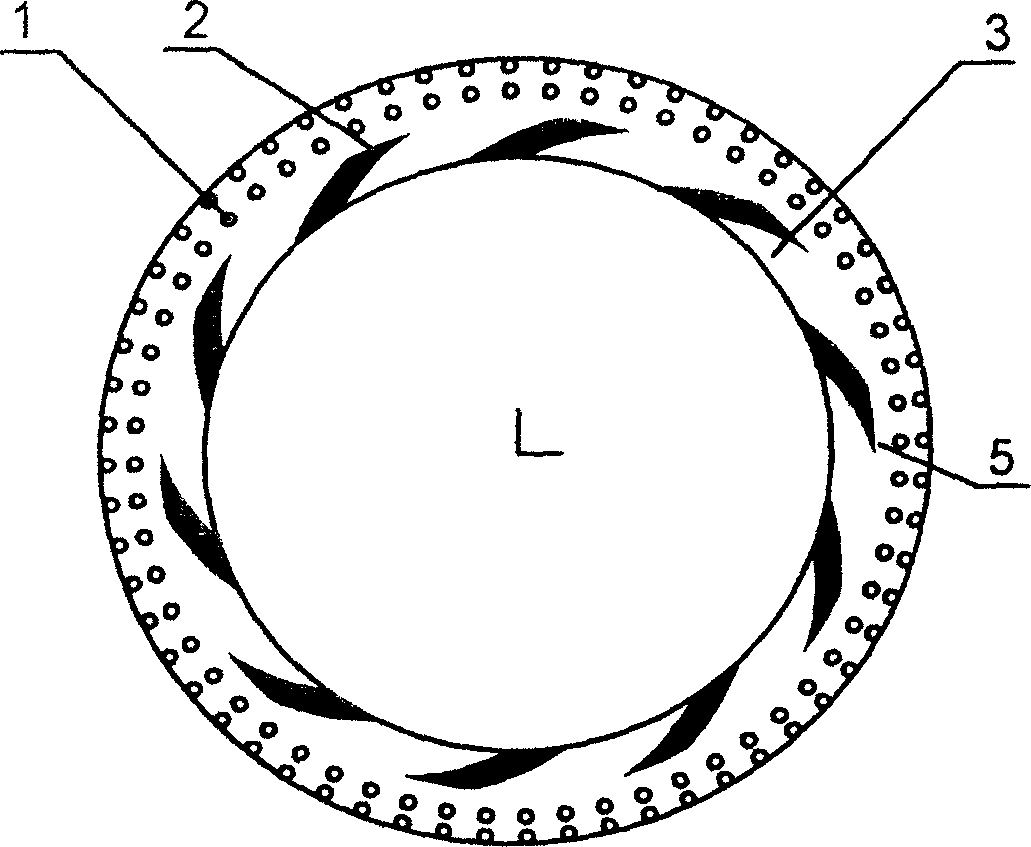

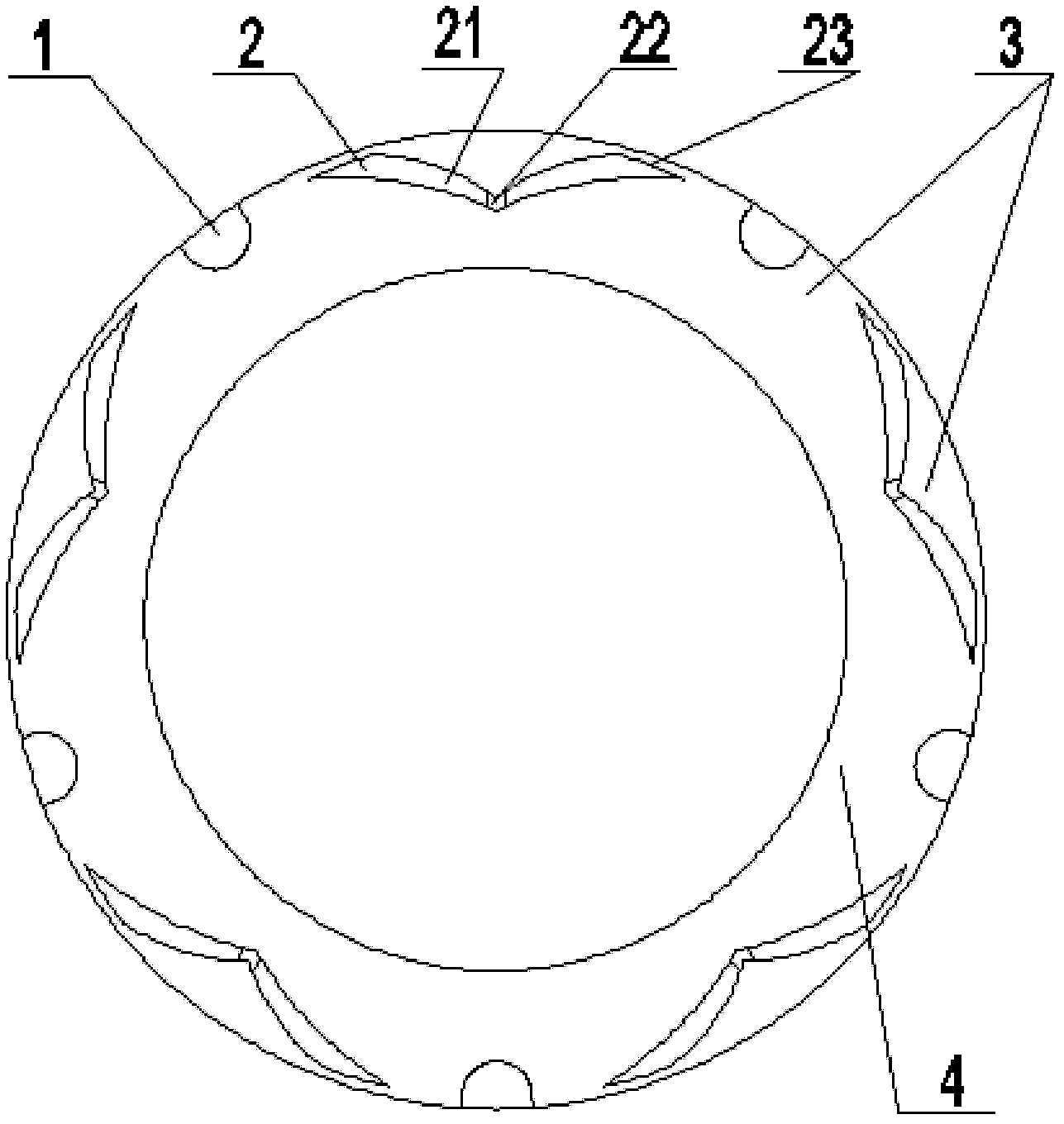

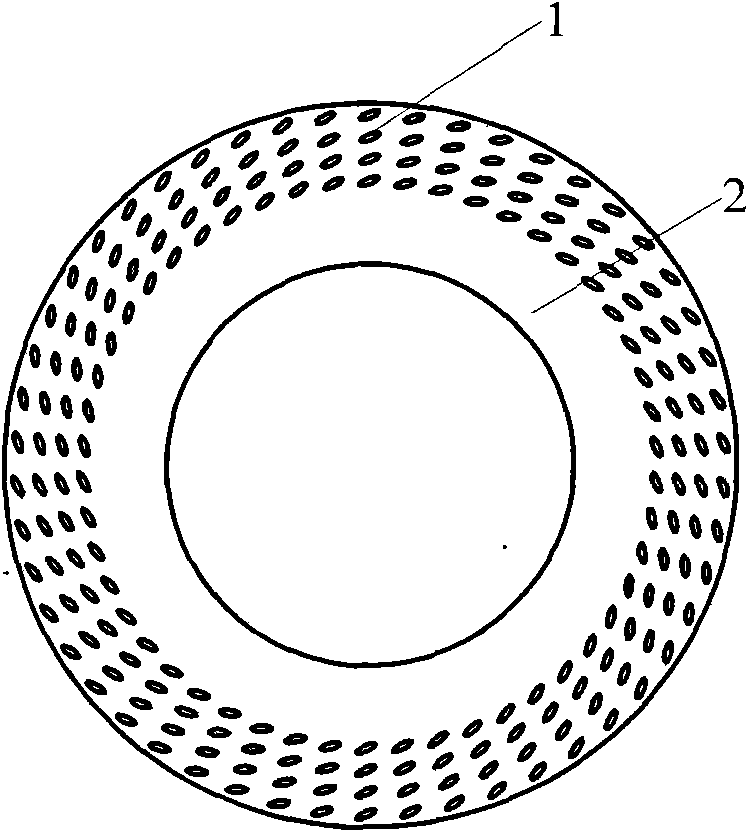

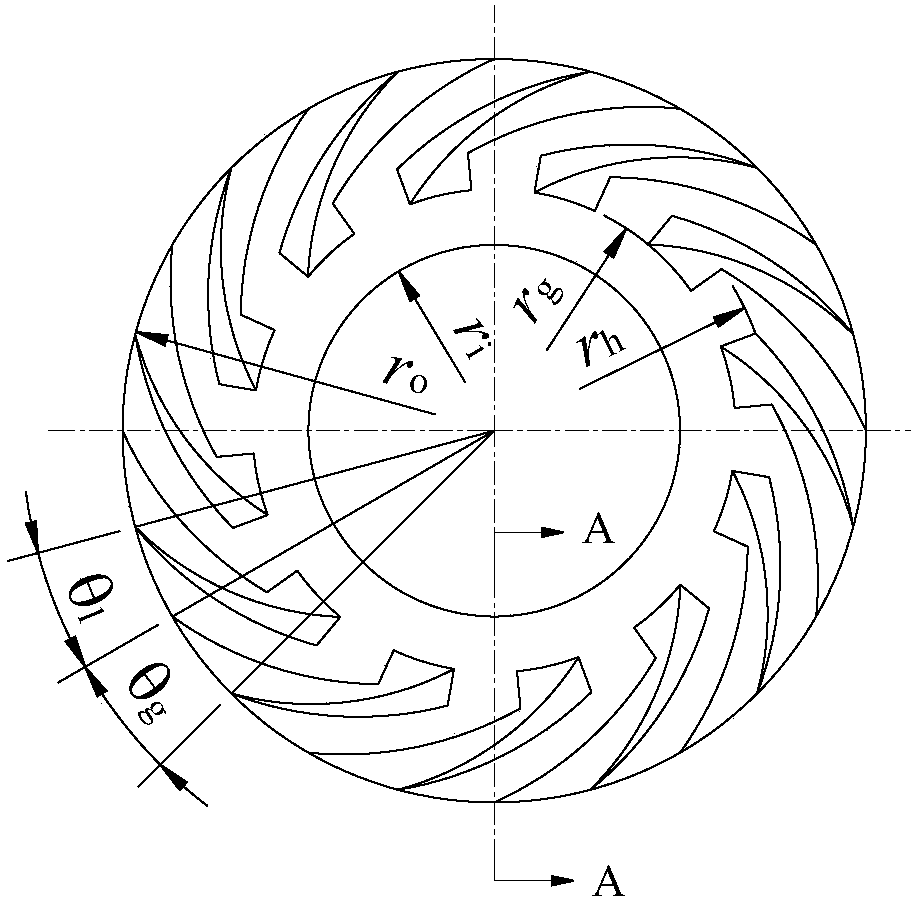

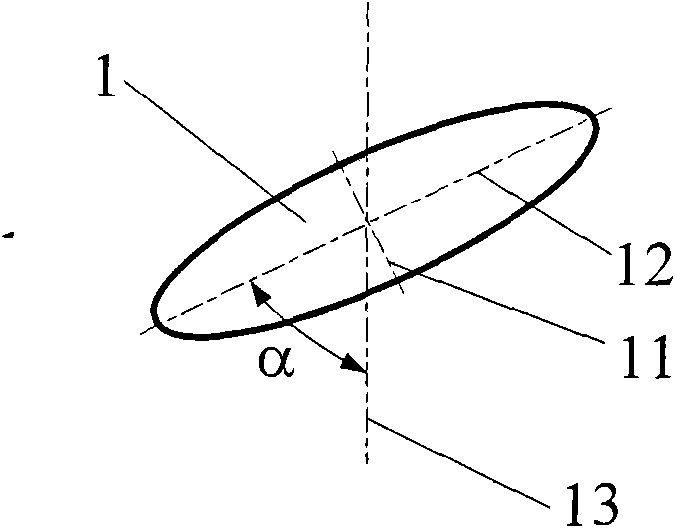

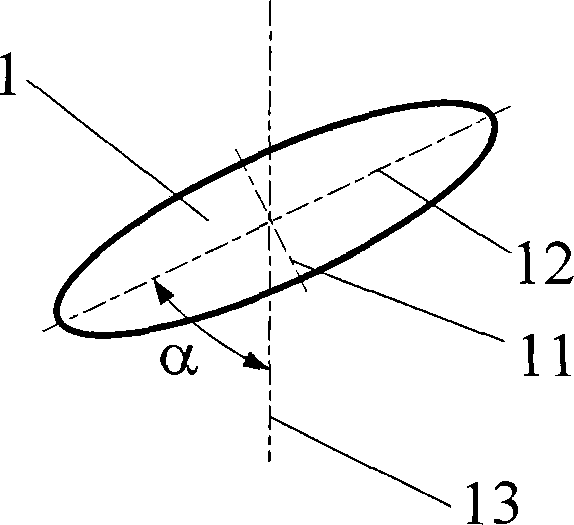

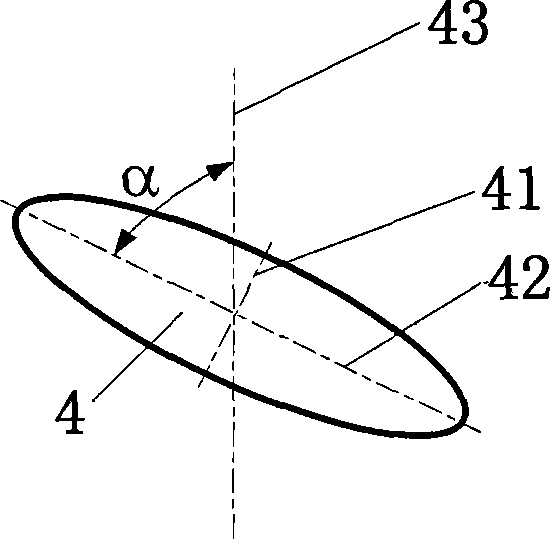

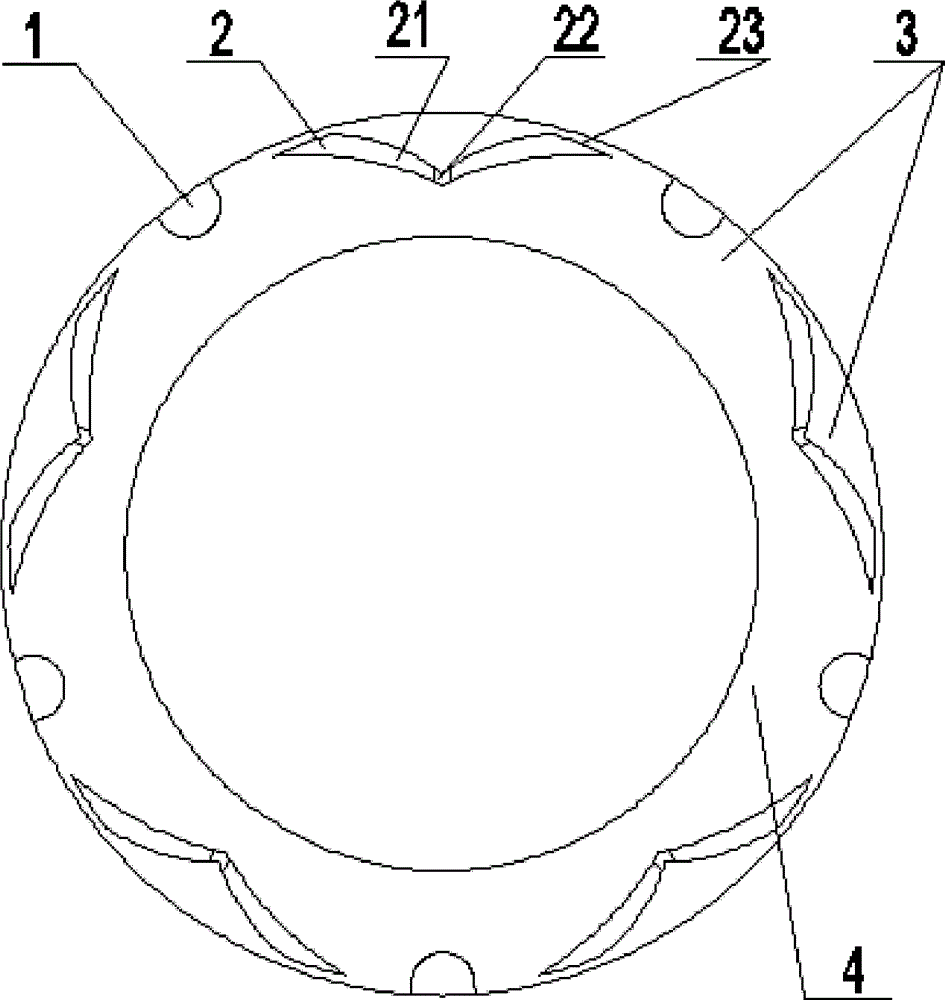

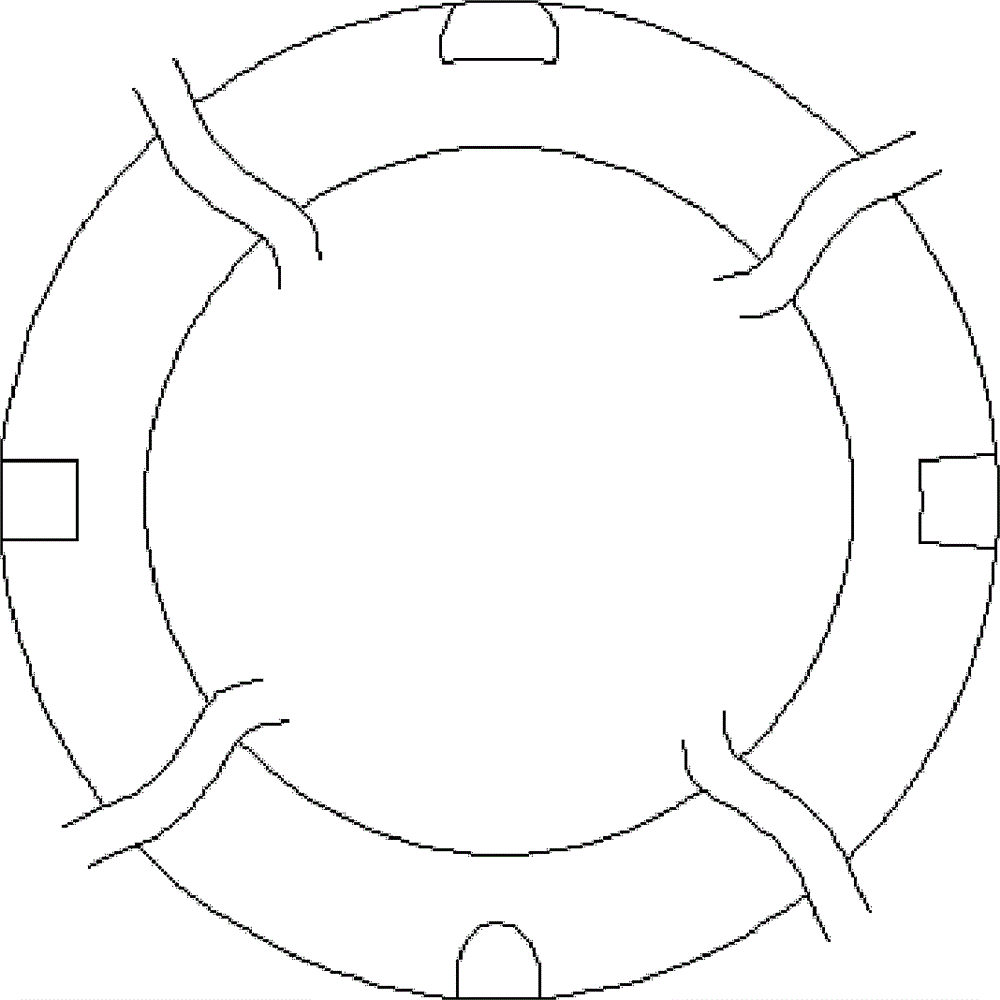

Tilting directional microporous end surface mechanical sealing structure

ActiveCN101672366AImprove reliabilityEnhanced hydrodynamic effectEngine sealsStart stopLiquid medium

The invention relates to a tilting directional microporous end surface mechanical sealing structure comprising a dynamic ring and a static ring which are sealed mechanically, one side of the end surface of the dynamic ring and the static ring is a high-voltage side, namely, an upstream part, and the other side thereof is a low-voltage side, namely, a downstream part; the end surface of the dynamicring or the static ring is provided with a microporous ring belt which is arranged on the upstream part of the end surface; the downstream part of the microporous ring belt is provided with a continuous ring-shaped sealing dam; and a long shaft of the micropore forms a tilting angle with the diameter of the sealing end surface passing through the center of the micropore. The tilting directional micropore end surface mechanical sealing structure has the beneficial effects of: greatly improving hydrodynamic effect of the microporous end surface, leading the sealing to have good starting-stopping effect under low-voltage condition, being capable of being applied in a liquid medium and a gas medium by setting the depth of the micropore, being capable of fully exerting the capabilities and advantages of microporous solid particles, realizing no contact, wear resistance and no leakage of sealing, prolonging the service life and improving the sealing reliability.

Owner:ZHEJIANG UNIV OF TECH

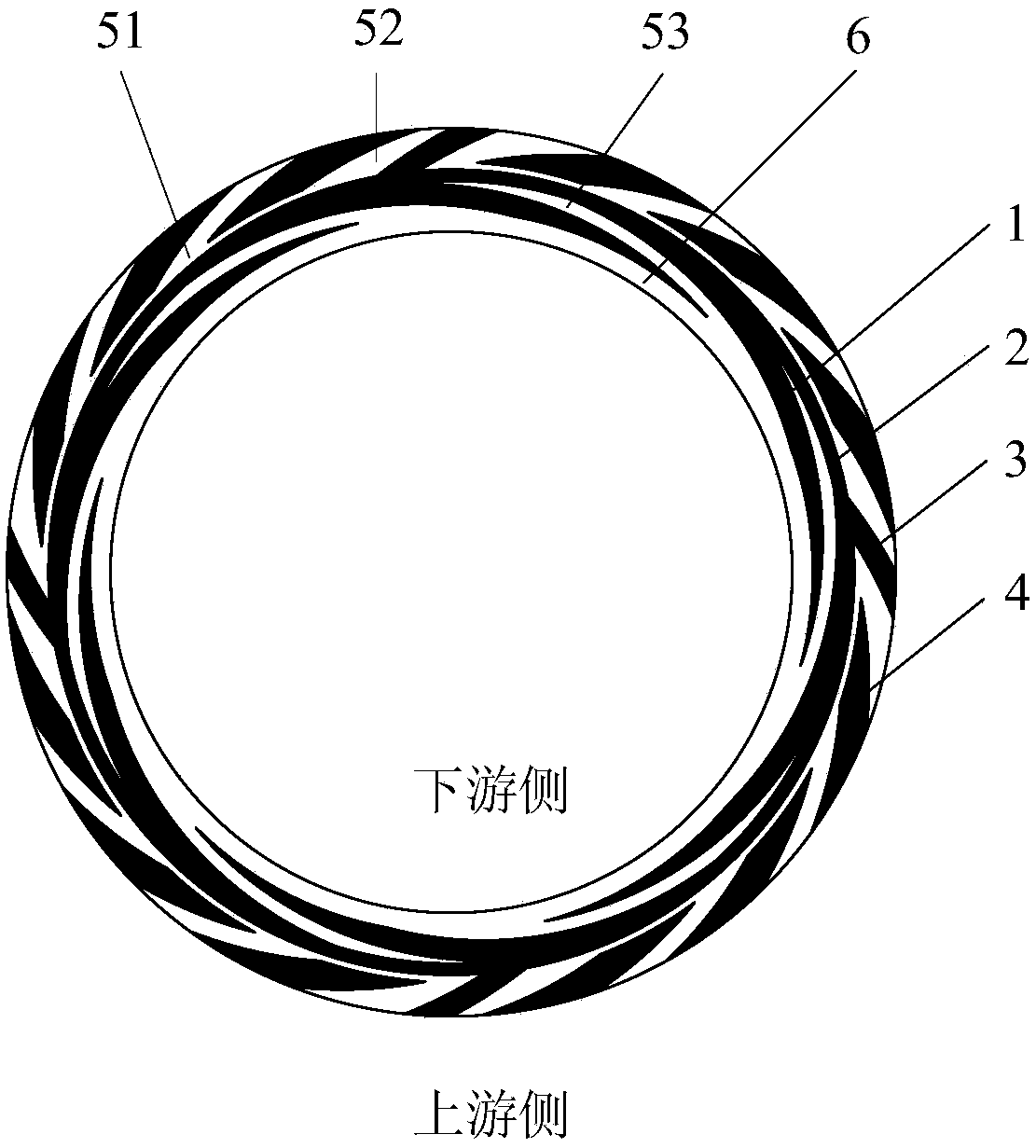

Low-leakage spiral groove liquid film mechanical seal end face structure

ActiveCN107166036AFlow is easy to controlGood pump back flow capabilityEngine sealsEngineeringLow leakage

A low-leakage spiral groove liquid film mechanical seal end face structure comprises a dynamic ring and a static ring of a mechanical seal; one side of the end face of the dynamic ring or the static ring is a high-pressure side, namely, the upstream side; the other side of the end face of the dynamic ring or the static ring is a low-pressure side, namely, the downstream side; the end face of the dynamic ring or the static ring is provided with a series of launders, the downstream side is provided with a series of reverse spiral grooves uniformly distributed in the circumferential direction, the middle is provided with an annular groove communicating with the reverse spiral grooves, the upstream side is provided with outlets communicating with the annular groove and a medium side, and a series of forward spiral grooves are formed between the two adjacent outlets; and sealing dams are arranged between the reverse spiral grooves and the downstream side, and sealing weirs are arranged between the annular groove and the forward spiral grooves. The low-leakage spiral groove liquid film mechanical seal end face structure is each to achieve low leakage under various complex working conditions, excellent in tribological property, good in bearing performance and stability and long in service life.

Owner:ZHEJIANG UNIV OF TECH

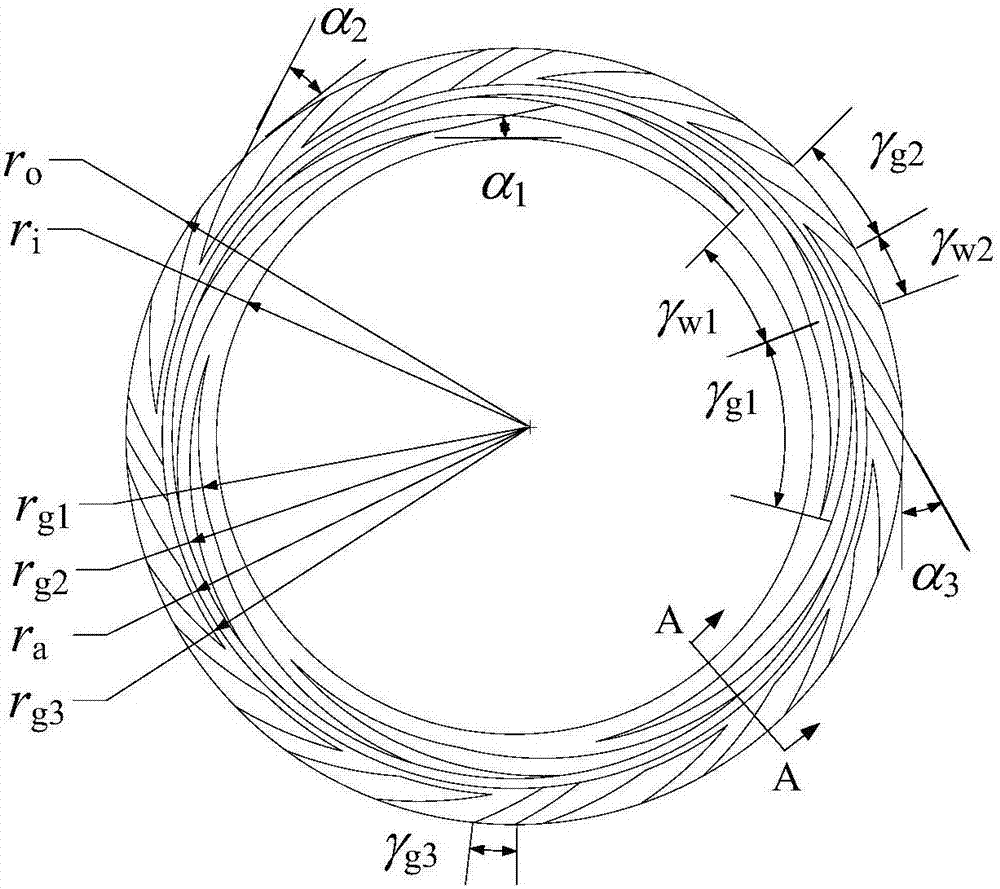

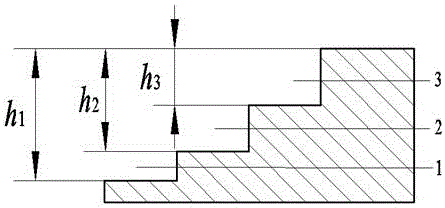

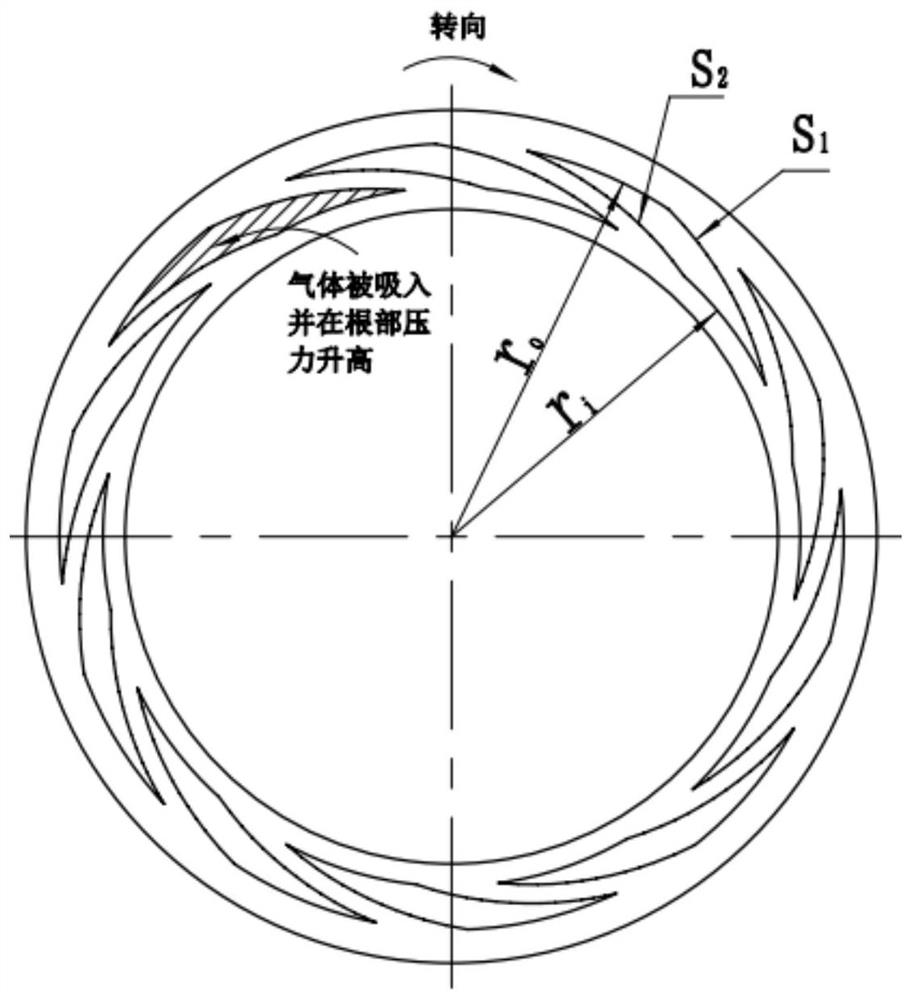

Upstream pumping machinery sealing ring with multiple stages of helical grooves

ActiveCN106763778AAids in compression boostContribute to local pressurizationEngine sealsEngineeringHigh pressure

The invention relates to an upstream pumping machinery sealing ring with multiple stages of helical grooves. The multiple stages of helical grooves uniformly distributed along the circumference of the end surface are formed in the end surface; openings of the multiple stages of helical grooves are formed in the low pressure side of the end surface; the circumferential width and the depth of each stage of helical groove are gradually decreased from the low pressure side to the high pressure side, thus overall forming convergent gaps and greatly enhancing the hydrodynamic pressure effect of the end surface; and therefore, the friction resistance of a machinery seal in an operation process is reduced, and the service life is greatly prolonged.

Owner:云南流体规划研究院有限公司

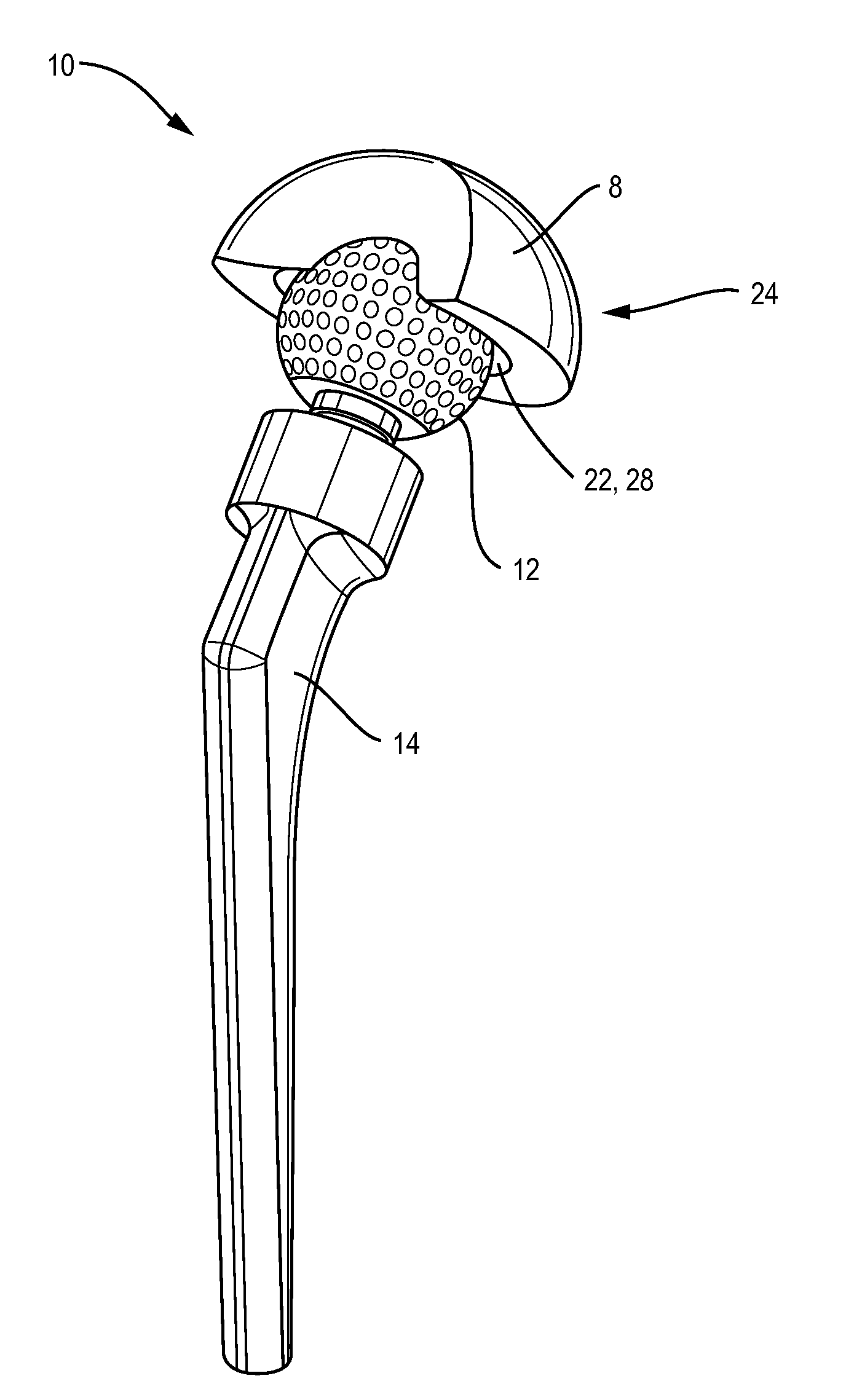

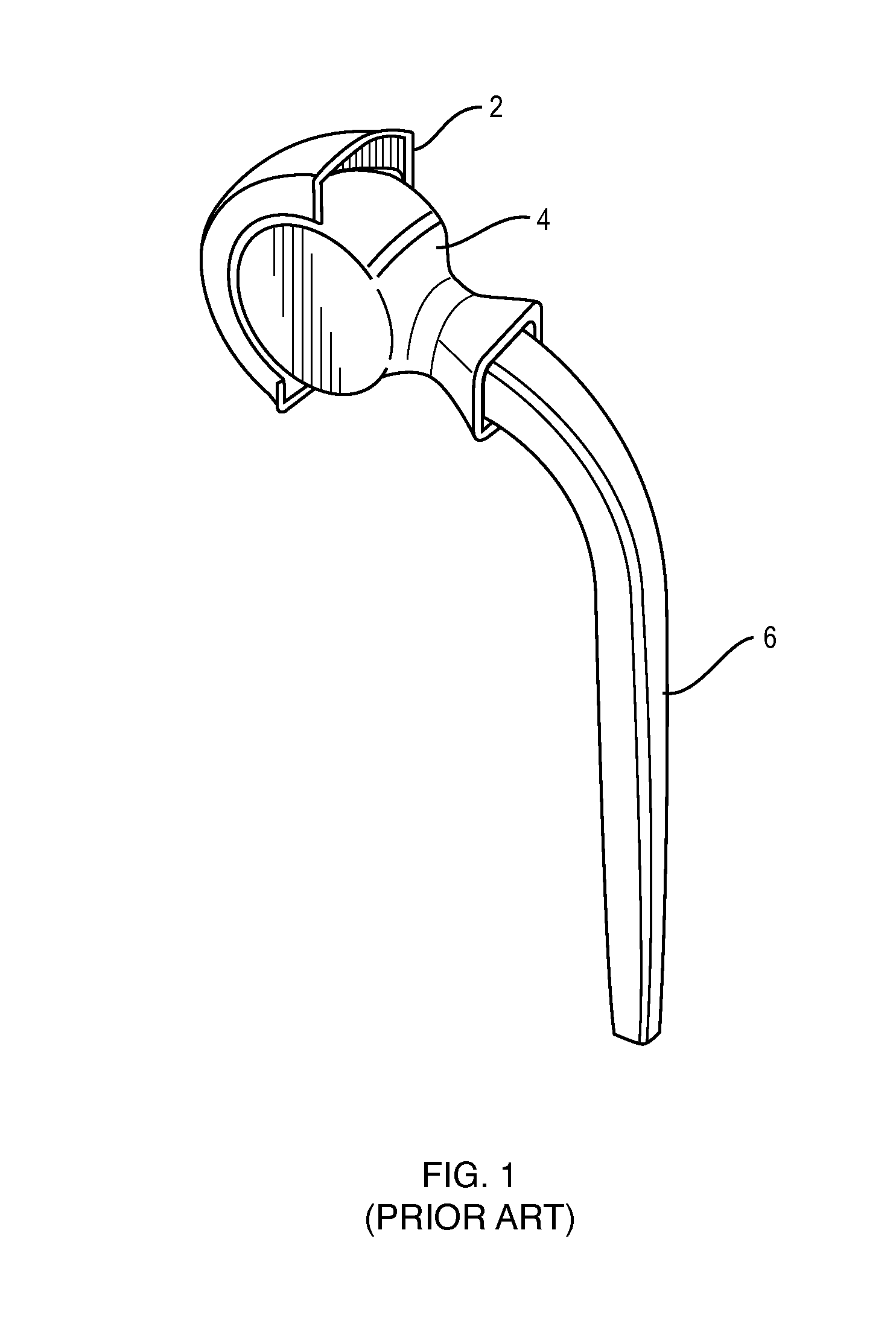

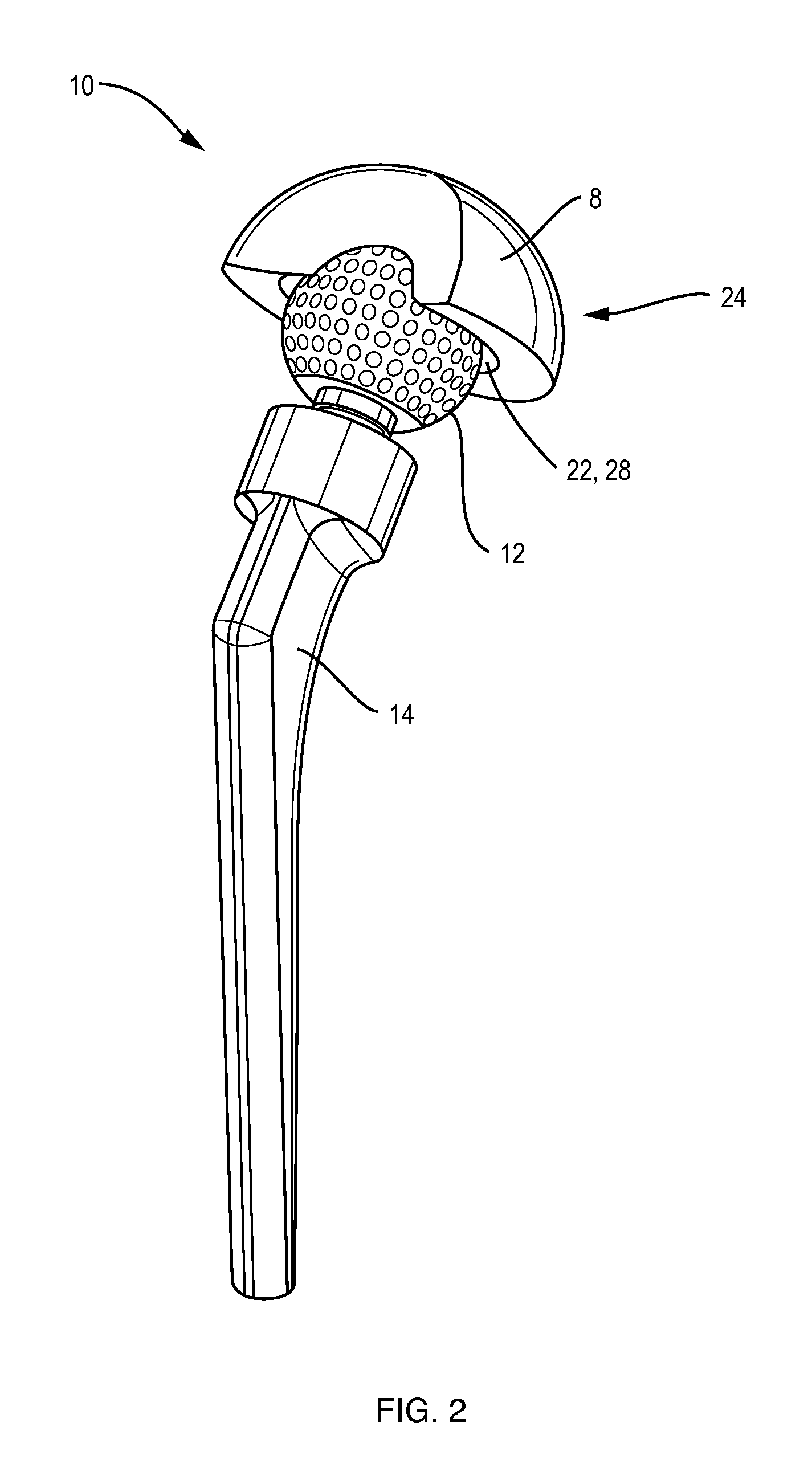

Extended life prosthetic hip joint

InactiveUS20120203351A1High sphericityImprove surface roughnessJoint implantsHip jointsRight femoral headLeft femoral head

A prosthetic hard-on-hard orthopaedic hip joint comprising a femoral head with a diameter of approximately 40 mm and a dimpled surface, an acetabular cup with a diameter such that the diametric clearance is less than or equal to 50 μm, a sphericity less than 10% of the diametric clearance, a composite surface roughness less than 20 nm, and a femoral stem integral to said femoral head.

Owner:THOMPSON DANIEL C

Mechanical seal ring provided with multi-sawteeth-shaped spiral grooves

ActiveCN106763779AImprove compression performanceImprove lubrication statusEngine sealsMechanical engineeringHelix

Owner:云南流体规划研究院有限公司

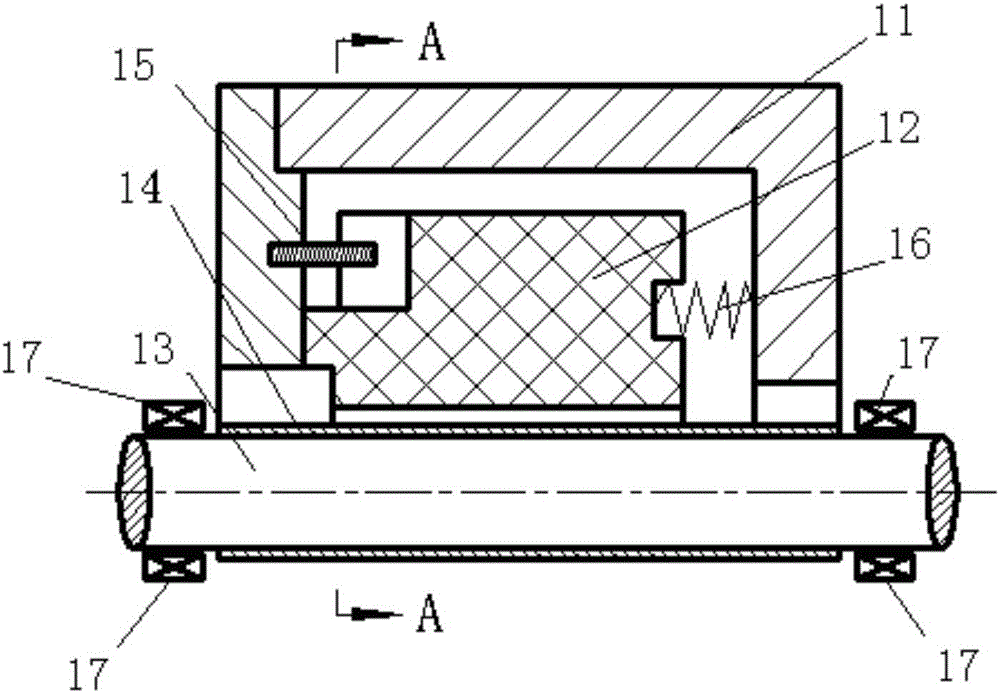

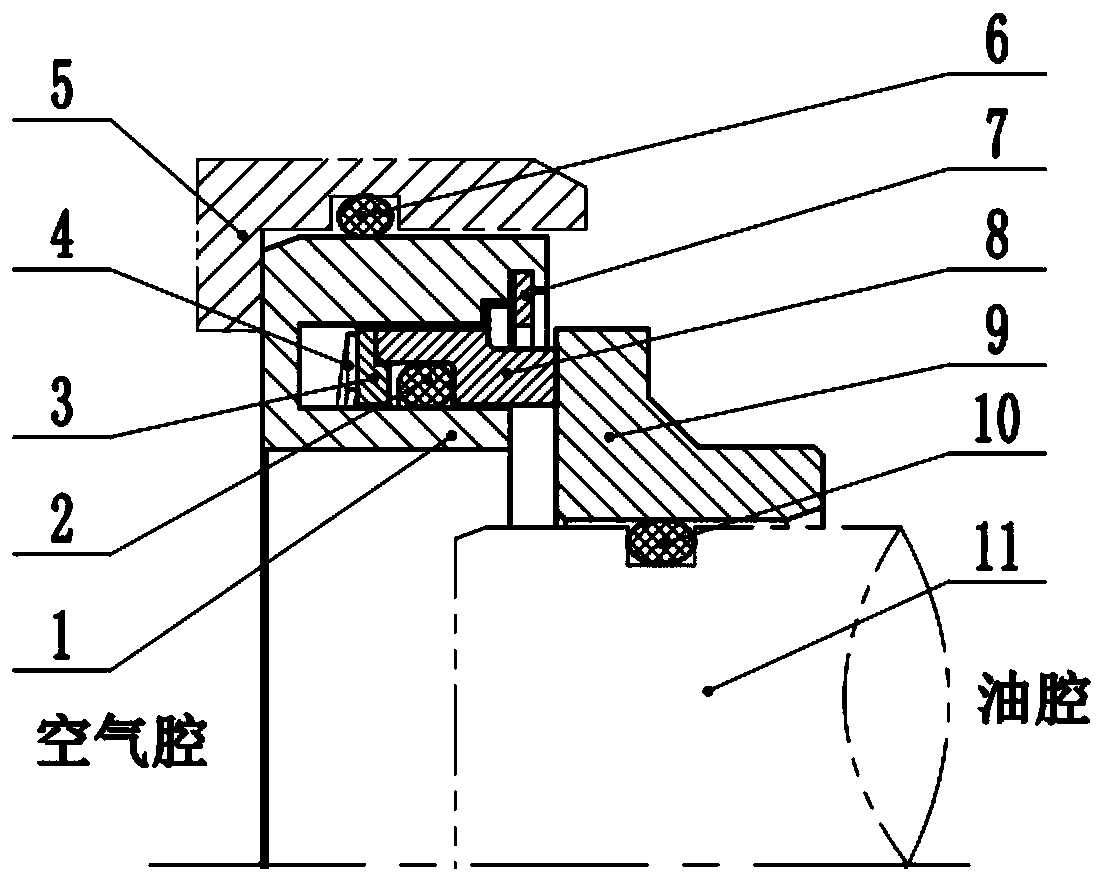

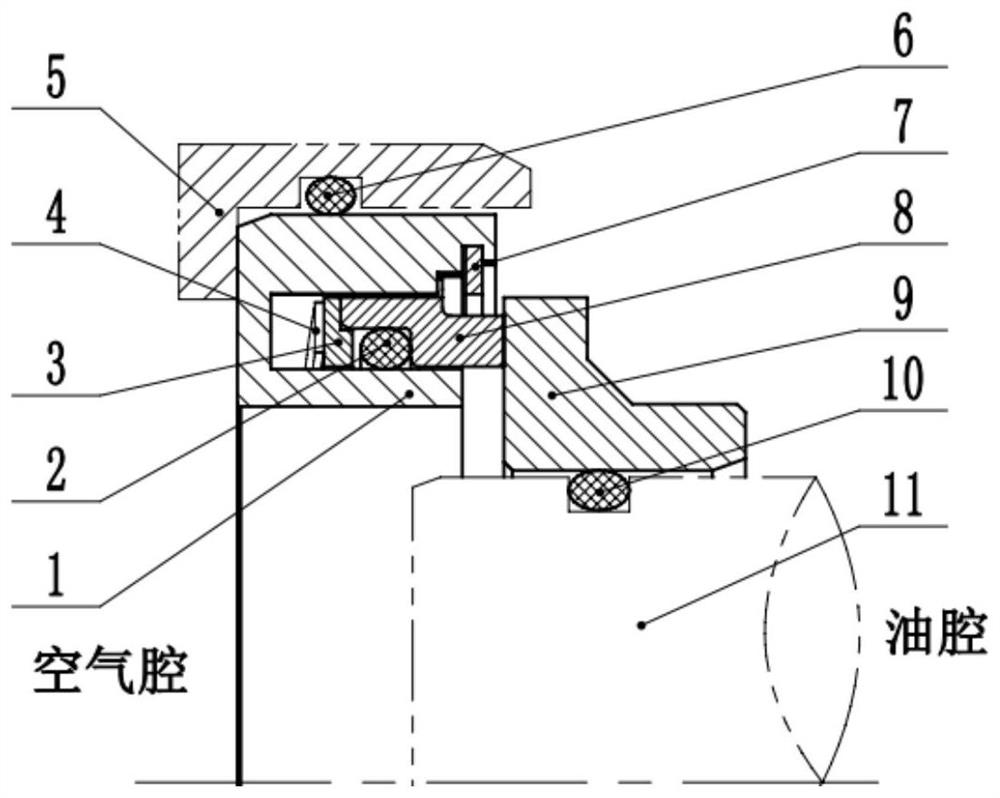

Constant-elasticity film-coating involute spiral groove long-life sealing device

ActiveCN110285218AReduce wearImprove corrosion resistanceEngine sealsGas turbine plantsRubber ringGraphite

The invention discloses a constant-elasticity film-coating involute spiral groove long-life sealing device, particularly relates to a shaft end sealing device suitable for an aero-engine with high rotating speed, high maneuverability and the complex load, and belongs to the technical field of mechanical sealing. The constant-elasticity film-coating involute spiral groove long-life sealing device comprises a sealing shell, a first sealing rubber ring, a pressing plate, a lap joint wavy spring, a second sealing rubber ring, a check ring, a graphite ring, a sealing movable ring and a third sealing rubber ring. The constant-elasticity film-coating involute spiral groove long-life sealing device is used for isolating an oil cavity from an air cavity and preventing lubricating oil in the oil cavity from leaking to the air cavity so as to fulfill the oil sealing aim. The lap joint wavy spring is used for generating an axial force, the axial force is transmitted to the graphite ring through the pressing plate, tight contact of the graphite ring and the sealing movable ring is guaranteed and a main sealing surface is formed. The constant-elasticity film-coating involute spiral groove long-life sealing device can reduce abrasion of a mechanical sealing device and can improve the sealing property and the stability of the mechanical sealing device, so that the life of the constant-elasticity film-coating involute spiral groove long-life sealing device is prolonged.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

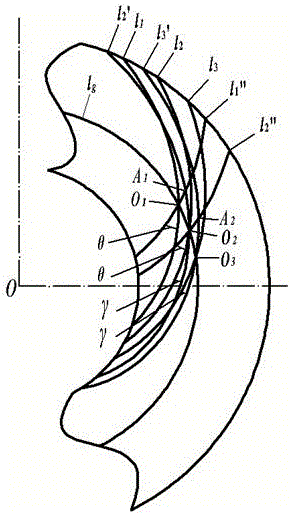

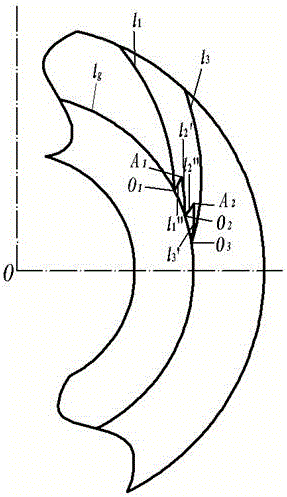

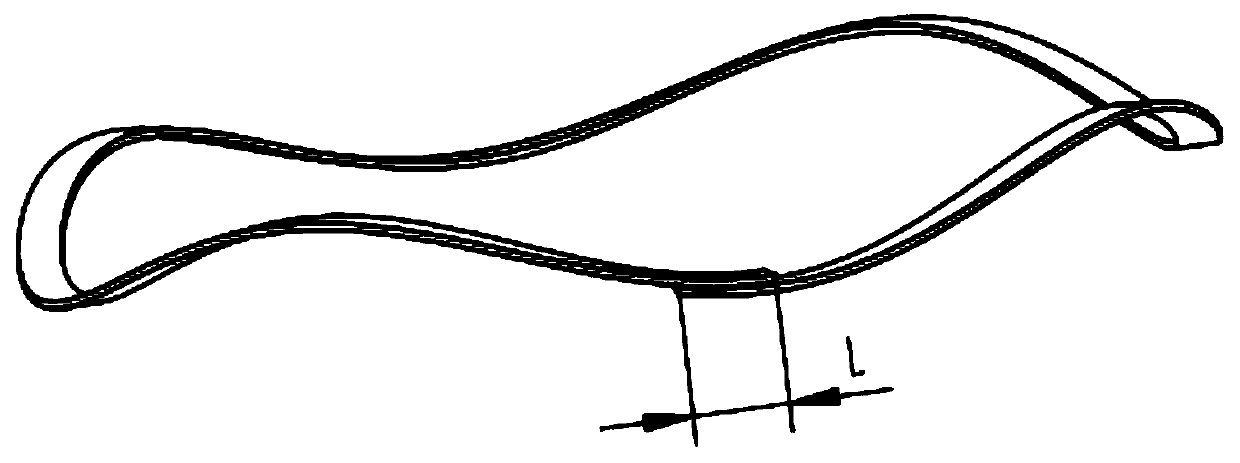

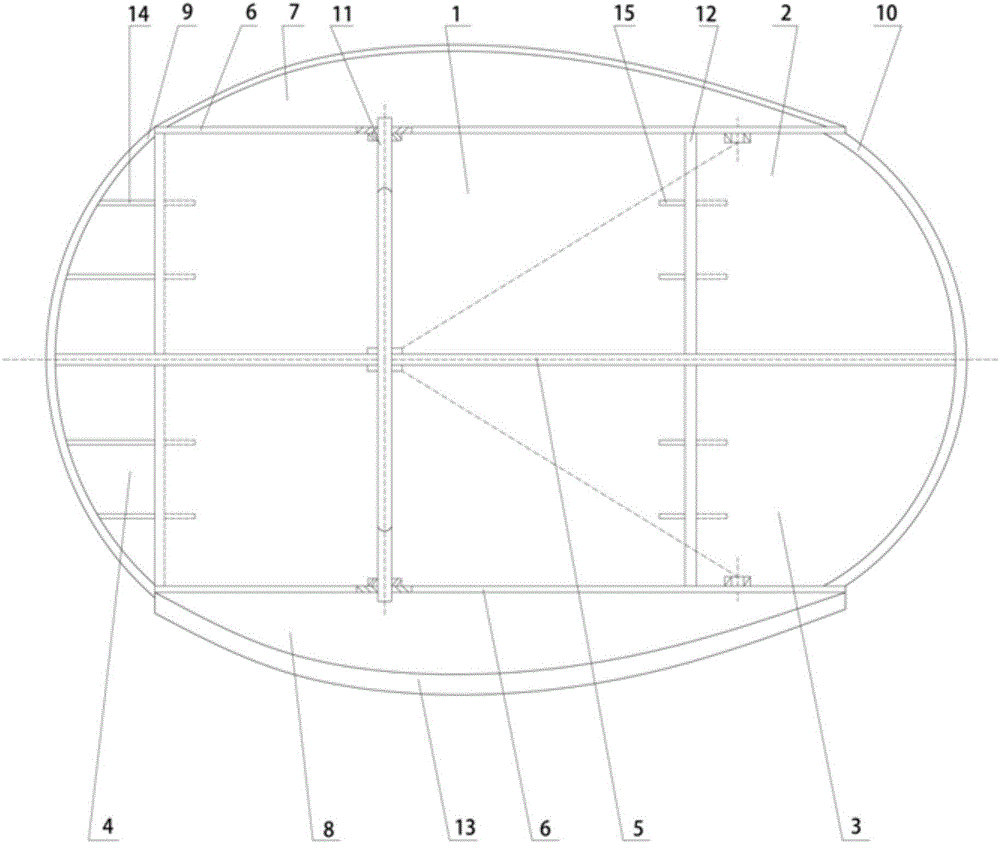

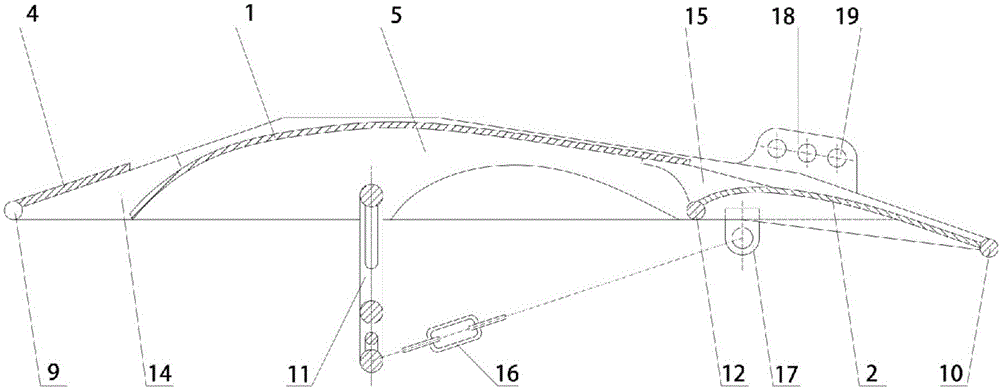

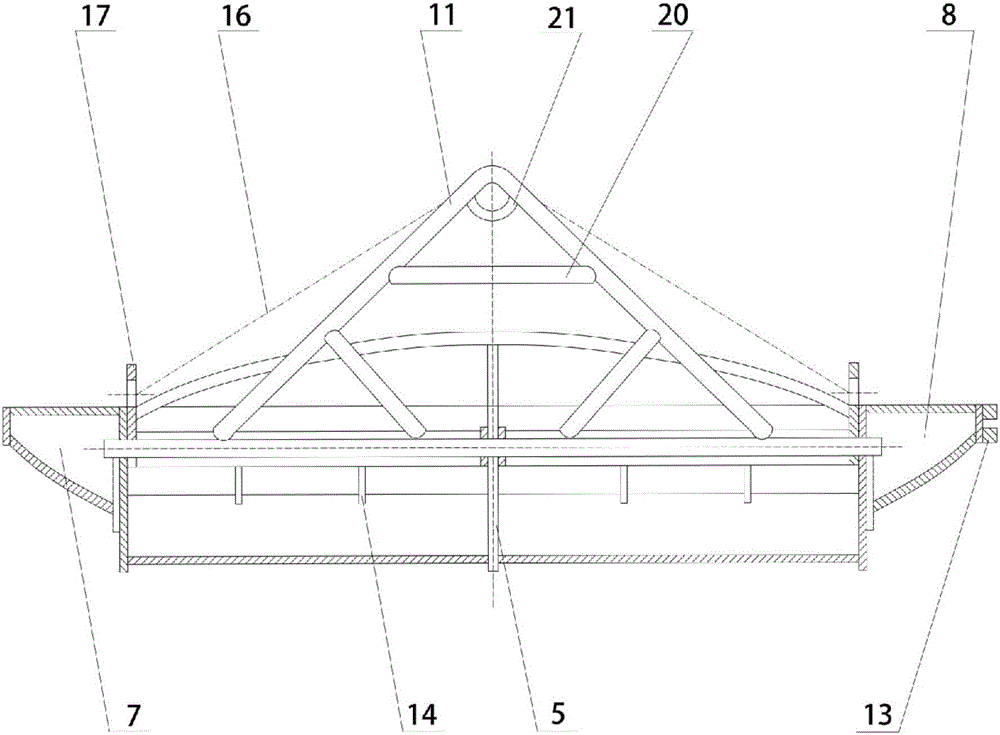

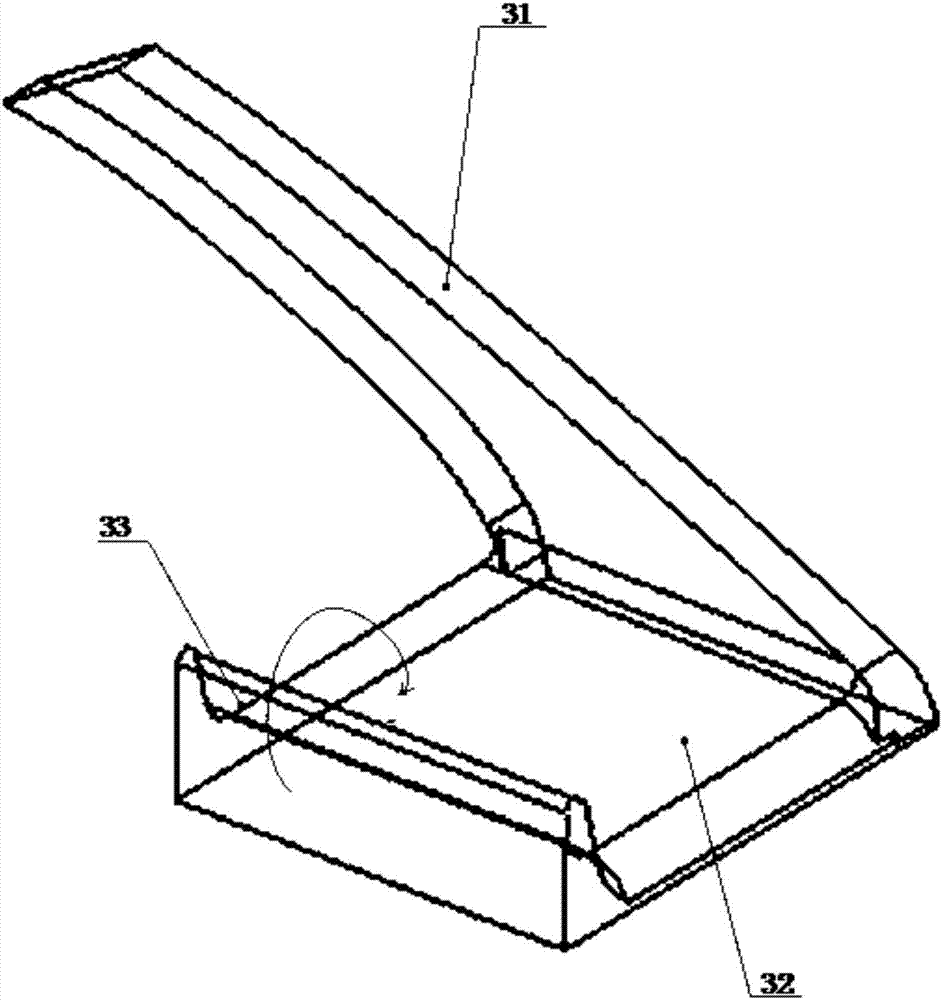

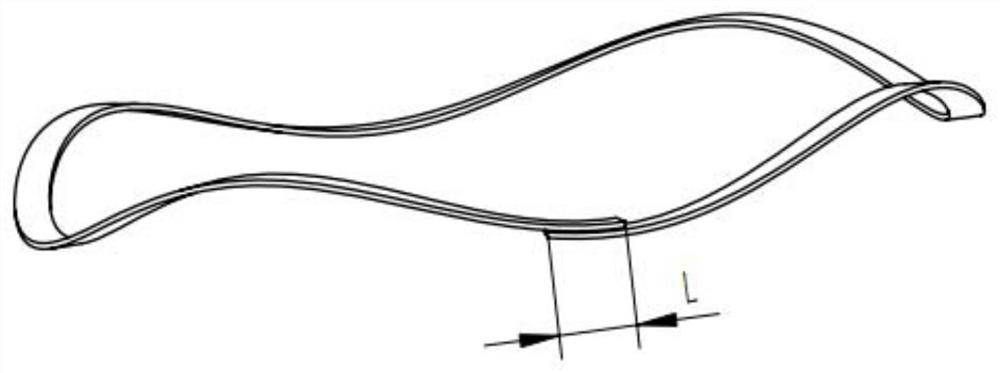

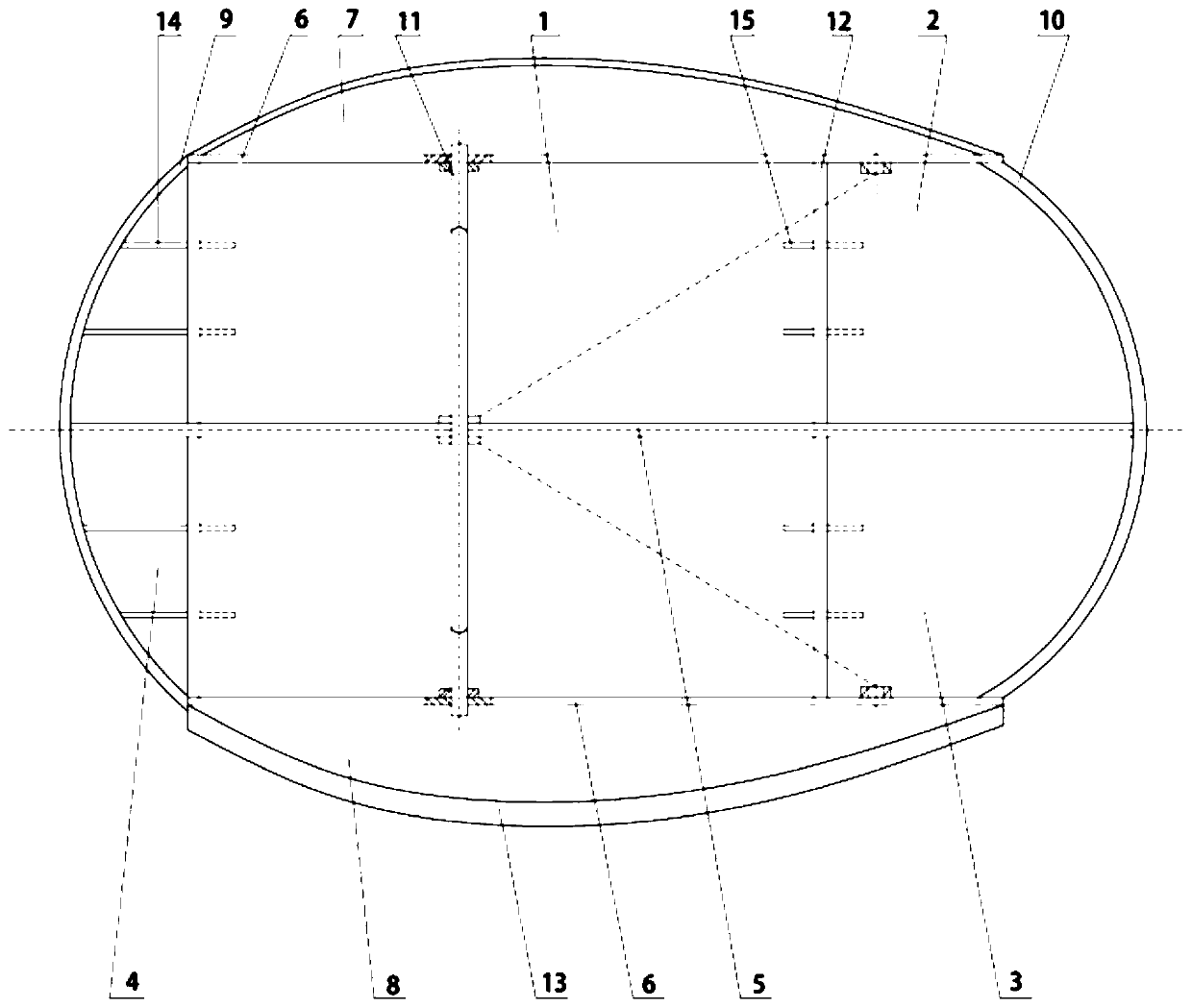

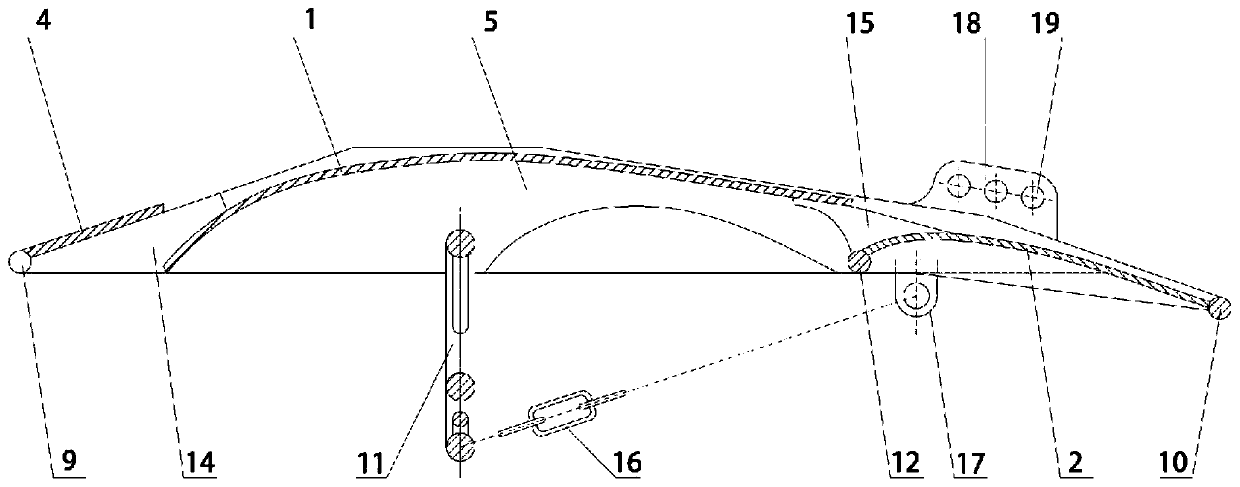

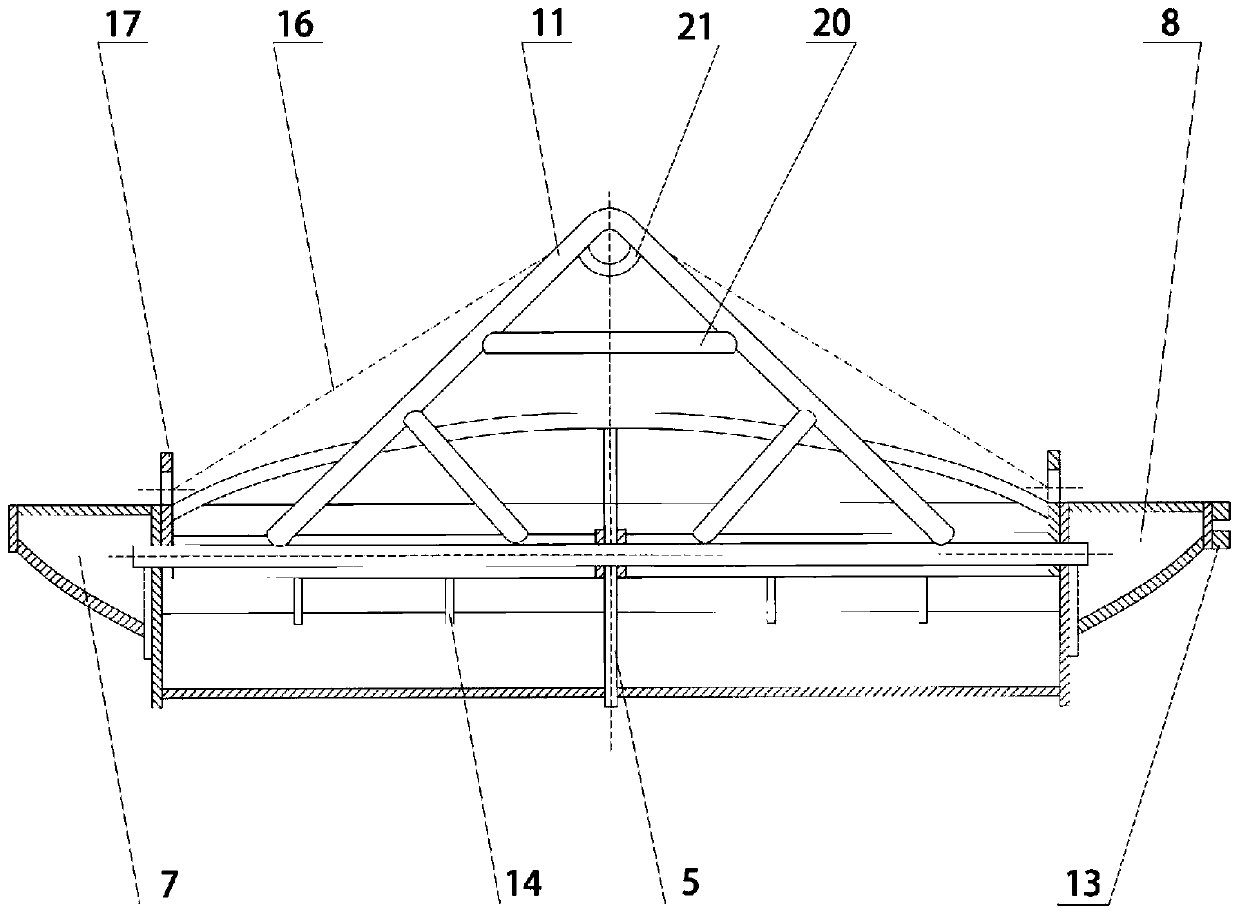

Fishing device and otter board assembly thereof

The invention discloses an otter board assembly. The otter board assembly comprises a triangular support and a main rib plate, wherein the triangular support is transversely arranged and capable of rotating along a fixed shaft of a bottom edge, and the main rib plate is longitudinally arranged and are linked with the triangular support. The triangular support is located in the middle of the main rib plate, and a leading edge wing, a main wing and a wing flap are sequentially arranged on the main rib plate in an imbricate mode from front to back. The sections of the leading edge wing, the main wing and the wing flap are in an arc shape, a flow guiding gap is formed between the leading edge wing and the main wing, and a flow guiding gap is formed between the main wing and the wing flap; the two sides of the main rib plate are symmetrically provided with side rib plates, and each side rib plate is provided with an upper side wing, trawl iron and a guide rail, wherein the trawl iron and the guide rails are matched with a fishing net. The front end of the leading edge wing is provided with a front coil side, and the rear end of the wing flap is provided with a rear coil side. The resistance of the otter board assembly is low, the stability of the otter board assembly is high, and the performance of a fishing device can be improved. The invention further discloses a fishing device with the otter board assembly.

Owner:GUANGDONG OCEAN UNIVERSITY

Mechanical seal end face structure of variable-depth spiral T-shaped groove

ActiveCN110410504AEnhance the dynamic pressure effectImprove work performanceEngine sealsEngine lubricationSolid particleEngineering

The invention discloses a mechanical seal end face structure of a variable-depth spiral T-shaped groove. The structure comprises a mechanical seal movable ring and a mechanical seal static ring, wherein one side of the end face of the movable ring or the static ring is provide with a high-pressure side, namely an upstream side, and the other side of the end face of the movable ring or the static ring is provide with a low-pressure side, namely a downstream side; variable-depth spiral T-shaped grooves are formed in the end face of the movable ring, seal weirs are arranged among the variable-depth spiral T-shaped grooves, the variable-depth spiral T-shaped grooves communicate with a circumferential annular groove, and a seal dam is arranged between the circumferential annular groove and thedownstream side; and the number of the variable-depth spiral T-shaped grooves is an even number in 8 - 24, and the radial width of the whole variable-depth spiral T-shaped grooves accounts for less than one third of the radial width of the whole seal end face. According to the mechanical seal end face structure of the variable-depth spiral T-shaped groove, the fluid dynamic pressure effect is effectively improved, the working efficiency of mechanical seal is improved, and the sealing performance of the mechanical seal in a static state is ensured; and solid particles and the like can be timely discharged out of the seal end face, so that the friction between end surfaces is reduced, the temperature distribution is improved, and the problems of deformation and even mechanical seal end surface cracking caused by uneven heating of a seal ring are avoided.

Owner:BEIHANG UNIV

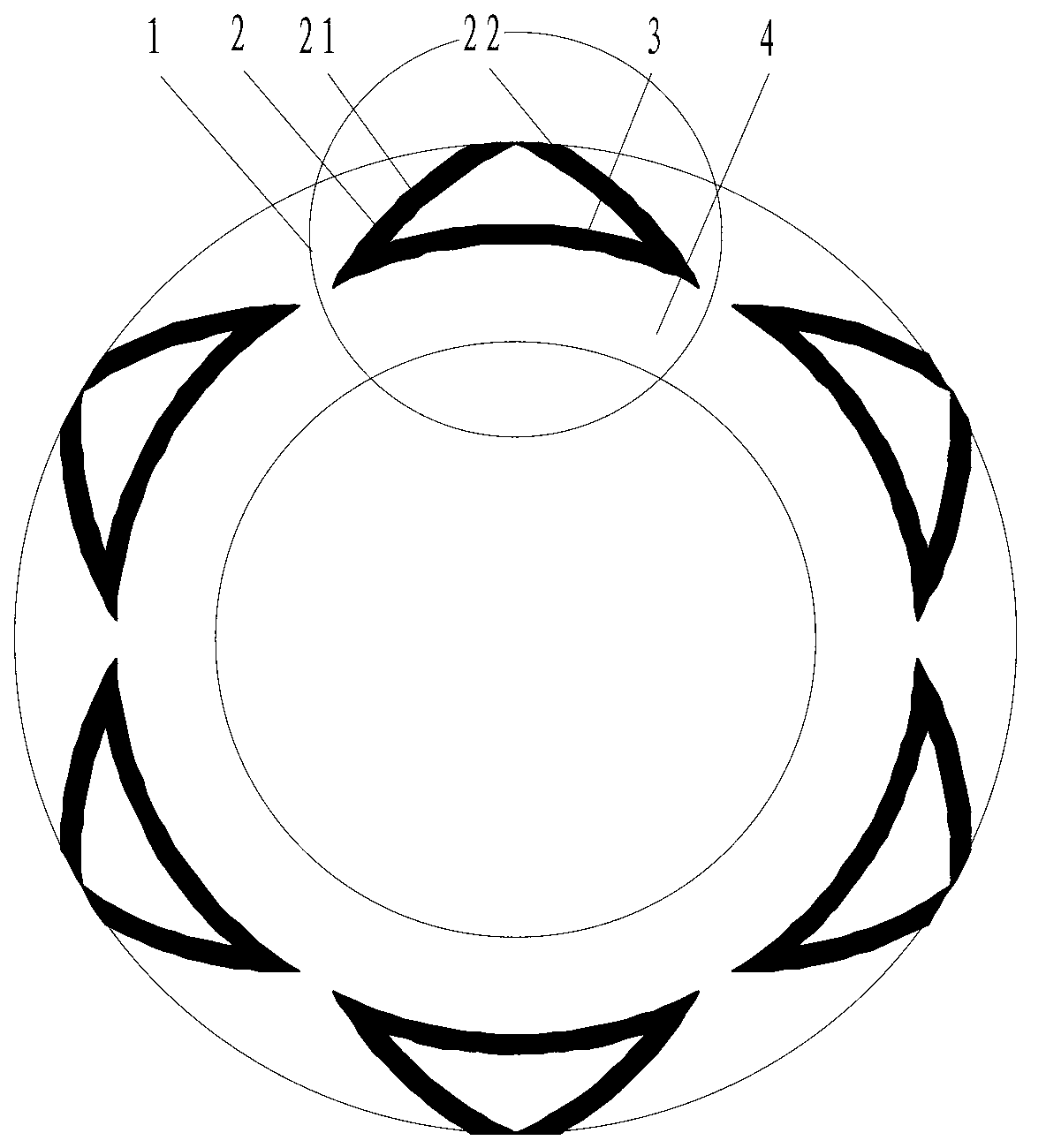

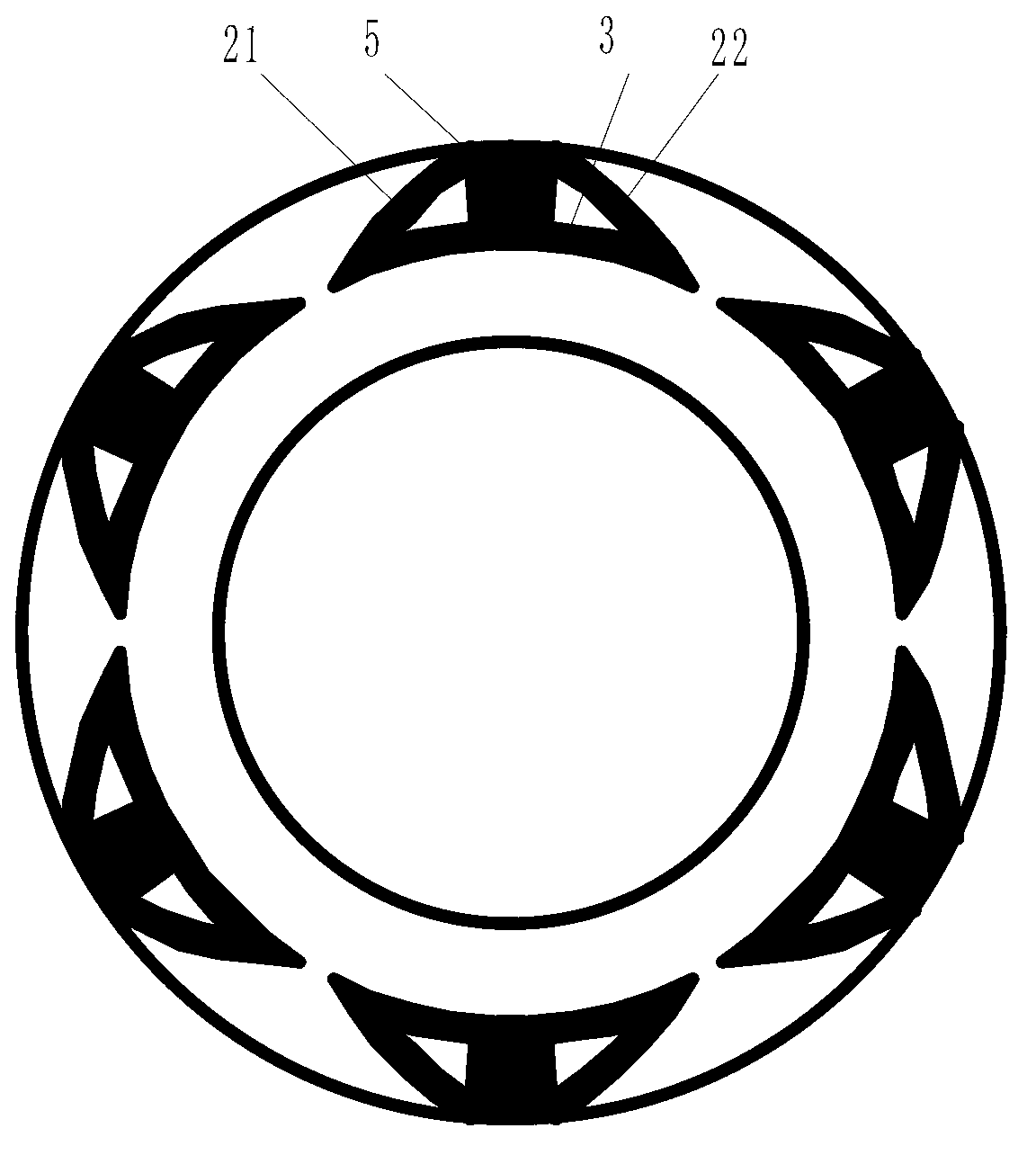

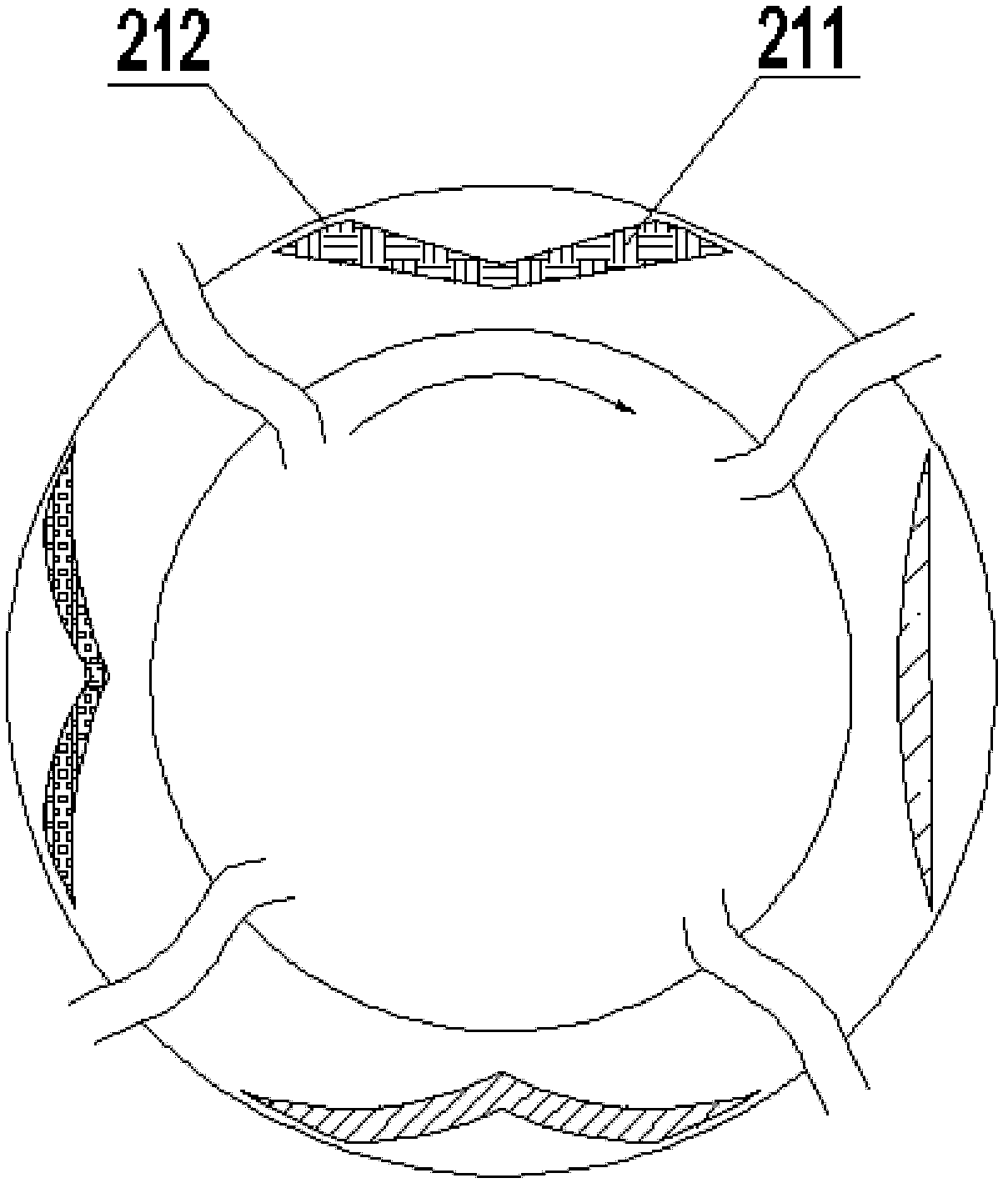

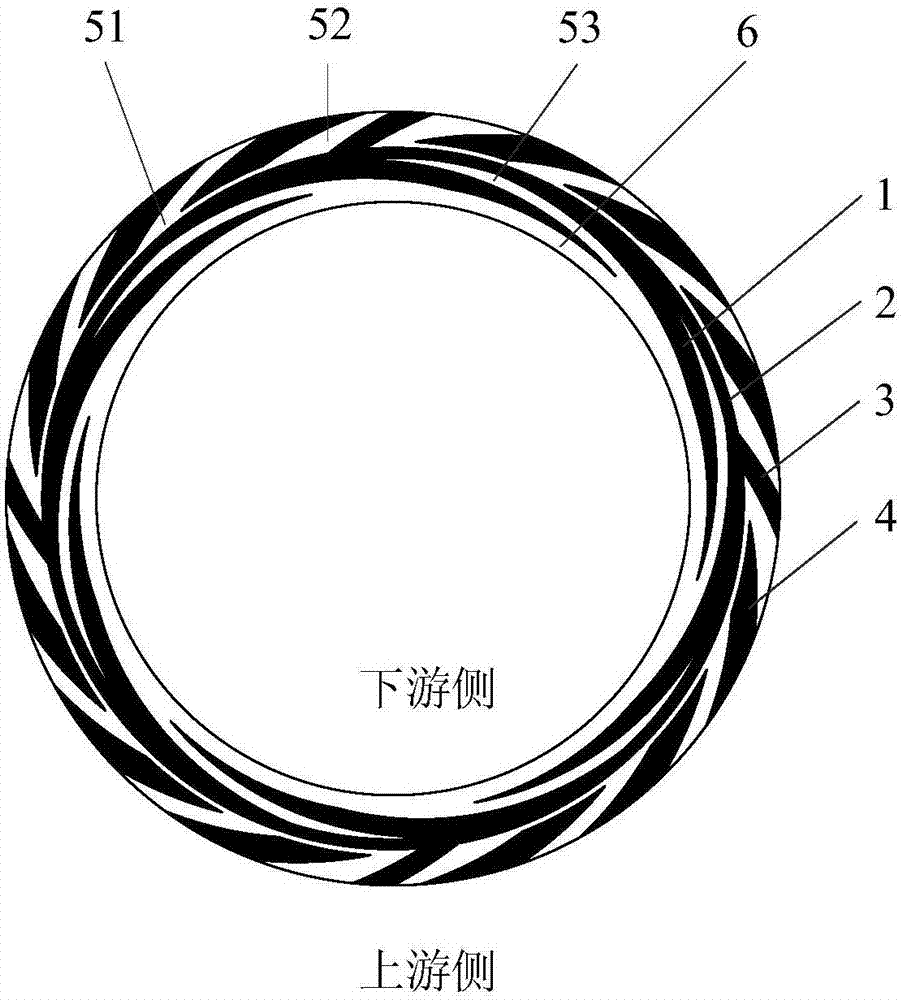

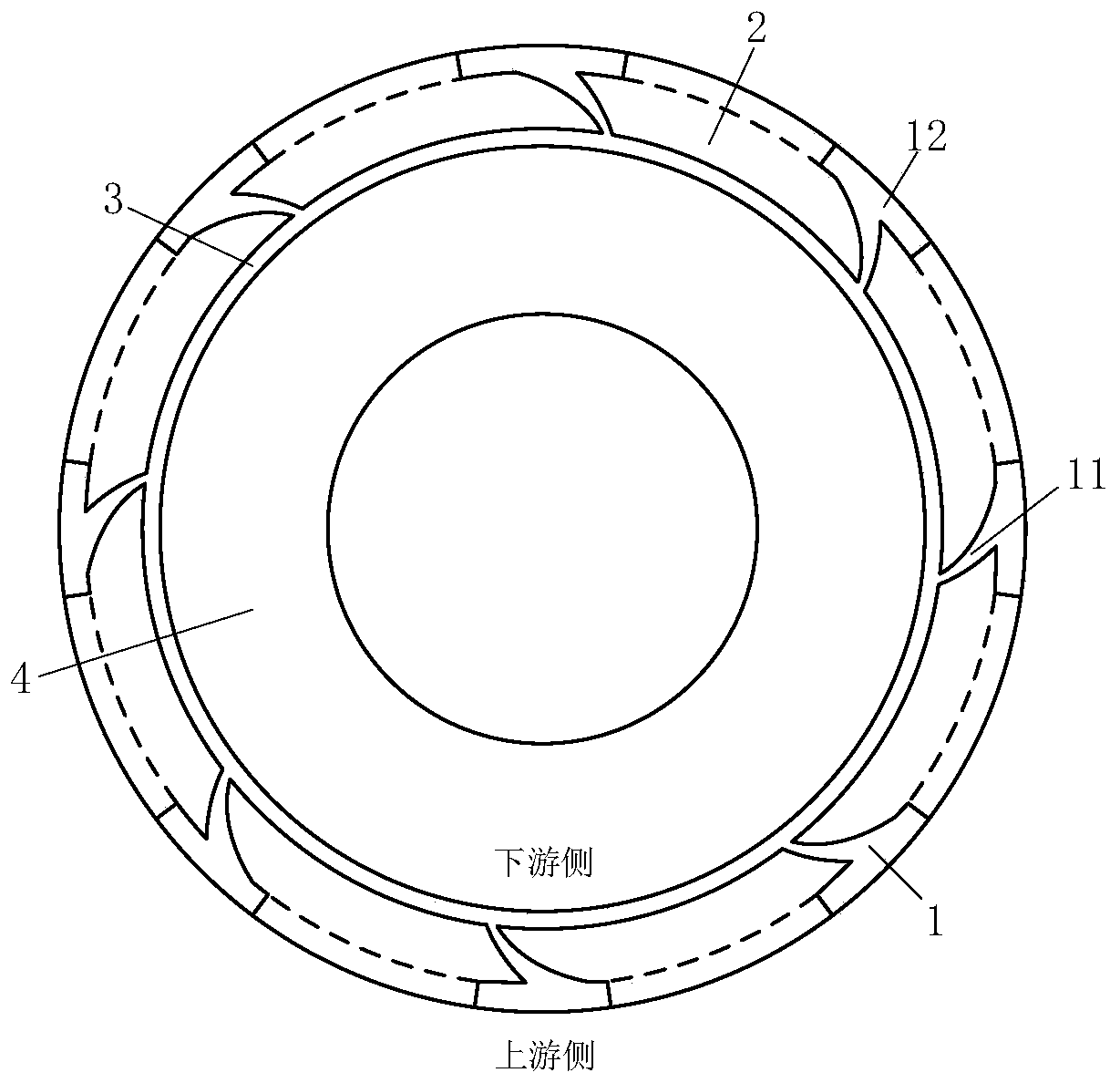

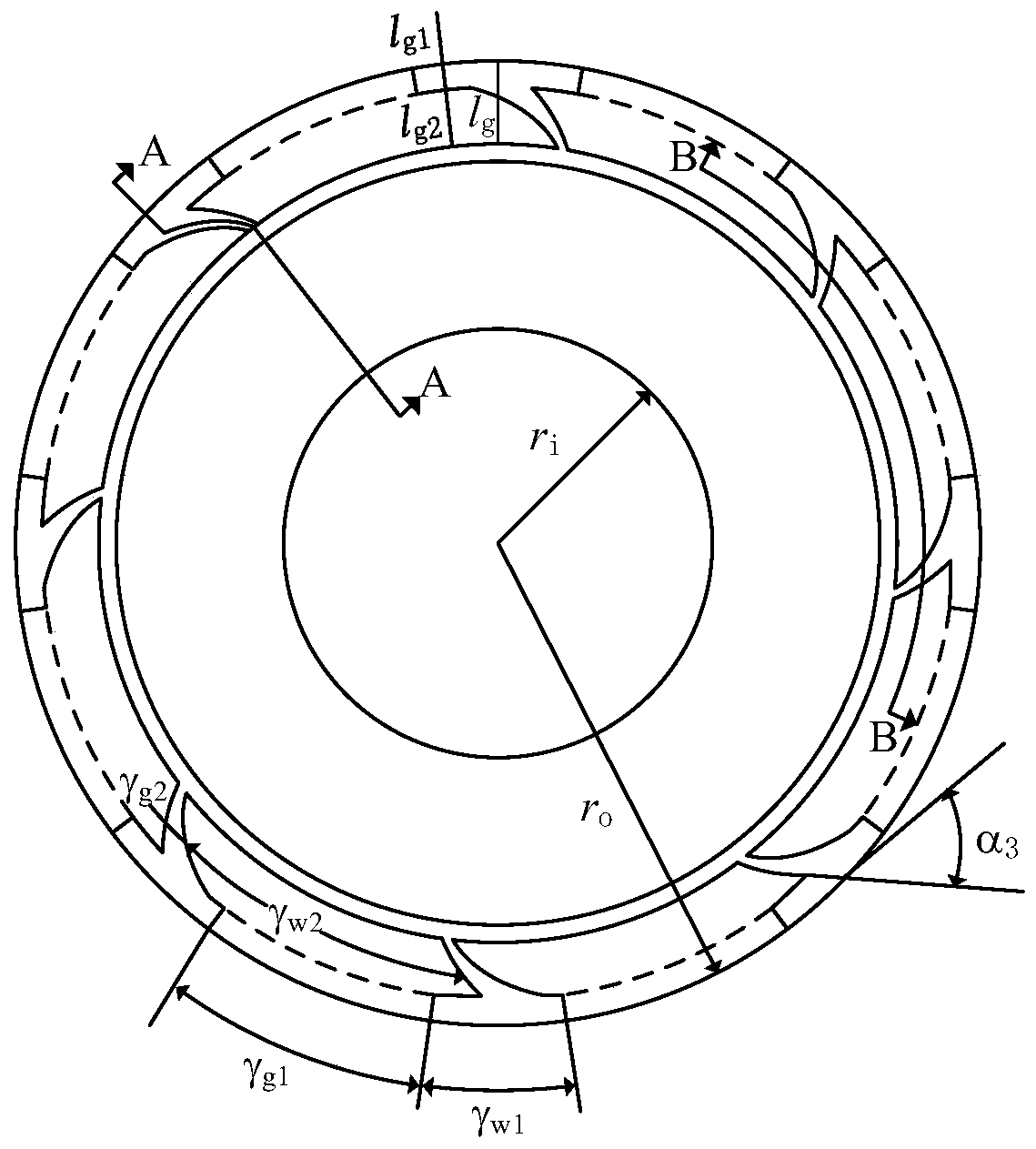

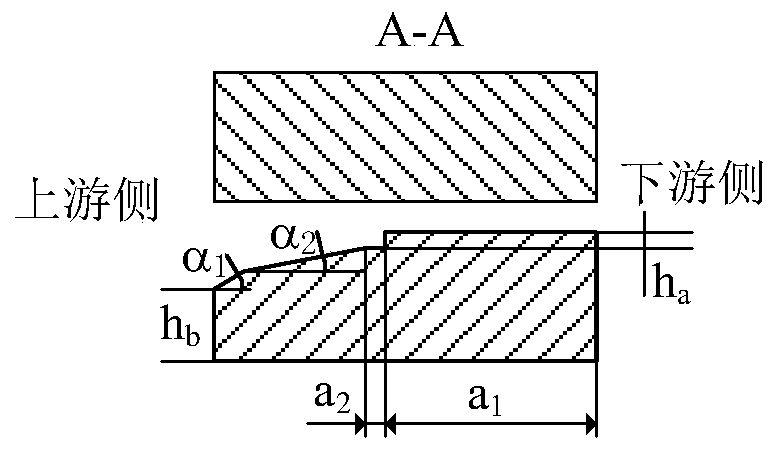

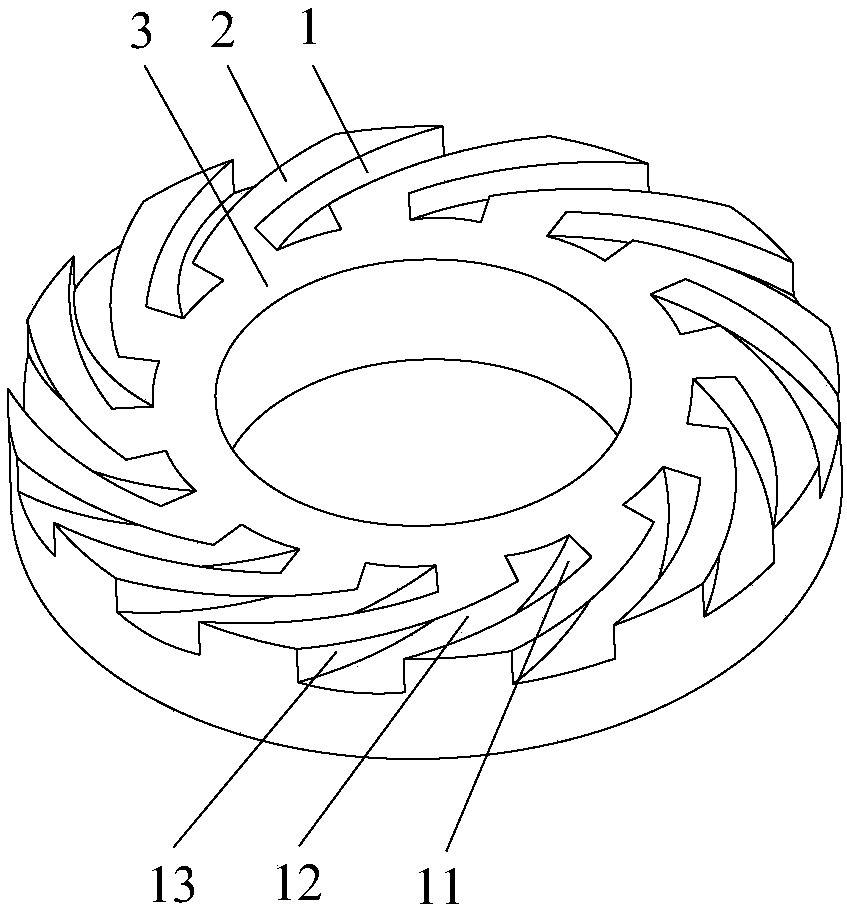

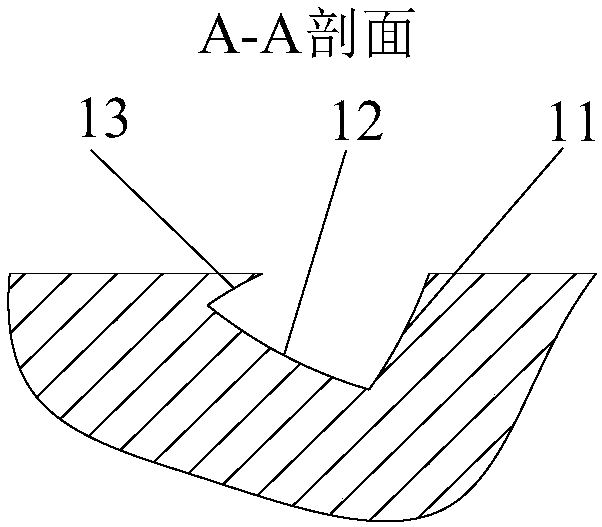

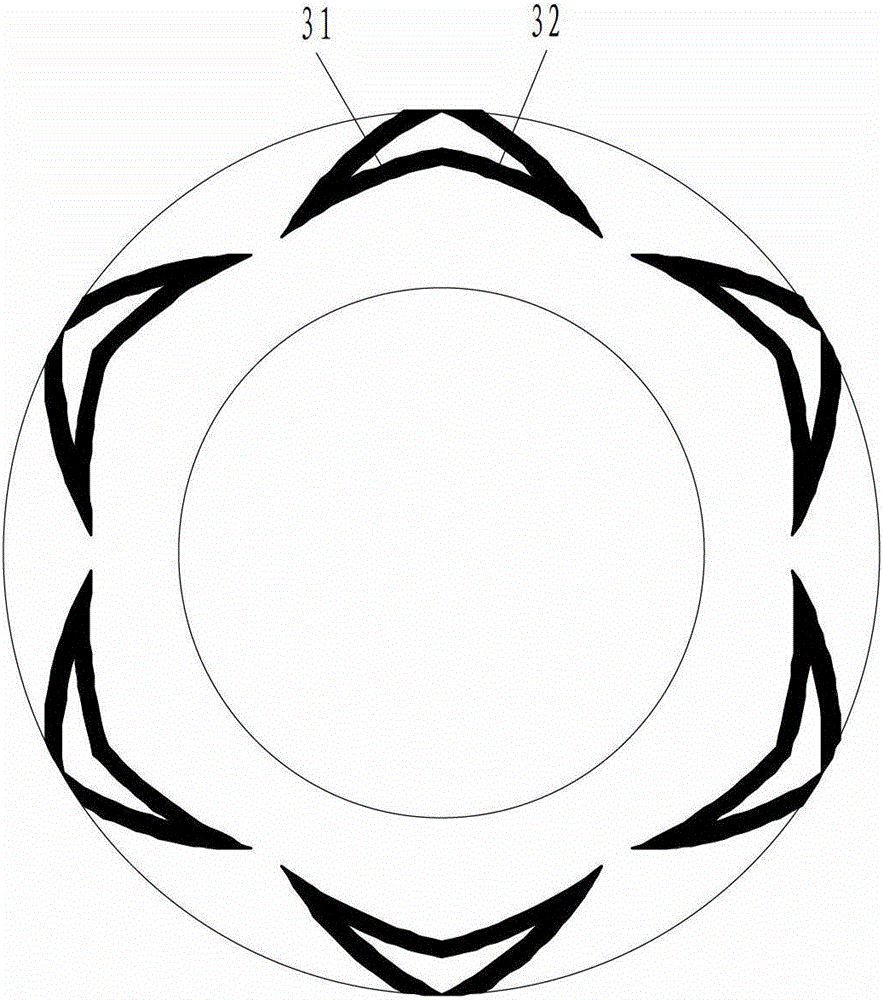

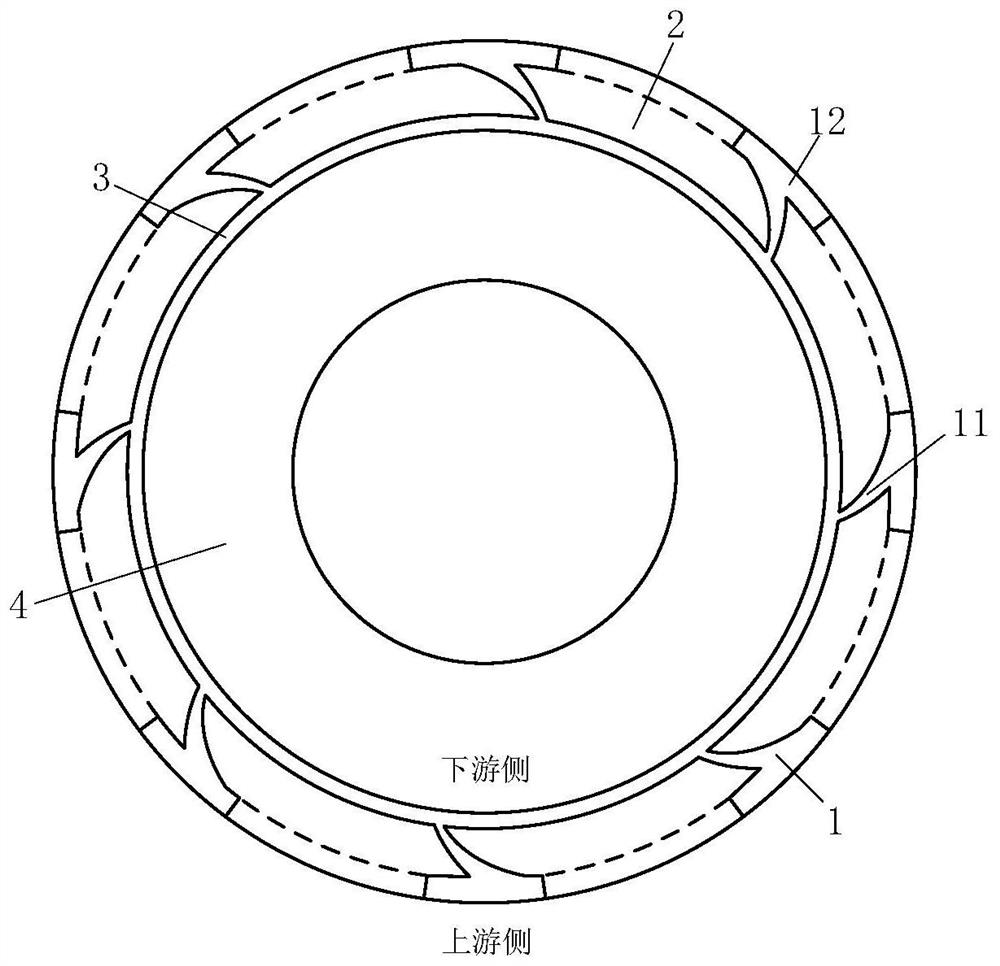

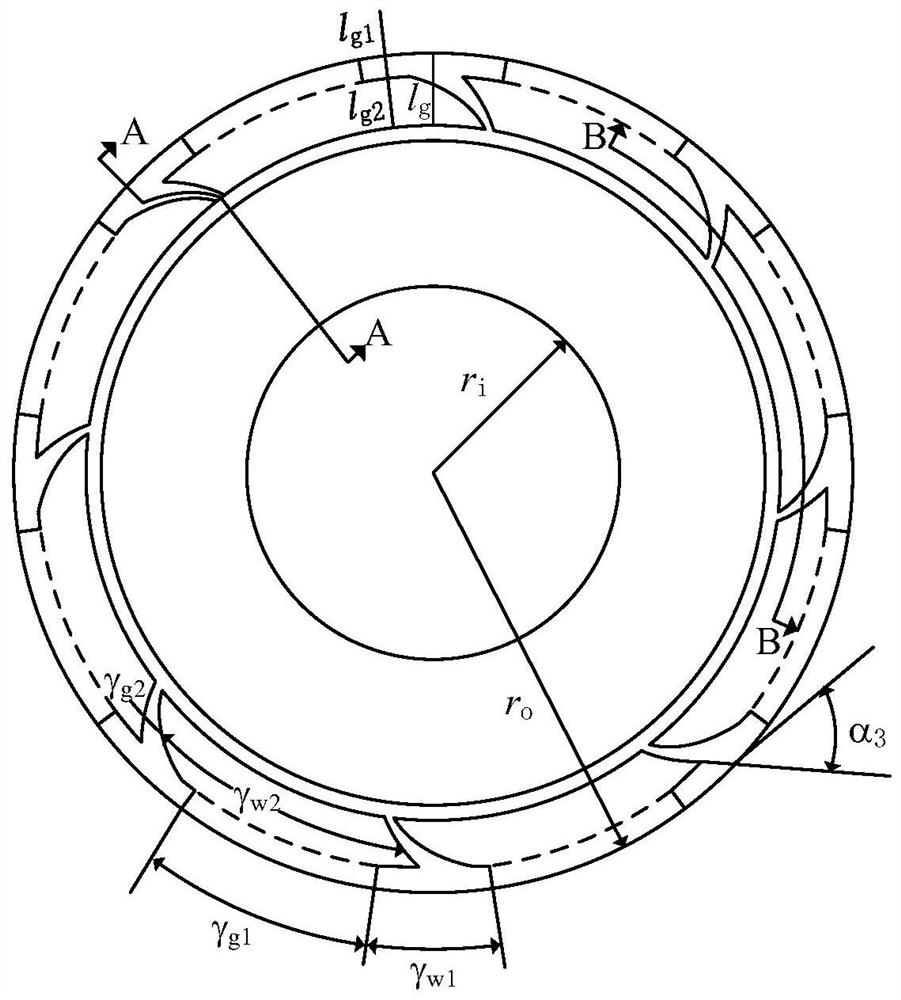

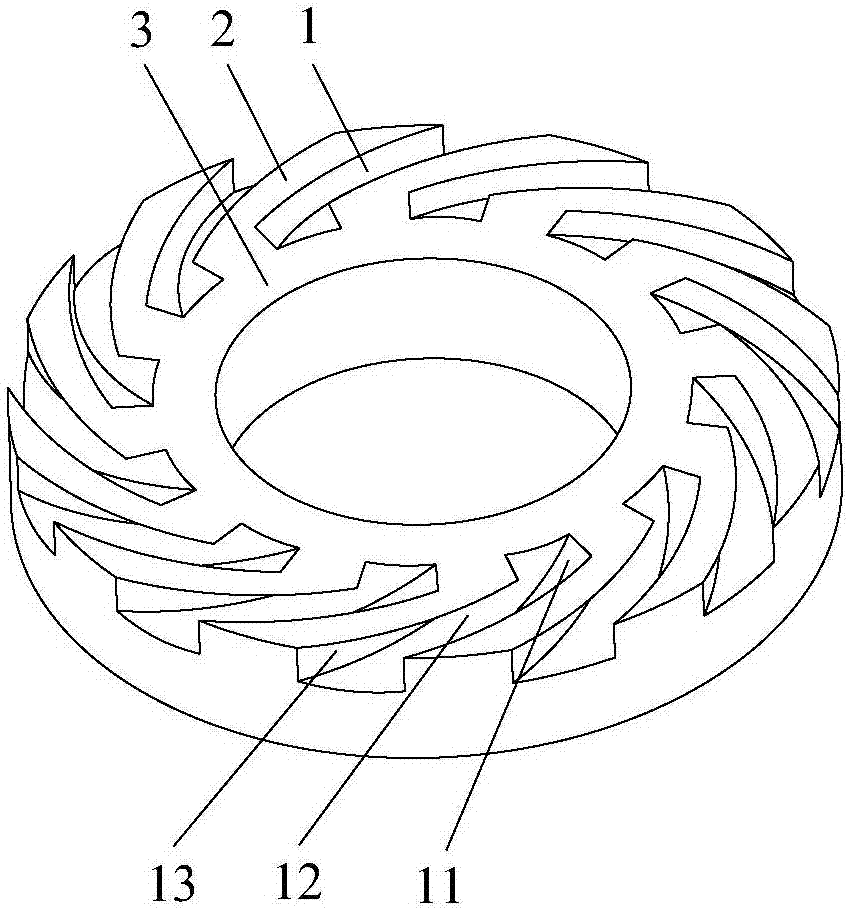

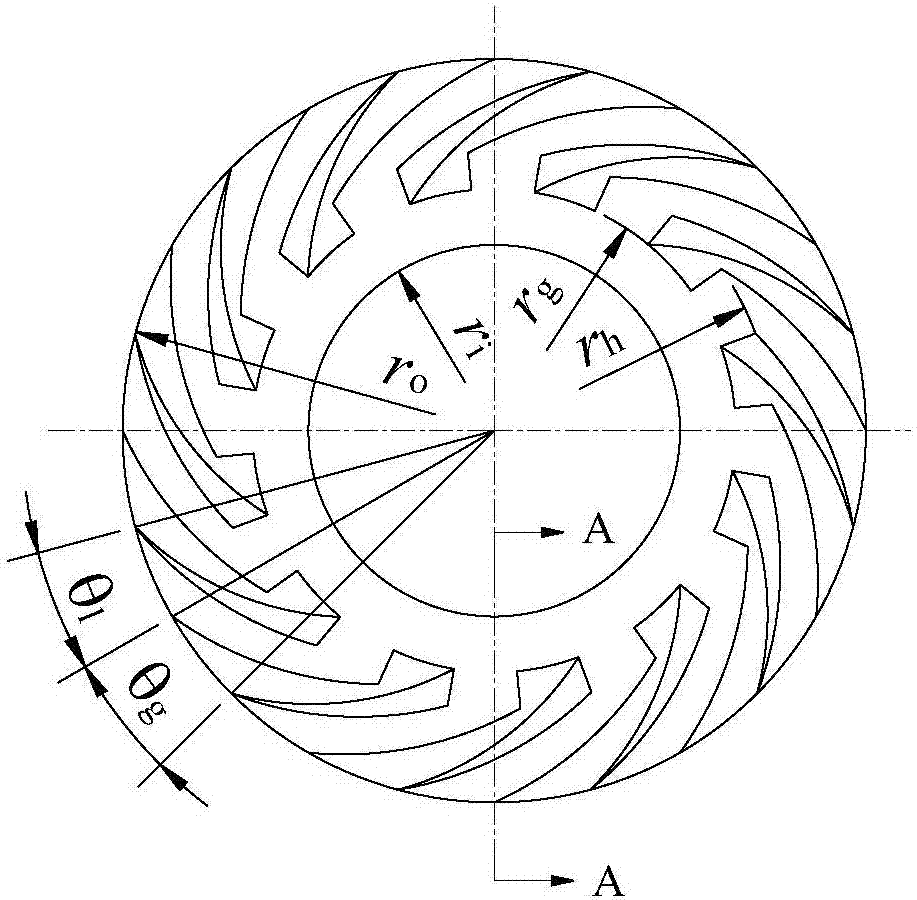

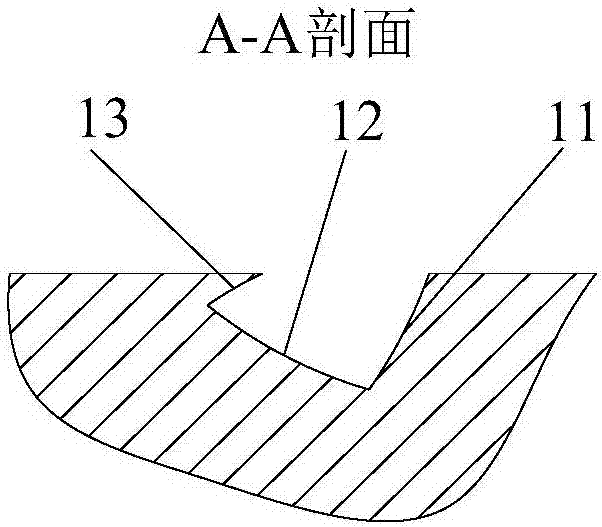

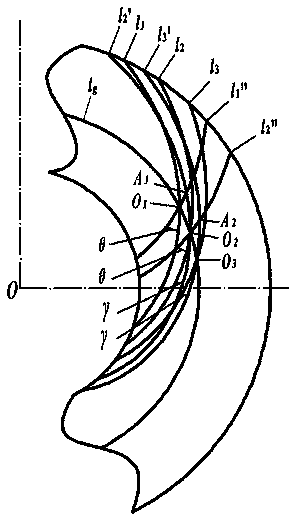

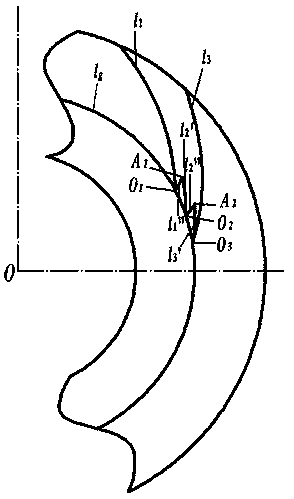

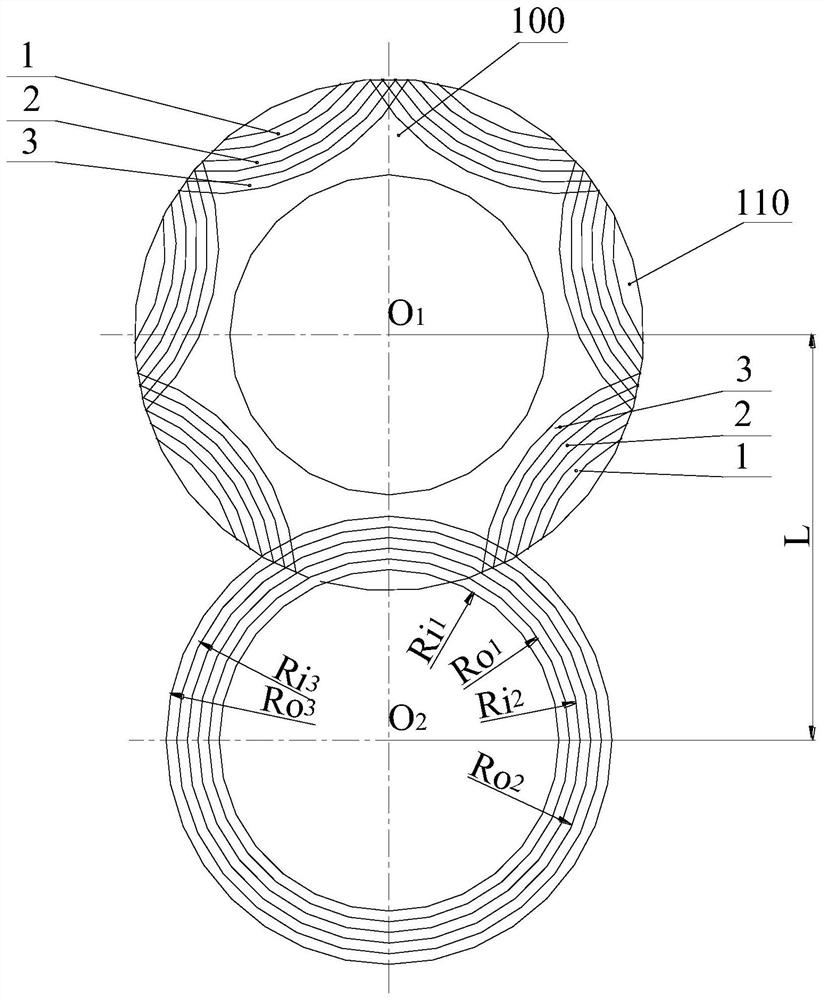

Ternary twisted groove end face mechanical seal structure

A ternary distortion-type groove end surface mechanical sealing structure comprises a dynamic ring and a static ring which are used for mechanical sealing, ternary distortion-type grooves 1 evenly distributed in the circumferential direction are machined in the sealing end surface of at least one sealing ring of the dynamic ring and the static ring, and each ternary distortion-type groove is formed by two side walls and a three-dimensional distortion variable-depth groove bottom surface; the side walls of each ternary distortion-type groove comprise the windward side ternary distortion wall surface 11 and the leeward side ternary distortion wall surface 13, and the three-dimensional distortion variable-depth groove bottom surfaces 12 gradually shallow in a distortion shape from the outer circumferential side walls of the sealing rings to the centers of the sealing rings and intersect with the sealing end surfaces on the outer sides of sealing dams 3; the intersection lines of the side walls of the ternary distortion-type grooves 1 and the outer circumferential side walls of the sealing rings are perpendicular to the sealing end surfaces; the intersection lines of the side walls of the first ternary distortion-type grooves and the sealing end surfaces are each divided into two sections, the intersection lines on the medium inlet sides are helical lines, and the intersection lines on the medium leakage sides are radial straight lines.

Owner:ZHEJIANG UNIV OF TECH

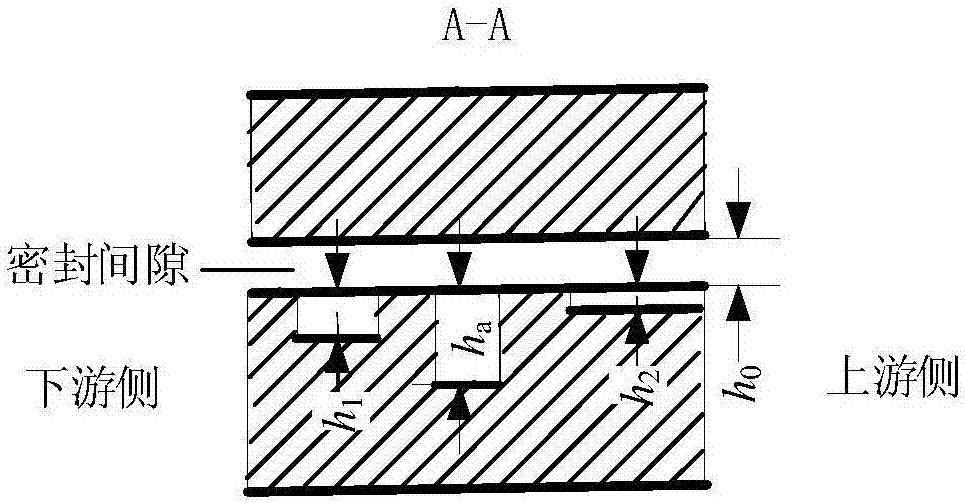

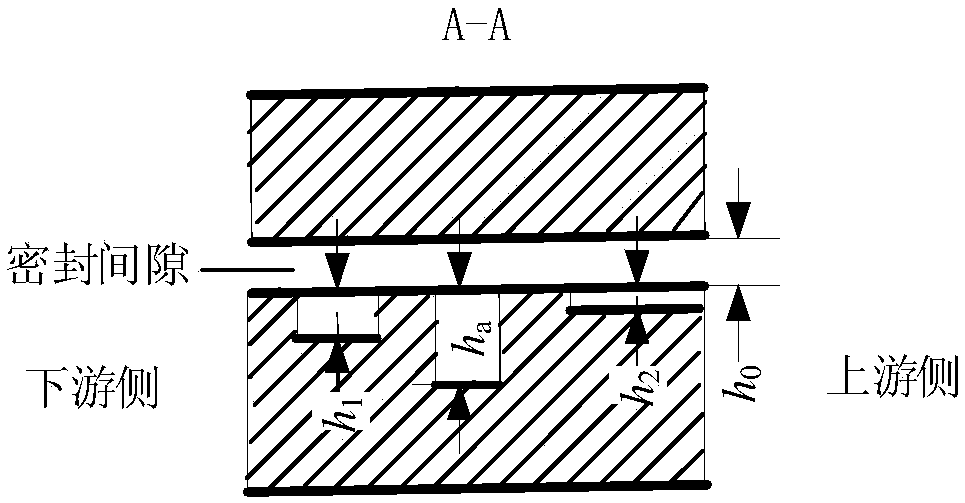

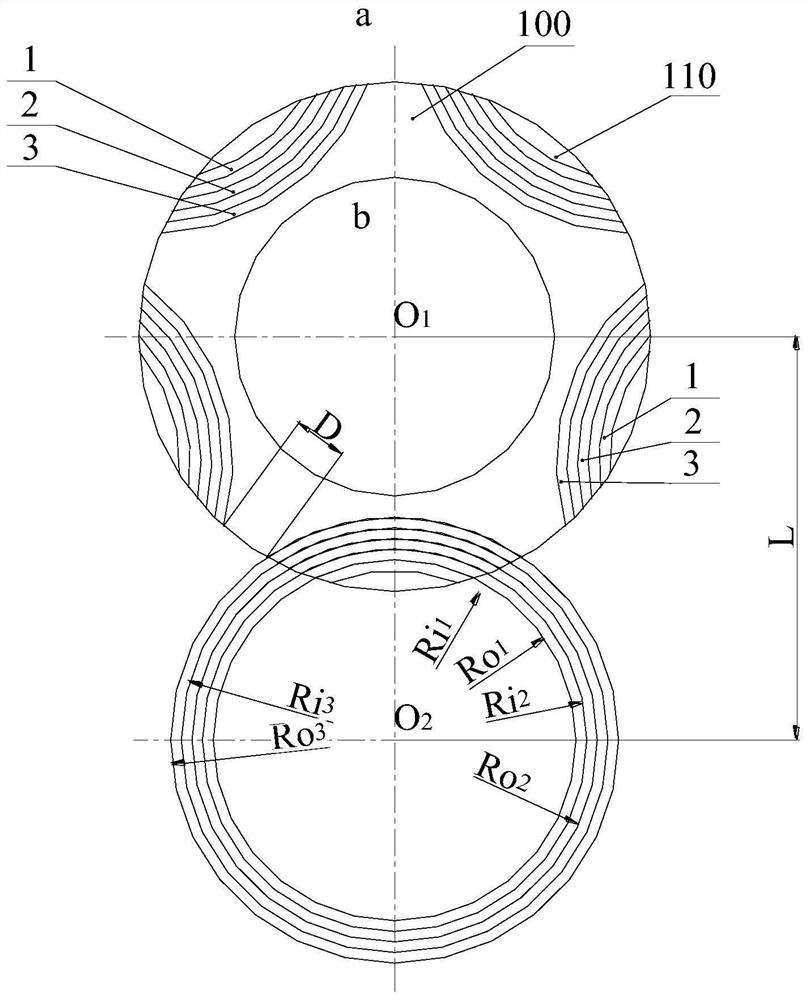

Low-leakage fingertip seal structure for increasing lift force of sealing shoe

ActiveCN107366557AIncrease buoyancy efficiencyEnhanced hydrodynamic effectLeakage preventionMachines/enginesClassical mechanicsEngineering

The invention discloses a low-leakage fingertip seal structure for increasing lift force of a sealing shoe. The low-leakage fingertip seal structure comprises a front baffle, a high-pressure sealing piece, a low-pressure sealing piece and a rear baffle which are sequentially connected through rivets from the high-pressure side to the low-pressure side. The low-pressure sealing piece comprises a fingertip beam, the sealing shoe and a shoe tip small wing. The sealing shoe is vertically connected to the bottom end of the fingertip beam and extends towards the low pressure side, a sealing gap is formed between the lower portion of the high-pressure sealing piece and the outer surface of a rotor, a sealing gap is formed between the bottom of the sealing shoe and the outer surface of the rotor, the shoe tip small wing is arranged on the side, axially close to the low-pressure area, of the sealing shoe, and the shoe tip small wing extends outwards in the radial direction of the rotor. According to the low-leakage fingertip seal structure for increasing lift force of the sealing shoe, the fluid dynamic pressure effect of the non-contact type fingertip seal is enhanced through the shoe tip small wing, the lift force of the sealing shoe is improved, the fingertip beam bounces along with a rotor and has better following performance, abrasion to the sealing shoe due to rotor bounce is reduced, the service life of the fingertip seal is prolonged, and the sealing character of the fingertip seal is improved.

Owner:SHENYANG AEROSPACE UNIVERSITY

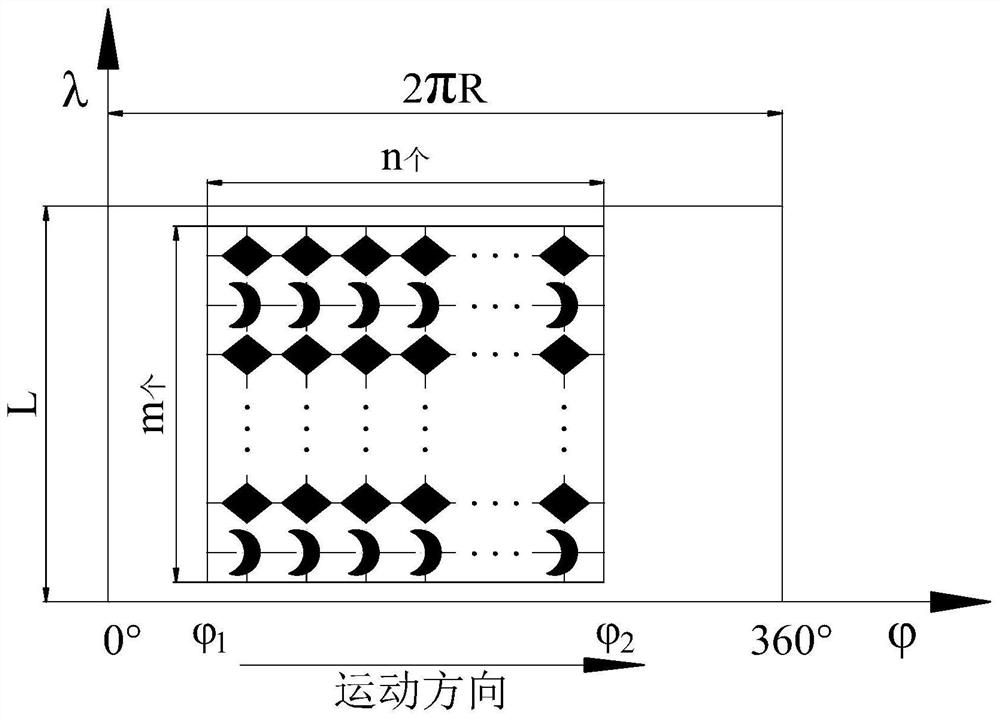

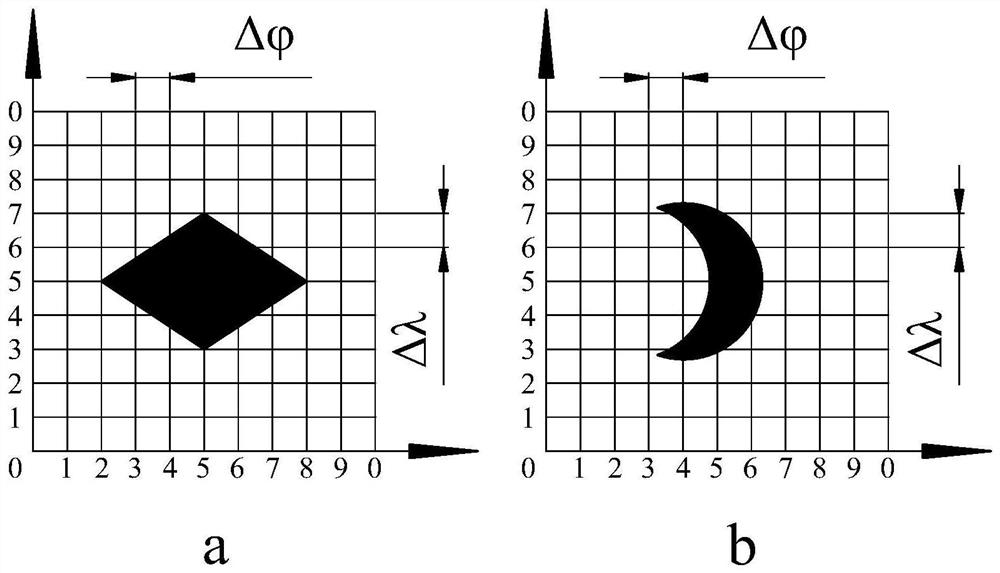

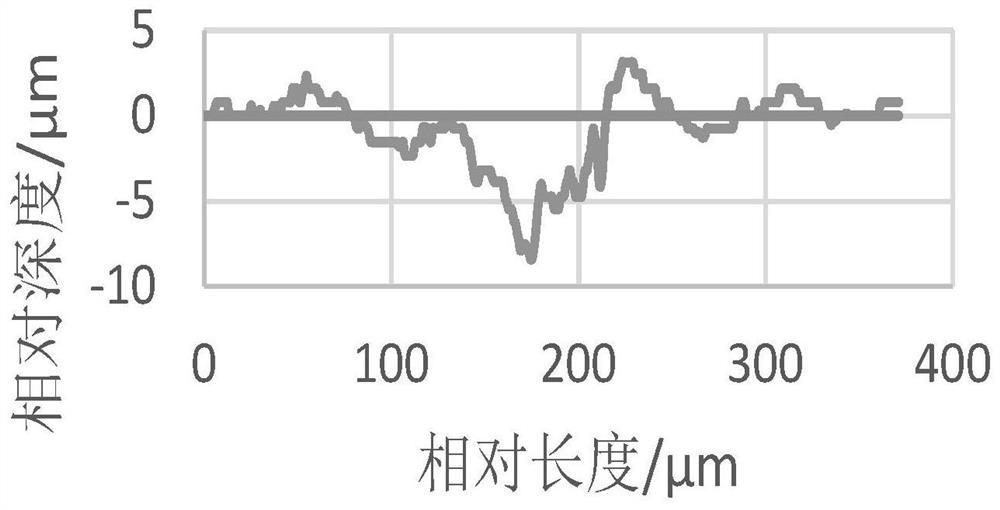

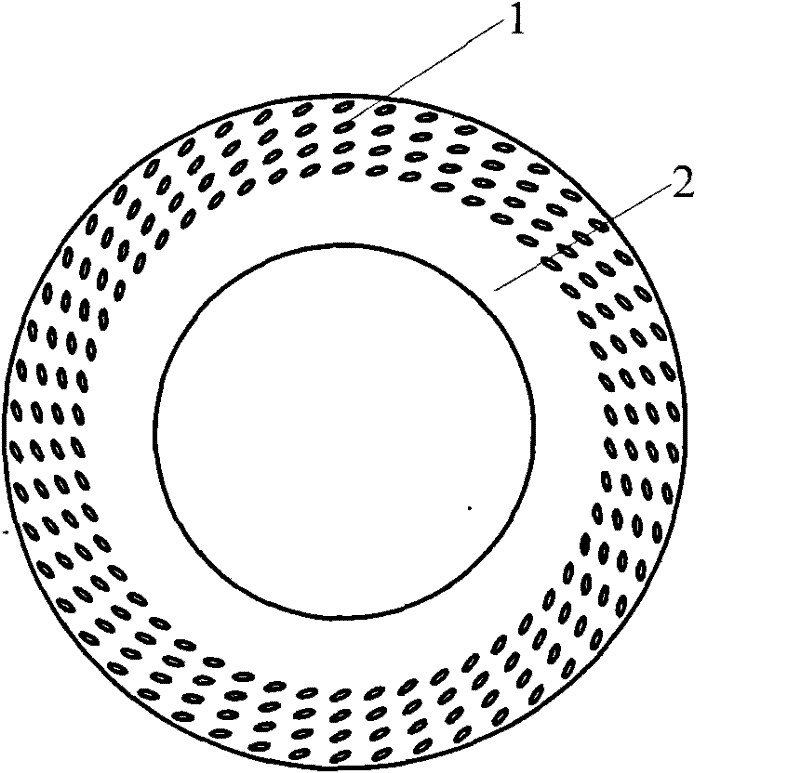

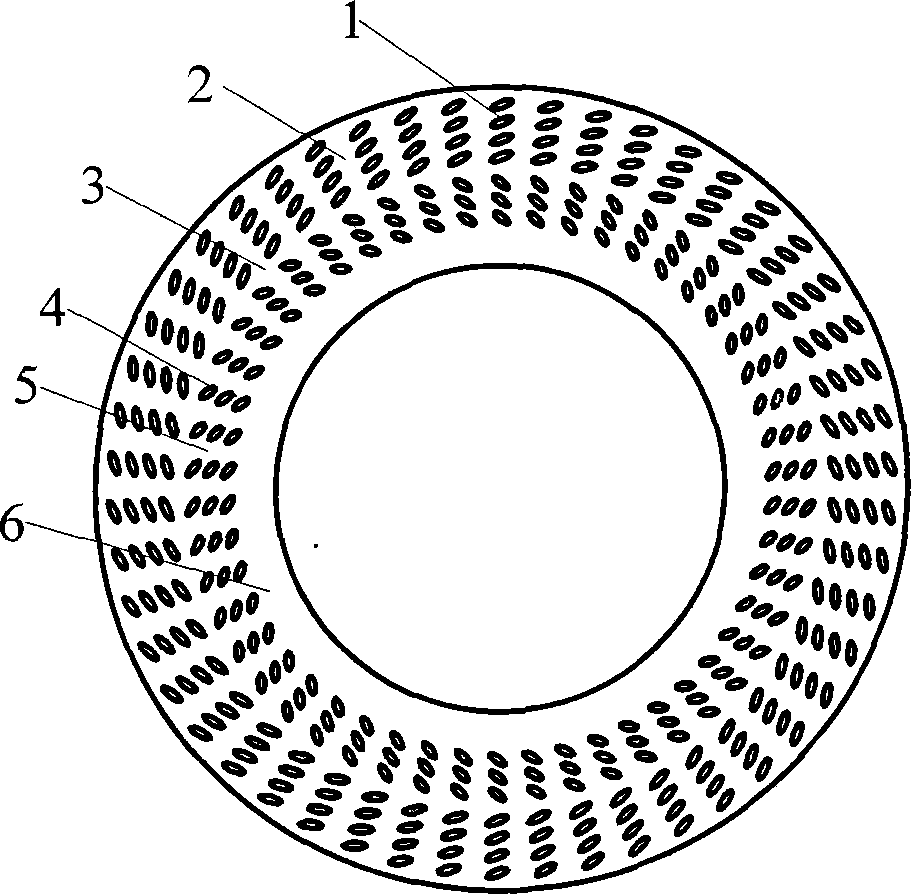

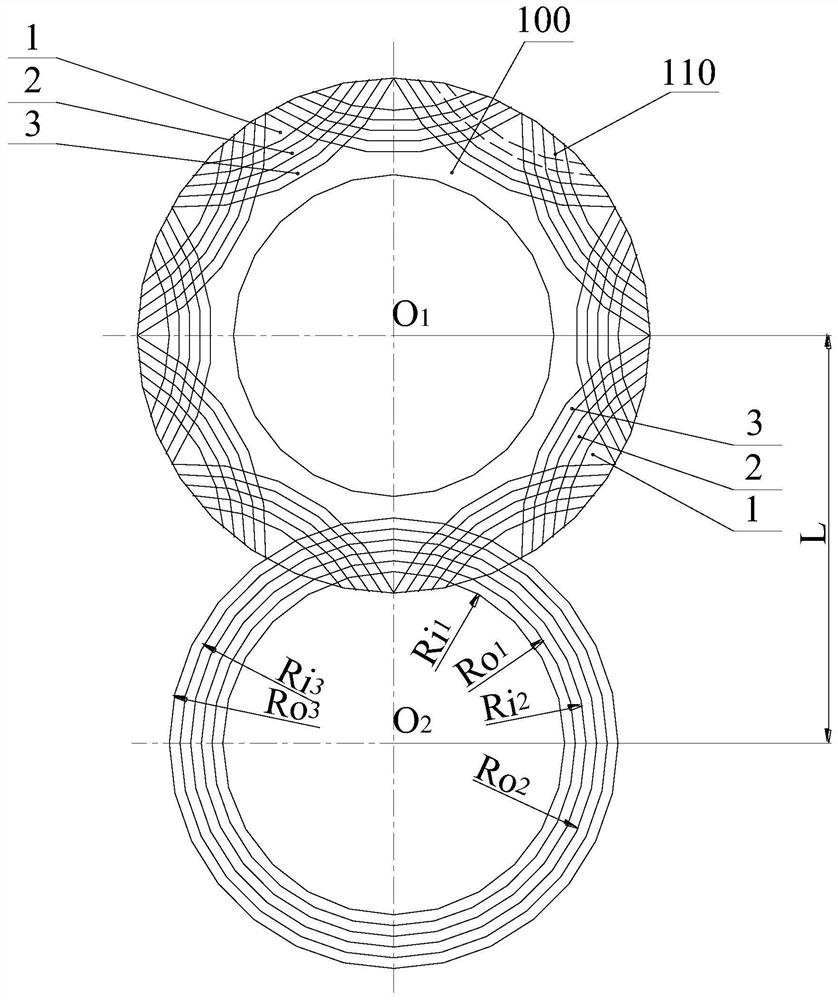

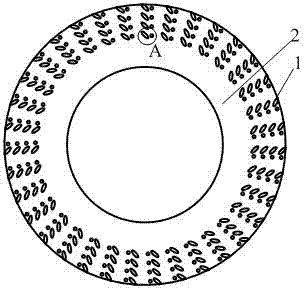

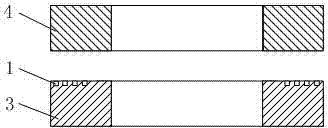

Composite textured surface for radial sliding bearing

ActiveCN113700748AImproved tribological propertiesExtended service lifeBearing componentsRolling resistance optimizationBearing surfaceFriction force

The invention discloses a composite textured surface for a radial sliding bearing. The composite textured surface is arranged on the inner surface of a bearing bush. According to the composite textured surface, composite textures are distributed at an inlet of the radial sliding bearing and are composed of at least two textures in different shapes, the textures in different shapes are alternately arranged and are distributed in a rectangular matrix mode, the overall width of the composite textures accounts for one third of the length of the bearing, the area density of the textures is 5%-15%, the depth of the textures is 5-30 micrometers, and the areas of the textures in different shapes are equal. The composite textured surface has the advantages that the tribological performance of the radial sliding bearing is favorably improved, the fluid dynamic pressure effect which is more remarkable compared with that of a smooth bearing surface and a single-shape bearing surface is generated, lower friction force and higher bearing capacity are obtained, the oil film thickness of a friction matching pair is effectively increased, the possibility of oil film (direct metal contact) fracture is reduced, and the service life of the radial sliding bearing is prolonged.

Owner:SHANDONG UNIV OF SCI & TECH

Wear-resistant piston ring with hard-soft composite coating and textured surface and preparation method

InactiveCN103089479BImprove wear resistanceImprove wear and tearPiston ringsSolid state diffusion coatingSilver overlayWear resistant

The invention discloses a wear-resisting piston ring with a hard-soft composite coating and the textured surface and a wear-resisting piston ring manufacture method. A hard coating like a chromium coating or a carburization / nitriding layer or a nickel base layer is deposited on an outer circle face of the piston ring, the hard coating is textured by pulse laser to achieve a regular and even micropore array, and a soft coating like a silver coating or a tin coating or a magnetic control sputtering MoS2 coating is prepared on the textured surface. The hard coating can serve as a hard support layer to improve wear resistance of the outer circle face of the piston ring. The surface micropore array can enhance fluid hydrodynamic effects of lubrication oil, can serve as a storage tank for lubrication oil / agent and can collect abrasive dust particles. The soft coating can serve as lubrication phase to achieve self lubrication and self repair of the friction surface.

Owner:NANJING UNIV OF SCI & TECH

Dovetail groove end face mechanical seal structure that can be rotated in both directions

ActiveCN103133697BImprove compression performanceImprove carrying capacityEngine sealsEngineeringHigh pressure

Owner:ZHEJIANG UNIV OF TECH

Tilting directional microporous end surface mechanical sealing structure

Owner:ZHEJIANG UNIV OF TECH

A mechanical seal end face structure with variable depth helical T-shaped groove

ActiveCN110410504BPromotes even distributionEvenly distributedEngine sealsEngine lubricationEngineeringSolid particle

The invention discloses a mechanical seal end face structure of a variable-depth spiral T-shaped groove, which includes a moving ring and a static ring of the mechanical seal. On the downstream side, a variable-depth spiral T-shaped groove is provided on the end surface of the moving ring, and a sealing weir is arranged between the variable-depth spiral T-shaped grooves. The number of variable-depth spiral T-shaped grooves is an even number between 8 and 24; the radial width of the entire variable-depth spiral T-shaped groove accounts for no more than one-third of the radial width of the entire sealing end face. The invention effectively improves the fluid dynamic pressure effect, improves the working efficiency of the mechanical seal; ensures the static sealing performance of the mechanical seal; solid particles can be discharged from the sealing end face in time, reduces the friction between the end faces, and improves the temperature distribution. The problem of deformation of the sealing ring or even cracking of the end face of the mechanical seal due to uneven heating is avoided.

Owner:BEIHANG UNIV

A constant elastic coating involute spiral groove long-life sealing device

ActiveCN110285218BReduce wearImprove corrosion resistanceEngine sealsGas turbine plantsRubber ringContact formation

The invention discloses a constant-elasticity film-coating involute spiral groove long-life sealing device, particularly relates to a shaft end sealing device suitable for an aero-engine with high rotating speed, high maneuverability and the complex load, and belongs to the technical field of mechanical sealing. The constant-elasticity film-coating involute spiral groove long-life sealing device comprises a sealing shell, a first sealing rubber ring, a pressing plate, a lap joint wavy spring, a second sealing rubber ring, a check ring, a graphite ring, a sealing movable ring and a third sealing rubber ring. The constant-elasticity film-coating involute spiral groove long-life sealing device is used for isolating an oil cavity from an air cavity and preventing lubricating oil in the oil cavity from leaking to the air cavity so as to fulfill the oil sealing aim. The lap joint wavy spring is used for generating an axial force, the axial force is transmitted to the graphite ring through the pressing plate, tight contact of the graphite ring and the sealing movable ring is guaranteed and a main sealing surface is formed. The constant-elasticity film-coating involute spiral groove long-life sealing device can reduce abrasion of a mechanical sealing device and can improve the sealing property and the stability of the mechanical sealing device, so that the life of the constant-elasticity film-coating involute spiral groove long-life sealing device is prolonged.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Fishing device and its net plate assembly

InactiveCN106614428BReduce resistanceEasy to liftFishing netsMarine engineeringStructural engineering

The invention discloses an otter board assembly. The otter board assembly comprises a triangular support and a main rib plate, wherein the triangular support is transversely arranged and capable of rotating along a fixed shaft of a bottom edge, and the main rib plate is longitudinally arranged and are linked with the triangular support. The triangular support is located in the middle of the main rib plate, and a leading edge wing, a main wing and a wing flap are sequentially arranged on the main rib plate in an imbricate mode from front to back. The sections of the leading edge wing, the main wing and the wing flap are in an arc shape, a flow guiding gap is formed between the leading edge wing and the main wing, and a flow guiding gap is formed between the main wing and the wing flap; the two sides of the main rib plate are symmetrically provided with side rib plates, and each side rib plate is provided with an upper side wing, trawl iron and a guide rail, wherein the trawl iron and the guide rails are matched with a fishing net. The front end of the leading edge wing is provided with a front coil side, and the rear end of the wing flap is provided with a rear coil side. The resistance of the otter board assembly is low, the stability of the otter board assembly is high, and the performance of a fishing device can be improved. The invention further discloses a fishing device with the otter board assembly.

Owner:GUANGDONG OCEAN UNIVERSITY

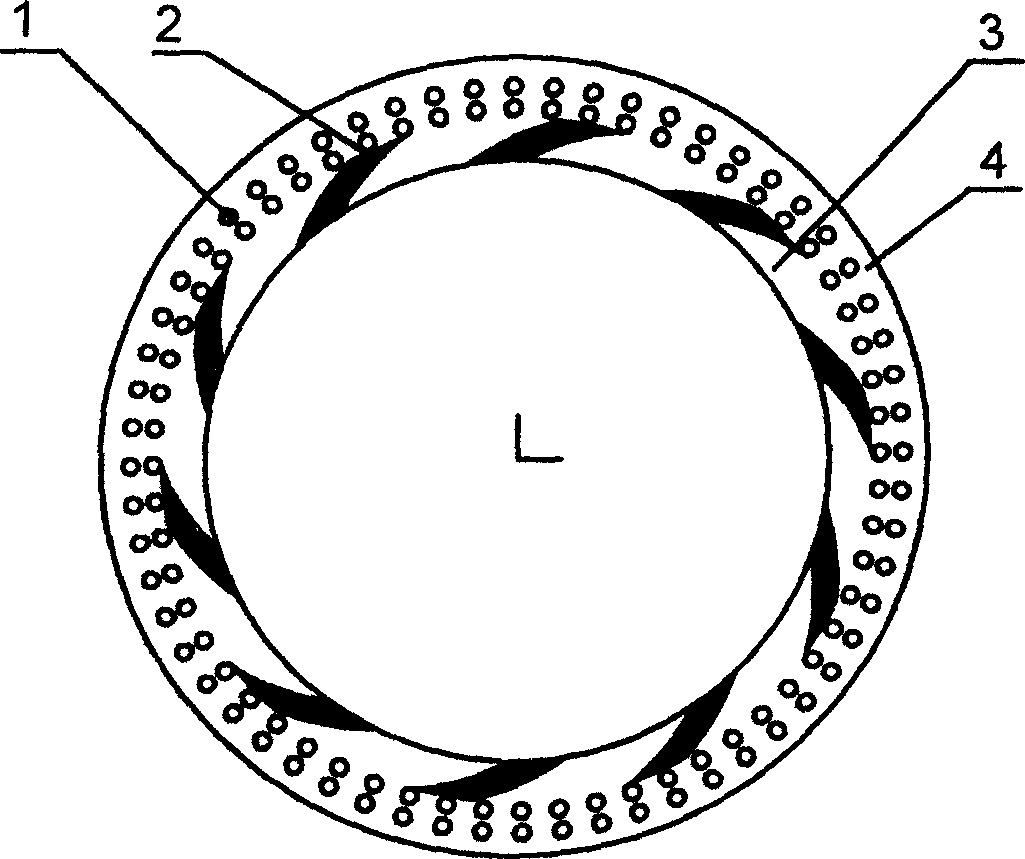

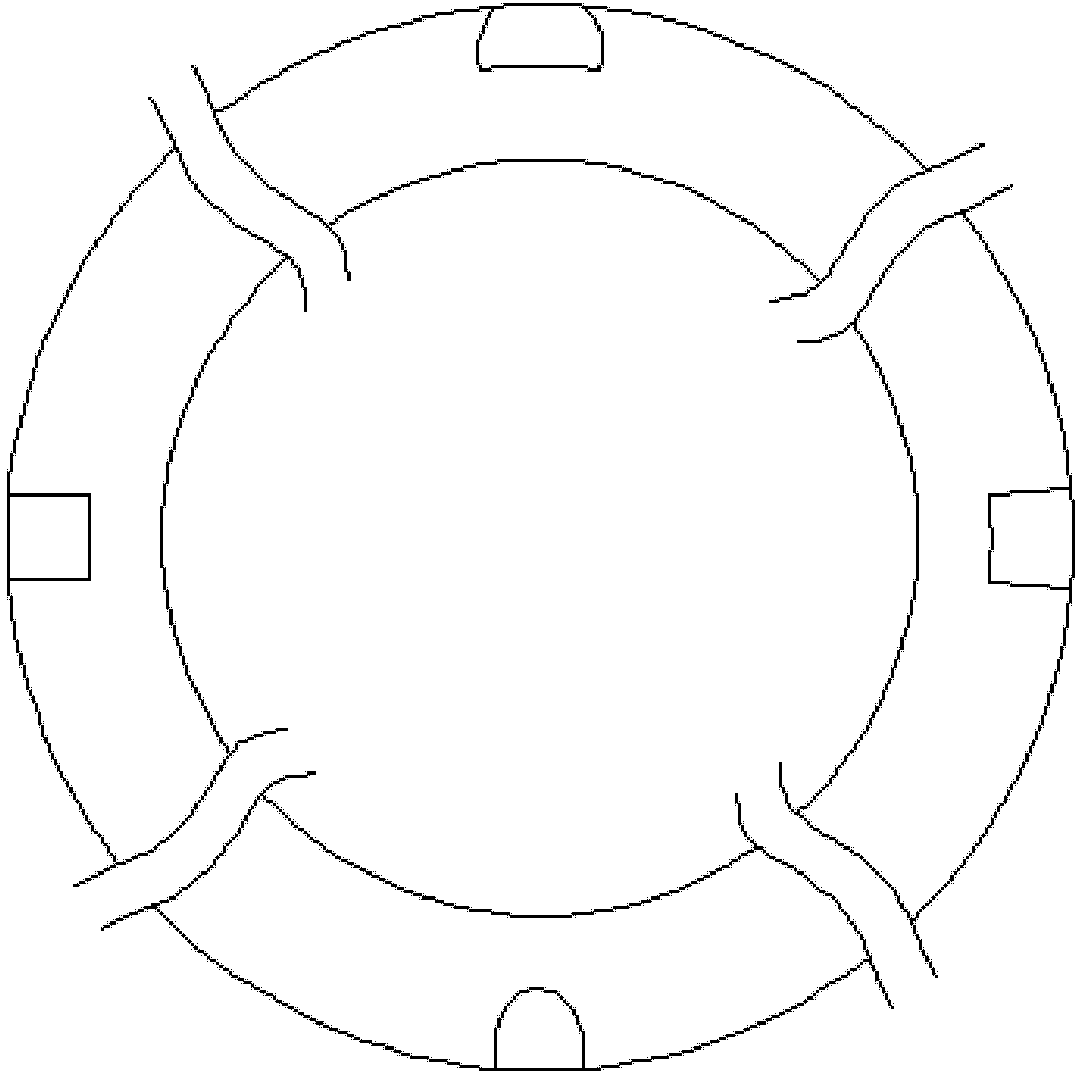

Double-row tilting directional microporous end surface no-leakage mechanical sealing structure

Owner:ZHEJIANG UNIV OF TECH

Profiled groove end surface non-contact mechanical seal with backflow function

The invention discloses a profiled groove end surface non-contact mechanical seal with a backflow function. The profiled groove end surface non-contact mechanical seal comprises a mechanical seal moving ring and a mechanical seal static ring, wherein one side of the end surface of each of the moving ring and the static ring is a high-pressure side, i.e. an upstream; the other side of the end surface of each of the moving ring and the static ring is a low-pressure side, i.e. downstream; the downstream of the end surface is provided with an annular sealing dam of a smooth plane; and at least one sealing end surface in the moving ring and the static ring is provided with a plurality of groups of fluid profiled grooves. The profiled groove end surface non-contact mechanical seal with a backflow function is characterized in that the fluid profiled groove is formed by compounding the drainage groove and a pumping reflux groove, wherein the average groove depth of the drainage groove is more than the average groove depth of the pumping reflux groove; the drainage groove is arranged on the upstream of the end surface and is communicated with sealing medium; the pumping reflux groove is the profiled groove with the appearance structure characteristic of a flying bird wing; the groove depth is in the variation rule that the middle is deep and two sides are shallow; and the tail ends of two sides of the pumping reflux groove has a certain space with the upper stream of the end surface. The profiled groove end surface non-contact mechanical seal has dual actions of upstream pumping and downstream pumping to the sealing medium, the leakage amount is reduced, and the operation reliability of sealing is improved.

Owner:ZHEJIANG UNIV OF TECH

Ternary distortion-type groove end surface mechanical sealing structure

ActiveCN107218395AImprove compression performanceStrong drainage abilityEngine sealsHelical lineEngineering

A ternary distortion-type groove end surface mechanical sealing structure comprises a dynamic ring and a static ring which are used for mechanical sealing, ternary distortion-type grooves 1 evenly distributed in the circumferential direction are machined in the sealing end surface of at least one sealing ring of the dynamic ring and the static ring, and each ternary distortion-type groove is formed by two side walls and a three-dimensional distortion variable-depth groove bottom surface; the side walls of each ternary distortion-type groove comprise the windward side ternary distortion wall surface 11 and the leeward side ternary distortion wall surface 13, and the three-dimensional distortion variable-depth groove bottom surfaces 12 gradually shallow in a distortion shape from the outer circumferential side walls of the sealing rings to the centers of the sealing rings and intersect with the sealing end surfaces on the outer sides of sealing dams 3; the intersection lines of the side walls of the ternary distortion-type grooves 1 and the outer circumferential side walls of the sealing rings are perpendicular to the sealing end surfaces; the intersection lines of the side walls of the first ternary distortion-type grooves and the sealing end surfaces are each divided into two sections, the intersection lines on the medium inlet sides are helical lines, and the intersection lines on the medium leakage sides are radial straight lines.

Owner:ZHEJIANG UNIV OF TECH

A mechanical seal ring with multi-serrated spiral grooves

ActiveCN106763779BImprove compression performanceImprove lubrication statusEngine sealsMechanical engineering

Owner:云南流体规划研究院有限公司

A low-leakage spiral groove liquid film mechanical seal end face structure

ActiveCN107166036BFlow is easy to controlGood pump back flow capabilityEngine sealsLow leakageEngineering

A low-leakage spiral groove liquid film mechanical seal end face structure comprises a dynamic ring and a static ring of a mechanical seal; one side of the end face of the dynamic ring or the static ring is a high-pressure side, namely, the upstream side; the other side of the end face of the dynamic ring or the static ring is a low-pressure side, namely, the downstream side; the end face of the dynamic ring or the static ring is provided with a series of launders, the downstream side is provided with a series of reverse spiral grooves uniformly distributed in the circumferential direction, the middle is provided with an annular groove communicating with the reverse spiral grooves, the upstream side is provided with outlets communicating with the annular groove and a medium side, and a series of forward spiral grooves are formed between the two adjacent outlets; and sealing dams are arranged between the reverse spiral grooves and the downstream side, and sealing weirs are arranged between the annular groove and the forward spiral grooves. The low-leakage spiral groove liquid film mechanical seal end face structure is each to achieve low leakage under various complex working conditions, excellent in tribological property, good in bearing performance and stability and long in service life.

Owner:ZHEJIANG UNIV OF TECH

Tandem arc groove type bidirectional rotary sealing end face structure

The serial arc groove type bidirectional rotary sealing end face structure comprises a static ring and a movable ring, the static ring and the movable ring are each provided with a sealing end face, the outer ring edge of each sealing end face is a sealing high-pressure side, the inner ring edge of each sealing end face is a sealing low-pressure side, and an annular sealing dam is arranged on the sealing low-pressure side of each sealing end face. A plurality of serial arc dynamic pressure groove sets are evenly distributed in the sealing end face in the circumferential direction of the sealing end face, each serial arc dynamic pressure groove set comprises a plurality of concentric arc grooves, the two ends of each arc groove are communicated with the sealing high-pressure side, and arc-shaped recesses of the arc grooves face the sealing high-pressure side. The invention has the following beneficial effects: the rigidity of a fluid film on the sealing end surface is improved, the sealing operation stability is improved, and a reverse rotation operation condition is provided.

Owner:ZHEJIANG UNIV OF TECH

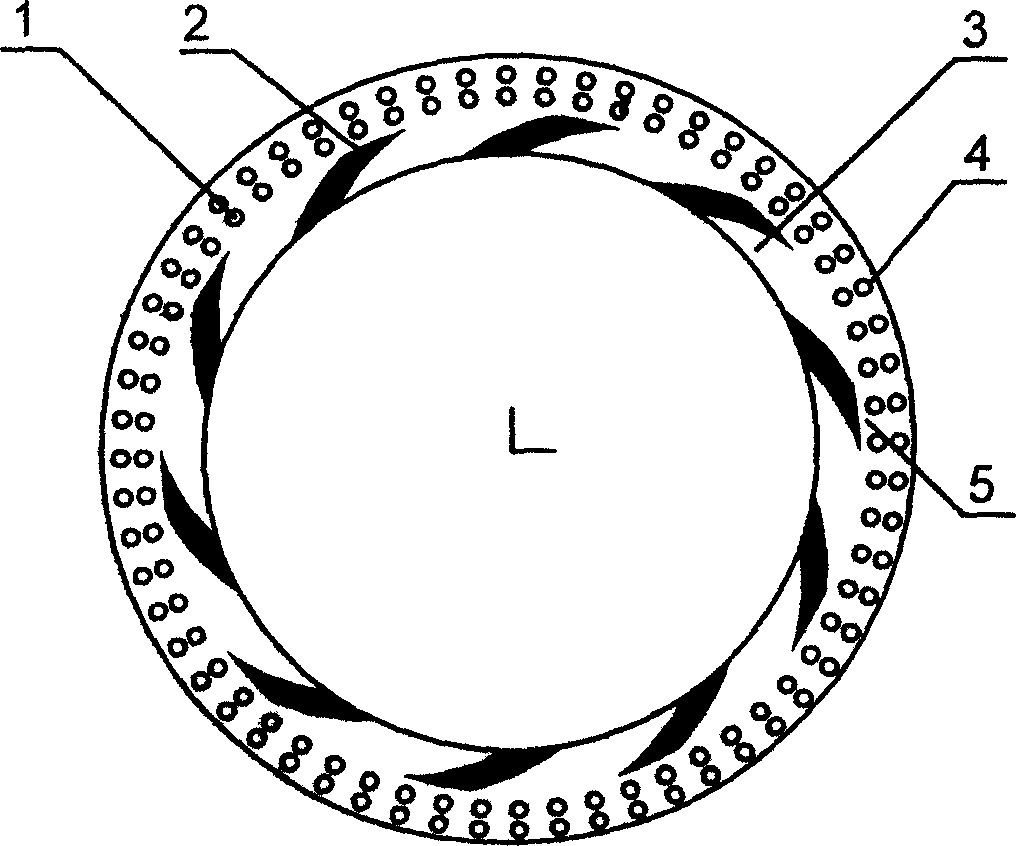

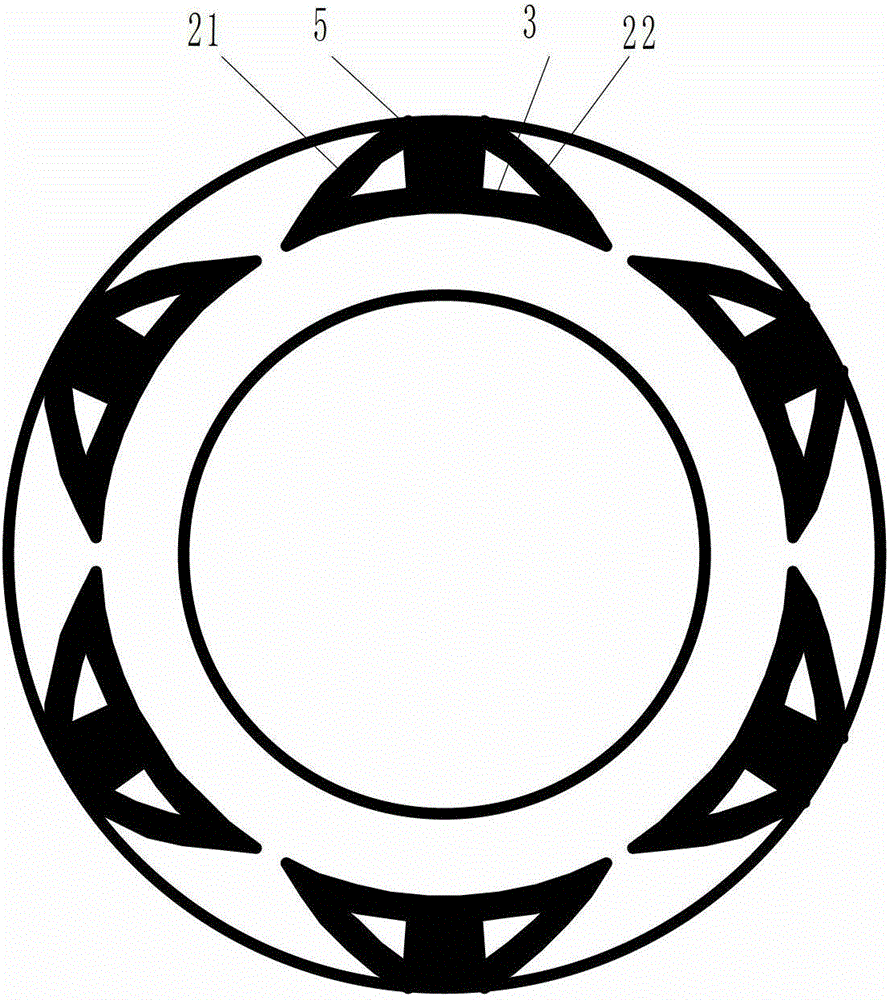

Mechanical seal structure of spike-shaped distribution microporous end surface

The invention provides a mechanical seal structure of a spike-shaped distribution microporous end surface, comprising a moving ring and a static ring which are mechanically sealed, wherein the one side of the end surface of the moving ring and one side of the end surface of the static ring are high pressure sides, namely upstream; the other side of the end surface of the moving ring and the other side of the end surface of the static ring are low pressure sides, namely downstream; at least one end surface of the moving ring or static ring is provided with a group of spike-shaped micropores which are symmetrically distributed based on a rotation center and composed of inclined hydrodynamic micropores and nondirectional decompressed micropores, wherein the decompressed micropores are arranged at the tail ends of the hydrodynamic micropores; the spike-shaped micropore group forms a ring belt which is arranged on the upstream of the end surface; and the downstream of the ring belt is provided with an annular seal dam with a smooth plane. The mechanical seal structure has the beneficial effects that seal disturbance-resistant capability and stability are improved by controlling fluid hydrodynamic effect of the microporous end surface and increasing damp; the capability and advantage that micropores can prevent solid particles can be fully performed; and the fluid hydrodynamic effect and disturbance resistivity are enhanced so that noncontact stability and wear resistivity of seal are improved, the service life is prolonged, and the reliability of the seal is improved.

Owner:海宁市黄湾镇资产经营有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com