Labyrinth damping sealing device with low leakage and high damping performance

A sealing device and high damping technology, applied in the parts of the pumping device for elastic fluid, preventing leakage, supporting elements of blades, etc., can solve problems such as rotor system instability, poor rotor dynamic characteristics, and large cross stiffness , to achieve effective damping, prolong service life and enhance stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention is described in further detail below in conjunction with accompanying drawing:

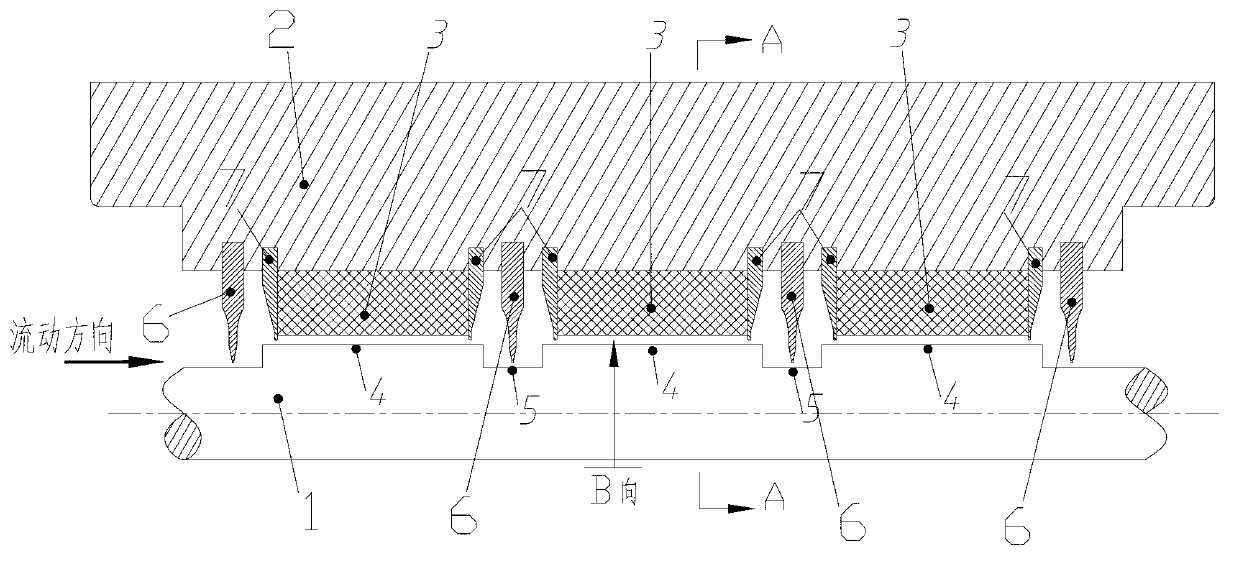

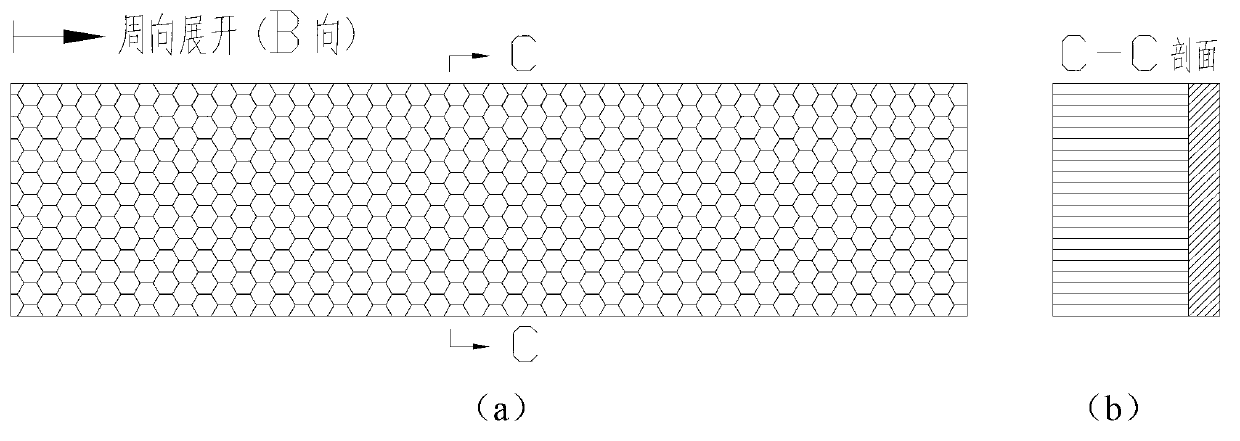

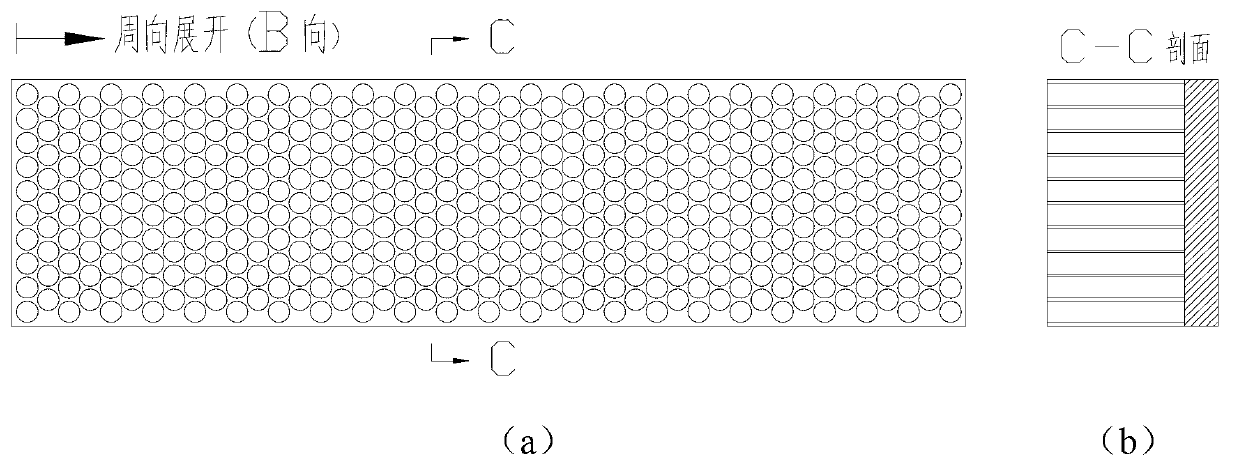

[0021] see figure 1 , which shows the structure diagram of the labyrinth damping sealing device with low leakage and high damping performance of the present invention. It includes a rotating shaft 1 with a stepped surface and a sealing stator 2 matched with the rotating shaft 1. The rotating shaft 1 is a stepped shaft and includes a plurality of adjacent large-diameter bosses 4 and small-diameter grooves 5. These bosses 4 and The grooves 5 are arranged alternately along the axial direction. The sealed stator 2 is composed of N (N=2, 4, 6, 8) sections of arc-shaped static parts to form a ring structure. Two kinds of sealing teeth are installed on the sealing stator 2: long sealing teeth 6 and short sealing teeth 7. Two short teeth 7 are arranged between every two adjacent long teeth 6, and the two are arranged alternately along the axial direction. The long sealing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com