Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

372results about How to "Avoid rubbing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Nose filter

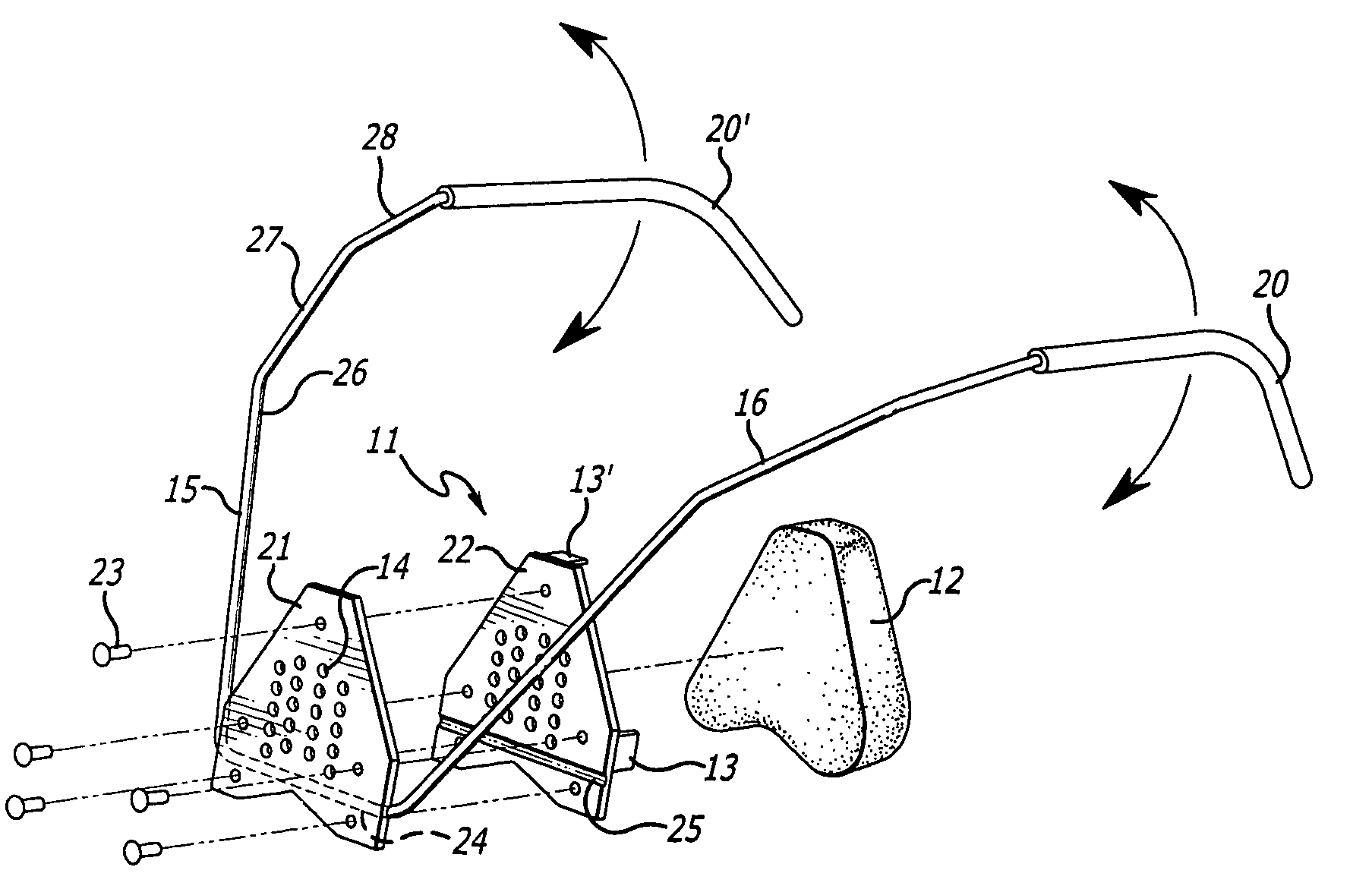

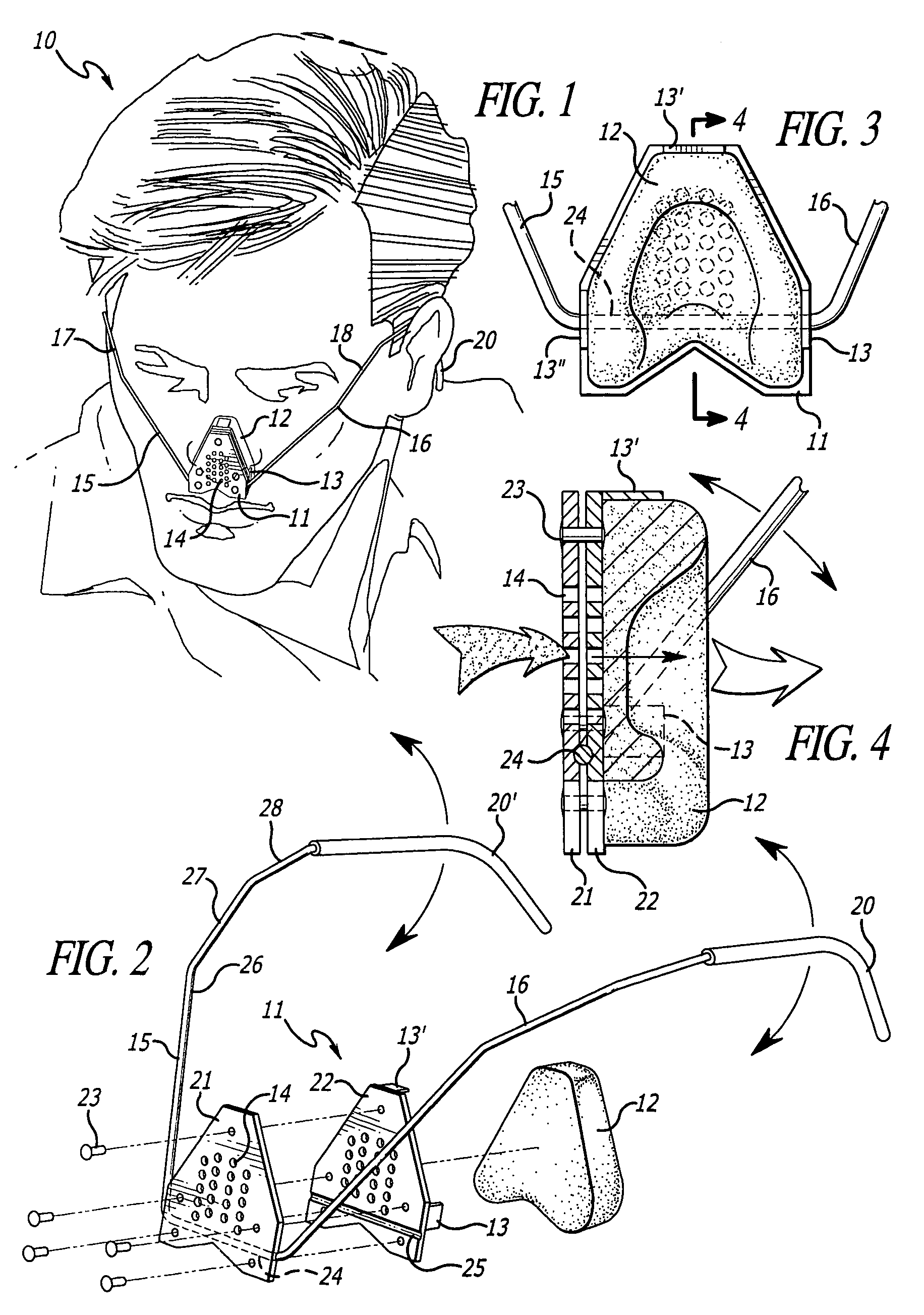

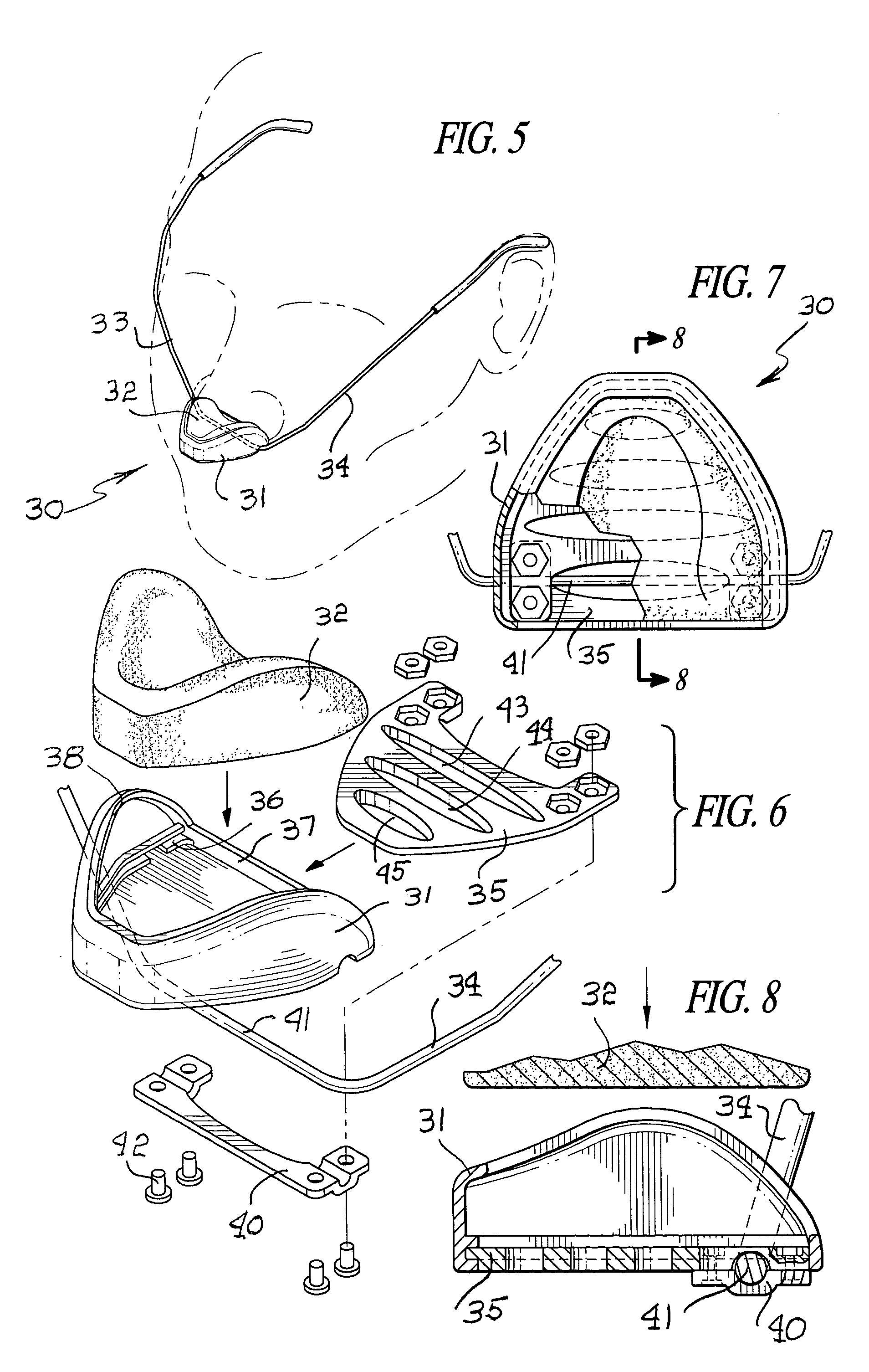

InactiveUS7004165B1Increase volumeAvoid rubbingBreathing filtersBreathing masksNostrilFilter material

A filtering apparatus fits adjacent to the nostrils and nose of the user and includes a rigid base for retaining a filtering material thereon through which the user may breathe. The filter material takes the form of an open-cell foam, in the form of a pad, which is removably held between retainer members carried on the rigid base. The foam pad includes a peripheral sidewall and defines an open cavity in the thickness thereof. A clamping device included in the base has an upper and lower plate that are joined together by fasteners. A supporting arrangement for facial wearing comprises a pair of elongated ear support members arranged in spaced-apart relationship and joined together to define a pivot or hinge mechanism that is captured beneath the opposing surfaces of the base plates.

Owner:SALCIDO EDWARD

UV-oxide hybrid drying type engraving intaglio printing ink

ActiveCN101250354AAchieve dryingWell mixedInksOther printing apparatusPulp and paper industryPrinting ink

The invention relates to UV-oxidation mixing drying type incising gravure printing ink, which is prepared through firstly producing by rolling UV drying components and oxidation drying components assisting volatilization drying, penetration drying and complex drying effect, and evenly mixing according to 1%-99% proportion of UV drying component and 99%-1% oxidation drying components assisting volatilization drying, penetration drying and complex drying effect. The printing ink of the invention conducts UV drying in the process of printing, instantly realizes partial drying of printing ink to form a drying ink film, can finish oxidation drying and assisting volatilization drying, penetration drying and complex drying effect to achieve the complete drying of printing ink. The printing ink solves the technical problems that thick ink film existing in current UV drying incising gravure printing ink is incomplete, complete drying can not be realized in the natural storage process, and has the advantages of economical, energy-saving and environment-friendly.

Owner:CHINA BANKNOTE PRINTING & MINTING

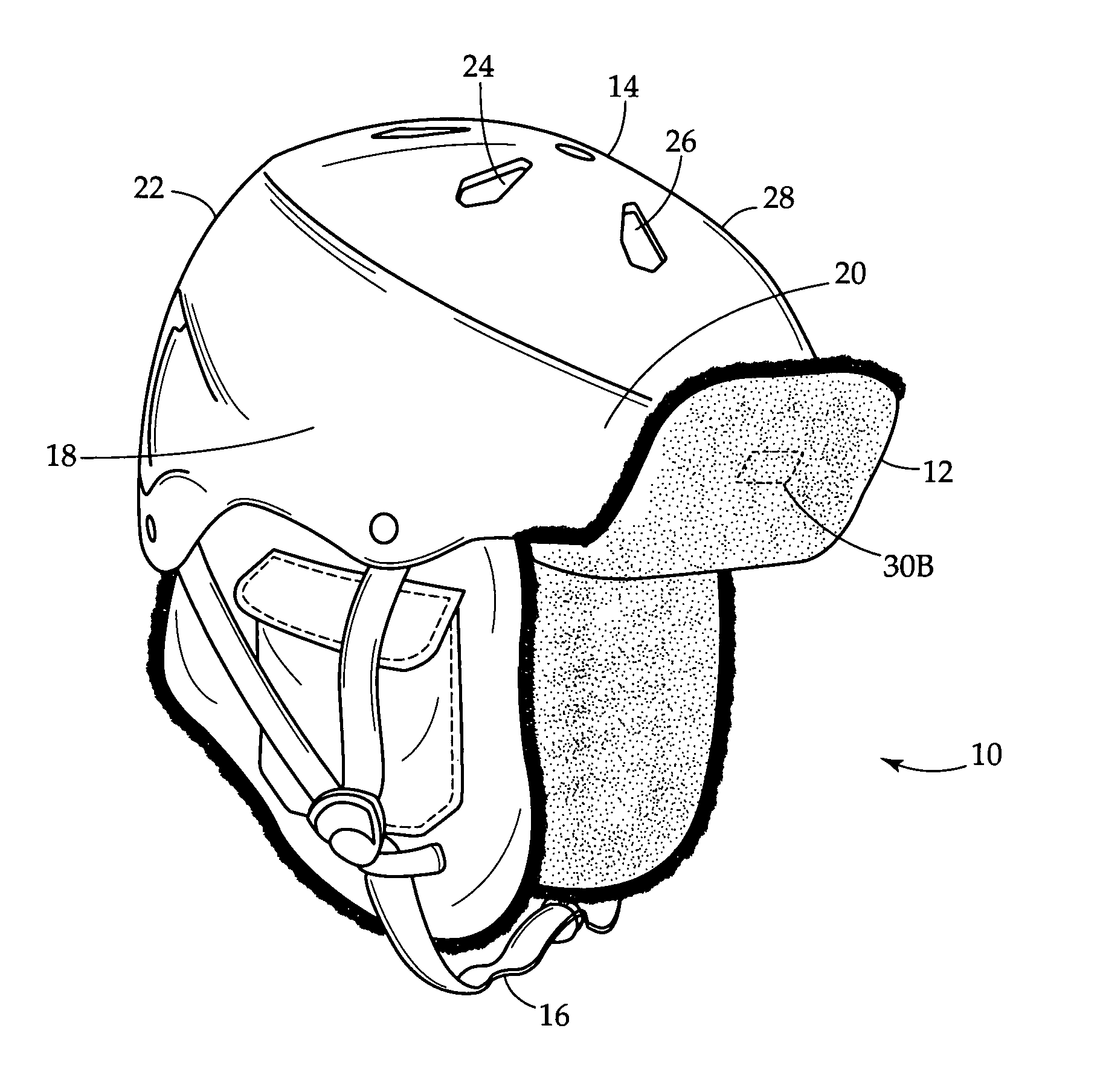

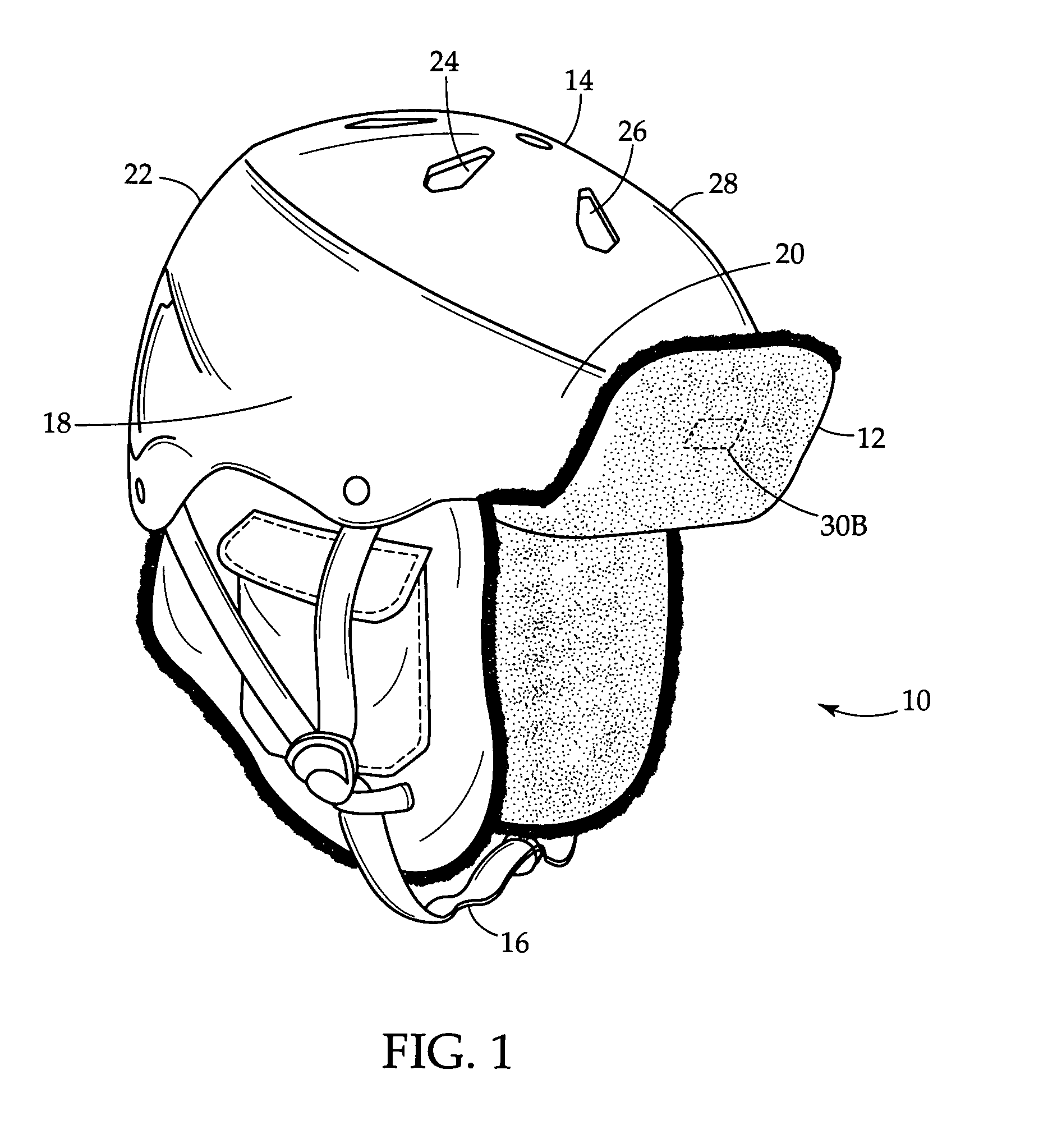

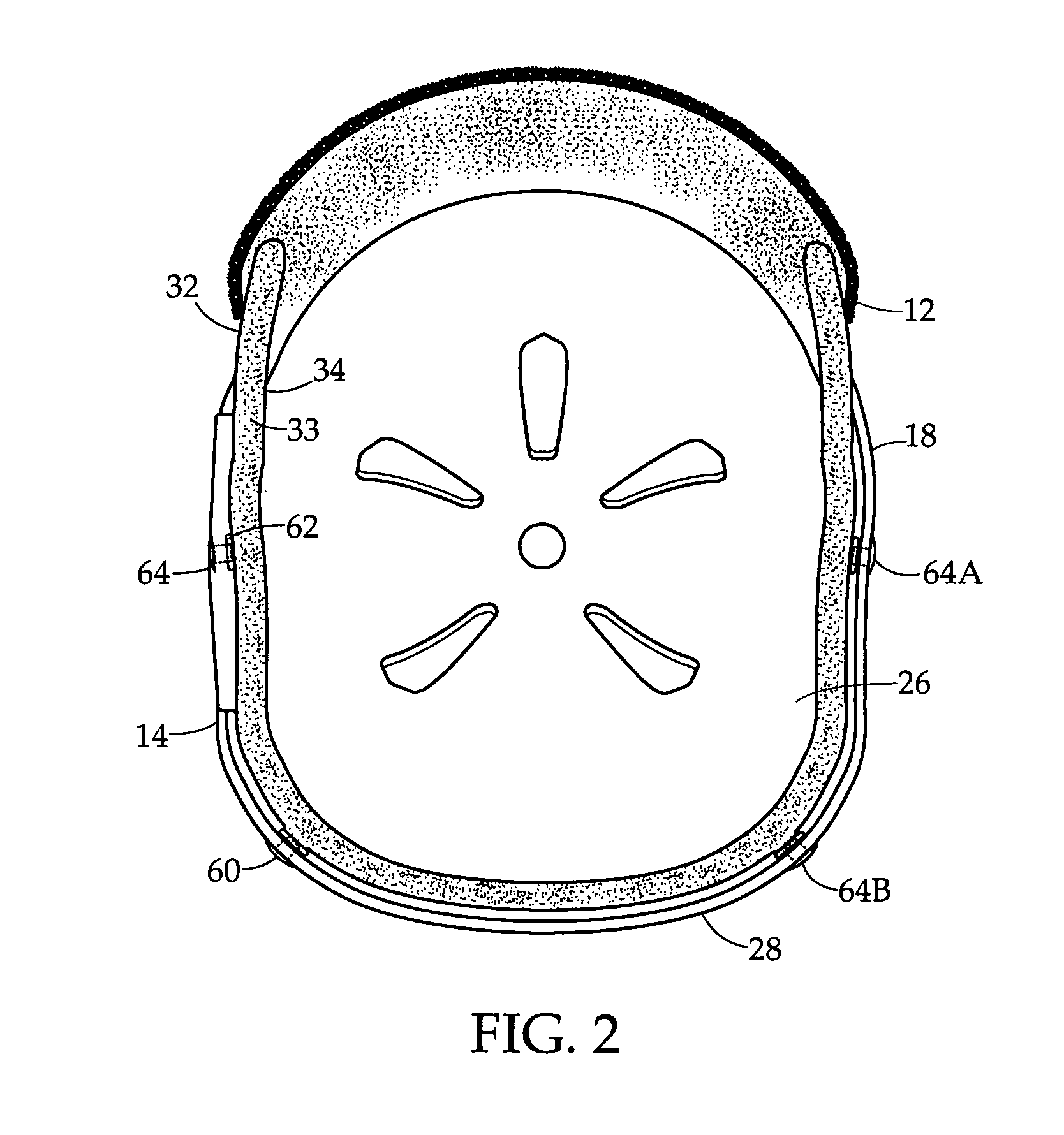

Removable hunter knit liner for use with a protective helmet

A winter liner system, including a hunter knit liner for wear underneath a protective helmet. The hunter knit liner fully encircles, and partially covers, the head of the wearer and includes a decorative exterior layer, an interior layer, and an interior foam layer sandwiched therebetween. The liner has two ear flaps extending downwardly to cover ears, and a looping band on each ear flap for holding the chinstrap of the helmet. At least one ear flap includes a side pocket integrated therein. The liner includes an elongated bill extending downwardly and horizontally across the front portion. The bill has an exterior surface which adheres directly to the front of the helmet. A plurality of snapping mechanisms, which include male snap heads embedded within the helmet and cooperating female snap receptacles integrated into the liner, removably securing the liner into the helmet.

Owner:BERN UNLIMITED

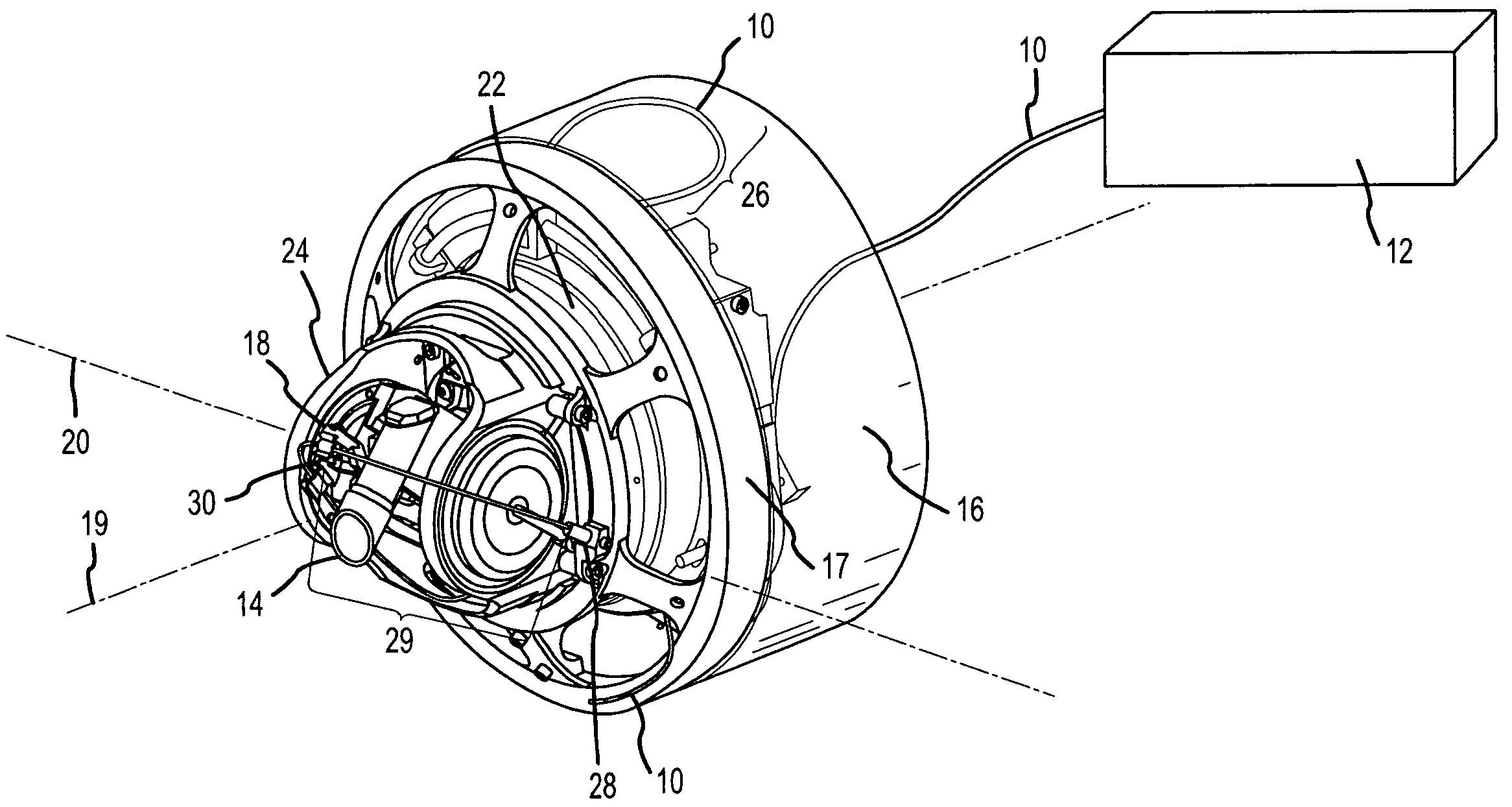

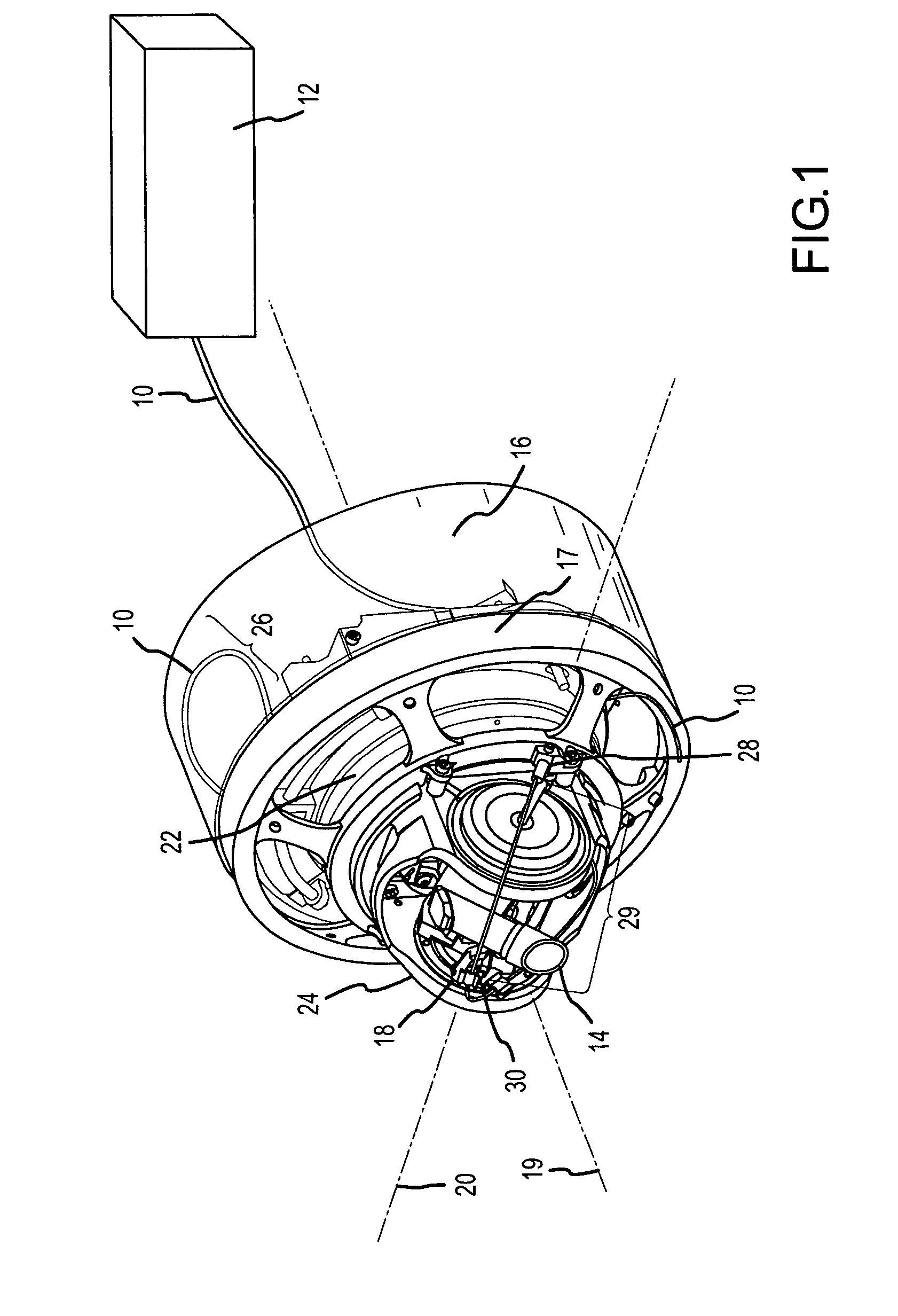

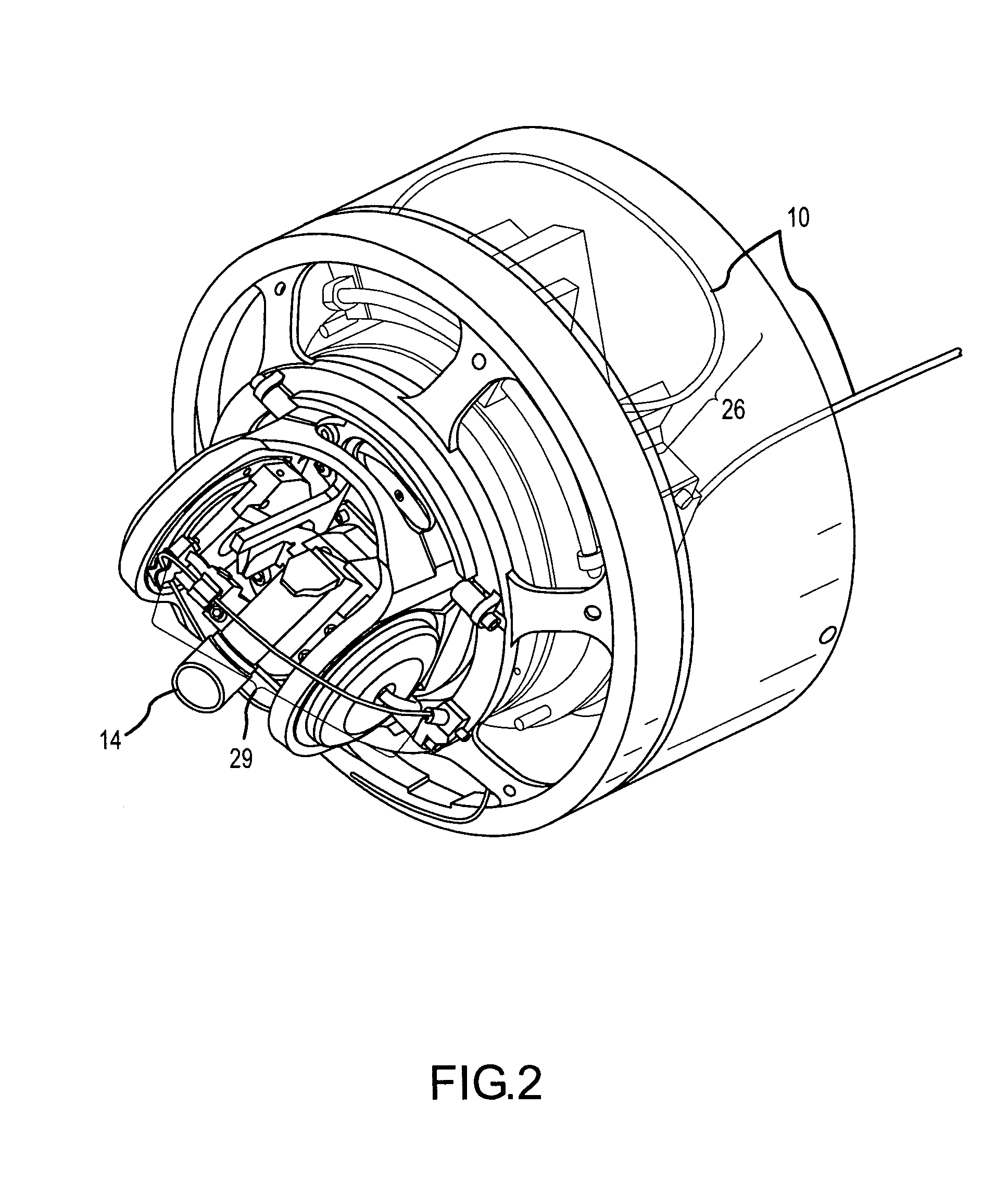

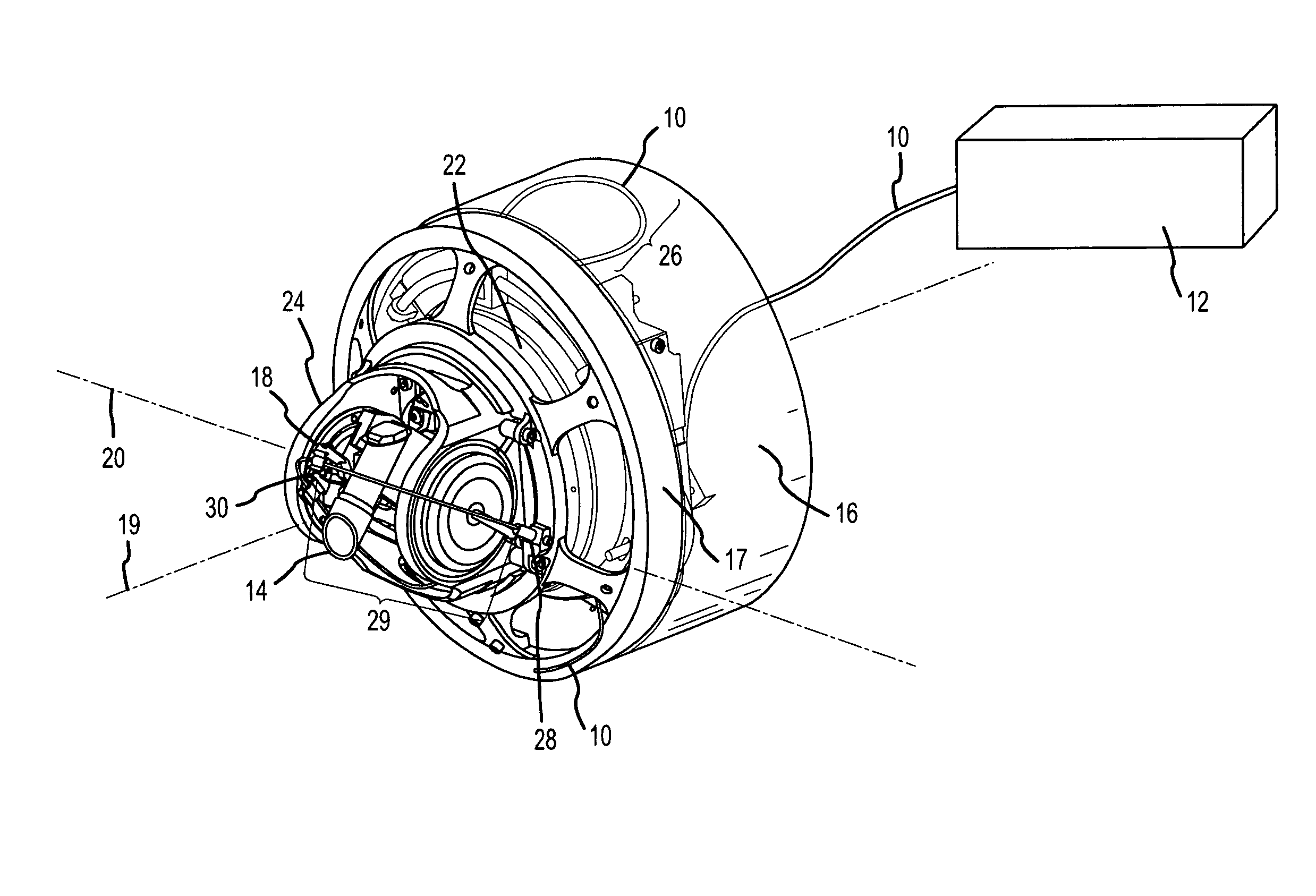

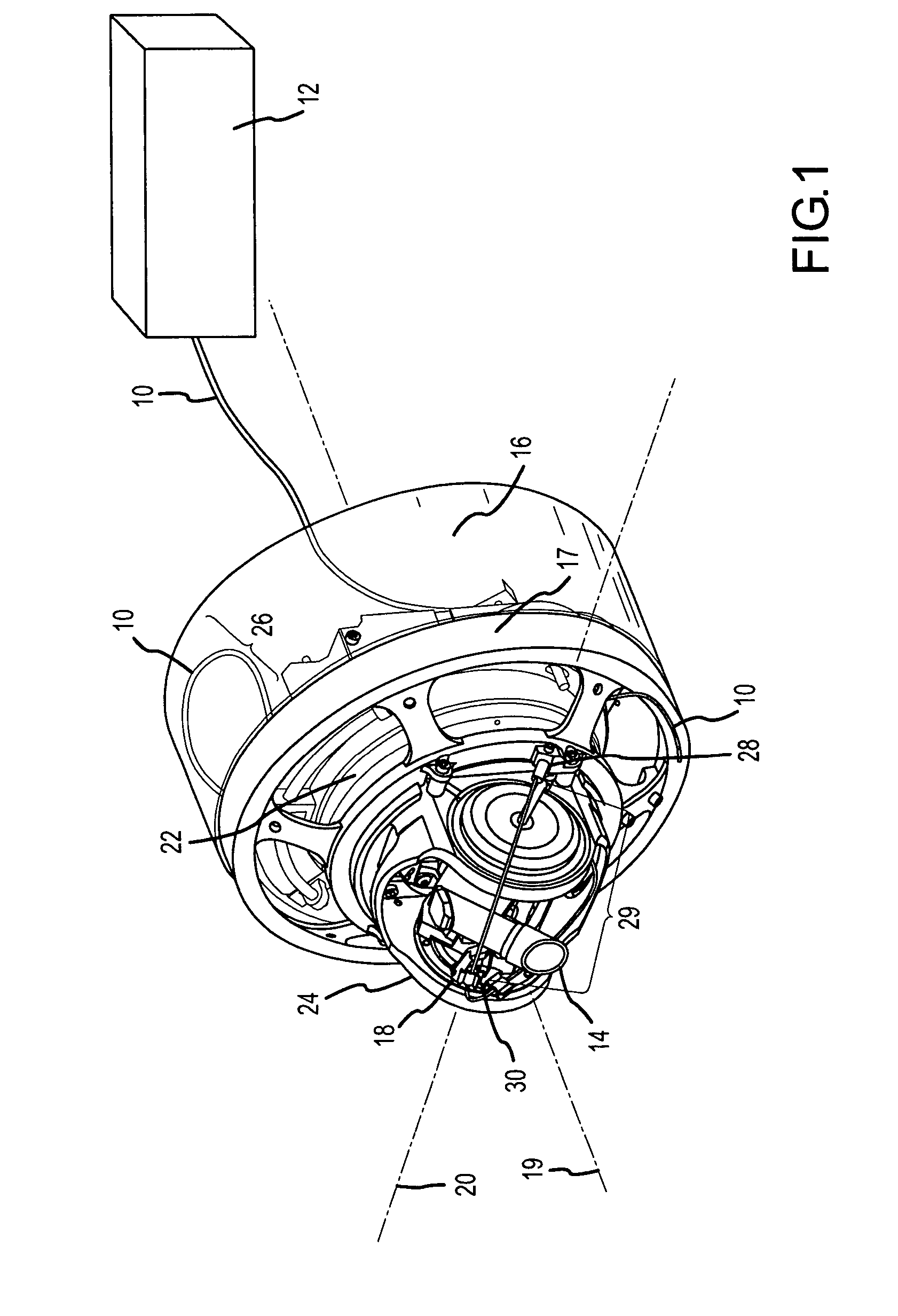

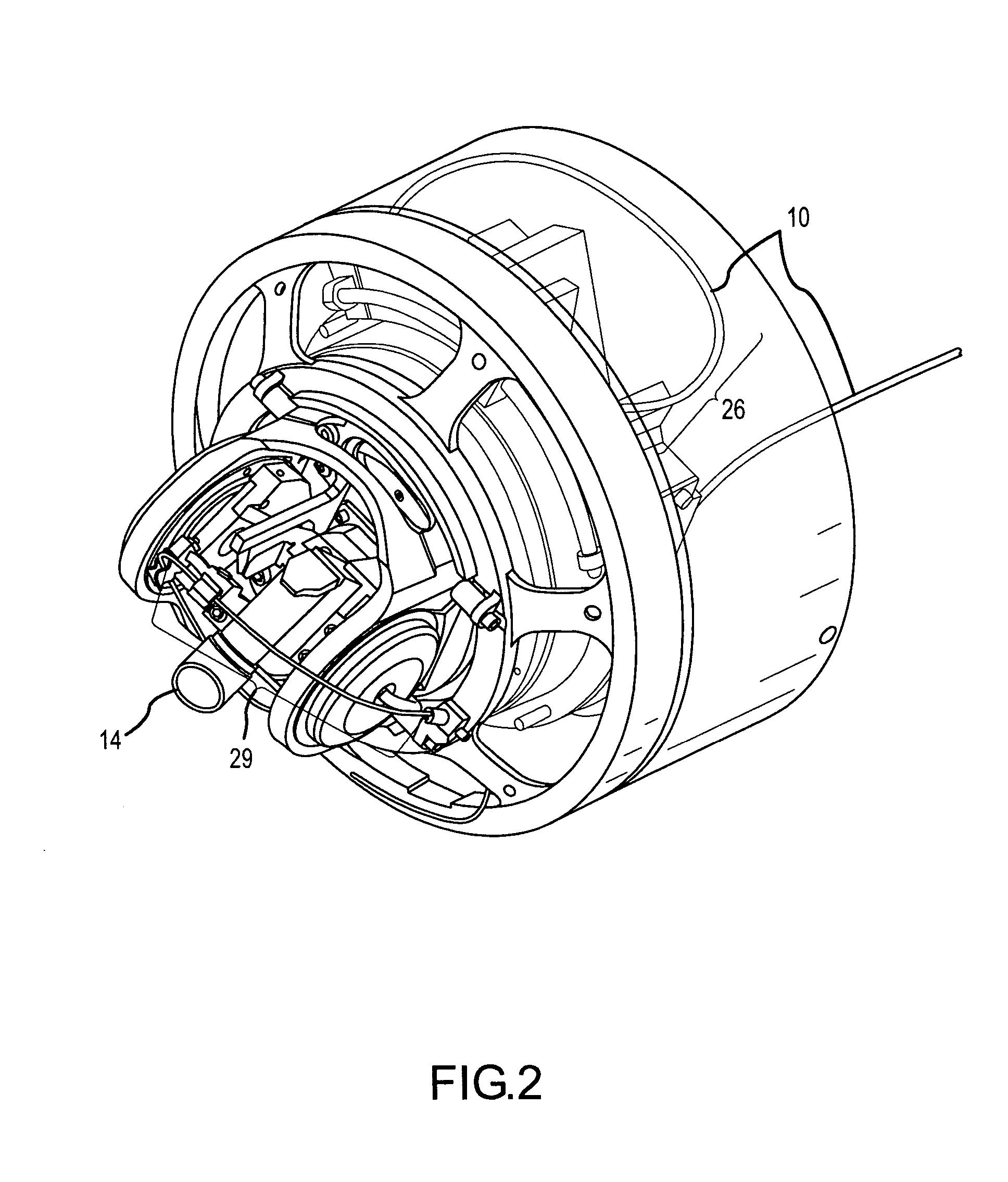

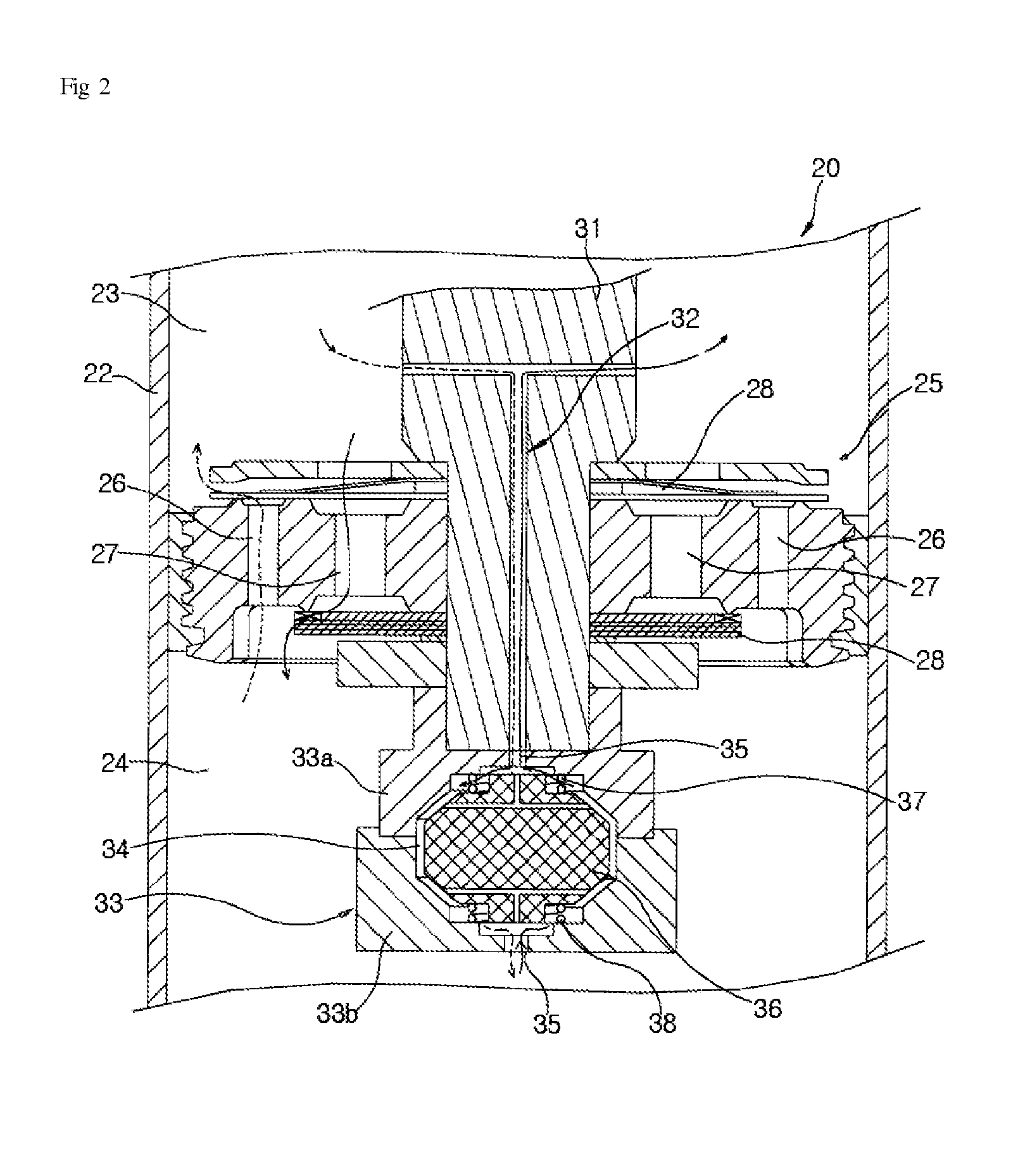

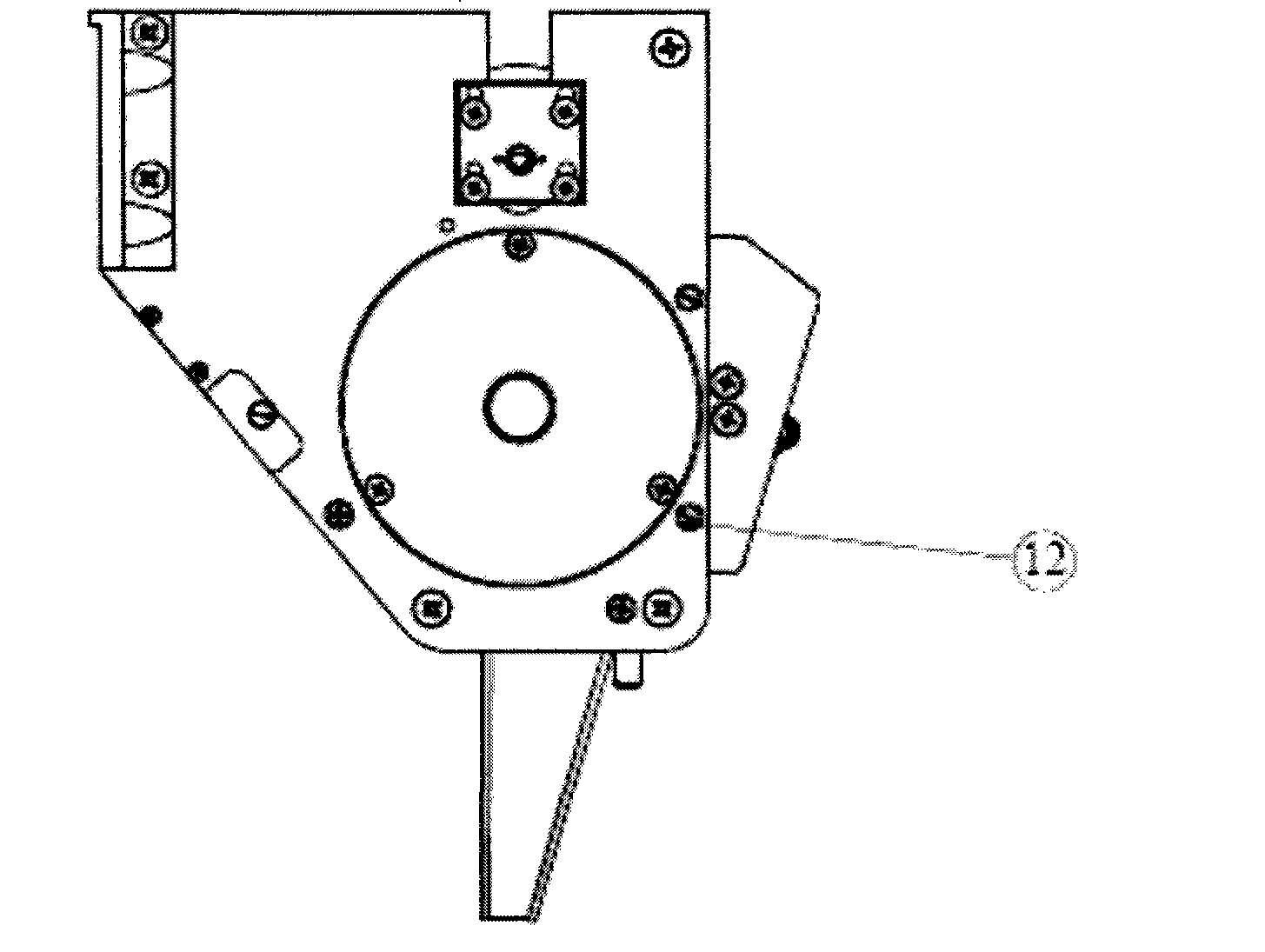

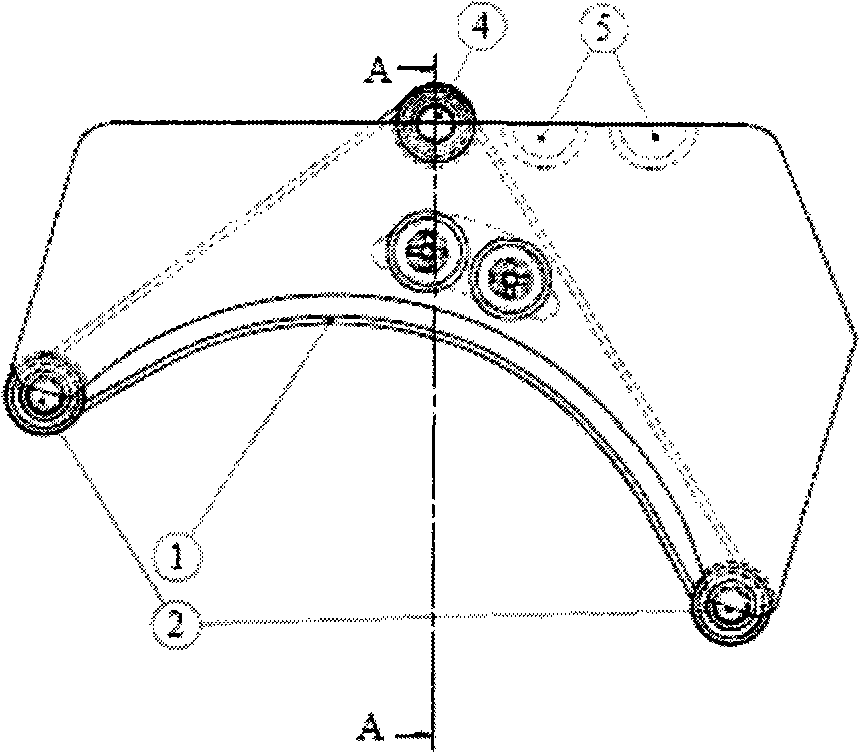

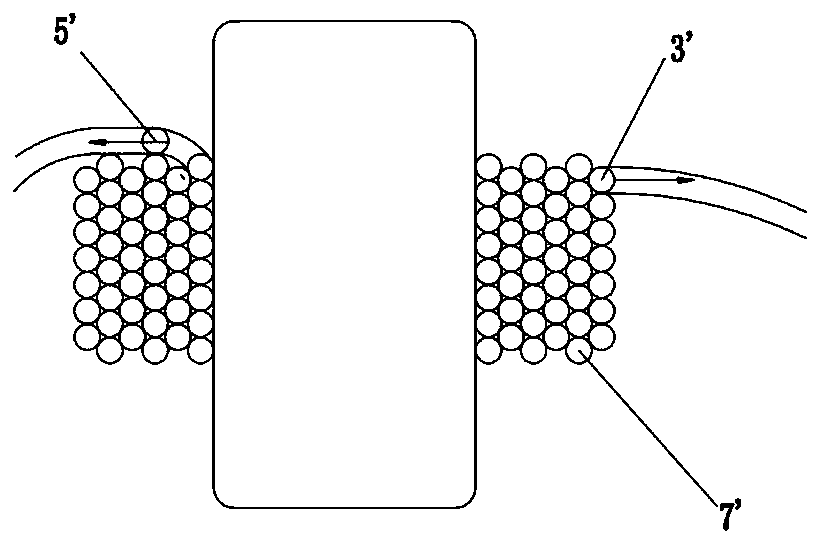

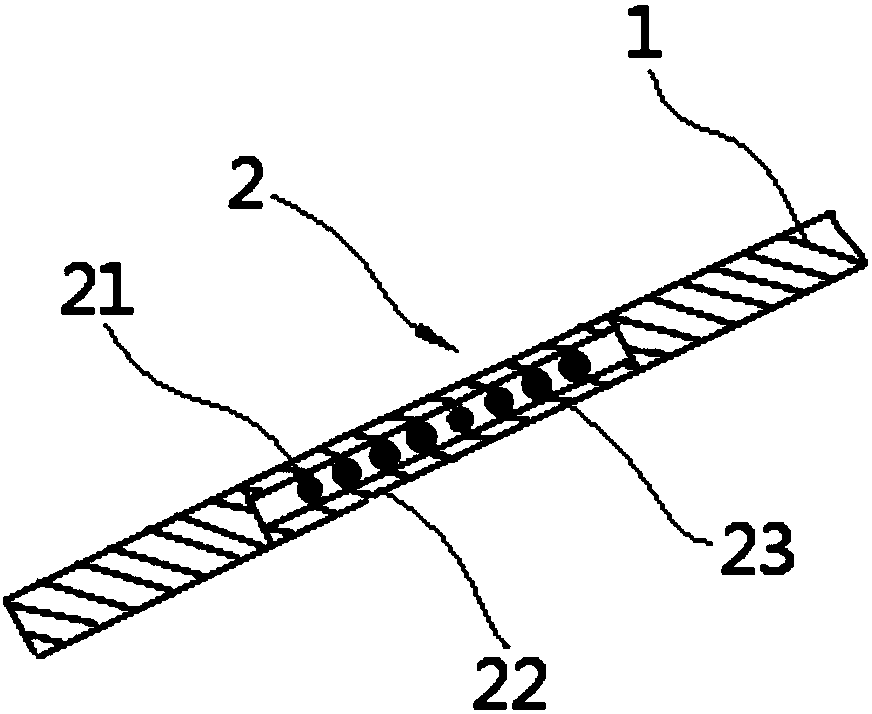

Optical fiber assembly wrapped across gimbal axes

ActiveUS7304296B2Efficient powerStress minimizationWave based measurement systemsDirection controllersFiberRange of motion

A control mechanism pins an optical fiber assembly on and off gimbal and between gimbals to route the assembly from an off-gimbal optical source across the gimbal axis / axes to an on-gimbal optical element so that the fiber assembly moves with the rotation of the gimbals. To accommodate a relatively large range of motion, the control mechanism is suitably configured to route the fiber assembly in a “U-shaped” loop with one end pinned off-gimbal in a stationary guide track and the other end pinned on-gimbal point in a rotating guide track so that the loose fiber assembly is constrained in the concentric tracks on and off gimbal. As the gimbal rotates, the loop seats onto one guiding track and peels off of the other guiding track while always maintaining its U shape. To accommodate a relatively small range of motion in other gimbal configurations, the control mechanism is suitably configured to pin one end of the fiber assembly off-gimbal and pass the fiber assembly directly over the gimbal where it is pinned on the other side of the gimbal. In a multi-gimbal pointer, the fiber assembly preferably exhibits different mechanical stresses as it crosses the different gimbals.

Owner:RAYTHEON CO

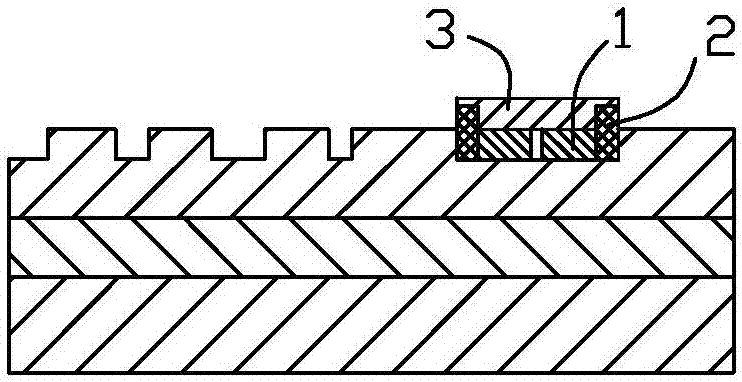

Anti-sliding glaze, anti-sliding brick and preparation method thereof

The invention discloses an anti-sliding glaze which contains the following chemical components by weight percent: 42.8%-48.5% of SiO2, 19.1%-22.8% of Al2O3, 0.1%-0.2% of Fe2O3, 7.0%-9.5% of CaO, 2.5%-5.2% of MgO, 2.1%-8.6% of Na2O, 0.9%-4.1% of K2O, 1.1%-3.3% of ZnO and 2.8%-6.2% of ZrO2. The invention also discloses an anti-sliding ceramic tile and a preparation method for the anti-sliding ceramic tile. The anti-sliding ceramic tile disclosed by the invention can achieve an excellent anti-sliding effect after a layer of anti-sliding glaze is applied to the surface of the anti-sliding ceramic tile, the technology is simple and the cost is low.

Owner:DONGGUAN CITY WONDERFUL CERAMICS IND PARK

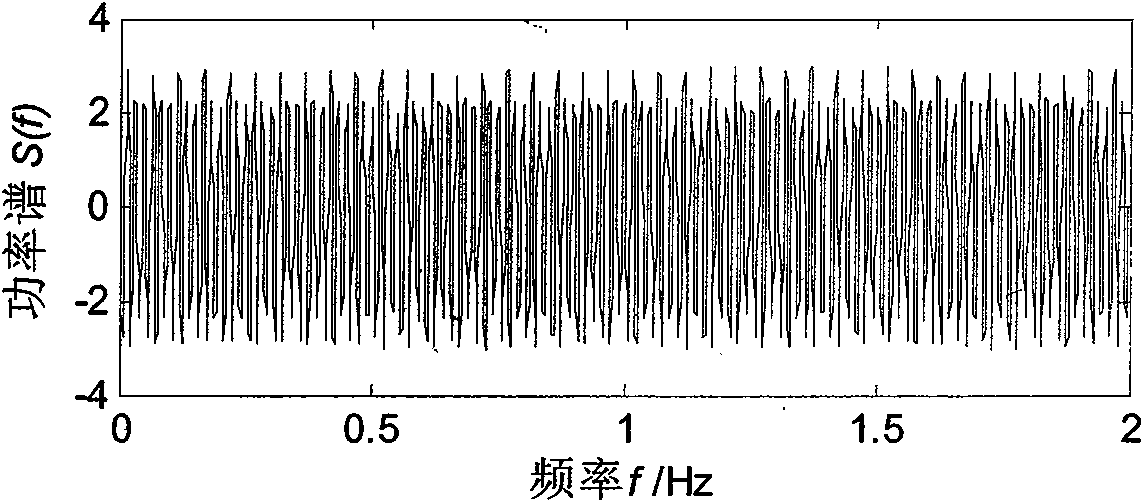

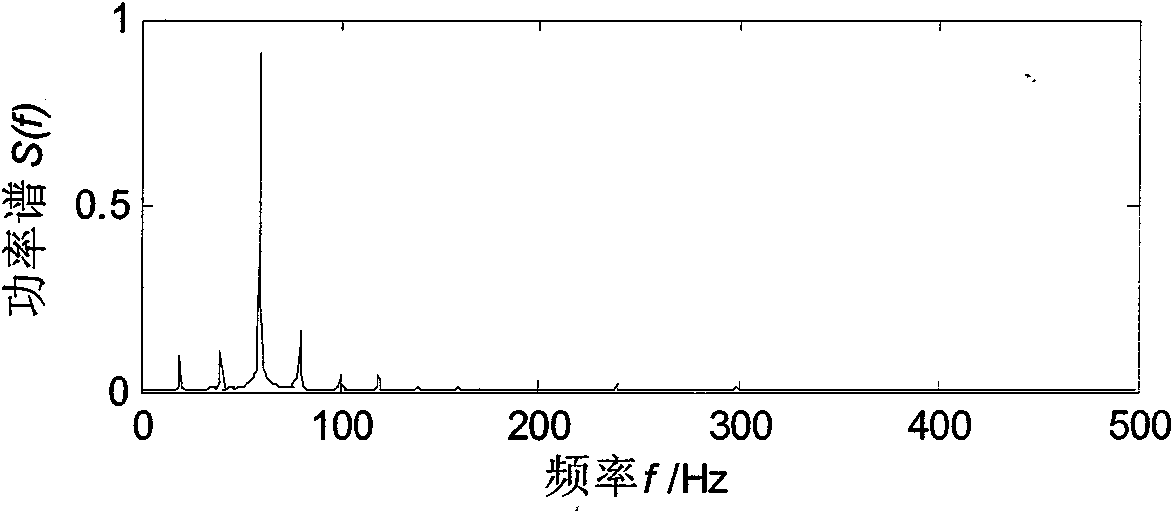

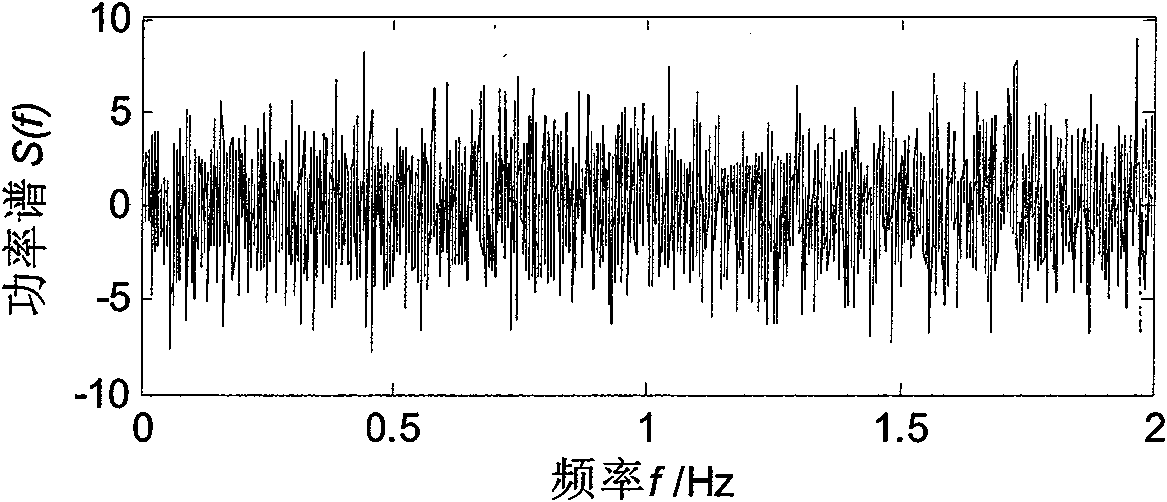

Method for testing stochastic resonance-chaotic weak signal

InactiveCN101561314AAvoid healthy runAvoid rubbingMachine part testingSubsonic/sonic/ultrasonic wave measurementSignal-to-noise ratio (imaging)Signal-to-quantization-noise ratio

The invention discloses a method for testing stochastic resonance-chaotic weak signal, comprising the following steps: firstly, testing whether a frequency signal with weak feature exists by means of self-adapting parameter adjusting stochastic resonance to obtain the magnitude of the most probable signal-to-noise ratio of the signal which is practically to be tested; on the basis, designing a corresponding duffing chaotic vibrator and computing conversion relationship between the input period encouragement of the chaotic vibrator and the output large magnitude periodic motion magnitude under the condition of different signal-to-noise ratio; and finally estimating to obtain the magnitude of the frequency signal with weak feature according to the magnitude of the signal which is practically to be tested by means of stochastic resonance. The method is applicable to test the frequency signal with weak feature in the early detection fields such as physics, chemistry, biology, mechanical failure, and the like, under the condition of low signal-to-noise ratio.

Owner:NAT UNIV OF DEFENSE TECH

Optical fiber assembly wrapped across gimbal axes

ActiveUS20070075237A1Power efficient and reliable and compactEfficient powerWave based measurement systemsDirection controllersFiberRange of motion

A control mechanism pins an optical fiber assembly on and off gimbal and between gimbals to route the assembly from an off-gimbal optical source across the gimbal axis / axes to an on-gimbal optical element so that the fiber assembly moves with the rotation of the gimbals. To accommodate a relatively large range of motion, the control mechanism is suitably configured to route the fiber assembly in a “U-shaped” loop with one end pinned off-gimbal in a stationary guide track and the other end pinned on-gimbal point in a rotating guide track so that the loose fiber assembly is constrained in the concentric tracks on and off gimbal. As the gimbal rotates, the loop seats onto one guiding track and peels off of the other guiding track while always maintaining its U shape. To accommodate a relatively small range of motion in other gimbal configurations, the control mechanism is suitably configured to pin one end of the fiber assembly off-gimbal and pass the fiber assembly directly over the gimbal where it is pinned on the other side of the gimbal. In a multi-gimbal pointer, the fiber assembly preferably exhibits different mechanical stresses as it crosses the different gimbals.

Owner:RAYTHEON CO

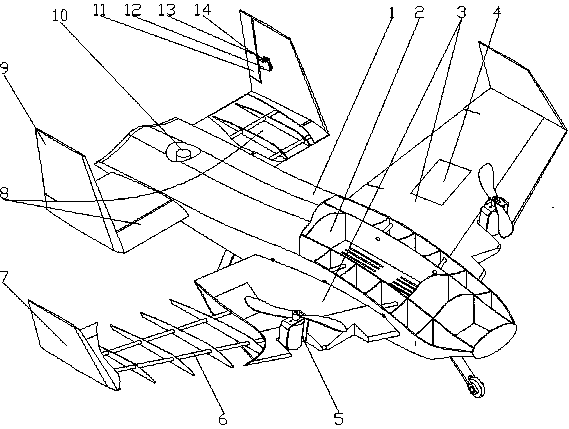

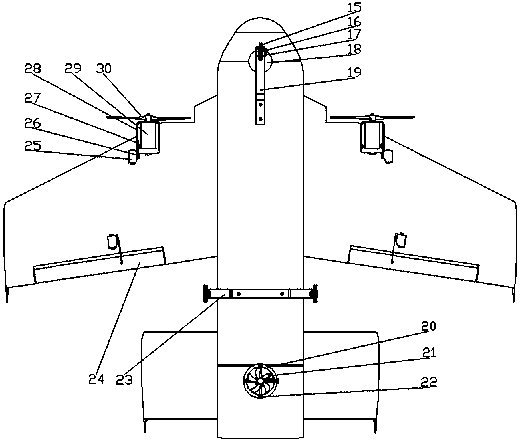

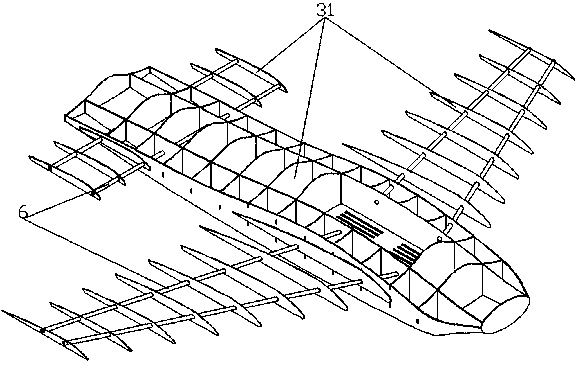

Vertical take-off and landing model aircraft unmanned aerial vehicle

InactiveCN103538714ALower requirementExtend flight durationWeight reductionPower plant typePropellerAutomotive engineering

The invention provides a vertical take-off and landing model aircraft unmanned aerial vehicle. The vertical take-off and landing model aircraft unmanned aerial vehicle is provided with a rotatable screw propeller, an undercarriage and a solar charging system, overcomes the defects of the conventional model aircraft unmanned aerial vehicle, can vertically take off and land in situ, reduces the requirements on the airfield, can quickly fly at the speed of a flying wing type unmanned aerial vehicle and can also suspend like a helicopter; the undercarriage can protect the body during landing to prevent collision with the ground, and the solar charging system can prolong the duration of flight. In addition, the body is a light wood thin plate framework; a body shell is formed by additionally coating epoxy resin on carbon fiber cloth and is then assembled with the framework; the structure has the beneficial effects that the overall weight of the unmanned aerial vehicle model is reduced, meanwhile the body strength is improved, the decoration to the outer surface is facilitated and a more attractive appearance is achieved.

Owner:张明 +1

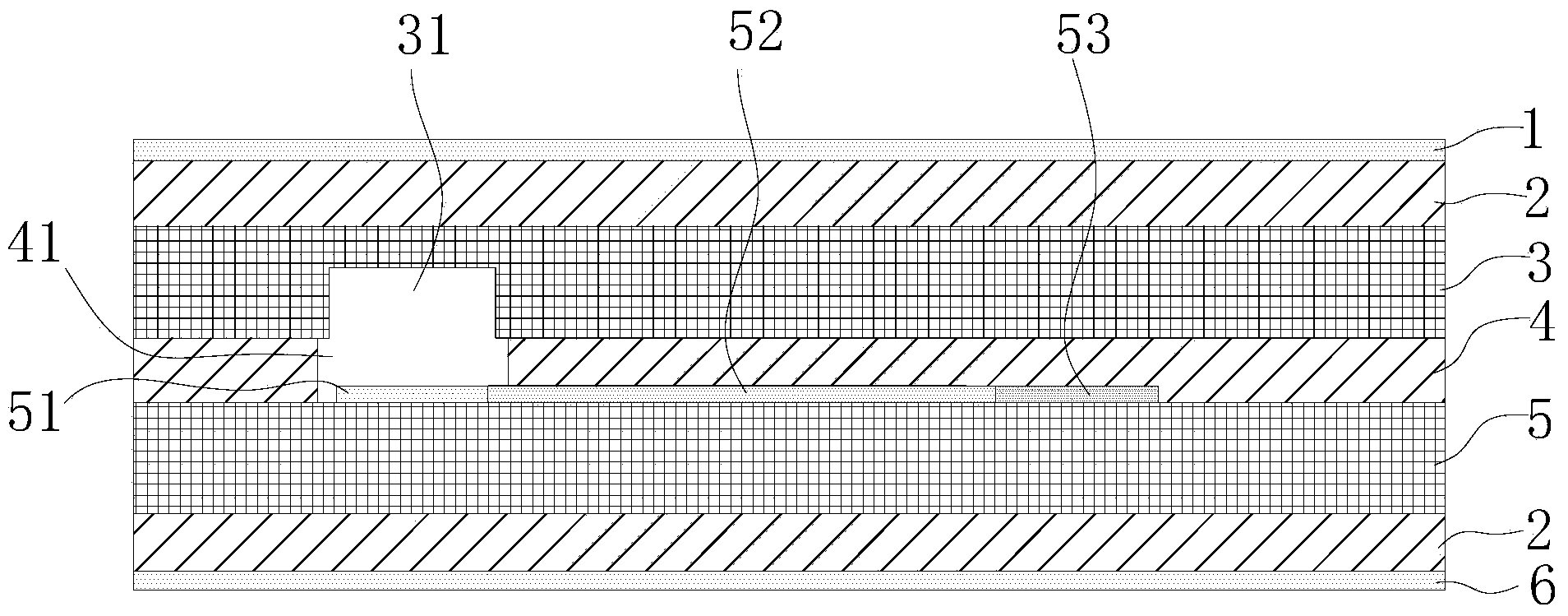

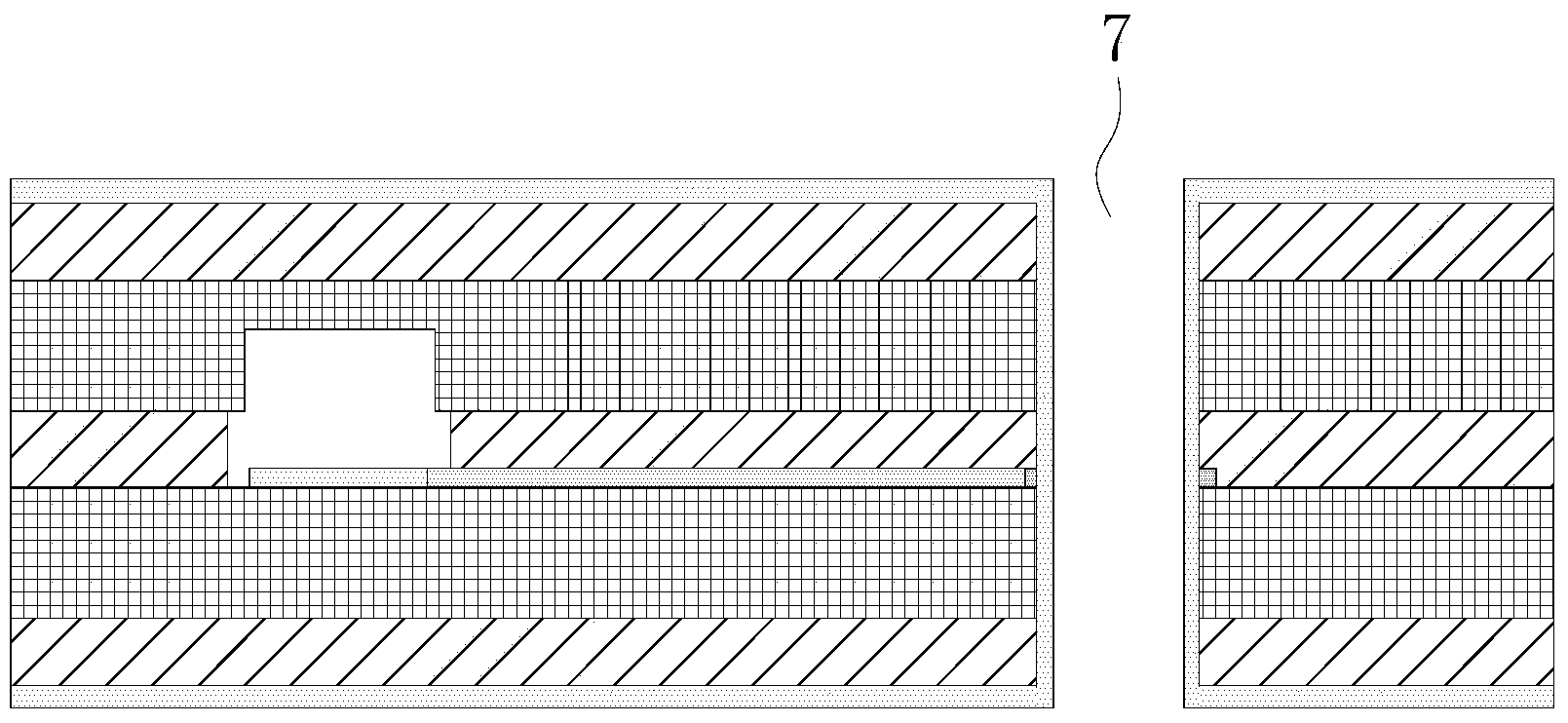

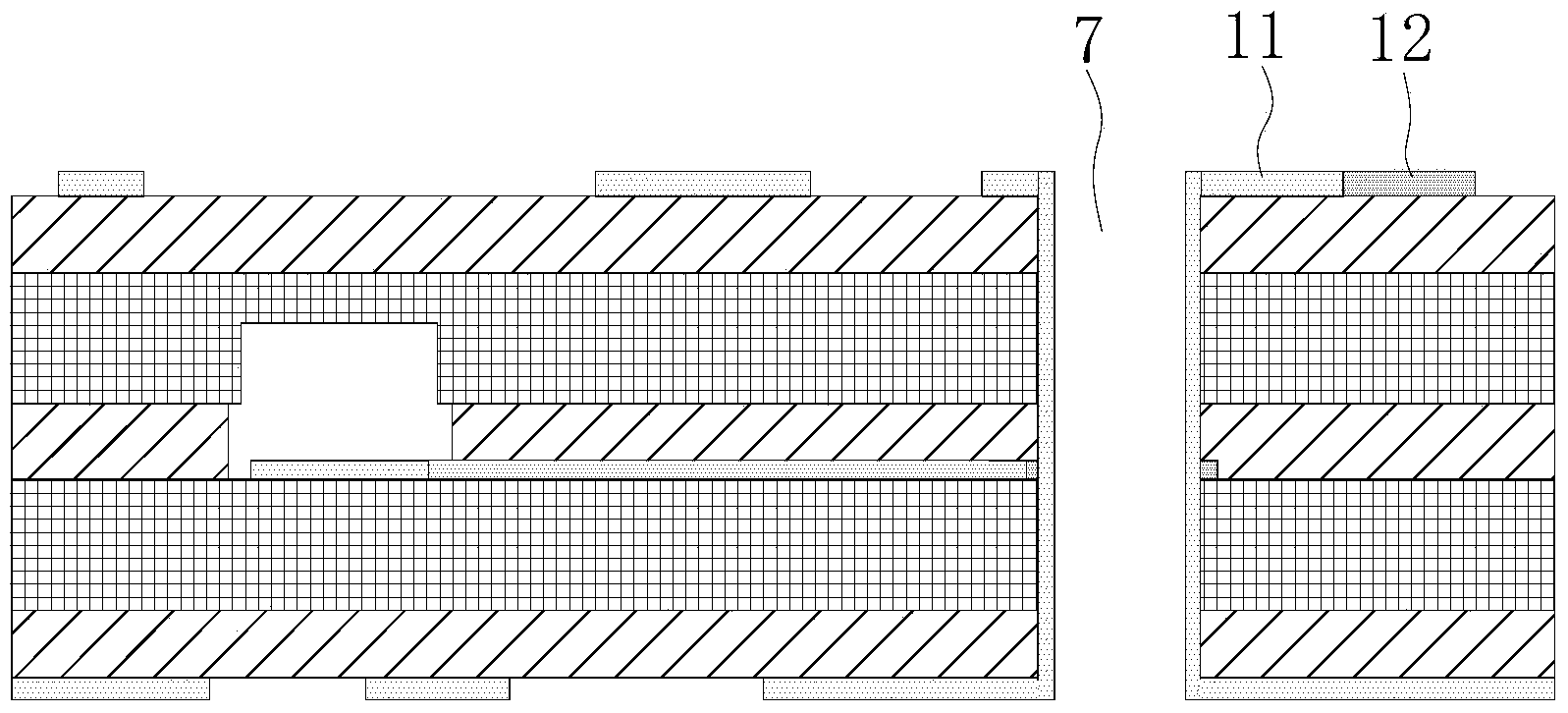

Method of forming deep blind groove in printed circuit board (PCB)

InactiveCN104363720AAvoid stickingAvoid poor fitMultilayer circuit manufacturePrinted element electric connection formationSolder maskArchitectural engineering

The invention relates to the technical field of printed circuit board (PCB) production, in particular to a method of forming a deep blind groove in a printed circuit board (PCB). The method includes forming a window in a first half cured sheet and pre-forming a groove in a second core plate before pressing, drilling a through groove after manufacturing a resistance welding layer, removing a block above the groove, and obtaining the deep blind groove. The depth of the through groove is reduced, dust can be discharged conveniently, and coked dust clinging to the welding disc of the bottom of the groove is eliminated; the depth of the groove is 2 / 3 of the thickness of the second core plate, and the unqualified pressing of a block below the bottom of the groove is avoided; the welding disc of the bottom of the groove is exposed after the resistance welding layer is obtained, the oxidation of the welding disc of the bottom of the groove in the air can be reduced, and the welding disc of the bottom of the groove is prevented from being scraped; a first guide wire, a first welding disc and a first metal through hole which are communicated with the welding disc of the bottom of the groove sequentially are arranged, the surface of the welding disc of the bottom of the groove is processed in an electroplating manner, and the problem that since the flowability of liquid drug of the deep blind groove is low and the liquid drug cannot be exchanged, planting omitting of the welding disc of the bottom of the groove occurs is overcome.

Owner:SHENZHEN SUNTAK MULTILAYER PCB

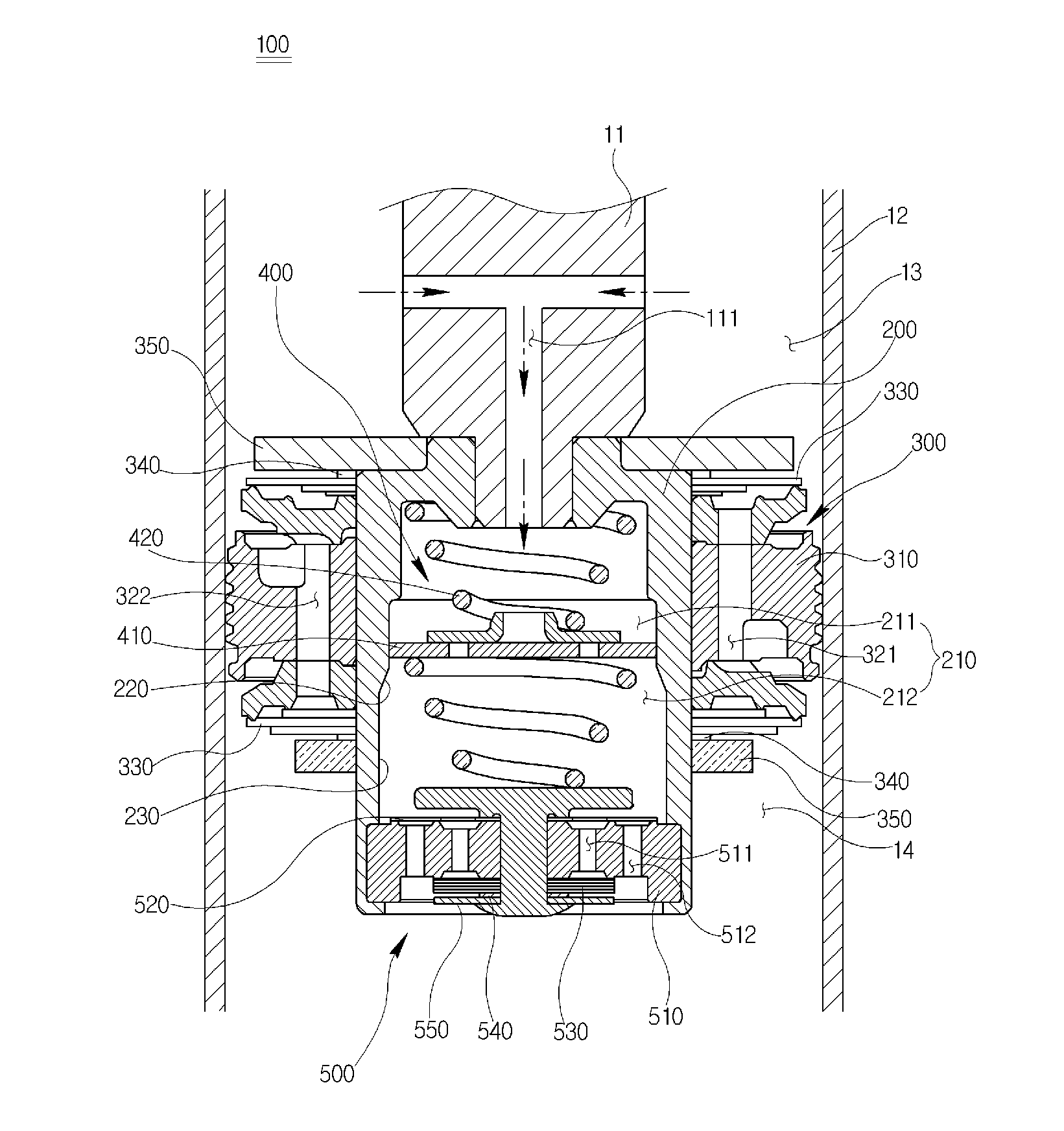

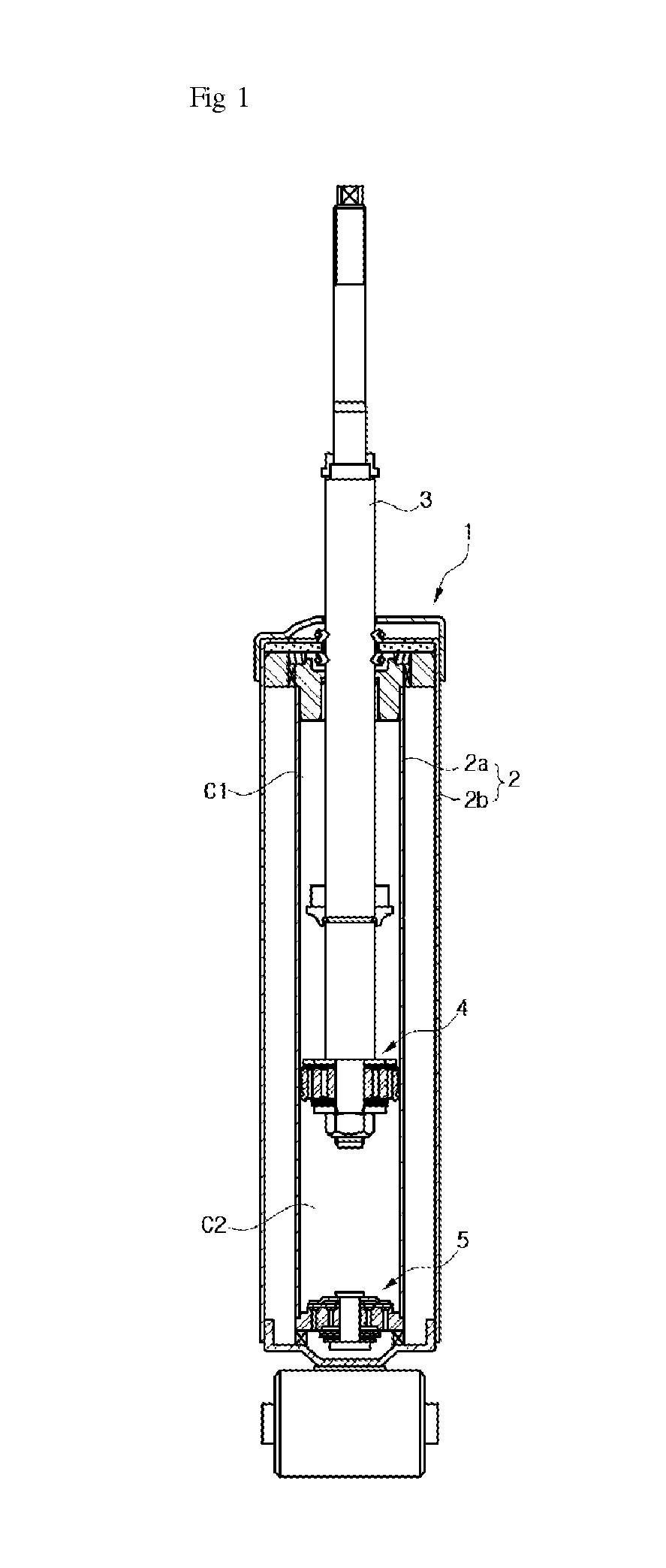

Piston valve of shock absorber

ActiveUS20140048366A1Good effectFully adsorbedSpringsShock absorbersUltrasound attenuationCylinder block

Provided is a piston valve of a shock absorber which can achieve both an effect of varying an attenuation force according to a pressure and an effect of varying an attenuation force according to a frequency region. The piston valve includes: a main valve unit coupled to a lower end of a piston rod formed with an orifice hole, to divide an inside of a cylinder into an extension chamber and a compression chamber, the main valve unit generating an attenuation force according to a difference of pressure between the extension chamber and the compression chamber; and a frequency sensitive valve unit installed at one side of the main valve unit and configured to generate an attenuation force according to a frequency of hydraulic fluid delivered through the orifice hole of the piston rod, wherein the frequency sensitive valve unit is installed within the main valve unit.

Owner:HL MANDO CORP

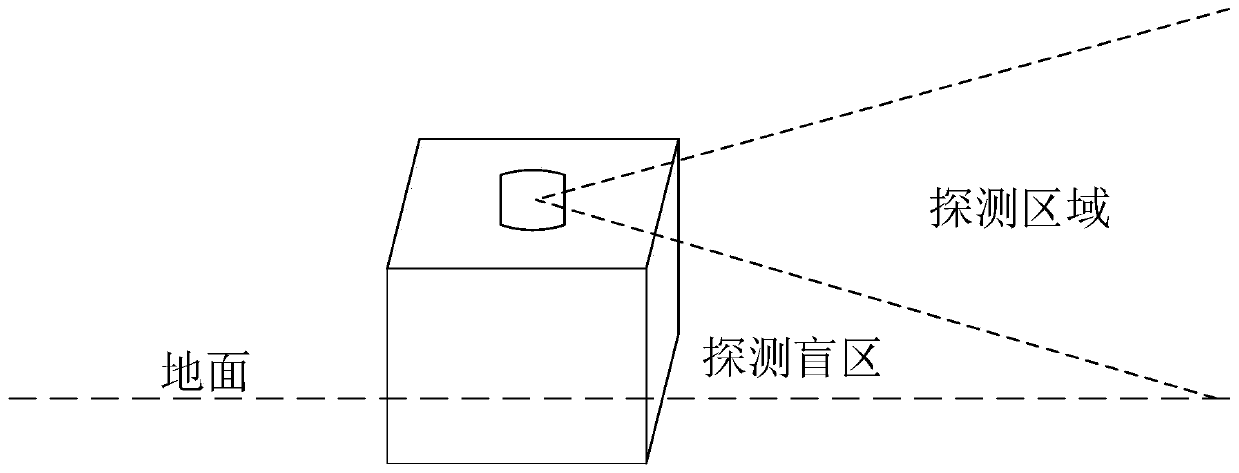

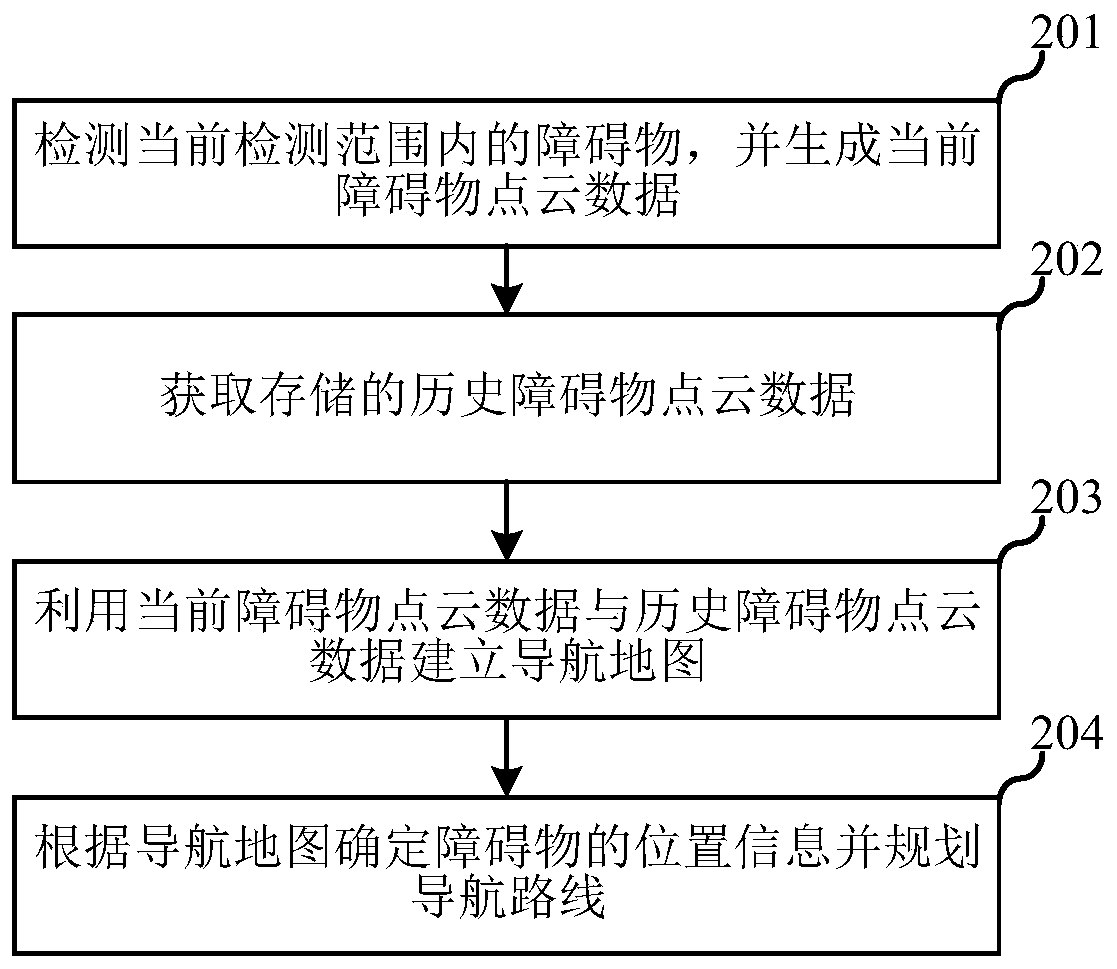

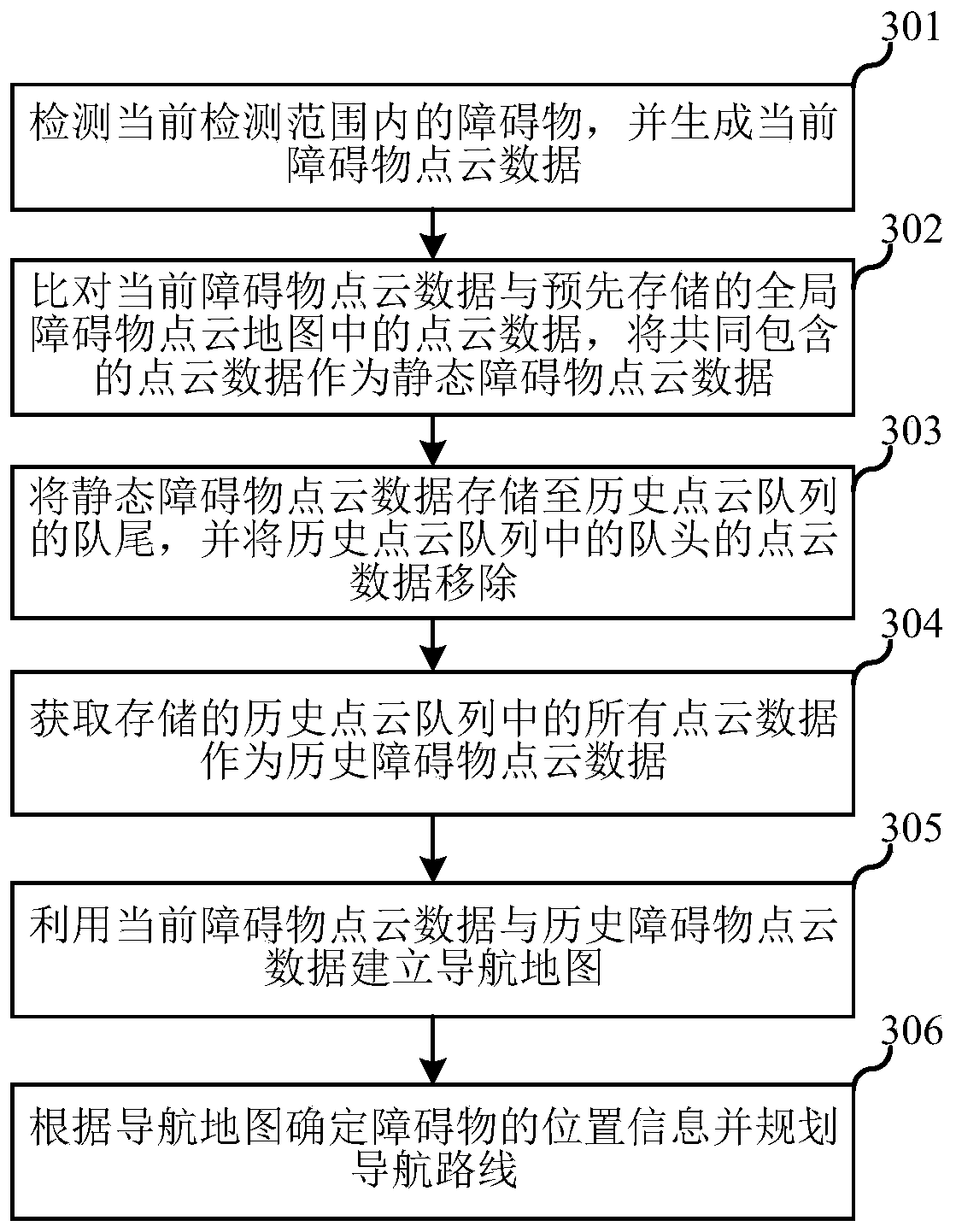

Robot obstacle avoidance method and device, robot and storage medium

ActiveCN111123949ASmooth travelAvoid rubbingPosition/course control in two dimensionsPoint cloudObstacle avoidance

The embodiment of the invention relates to the field of mobile robots, and discloses a robot obstacle avoidance method and device, a robot and a storage medium. The method comprises the following steps: detecting an obstacle in a current detection range, and generating current obstacle point cloud data; acquiring stored historical obstacle point cloud data; and establishing a navigation map by utilizing the current obstacle point cloud data and the historical obstacle point cloud data, determining position information of the obstacle according to the navigation map, and planning a navigation route. According to the method, the obstacle which can be detected by the robot exists in the navigation map of the robot, the obstacle in the blind area detected by the robot at the current moment also exists in the navigation map of the robot, and the robot can be effectively prevented from being scratched according to the navigation route planned by the established navigation map.

Owner:CLOUDMINDS SHANGHAI ROBOTICS CO LTD

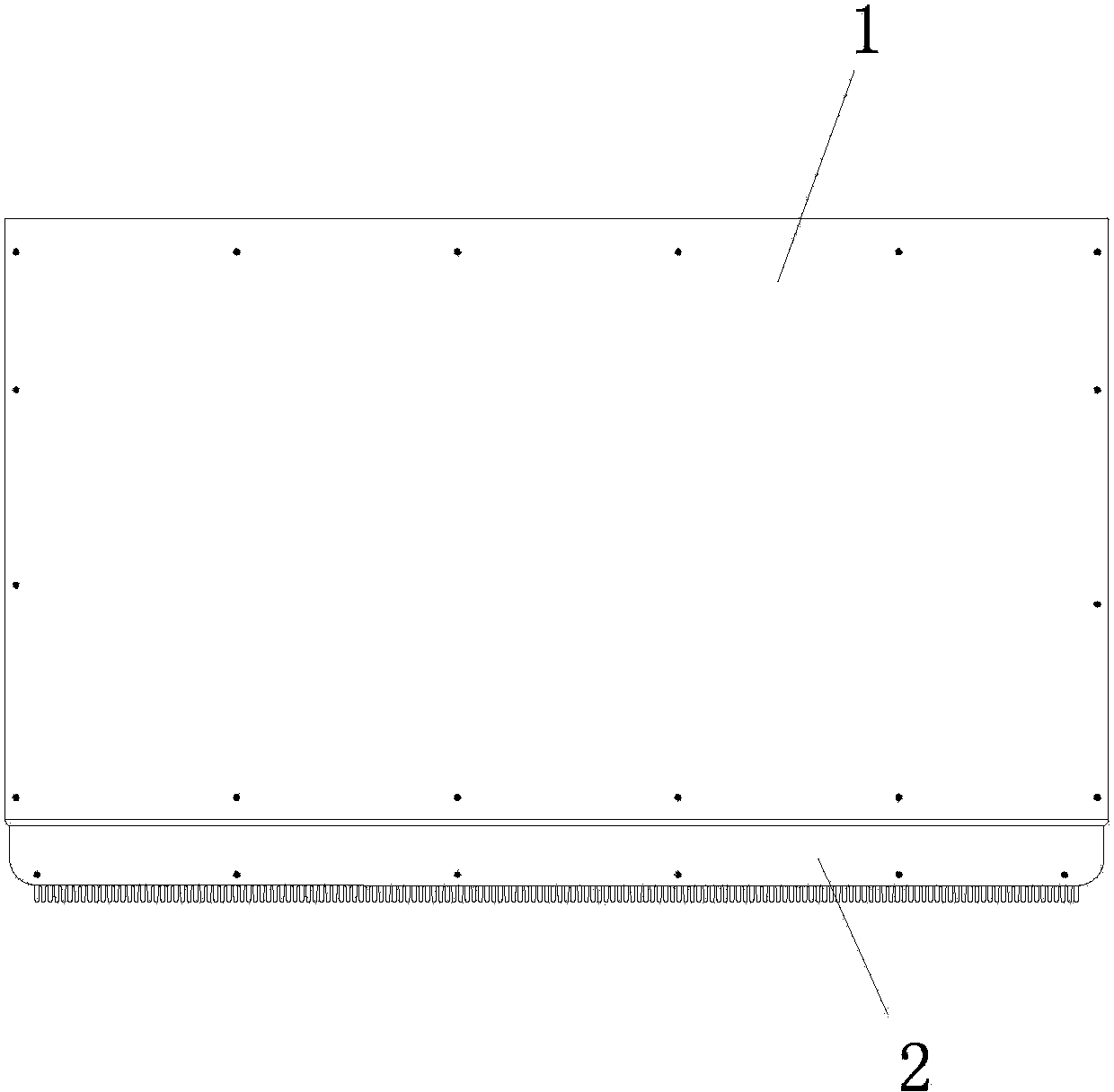

Cereal seed sowing device with detachable elastic rotating seed protection device

ActiveCN101278619AAvoid rubbingAvoid damageSeed depositing seeder partsBroadcast seedersGear wheelEngineering

The invention relates to a grain feed with a detachable elastic rotation seed retaining device; the grain feed mainly consists of a shell of the grain feed, a seed-metering wheel, a seed brushing wheel, a seed filling chamber, a seed control baffle of the seed filling chamber and a seed spout, and is characterized in that the invention further includes the detachable elastic rotation seed retaining device which consists of an elastic seed retaining band, a seed retaining band axis, a tension axis, a bearing and a bracket; the elastic rotation seed retaining device is matched with the seed-metering wheel for work, the seed retaining band is an elastic rubber band with an enclosed structure, one section of the elastic seed retaining band firmly leans on the outer surface of the seed-metering wheel to form a seed retaining zone between the seed brushing wheel and the seed spout in virtue of elasticity thereof. The power that drives the elastic rotation seed retaining band to rotate derives from the friction of the surface of the seed-metering wheel, or the power is transmitted to the seed retaining band axis from the axis of the seed-metering wheel through a gear or a chain so as to realize the rotation.

Owner:SOUTH CHINA AGRI UNIV

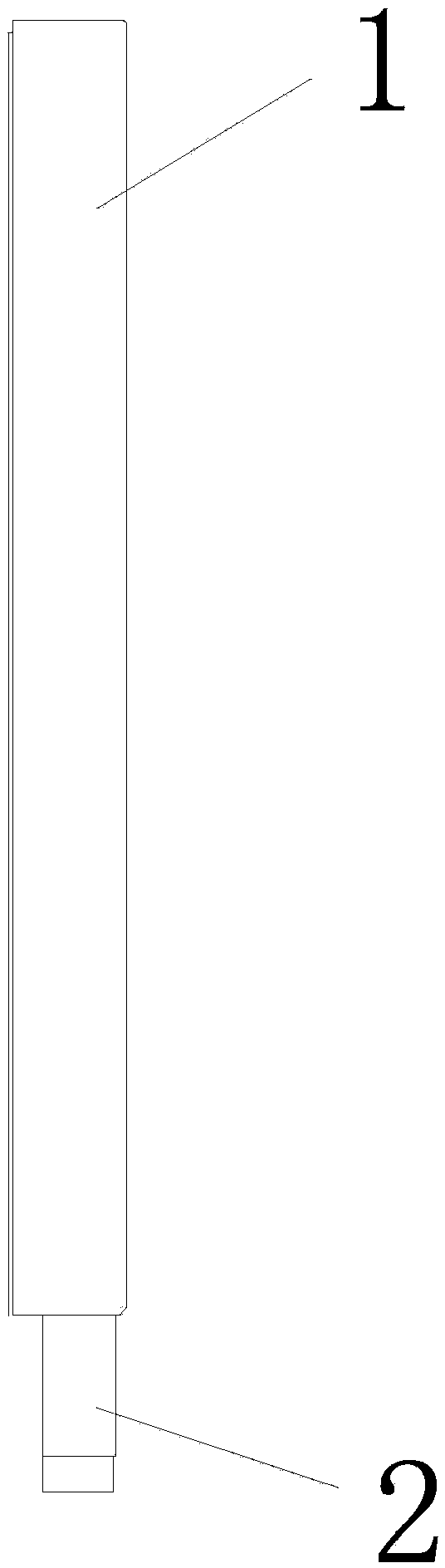

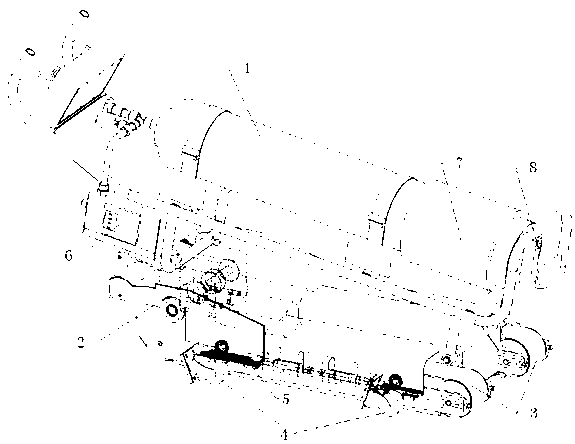

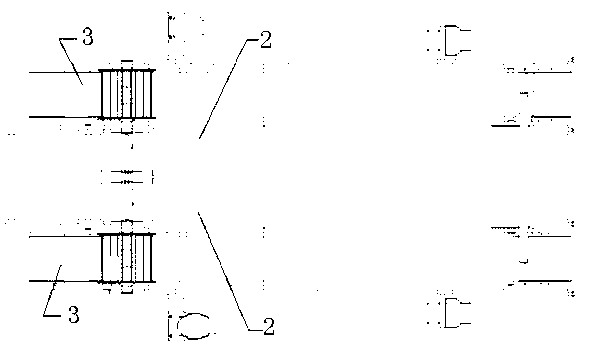

Platform extensible pedal

ActiveCN103879409AEasy and quick passAvoid rubbingRailway componentsRailway stationStops deviceEngineering

The invention discloses a platform extensible pedal which comprises a cuboid-shaped fixed pedal box (1) horizontally fixed on a platform. An opening is formed on one side, facing rails, of the fixed pedal box, a movable pedal (2) is arranged at the opening, a rack (3) is horizontally fixed on the inner side face, positioned inside the fixed pedal box, of the movable pedal and driven by a driving component to push the movable pedal to retract into or extend out of the fixed pedal box, and the driving component is controlled by a controller (23). Before a train draws up at a station, the movable pedal retracts to leave big space to the rails, quick passing of the train is facilitated, and friction and collision of the train and the platform are avoided; after the train draws up at the station and comes to a complete stop, the movable pedal extends out to enable a compartment of the train and the platform to be in seamless connection for the convenience of passengers to go in and out; a pressure sensor and a stopping device are mounted in the movable pedal, and the movable pedal does not retract when a person stands on, so that safety and reliability in use are realized.

Owner:FANGDA INTELLIGENT INNOVATION TECH CO LTD

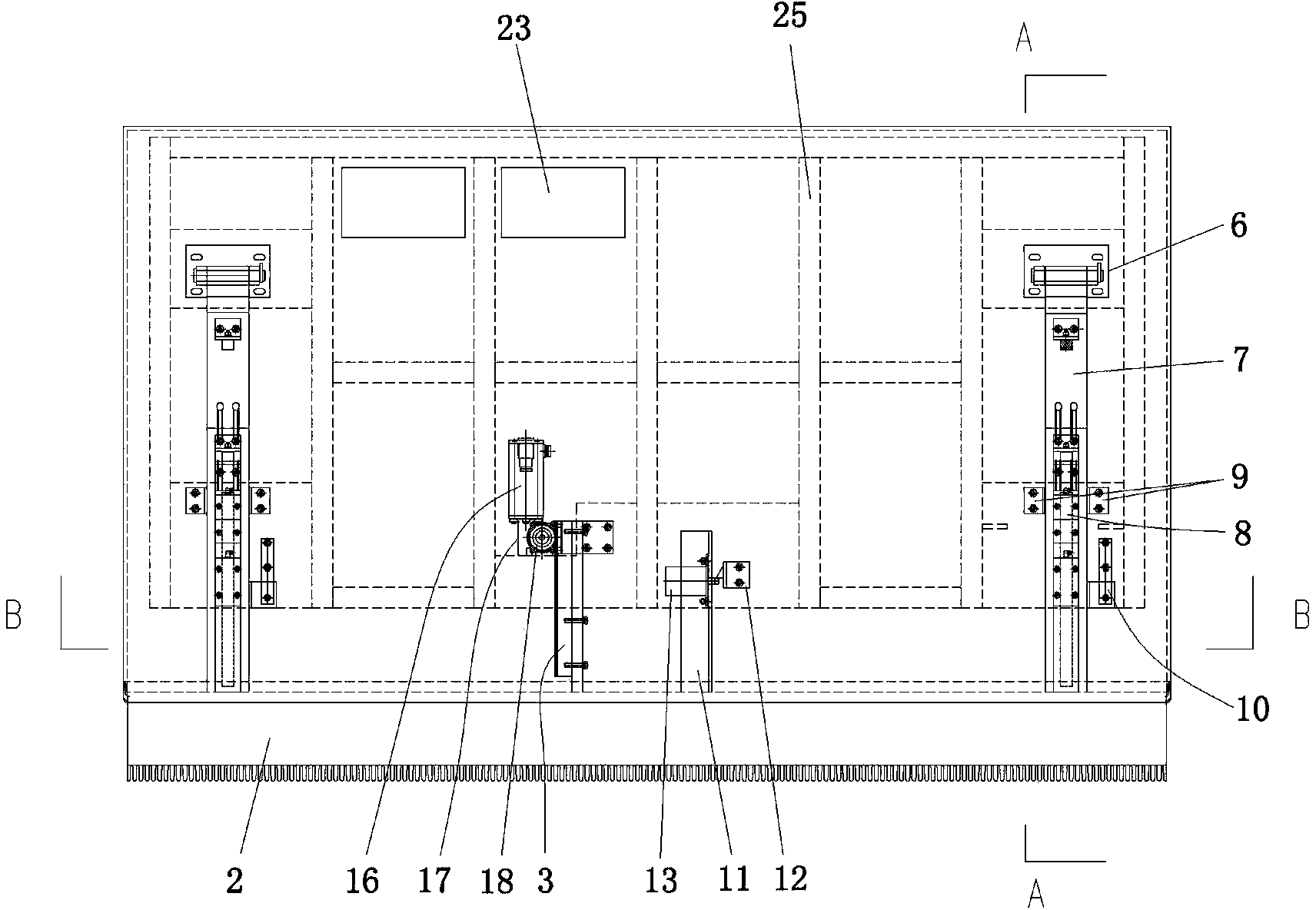

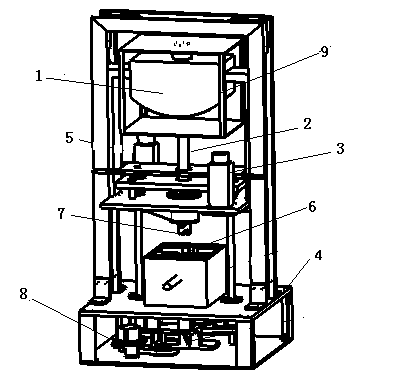

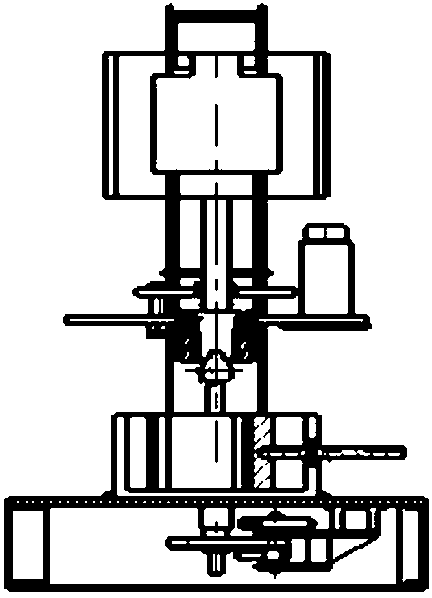

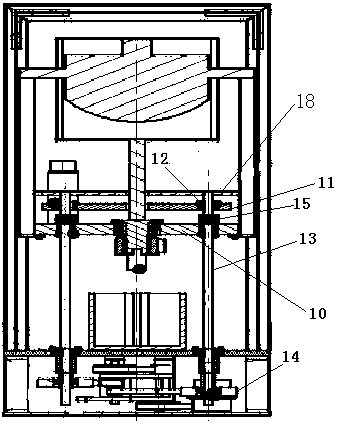

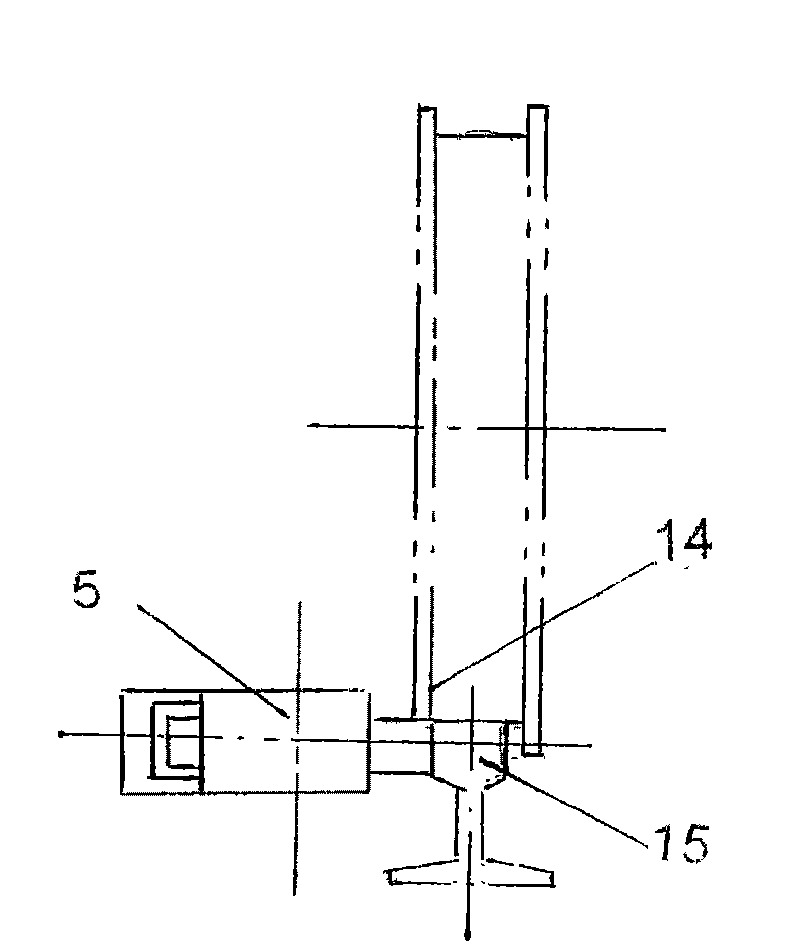

Vibration assisted well drilling simulation device

InactiveCN103233681AHigh speed percussion drillImpact drill fasterDrilling machines and methodsMotor driveWell drilling

A vibration assisted well drilling simulation device comprises a frame, a column, a servo motor, a rock clamping deivce, lead screw and nut mechanisms, a drill bit, a bearing plate, a loading plate, a rotating motor, a vibration excitation table, a four-side square framework and an impact rod. The clamping deivce is arranged on a base plate of the frame, and the servo motor is arranged at the bottom of the base plate. The lead screw and nut mechanisms are symmetrically arranged on two sides of the clamping deivce, the lower ends of lead screws penetrate through the base plate of the frame and are connected with gears disposed on a motor shaft of the servo motor through gears disposed on the lead screws and synchronous cog belts, the upper ends of the lead screws sequentially penetrate through the bearing plate and the loading plate, and nuts are fixed on the loading plate. The drill bit is arranged at the bottom of the bearing plate disposed above the rock clamping device, and the rotating motor drives and is connected with the drill bit. The vibration excitation table moves vertically through matching of an outer side guide rail and an inner side guide rail. The four-side square framework is vertical and surrounds the vibration excitation table, and the impact rod is vertically arranged at the bottom of the four-side square framework. The vibration assisted well drilling simulation device is ingenious in concept, simple in structure and high in well drilling efficiency, and greatly improves well drilling speed.

Owner:YANGZHOU UNIV

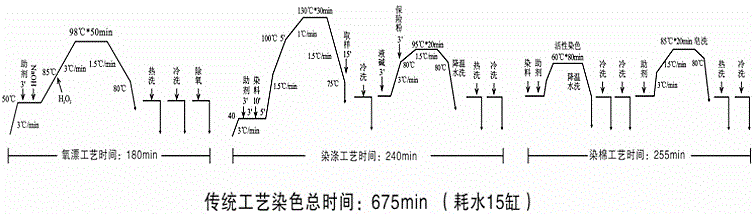

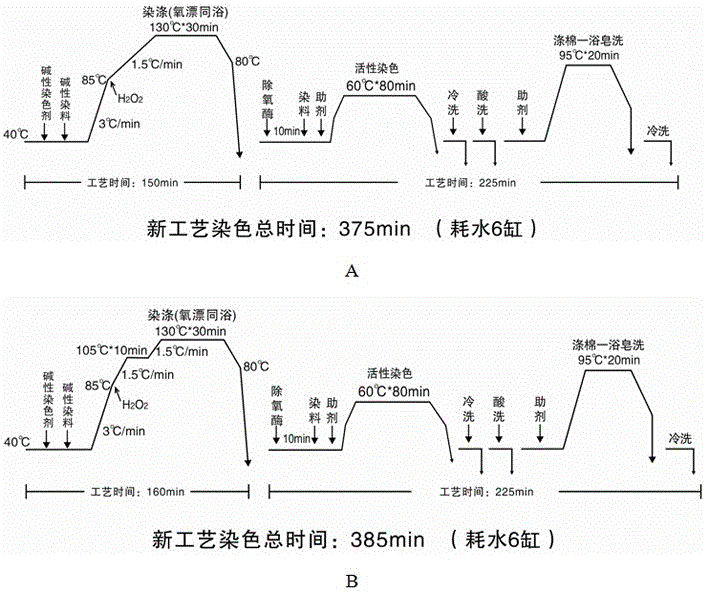

Dyeing method of polyester-cotton blended knitting fabric

ActiveCN106012610AAvoid scratchesAvoid rubbingBleaching apparatusDyeing processPolyesterPulp and paper industry

The invention discloses a dyeing method of polyester-cotton blended knitting fabric. The dyeing method comprises the steps of pre-treatment, dyeing of a polyester part and oxygen bleaching of a cotton part, dyeing of the cotton part and after-treatment. According to the dyeing method disclosed by the invention, dyeing is carried out by adopting a special alkaline polyester-cotton dyeing agent, the technologies of the oxygen bleaching of the cotton part and the dyeing of the polyester part are combined into one, washing of the polyester part can be omitted, and washing can be carried out only after the dyeing of the cotton part. Compared with traditional craftwork, the dyeing method disclosed by the invention has the advantages that the technological process is greatly simplified, the dyeing time is greatly shortened, the use of water, electricity and steam can be obviously reduced, the production cost is obviously reduced, and the pollution to the ecological environment, particularly the water resource, is reduced.

Owner:石狮市瑞鹰纺织科技有限公司

Multifunctional SF6 inflating trolley

InactiveCN103129591AAvoid rubbingExtended service lifeHand carts with multiple axesHand cart accessoriesFree rotationElectric machinery

The invention discloses a multifunctional SF6 inflating trolley. The multifunctional SF6 inflating trolley comprises a power transfer system for bearing and carrying air bottles and is characterized in that the power transfer system is a double-motor driven caterpillar band system for achieving 360-degree free rotation of a machine. The multifunctional SF6 inflating trolley further comprises a front flat ground walking wheel and a back flat ground walking wheel which are used for walking on the flat ground and are provided with a front flat ground walking wheel rising and falling mechanism and a back flat ground walking wheel rising and falling mechanism for controlling the walking wheels to perform rising and falling driving. The multifunctional SF6 inflating trolley is simple in structure, safe, reliable and labor-saving and improves carrying efficiency.

Owner:STATE GRID JIANGSU ELECTRIC POWER CO LTD MAINTENANCE BRANCH +2

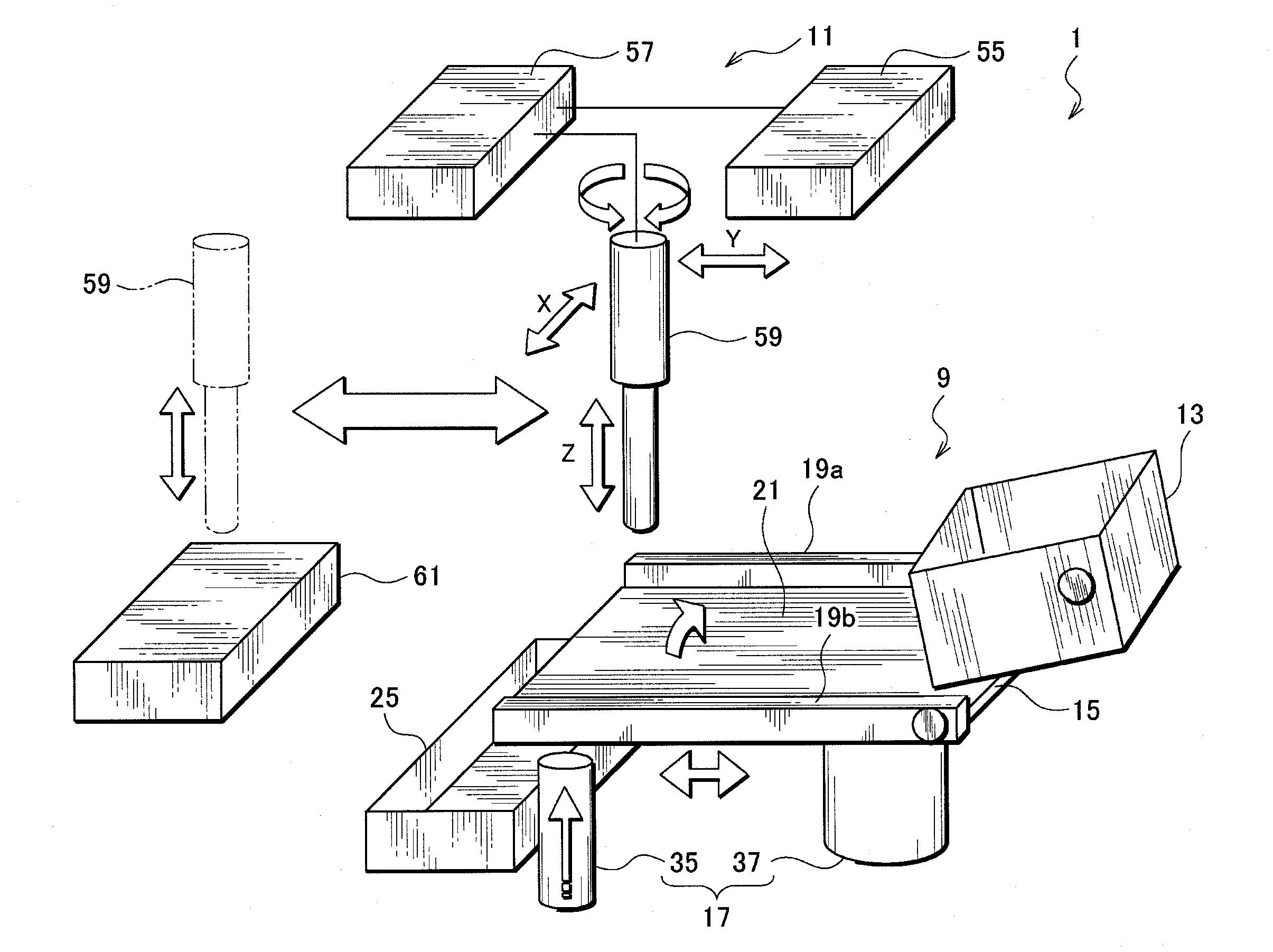

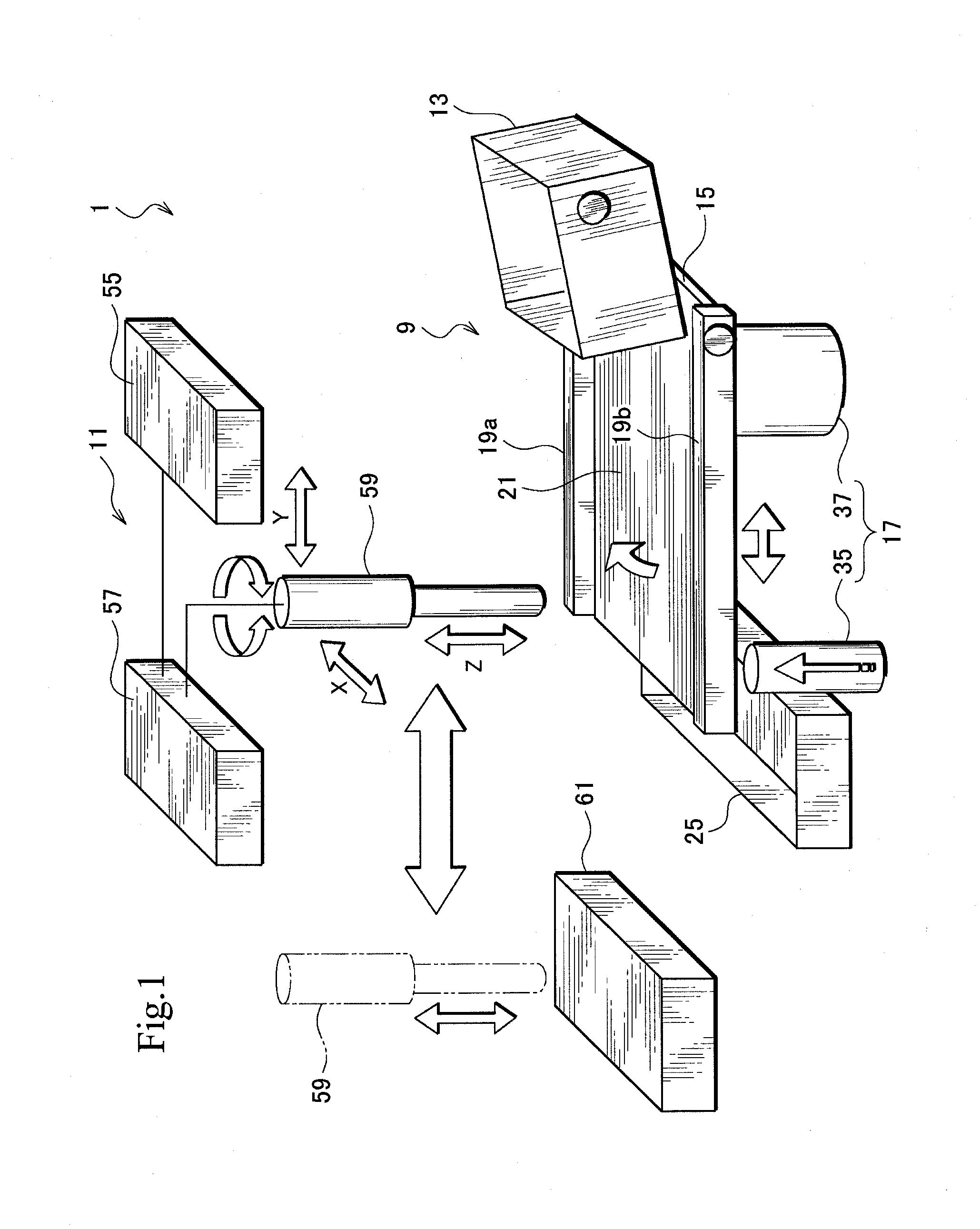

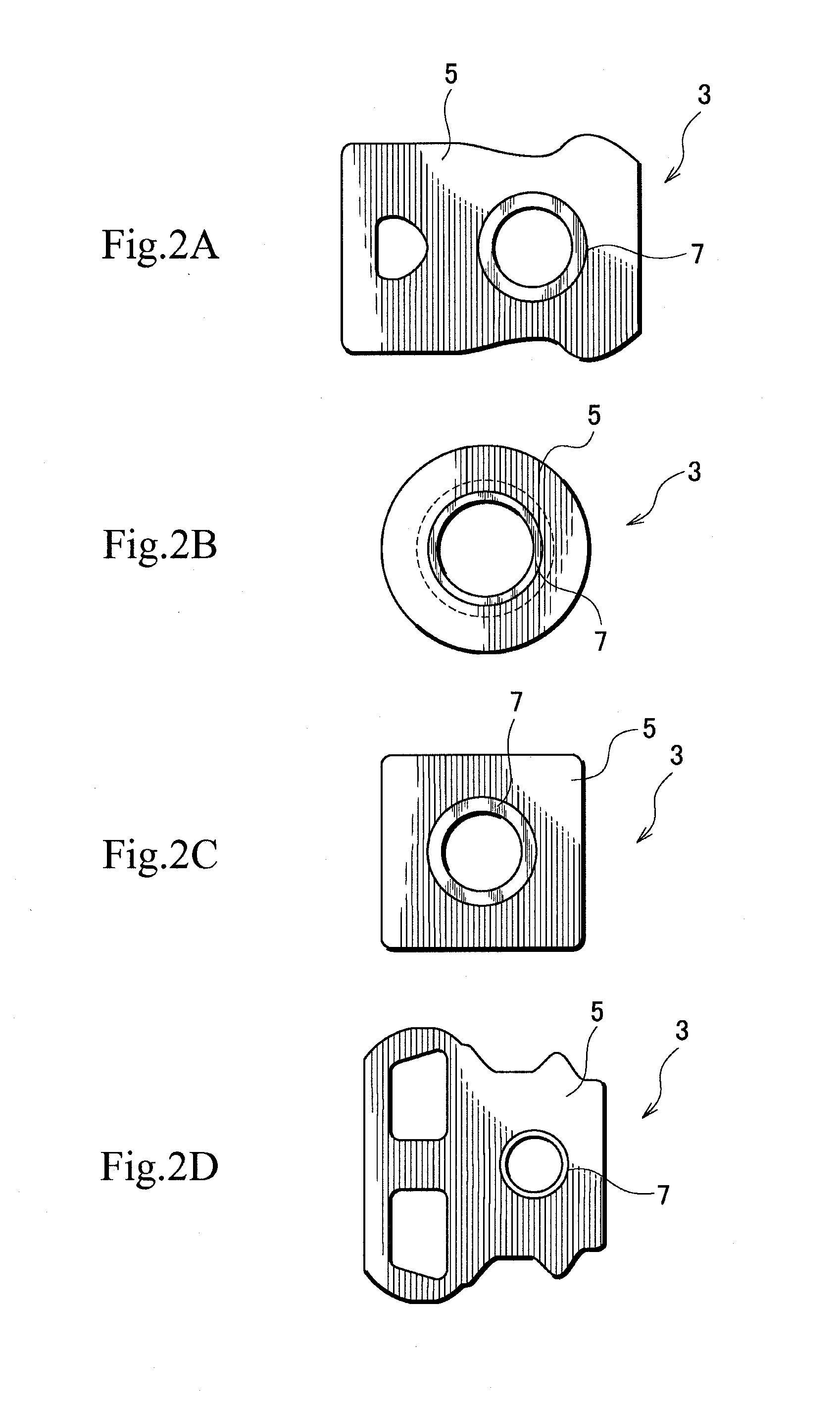

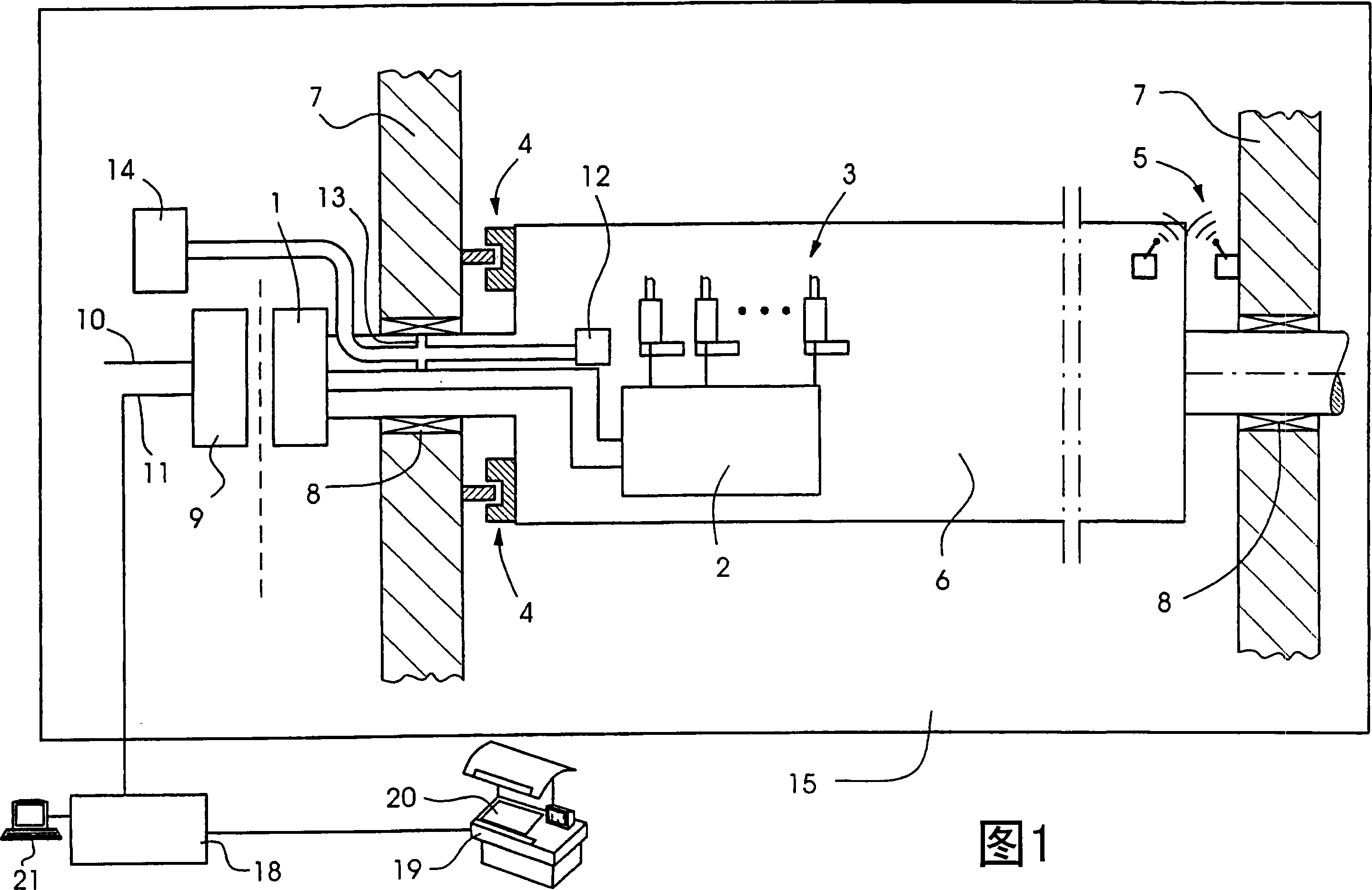

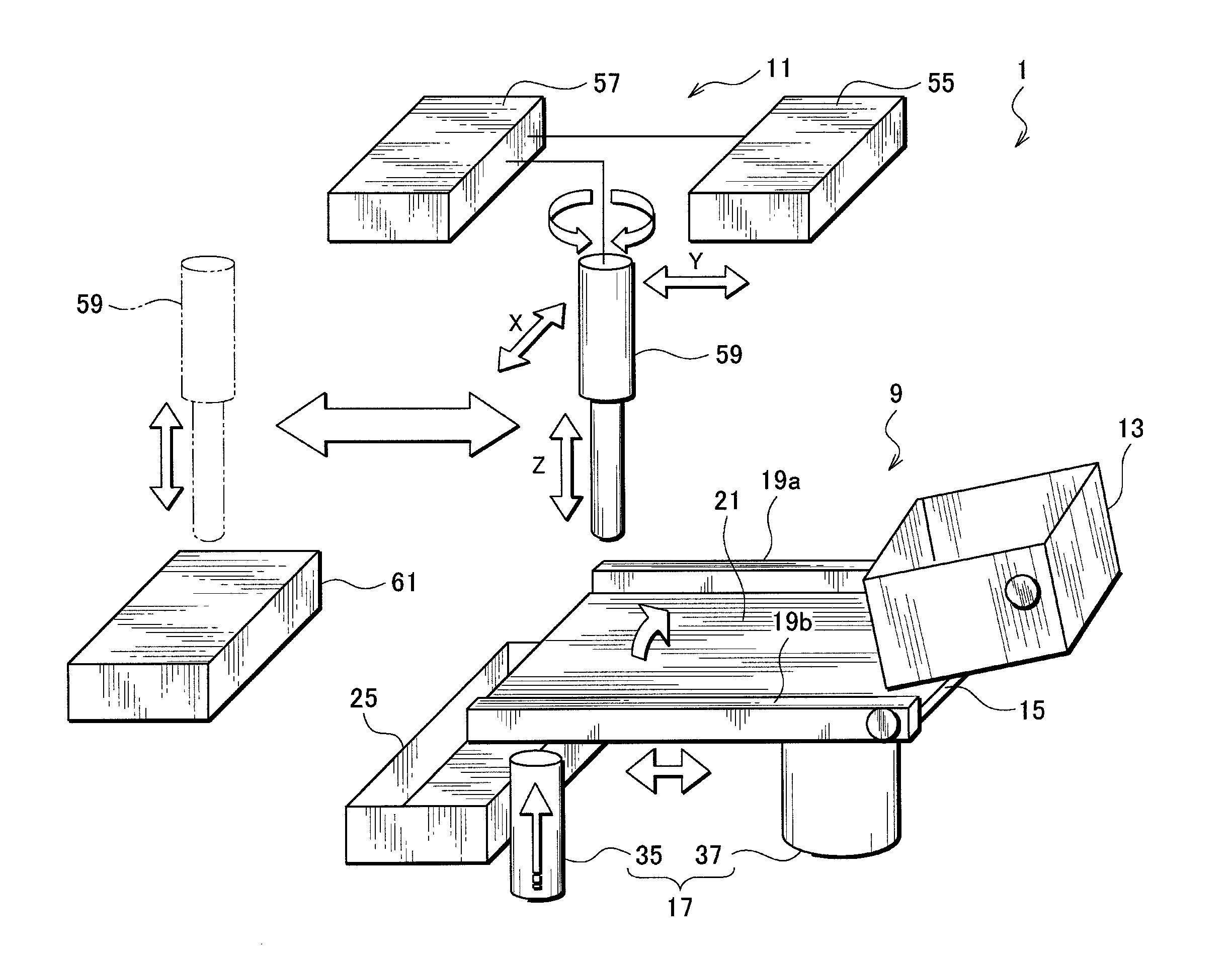

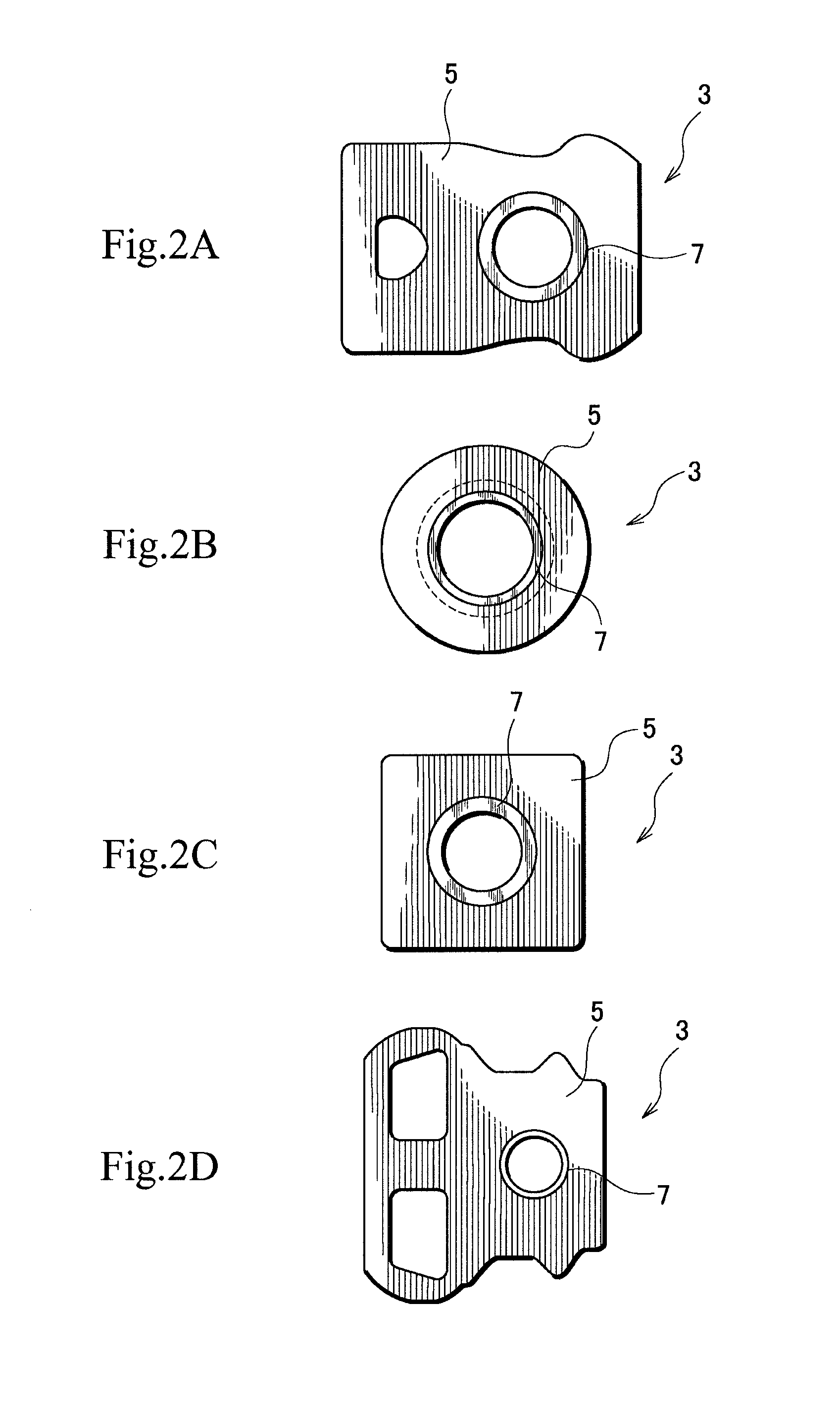

Workpiece feeder and adjustment-and-separation apparatus

ActiveUS20120261232A1Avoid hittingAvoid rubbingControl devices for conveyorsMechanical conveyorsEngineeringMechanical engineering

A workpiece feeder includes a forward stage that separates base plates from one another and adjusts the base plates into correct top-bottom orientation and a pickup unit that individually holds the separated and adjusted base plates and horizontally aligns the held base plate into correct planar posture while feeding the held base plate to a destination. The forward stage includes a stage body that has a stage surface on which the base plates are placed and is movably supported so as to shift the stage surface and a drive unit that applies separate impacts to the stage body so that the stage body moves to apply a bouncing force and a shifting force orthogonal to the bouncing force due to the separate impacts to the base plates.

Owner:NHK SPRING CO LTD

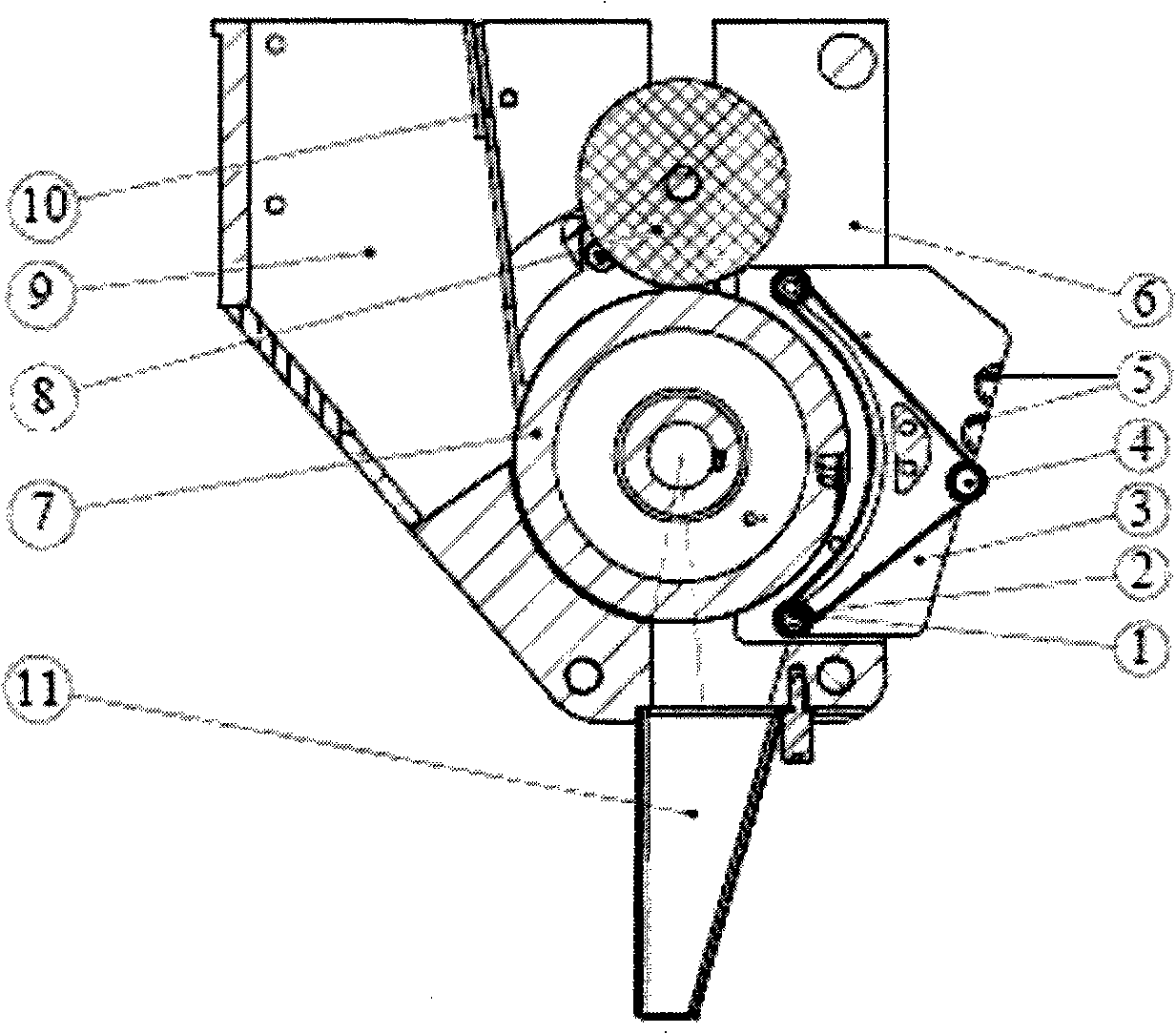

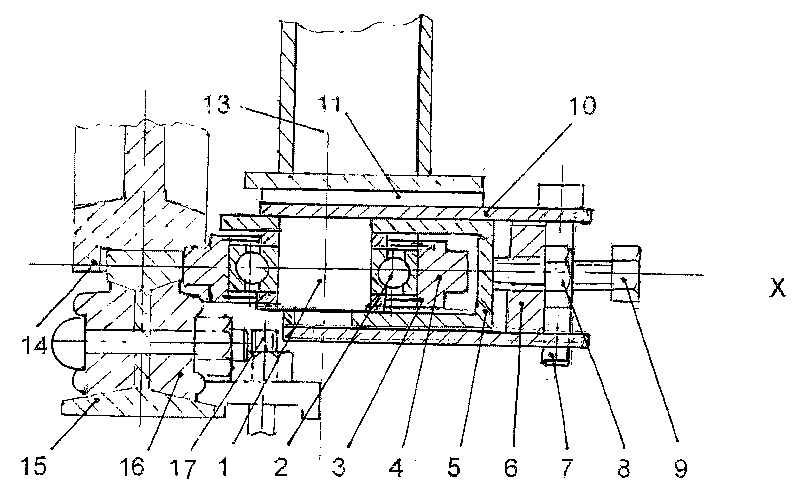

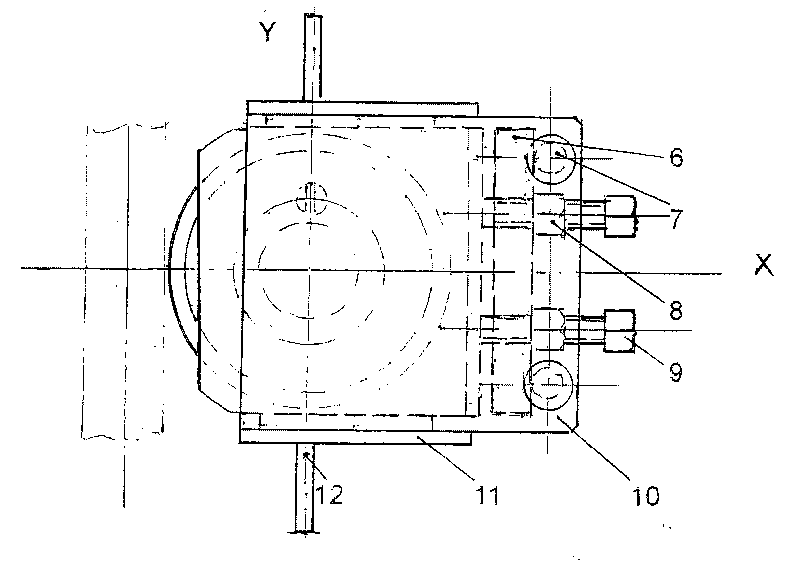

Side guide wheel of crane for preventing track biting of rim

The invention relates to a side guide wheel assembly of bridge type and gantry type cranes for preventing the track biting of a rim. The side guide wheel assembly comprises a side guide wheel (4), a bearing (2), a guide wheel shaft (1) and a guide wheel frame (5). In box-shaped slide slots (10) (11), the acting position of the side guide wheel of the assembly is regulated by a screw rod (9) so as to ensure that a minute gap is reserved between a crane rim (14) and the side face of a steel wheel to prevent that the rim has contacts and frictions with the side face of a steel track and thoroughly avoid a phenomenon that the rim bites the side face of the steel track.

Owner:沈炎源

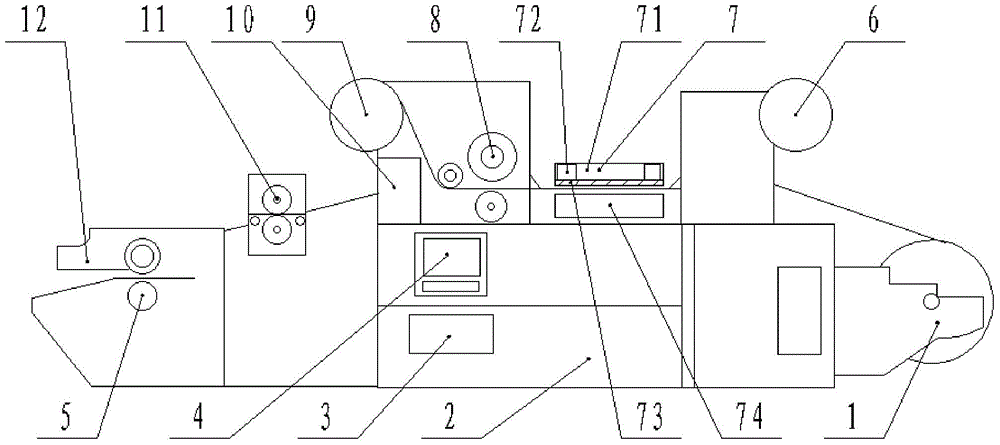

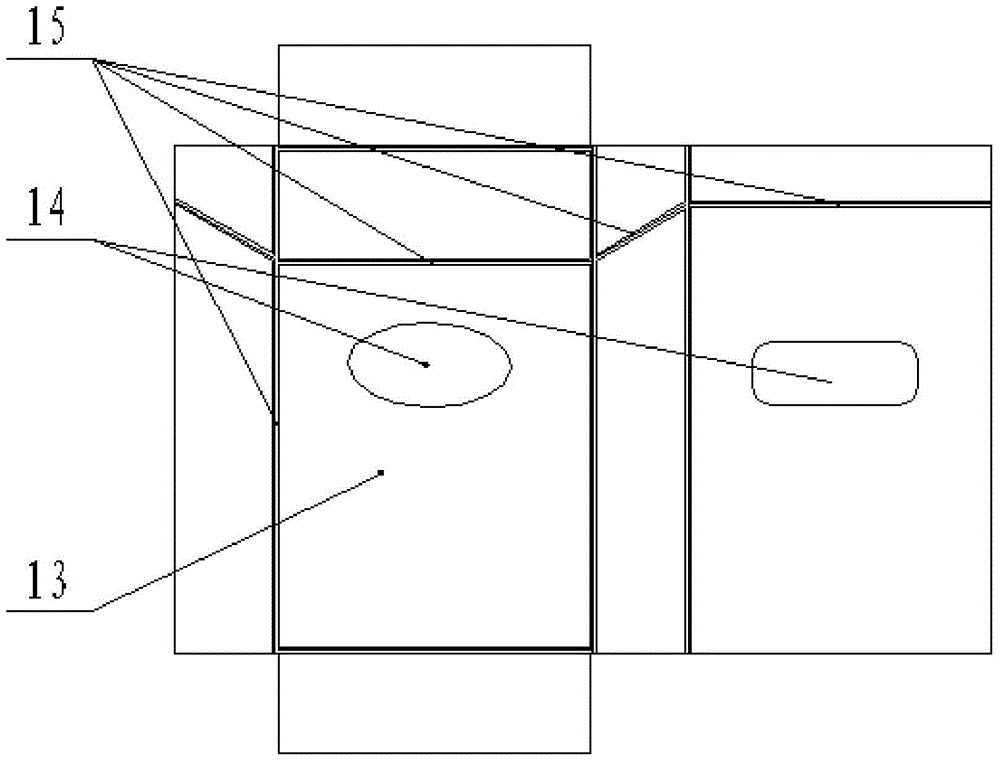

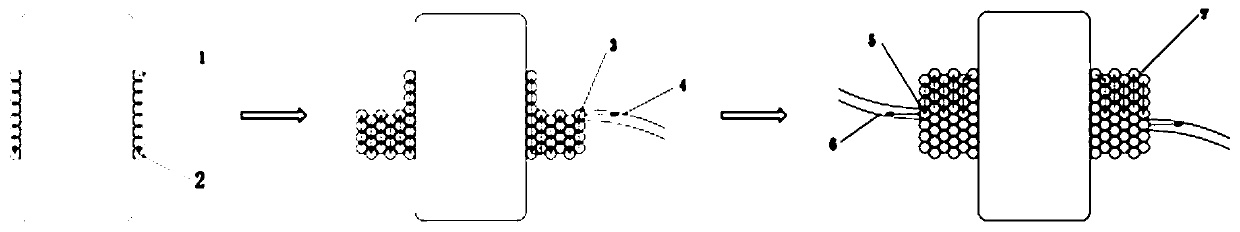

Processing method and integrated processing device for hard shell cigarette packaging box

InactiveCN104626738AIncrease productivityAvoid rubbingRotary pressesBronze printingCardboardEngineering

The invention belongs to the technical field of printing and packaging devices, and particularly relates to a processing method and integrated processing device for a hard shell cigarette packaging box. The processing method comprises the following steps that white cardboard rolls are uncoiled, gilded and printed to form semi-finished paperboards; the paperboard are dried; the pressing mark technology is carried out on the semi-finished paperboards to form a plurality of folding marks; die cutting is carried out on the semi-finished paperboards to form packaging paper; the packaging paper is folded and stuck to form the square and strips-shaped hard shell cigarette packaging box. The integrated processing device comprises a rack, an uncoiling mechanism, a gilding film paying-off device, a gilding mechanism, a printing mechanism, a waste film taking-up mechanism, a drying device, a pressing mark mechanism and a die cutting mechanism which are sequentially arranged on the rack. The gilding mechanism comprises an upper gilding and printing film and a gilding bearing base. A heating disc and a temperature sensor are arranged on the upper gilding and printing film. According to the processing method and device, the cigarette packaging and printing quality is better ensured, the production efficiency is high, and the production cost is saved.

Owner:CHUXIONG JIXING COLOR PRINTING

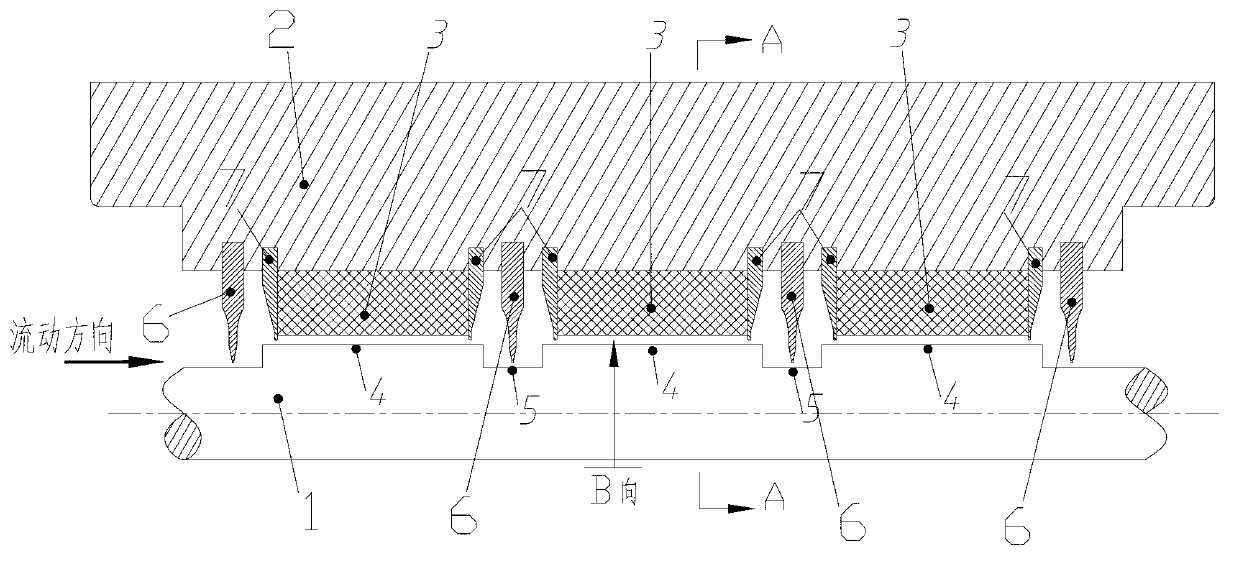

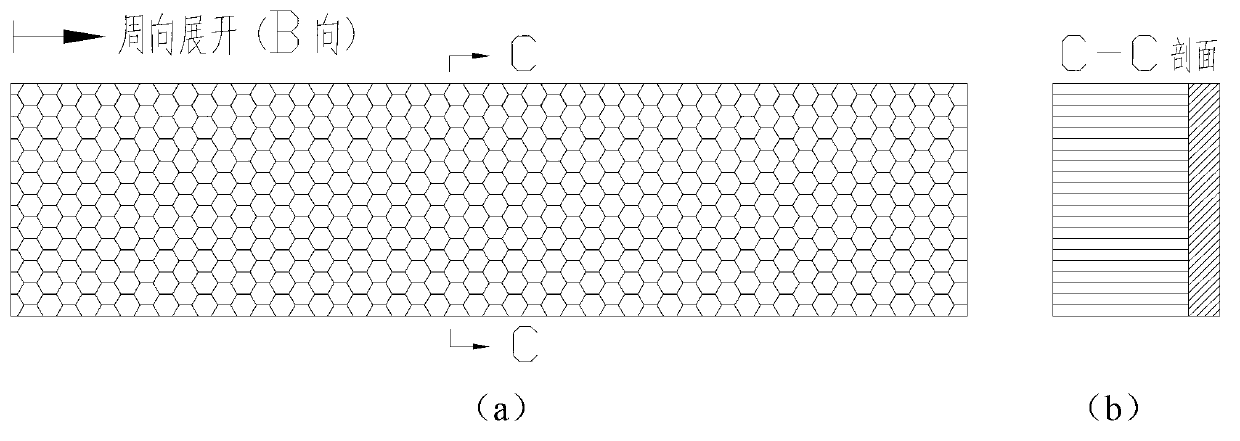

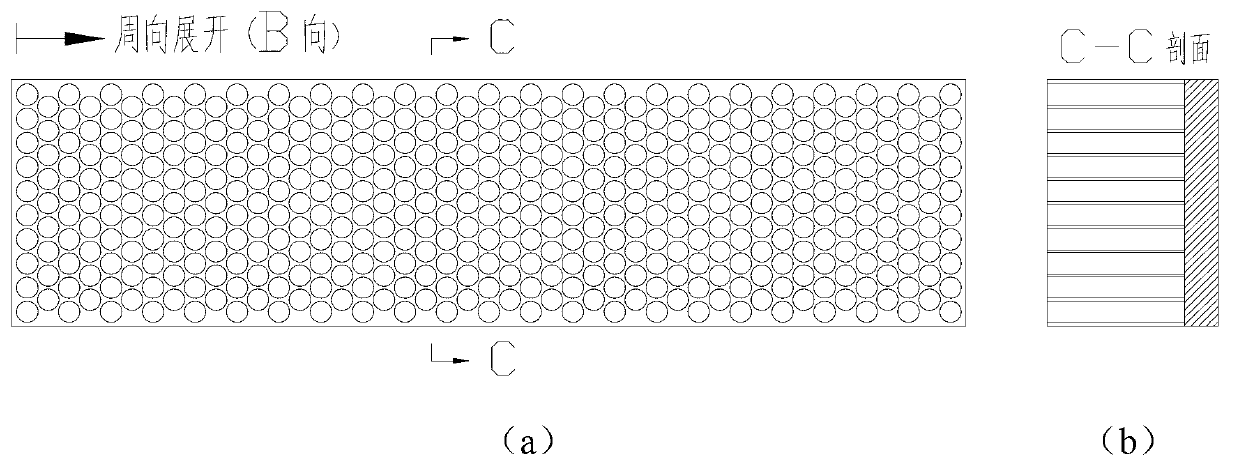

Labyrinth damping sealing device with low leakage and high damping performance

InactiveCN102953771AImprove stabilityHigh damping characteristicsPump componentsBlade accessoriesEngineeringLow leakage

The invention discloses a labyrinth damping sealing device with low leakage and high damping performance. The sealing device comprises a rotating shaft, sealing long teeth, sealing short teeth and a damping part, wherein the rotating shaft is provided with a plurality of bosses and grooves, which are axially and alternately arranged; and the sealing long teeth, the sealing short teeth and the damping part are fixed on a sealing stator ring. The damping part has the following three structures: a honeycomb structure, a hole structure and a bag structure. The labyrinth damping sealing device has the characteristics of low leakage and high damping; the possibility of causing damage to a rotor and a sealing part due to impact and rubbing between the damping sealing part (which is of a honeycomb structure or a hole structure) and the rotor is also eliminated; and not only can the energy conversion efficiency and the operation stability of a turbomachinery be further improved, but also the service life of the sealing part can be prolonged.

Owner:XI AN JIAOTONG UNIV

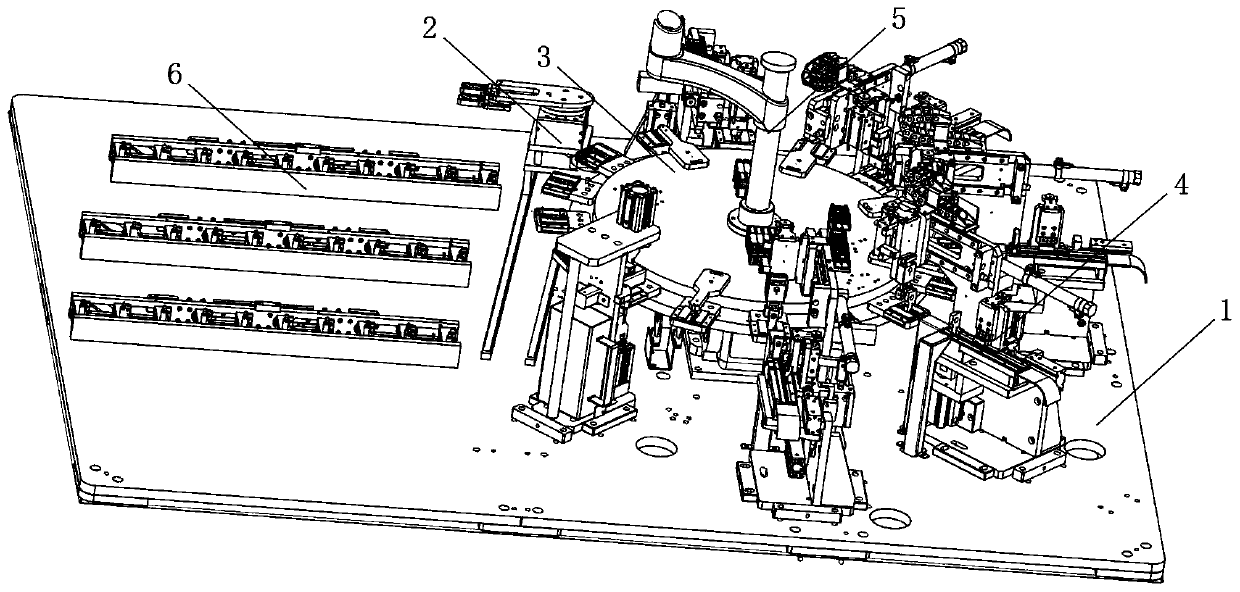

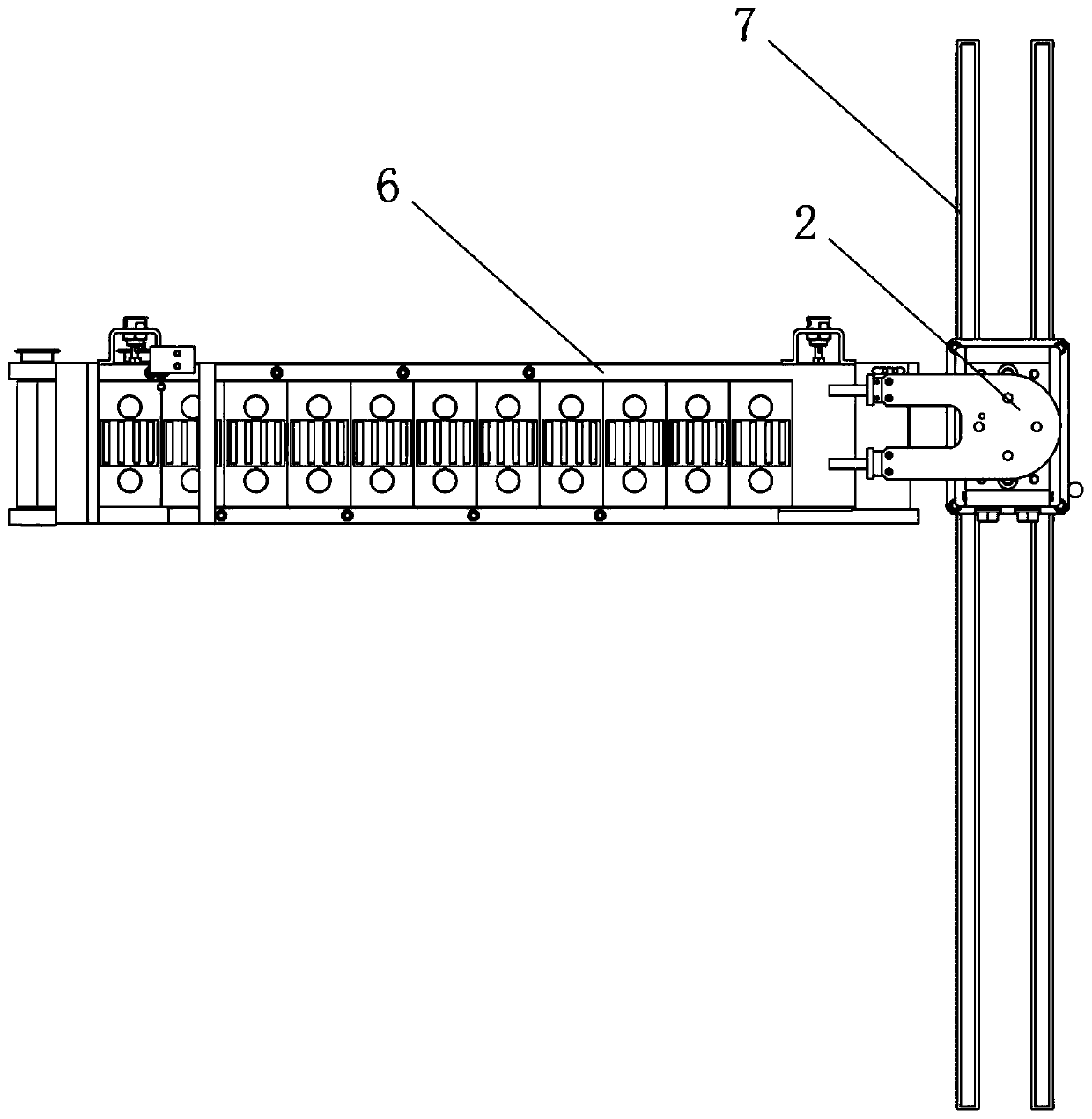

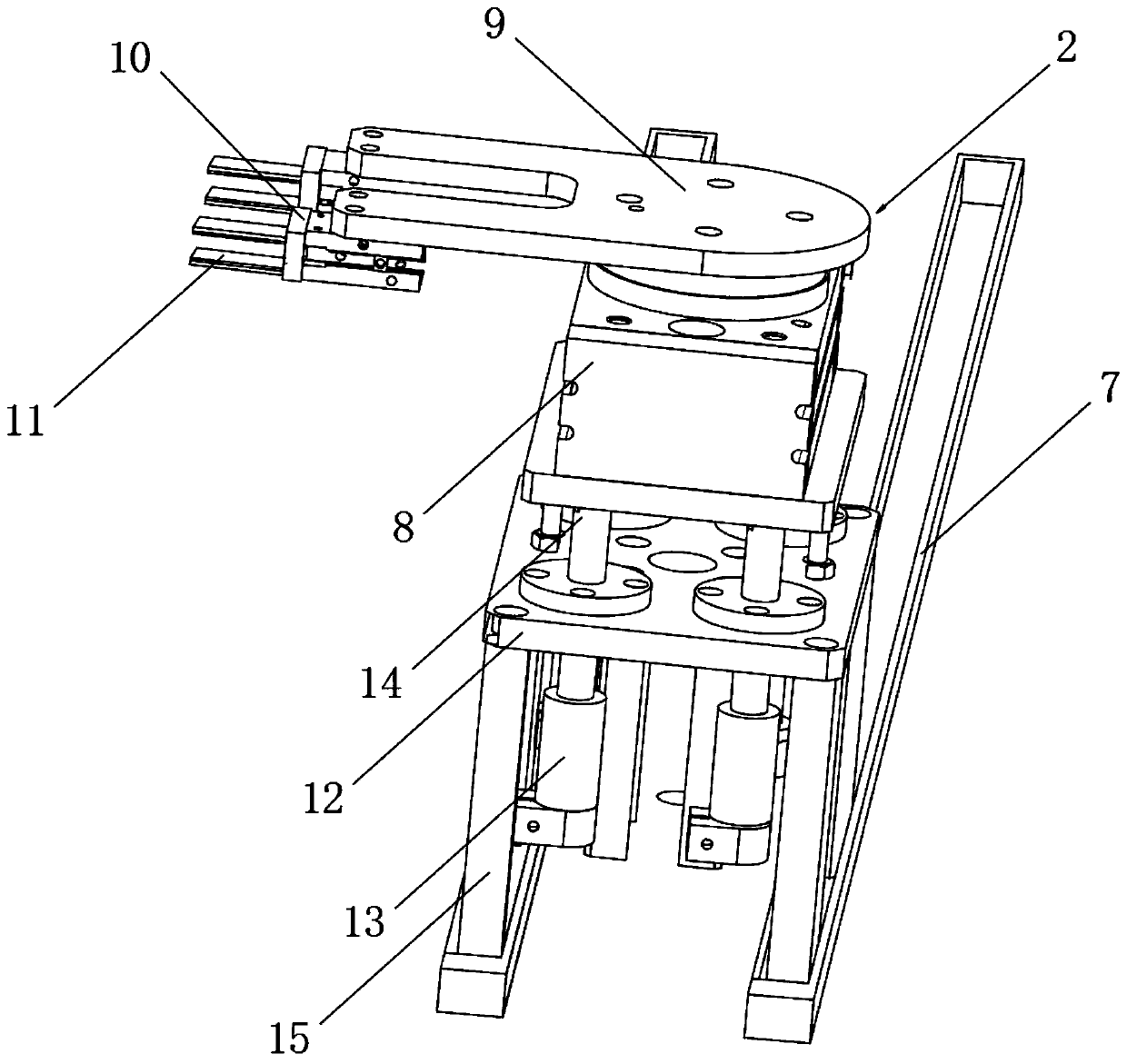

Rotary robot welding fixture and working method thereof

ActiveCN110000503APrevent fallingPrecise positioning of welding workWelding/cutting auxillary devicesAuxillary welding devicesMotor driveEngineering

The invention discloses a rotary robot welding fixture comprising an arranging and installing table, a front clamping seat, a rear chuck and side pressure seats. The front clamping seat is arranged above the arranging and installing table, one side of the front clamping seat is provided with the circular rear chuck, and the multiple side pressure seats are arranged at the edge of the rear chuck inan equal-radian manner. A first motor is arranged above the front clamping seat. The rotary robot welding fixture has the beneficial effects that when a welding mechanism performs welding work, a fourth motor drives robot components on a clamping and connecting seat to rotate to achieve fine adjustment of the positions, and it is ensured that the welding work of the welding structure on the robotcomponents is more precise in position and higher in efficiency; and the automatic degree of rotary clamping fixing work by the welding fixture on the robot components is higher, and much time and labor are saved in the using process. Four second motors drive the front clamping seat to move in two mounting frames, a plurality of first hob gears cooperate with a gear to rotate to ensure that the front clamping seat and the robot components are adjusted and moved more smoothly and securely, and collision and abrasion between all parts of the front clamping seat are reduced.

Owner:昆山高科创志机器人自动化有限公司

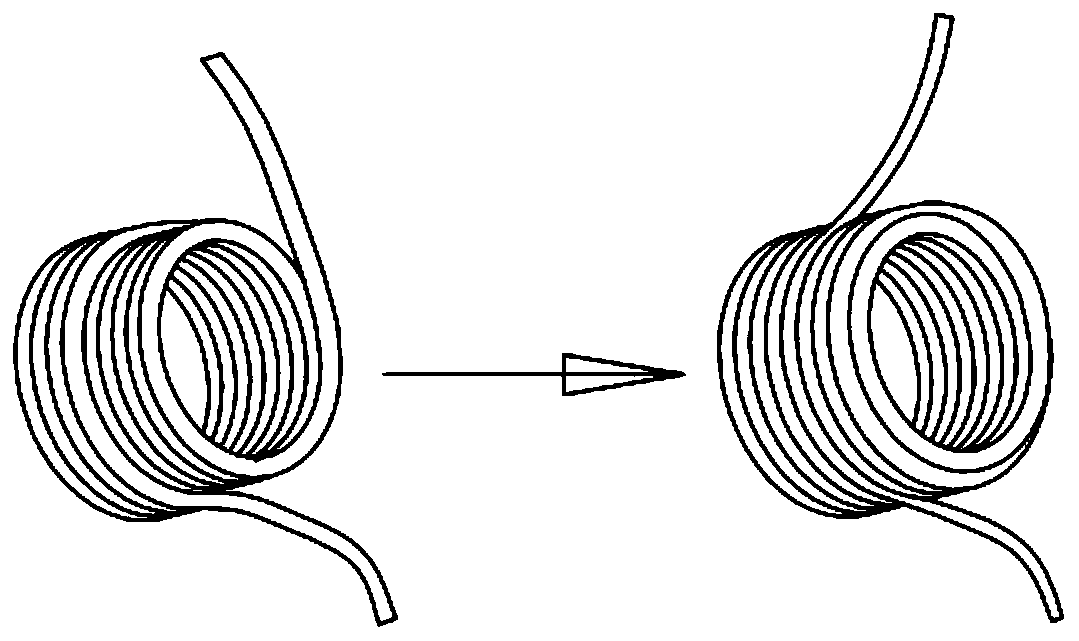

Voice coil, loudspeaker and manufacturing method of voice coil

ActiveCN110856083AAvoid the problem of an extra layer of wire diameter heightImprove stabilityElectrical transducersEngineeringAcoustic effect

The invention relates to a voice coil, a loudspeaker and a manufacturing method of the voice coil. The voice coil comprises a voice coil body formed by winding an enameled wire, a starting wire end and a tail wire end,wherein the voice coil body is provided with a starting wireoutgoing position and a tail wireoutgoing position, the starting wireend is led out from the starting wireoutgoing position, the tail wireend is led out from the tail wireoutgoing position, the starting wireoutgoing position and the tail wireoutgoing position are located at any position in the middle of the voice coil body, and the height of the voice coil body is formed to be the height of the voice coil. The problem that in an existing winding mode, the height of one more layer of wire diameter of the voice coil isincreased due to the fact that wires are led out from two ends of the starting wire is effectively solved, the occupied vibration space of winding is reduced, collision between the voice coil and parts such as a basin stand is prevented, the stability and durability of the voice coil are improved, and the acoustic effect is more excellent.

Owner:GOERTEK INC

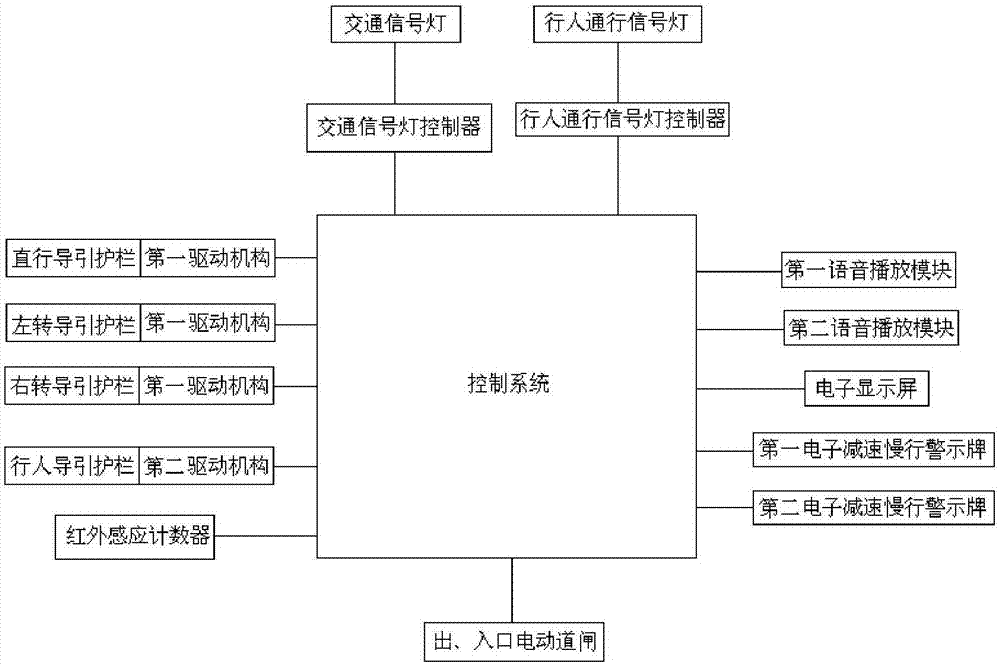

Intelligent intersection safe passing system

InactiveCN107085957APlay the role of guiding traffic flowEnsure driving safetyArrangements for variable traffic instructionsTraffic signalsElectricityTraffic signal

The invention discloses an intelligent intersection safe passing system which comprises a control system, traffic signal lamps, pedestrian traffic signal lamps, a traffic signal lamp controller, a pedestrian traffic signal lamp controller, through, left-turn and right-turn guide guardrails, a pedestrian guide guardrail, first and second electric jacking mechanism, entrance and exit electric barrier gates, an infrared induction counter, first and second voice playing modules, an electronic display screen, and first and second electronic slowdown warning signs. The control system, on the one hand, is electrically connected with the traffic signal lamp controller, the pedestrian traffic signal lamp controller, the first and second electric jacking mechanism, and the infrared induction counter, and on the other hand, is electrically connected with the first and second voice playing modules, the electronic display screen, and the first and second electronic slowdown warning signs. The intelligent intersection safe passing system makes vehicles and pedestrians pass through an intersection safely and orderly, and eliminates violated and uncivilized behaviors of the vehicles and the pedestrians.

Owner:ANHUI CHAOQING INFORMATION ENG

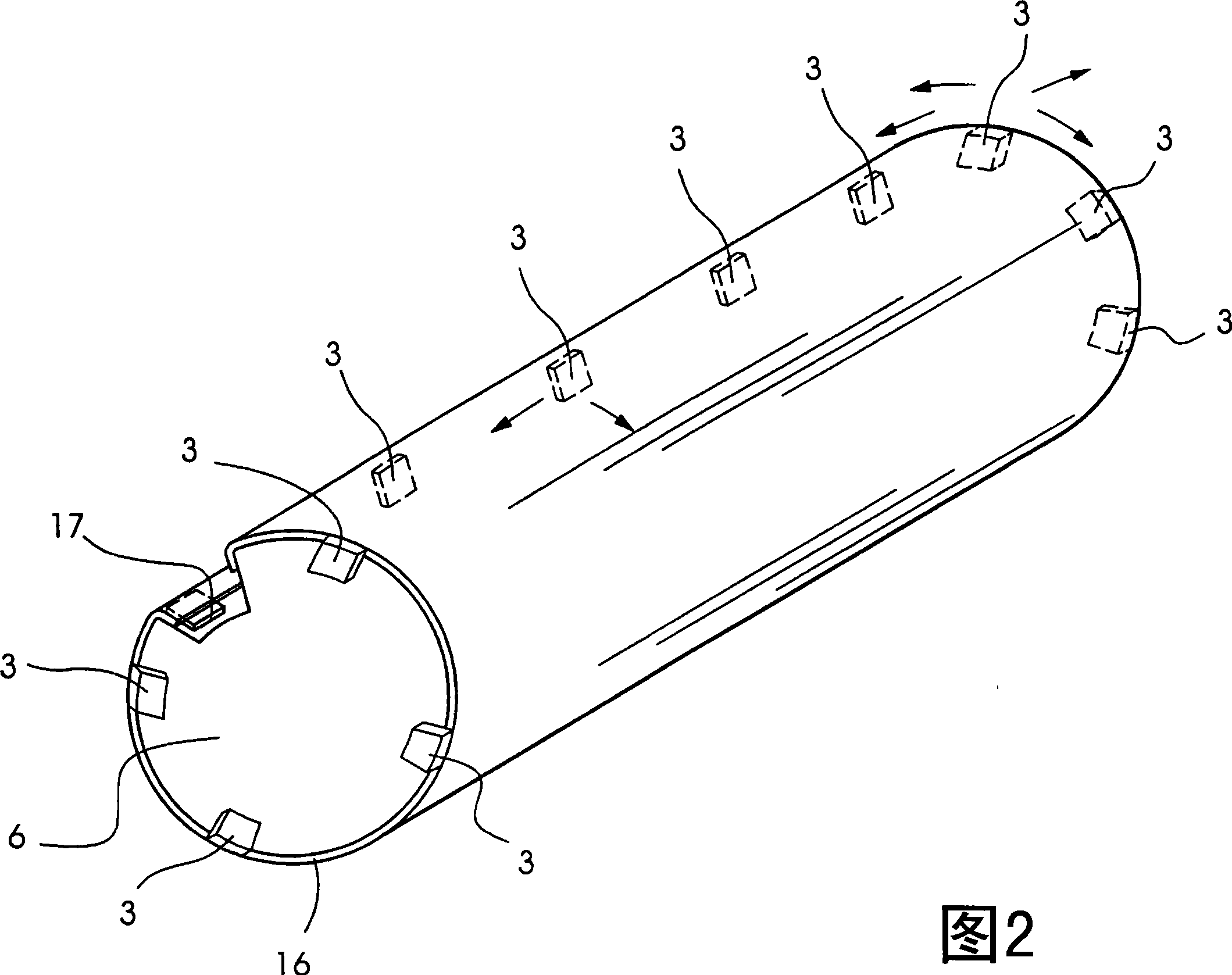

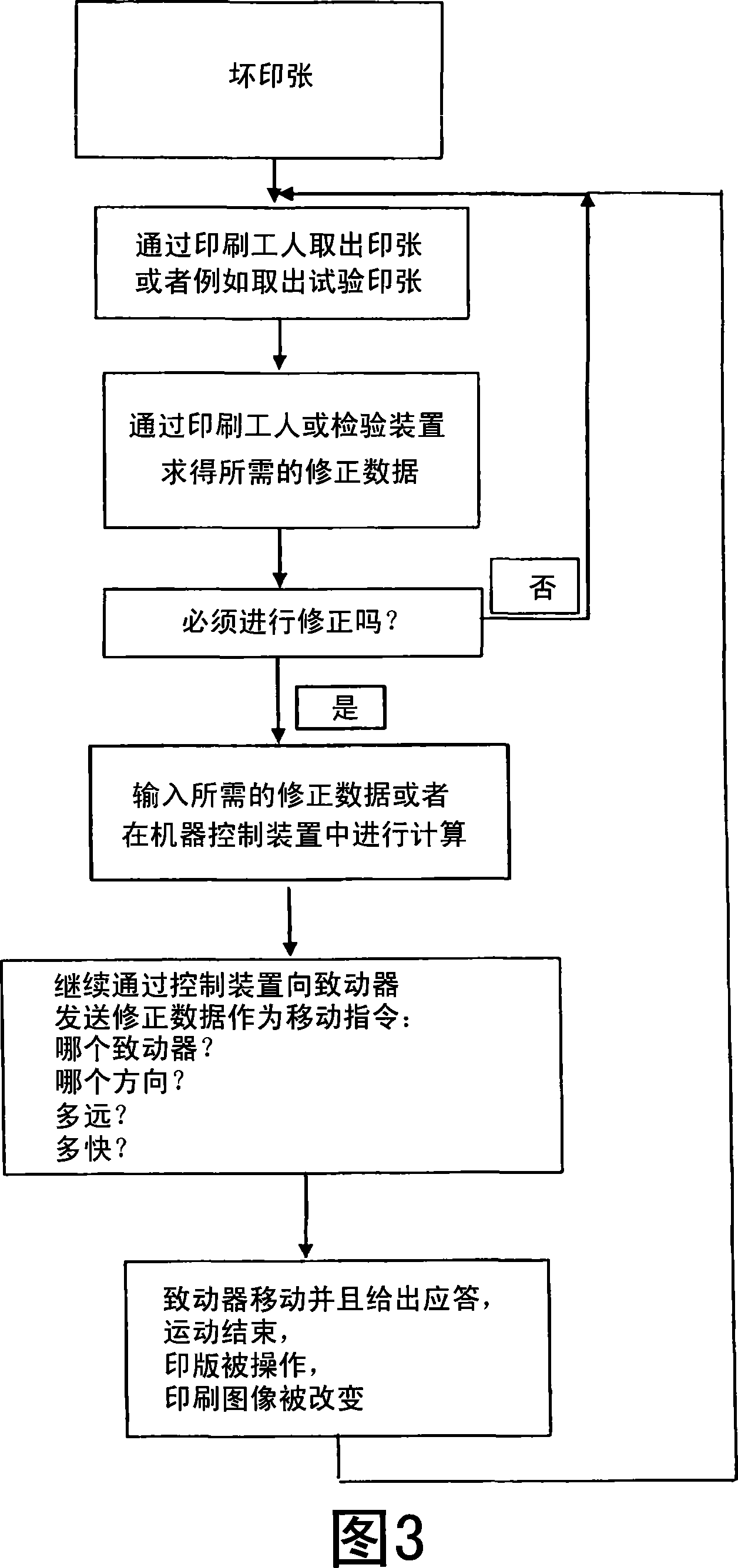

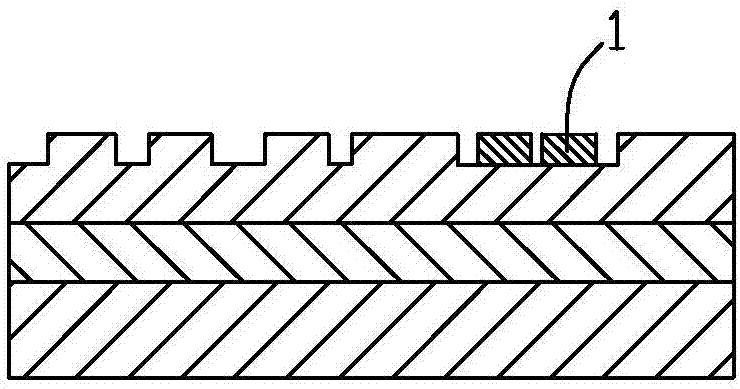

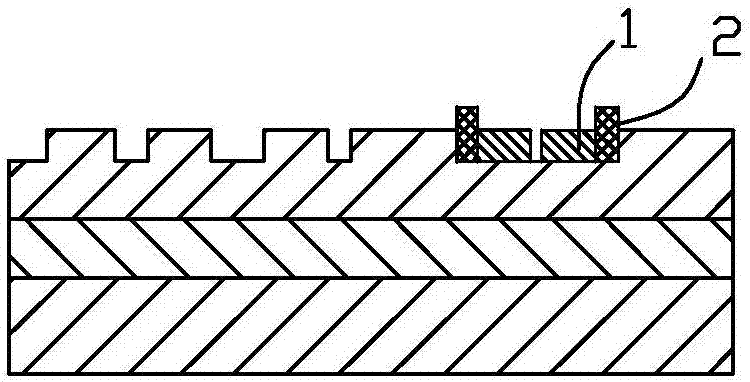

Printing press with printing plate manipulation device

InactiveCN101204869AGeometry Deviations OvercomeEasy to controlPrinting platesRotary pressesImage InspectionMachine control

A printing press includes at least one printing unit having a cylinder and a cover covering the cylinder. Actuators are associated with the cylinder for changing a geometry of the cover in axial and / or circumferential direction of the cylinder. Positioning electronics are connected to the actuators and a printing press machine control system is connected to the positioning electronics. An image inspection device is connected to the printing press machine control system at least for geometric measurement of printed printing materials. A printing press computer processes measured results from the image inspection device for carrying out a desired / actual value comparison and for driving the actuators to minimize determined deviations, in the event that deviations are determined.

Owner:HEIDELBERGER DRUCKMASCHINEN AG

Manufacturing method of golden fingers at ladder position

InactiveCN107889377AIntegrity guaranteedAvoid voidsConductive pattern reinforcementPrinted element electric connection formationAdhesiveBinding force

The invention relates to the field of printed circuit boards, and specifically relates to a manufacturing method of golden fingers at a ladder position. The surface of a ladder position area is attached with a high temperature protection adhesive tape, golden finger patterns and golden finger leads arranged inside the ladder position area are covered with the high temperature protection adhesive tape, then core plates or multiple laminated daughter boards above the high temperature protection adhesive tape in the ladder position area are removed after the working procedure of lamination, nickel and gold electroplating is carried out on the gold finger patterns after the high temperature protection adhesive tape is torn off to prepare the golden fingers, the surface completeness of the golden fingers is guaranteed, contamination or scratching is avoided, so that the completeness of signal transmission is guaranteed. Simultaneously, prepregs are used for replacing prepregs without gumming, the problem of hollow resin, between two layers of the ladder position, caused by excessive glue insufficiency is avoided, the problem that the binding force among the core plates at the ladder position is insufficient is solved, and the quality of a PCB is integrally improved.

Owner:JIANGMEN SUNTAK CIRCUIT TECH +1

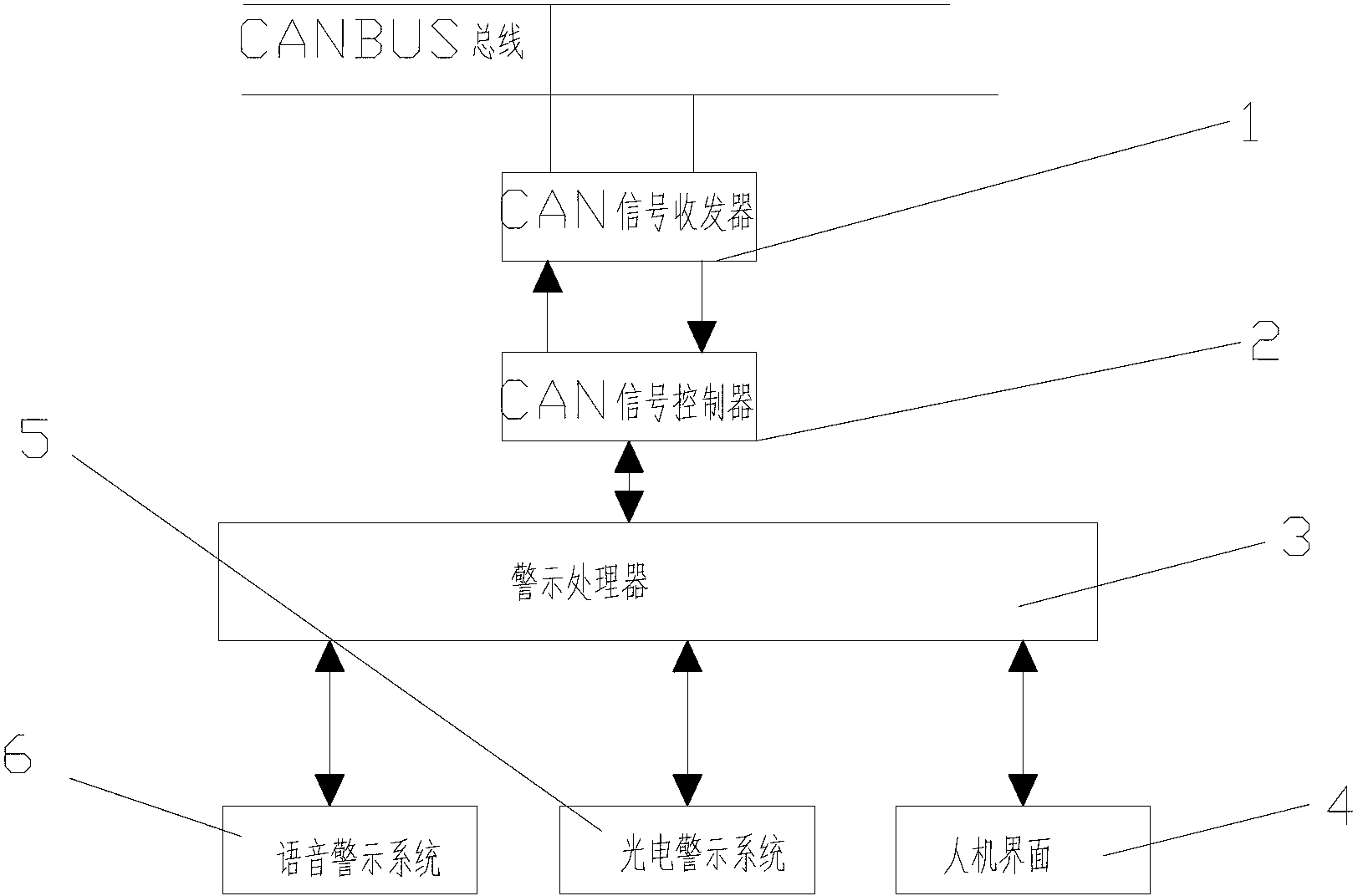

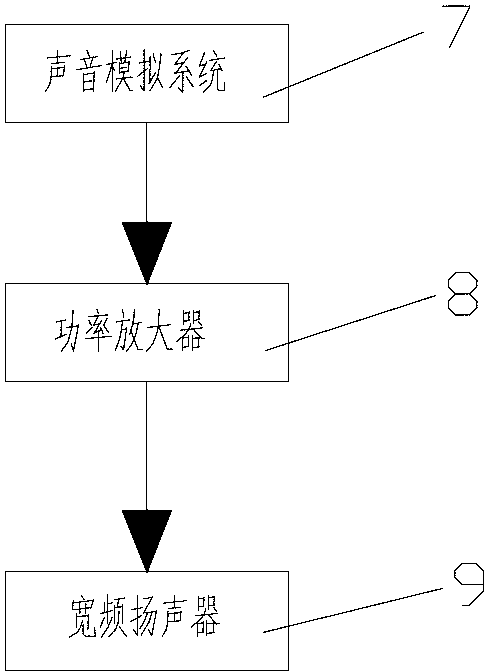

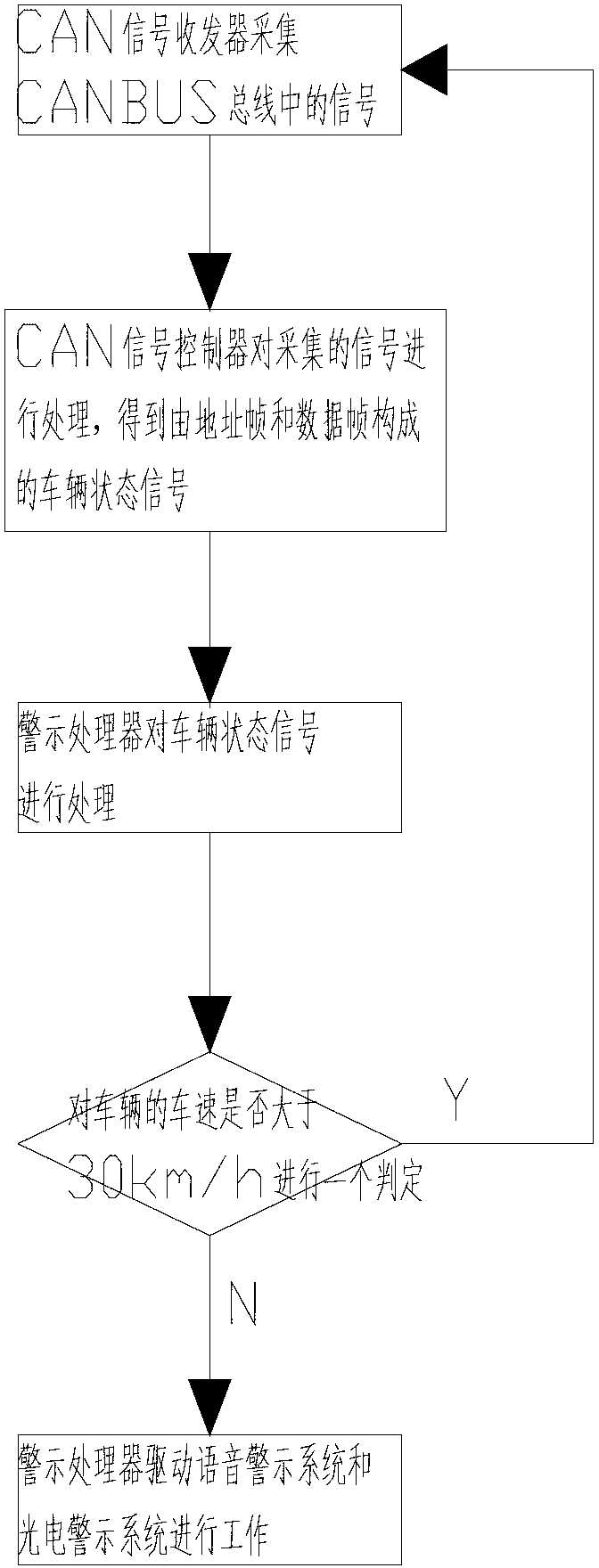

Multifunctional warning system for new energy automobile

The invention belongs to parts of a new energy automobile and in particular relates to a multifunctional system for warning pedestrians and non-motor vehicle personnel. The multifunctional warning system for the new energy automobile is characterized by comprising a controller area network (CAN) signal transceiver which is connected with a CAN bus (BUS) of the automobile, wherein the CAN signal transceiver is connected with a CAN signal controller for screening the acquired CAN signal; the CAN signal controller transmits a screened status signal of the vehicle to a warning processor; and the warning processor is connected with a voice warning system and a photoelectric warning system.

Owner:BESTAR HLDG

Workpiece feeder and adjustment-and-separation apparatus

ActiveUS8955666B2Avoid hittingAvoid rubbingControl devices for conveyorsSortingMechanical engineeringEngineering

A workpiece feeder includes a forward stage that separates base plates from one another and adjusts the base plates into correct top-bottom orientation and a pickup unit that individually holds the separated and adjusted base plates and horizontally aligns the held base plate into correct planar posture while feeding the held base plate to a destination. The forward stage includes a stage body that has a stage surface on which the base plates are placed and is movably supported so as to shift the stage surface and a drive unit that applies separate impacts to the stage body so that the stage body moves to apply a bouncing force and a shifting force orthogonal to the bouncing force due to the separate impacts to the base plates.

Owner:NHK SPRING CO LTD

Preparation method of offset paper

InactiveCN102644215AFast dryingShorten drying timeWater-repelling agents additionPaper/cardboardFiberEmulsion

The invention provides a preparation method of offset paper. The method comprises the following steps of: preparing 1.0 mass percent of oxidized starch solution and 0.8 mass percent of anionic dispersed rosin emulsion, evenly mixing the oxidized starch solution and the anionic dispersed rosin emulsion in equal quantity, so as to prepare sizing agent solution; adding ethyl cellulose into the sizing agent solution, stirring and evenly mixing, preparing surface sizing solution of the ethyl cellulose, the oxidized starch and the anionic dispersed rosin emulsion; and performing sizing, drying and press finishing on the raw offset paper on a surface sizing machine by using the surface sizing solution. The ethyl cellulose solution, the oxidized starch solution and the anionic dispersed rosin emulsion are mixedly coated on the surface of the raw offset paper; the composite film formed by ethyl cellulose, oxidized starch and neutral rosin has lipophilicity; the affinity of the paper and ink can be obviously improved; binders of the ink can rapidly permeate into fiber clearances of the paper; the drying speed of the ink on the surface of the paper can be accelerated; and the offset paper is low in cost, and has a good popularization and application value.

Owner:SHAANXI UNIV OF SCI & TECH

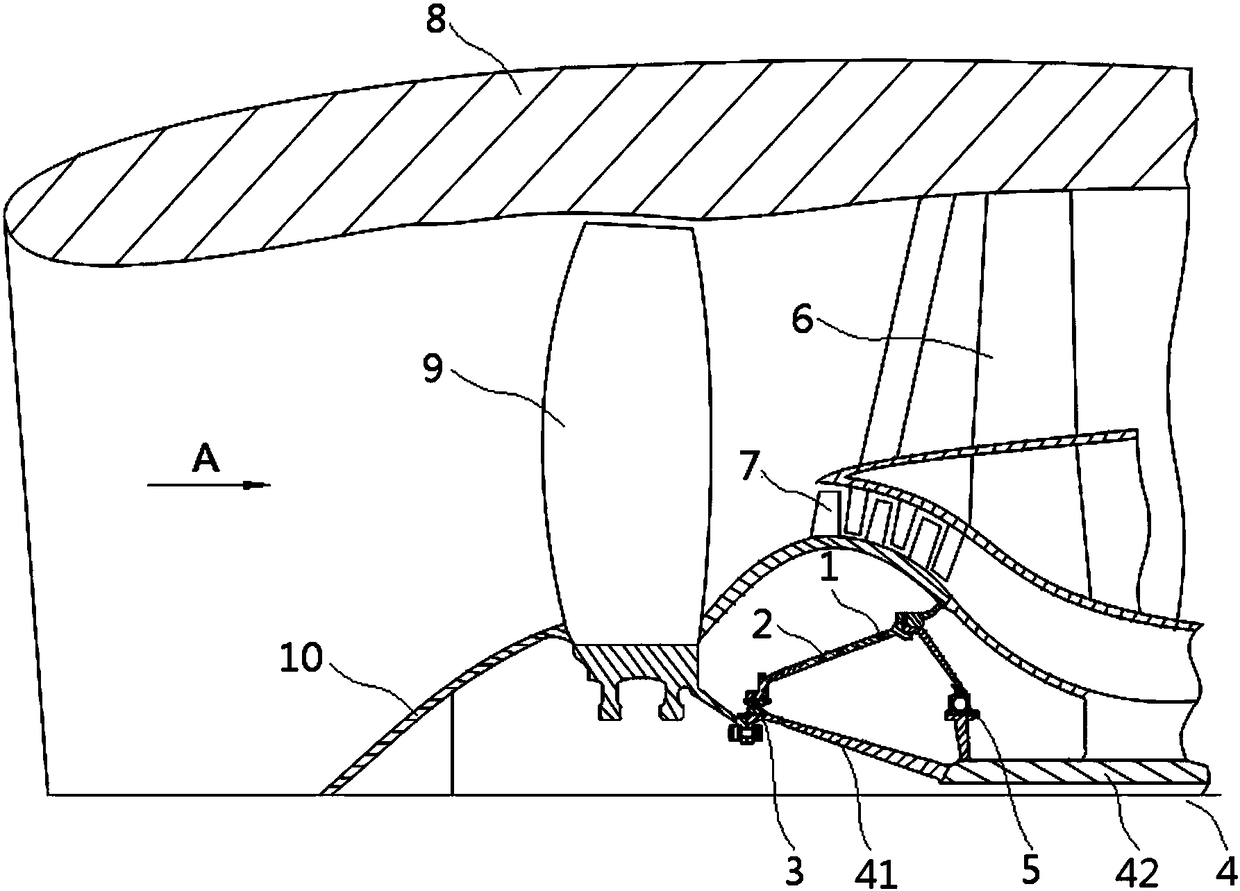

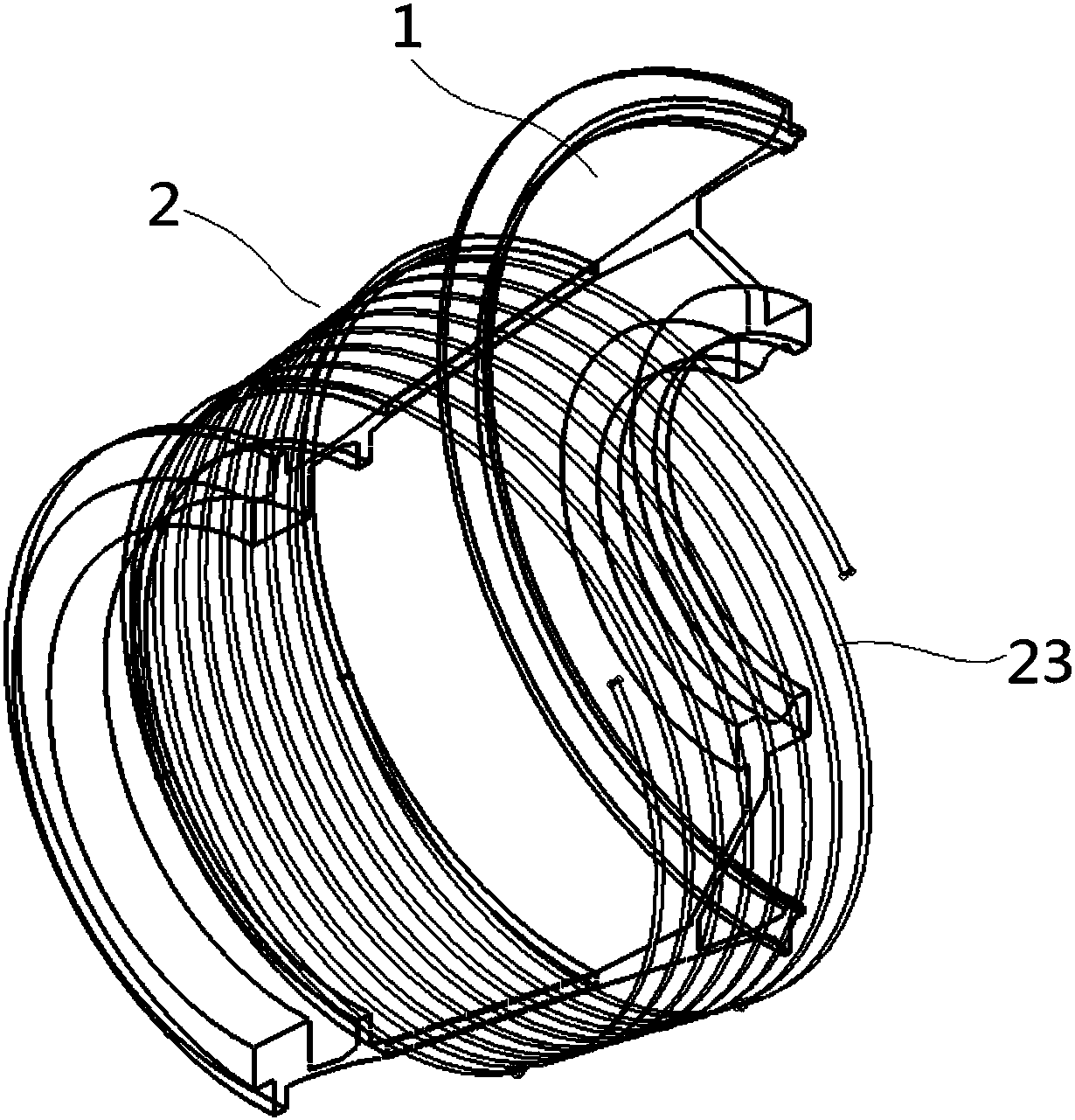

Voidable rotor support structure and aero-engine

ActiveCN108071429ALow balanceReduce vibration amplitudeBlade accessoriesMachines/enginesVibration amplitudeAviation

The invention relates to a voidable rotor support structure and an aero-engine. The voidable rotor support structure includes a support wall (1) and a portion fusing structure (2) which are arranged in the axial direction of an engine rotor (4) for supporting the rotor (4), the portion fusing structure (2) includes a connecting wall and an elastic component (23), the connecting wall can support the rotor (4) when the engine is normally operated and loses efficacy when the connecting wall is under acting force larger than a predetermined threshold value, and the elastic component is converted to support the rotor (4). According to the voidable rotor support structure, after the connecting wall loses efficacy when the engine is under the acting force larger than the predetermined threshold value, the elastic component can still support the rotor to some extent to reduce unbalanced load and vibration amplitude of a low pressure rotor, and energy can be further absorbed by generating elasticity and plastic deformation to prevent the unbalanced load and impulse load from being transmitted to subsequent bearing and intermediate cases.

Owner:AECC COMML AIRCRAFT ENGINE CO LTD

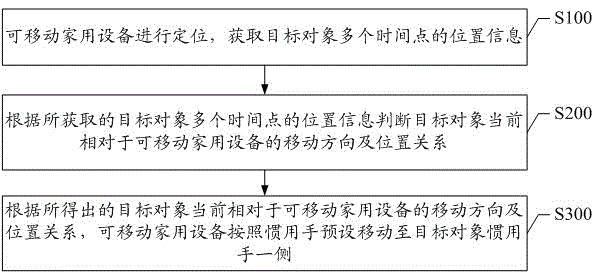

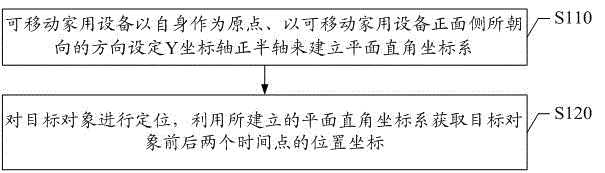

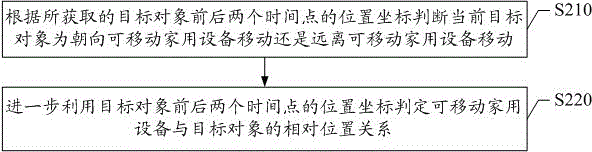

Method for adjusting and controlling relative position between movable household equipment and person and system thereof

ActiveCN104062972AHigh degree of intelligenceAvoid rubbingAutonomous decision making processComputer controlHuman–computer interaction

The invention discloses a method for adjusting and controlling the relative position between movable household equipment and a person and a system thereof. The method comprises the steps that (A) the movable household equipment is located, and the position information of a target object at multiple time points is obtained; (B) the current moving direction and the position relation of the target object relative to the movable household equipment are judged according to the obtained position information of the target object at the multiple time points; (C) the movable household equipment moves to the side of the strong hand of the target object according to preset conditions and the obtained current moving direction and the position relation of the target object relative to the movable household equipment. The system enables the movable household equipment to adjust its movement initiatively by detecting and analyzing the states of a user according to preset using habits of the user, collision with the user is avoided, the movable household equipment can be located in the direction and position where the user is used to operate, the intelligentization degree of the movable household equipment is improved, and the convenience of man-machine interaction of related equipment is further improved.

Owner:HUIZHOU TCL MOBILE COMM CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com