Dovetail groove end face mechanical seal structure that can be rotated in both directions

A technology of end face mechanical seal and sealing structure, which is applied in the direction of engine seal, mechanical equipment, engine components, etc. It can solve the problems of weak dynamic pressure effect, small opening force of end face, and small air film rigidity, etc., and improve the air film Stiffness, large air film rigidity, the effect of reducing power consumption and sealing gas consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

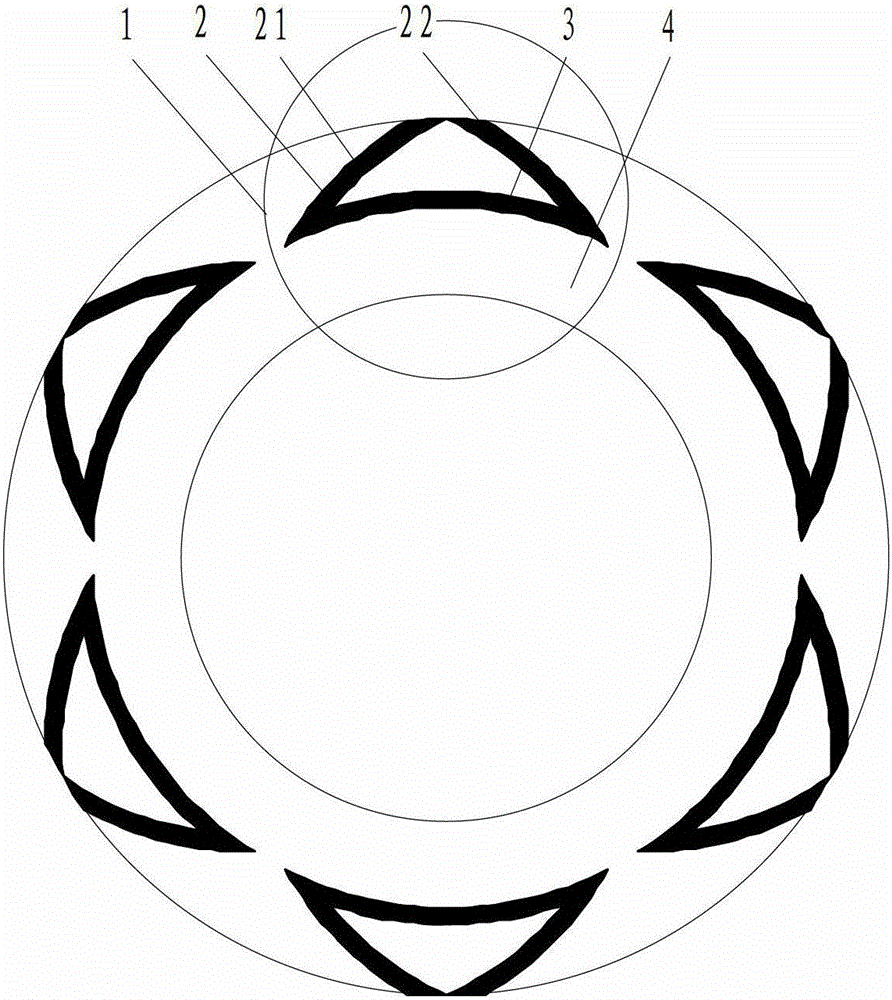

[0026] refer to figure 1 , a bidirectionally rotatable dovetail groove end face mechanical seal structure, including a moving ring, a static ring, etc. Two-way rotating dovetail grooves, each dovetail groove is composed of a pair of reversely arranged spiral grooves 21 and 22 and an arc groove 3 connecting the roots of the two spiral grooves, forming a shape similar to a dovetail, in which the spiral groove 2 is located at the high pressure The side is upstream, and the arc groove 3 is located on the low pressure side, namely downstream; the direction of the helix angle of the reversely arranged spiral grooves 21 and 22 is opposite, so that the mechanical seal can be applied to occasions requiring different directions of rotation; the arc groove 3 makes The sealing medium does not form a dead zone in the spiral groove 2, which strengthens the cooling and lubrication of the end face and the rapid discharge of abrasive particles.

[0027] The depth of the spiral groove 2 is h ...

Embodiment 2

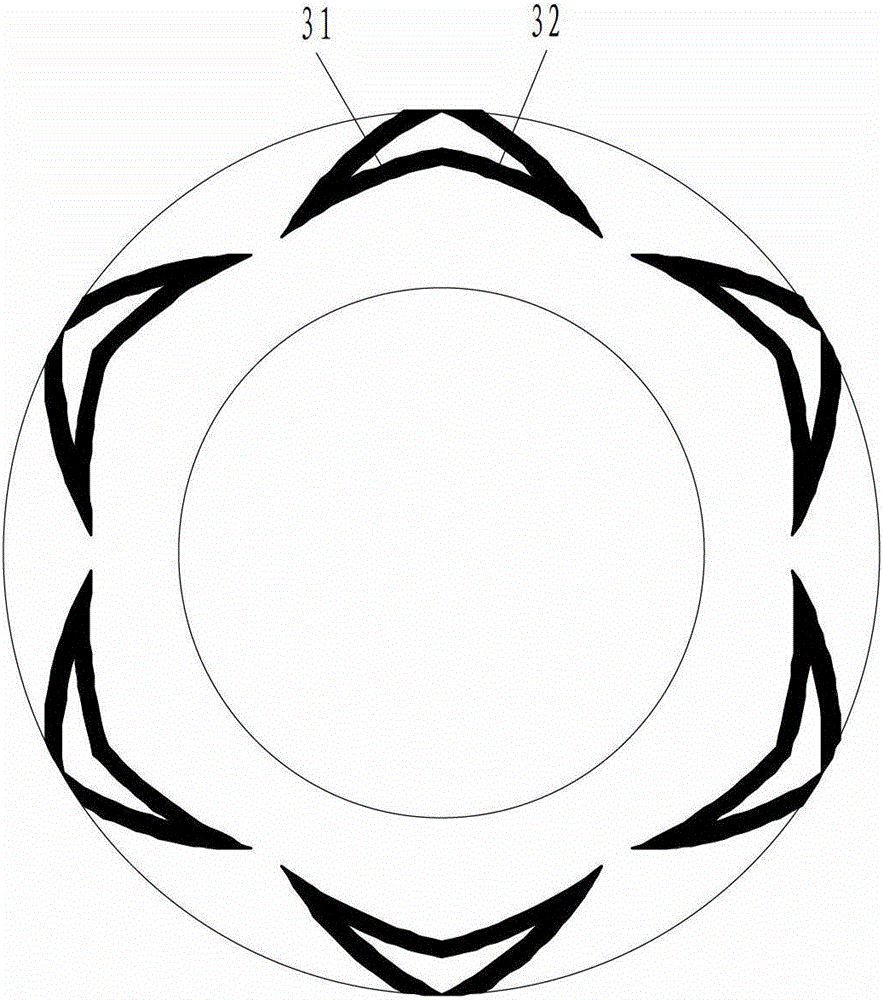

[0031] refer to figure 2 , The difference between this embodiment and Embodiment 1 is that the arc groove 3 is a pair of opposing communicating spiral grooves 31 and 32 . The rest of the structure and implementation are the same as in Embodiment 1.

Embodiment 3

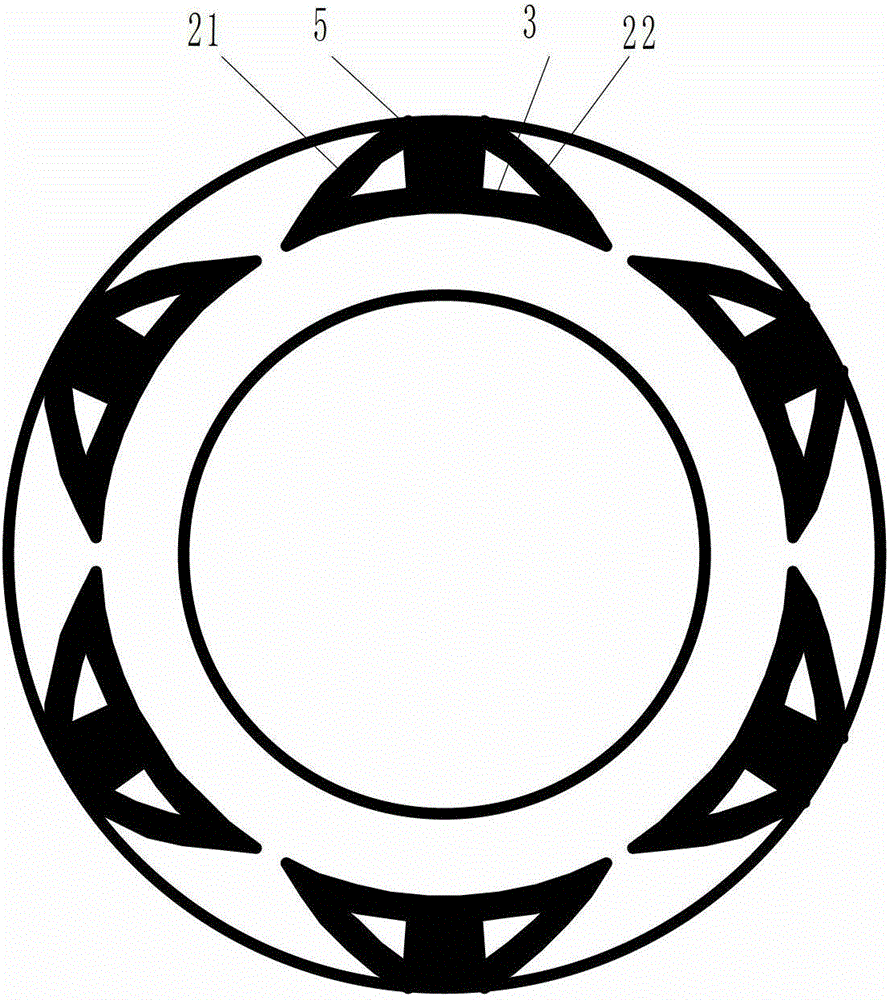

[0033] refer to image 3 The difference between this embodiment and Embodiment 1 is that there is a radial air inlet groove 5 between the spiral grooves 21 and 22, and the radial air inlet groove 5 forms a communication type with the spiral groove 2 and the arc groove 3. Dovetail groove. The rest of the structure and implementation are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com