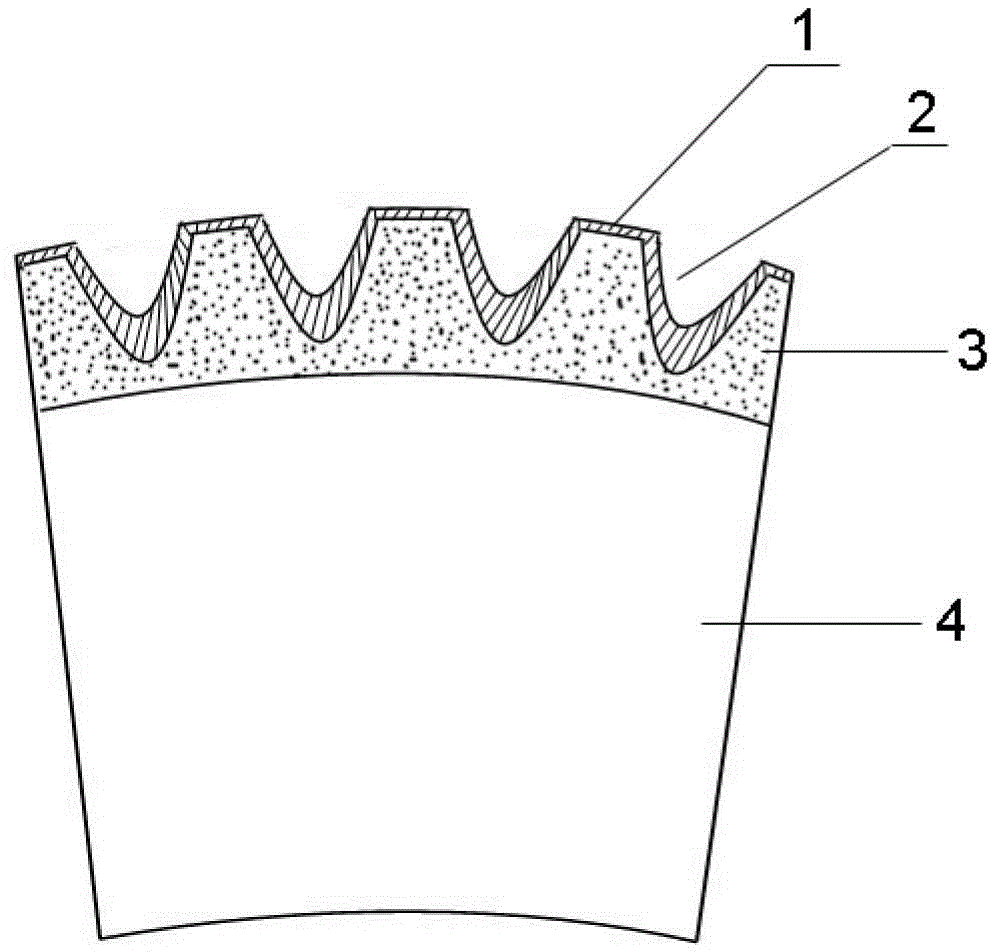

Wear-resistant piston ring with hard-soft composite coating and textured surface and preparation method

A composite coating and textured technology, applied in the field of piston rings, can solve the problems of cylinder liner aggressiveness, high friction coefficient, piston ring wear, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Degrease and ultrasonically clean the outer surface of the piston ring before plating; 2) Use a bidirectional pulse plating power supply for electrodeposition, and the plating solution contains chromic anhydride (CrO 3 ) 100 g / L, sulfuric acid 1 g / L, the weight ratio of the two is 100:1, Cr 3+ The content is controlled at 3 g / L, the bath temperature is 30 °C, and the cathode current density is 10 A / dm 2About, electroplating time 360 min; 3) Nd: YAG pulsed laser is used to texture the outer surface of piston ring, the microhole spacing is 400 μm, the laser pulse is repeated once at the same point, the microhole diameter is 50 μm and the depth is 6 μm , the micropore area occupancy rate is 1%; 4) Electroless silver plating is carried out on the surface of the textured chrome-plated piston ring. The plating solution contains 30 g / L silver nitrate, 200 g / L sodium thiosulfate, and 80 g / L sodium bisulfite. L, sodium acetate 20 g / L, thiosemicarbazide 0.5 g / L, pH controll...

Embodiment 2

[0031] 1) Degrease and ultrasonically clean the outer surface of the piston ring before plating; 2) Use a bidirectional pulse plating power supply for electrodeposition, and the plating solution contains chromic anhydride (CrO 3 ) 125 g / L, sulfuric acid 1 g / L, the weight ratio of the two is 125:1, Cr 3+ The content is controlled at 5 g / L, the bath temperature is 50 °C, and the cathode current density is 40 A / dm 2 About, electroplating time 360 min; 3) Nd: YAG pulsed laser was used to texture the outer surface of the piston ring, the microhole spacing was 800 μm, the number of laser pulses was repeated 4 times at the same point, the micropore diameter was 150 μm and the depth was 40 μm , the micropore area occupancy rate is 2.8%; 4) Electroless silver plating is carried out on the surface of the textured chrome-plated piston ring. The plating solution contains 40 g / L silver nitrate, 200 g / L sodium thiosulfate, and 80 g / L sodium bisulfite. L, sodium acetate 20 g / L, thiosemica...

Embodiment 3

[0033] 1) Degrease and ultrasonically clean the outer surface of the piston ring before plating; 2) Use a bidirectional pulse plating power supply for electrodeposition, and the plating solution contains chromic anhydride (CrO 3 ) 150 g / L, sulfuric acid 1 g / L, the weight ratio of the two is 150:1, Cr 3+ The content is controlled at 7 g / L, the bath temperature is 60 °C, and the cathode current density is 60 A / dm 2 About, electroplating time 360 min; 3) Nd: YAG pulsed laser is used to texture the outer surface of the piston ring, the microhole spacing is 400 μm, the number of laser pulses is repeated 8 times at the same point, the microhole diameter is 200 μm and the depth is 55 μm , the micropore area occupancy rate is 20%; 4) Electroless silver plating is carried out on the surface of the textured chrome-plated piston ring, the plating solution contains silver nitrate 50 g / L, sodium thiosulfate 200 g / L, sodium bisulfite 80 g / L L, sodium acetate 20 g / L, thiosemicarbazide 1 g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com