Dyeing method of polyester-cotton blended knitting fabric

A technology of polyester-cotton blending and dyeing method, applied in the field of dyeing and finishing technology, can solve the problems of low production volume, large labor amount, long process time, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

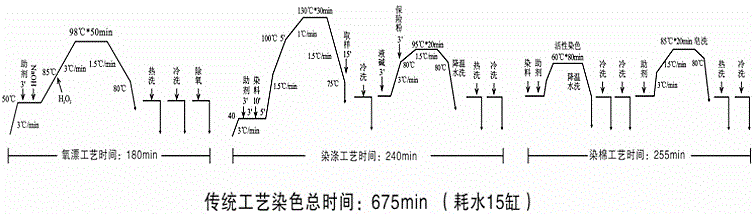

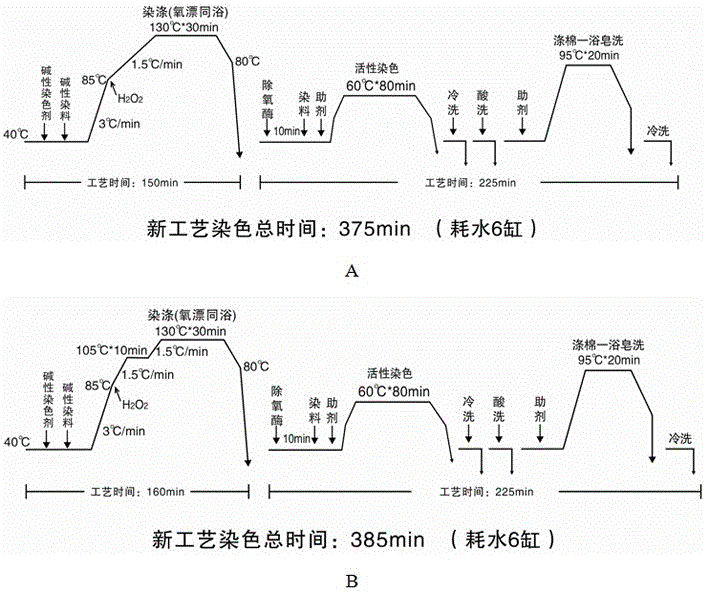

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] 1) Pretreatment: put 10.00kg of polyester-cotton blended knitted gray fabric to be dyed into 40°C water for 10 minutes, take it out, and dehydrate;

[0024] 2) Dyeing of the polyester part and oxygen bleaching of the cotton part: put the water at a bath ratio of 1:10, add 0.15kg of alkaline polyester-cotton dyeing agent, and add 0.1kg of dye particles according to the desired color, mix well, and make alkaline dyeing Liquid; The raw material composition of basic polyester cotton dyeing agent used comprises by weight: 5 parts of NaOH, NaOH 2 CO 3 20 parts, 20 parts of solid organic buffer base (composed of KOH and triisopropanolamine in a weight ratio of 1:10), 15 parts of lignin; then soak the gray cloth pretreated in step 1) in the alkaline dyeing solution, Cover and seal, heat up to 85°C at a rate of 3°C / min, open the cover, add 0.4 kg of hydrogen peroxide with a volume concentration of 27.5%, cover and seal, heat up to 105°C at a rate of 1.5°C / min, keep warm for 10...

Embodiment 2

[0028] 1) Pretreatment: put 10.00kg of polyester-cotton blended knitted gray fabric to be dyed into 45°C water for 10 minutes, take it out, and dehydrate;

[0029] 2) Dyeing of the polyester part and oxygen bleaching of the cotton part: put the water at a bath ratio of 1:10, add 0.15kg of alkaline polyester-cotton dyeing agent, and add 0.1kg of dye particles according to the desired color, mix well, and make alkaline dyeing liquid; the raw material composition of alkaline polyester-cotton dyeing agent used comprises by weight: 15 parts of NaOH, NaOH 2 CO 3 25 parts, 30 parts of solid organic buffer base (composed of KOH and triisopropanolamine in a weight ratio of 1:15), 20 parts of lignin; then soak the gray cloth pretreated in step 1) in the alkaline dyeing solution, Cover and seal, heat up to 85°C at a rate of 3°C / min, open the cover, add 0.4 kg of hydrogen peroxide with a volume concentration of 27.5%, cover and seal, heat up to 105°C at a rate of 1.5°C / min, keep warm fo...

Embodiment 3

[0033] 1) Pretreatment: put 10.00kg of polyester-cotton blended knitted gray fabric to be dyed into 50°C water for 10 minutes, take it out, and dehydrate;

[0034] 2) Dyeing of the polyester part and oxygen bleaching of the cotton part: put the water at a bath ratio of 1:10, add 0.15kg of alkaline polyester-cotton dyeing agent, and add 0.1kg of dye particles according to the desired color, mix well, and make alkaline dyeing Liquid; The raw material composition of basic polyester cotton dyeing agent used comprises by weight: 18 parts of NaOH, NaOH 2 CO 3 35 parts, 45 parts of solid organic buffer base (composed of KOH and triisopropanolamine in a weight ratio of 1:20), 25 parts of lignin; then soak the gray cloth pretreated in step 1) in alkaline dyeing solution, Cover and seal, heat up to 85°C at a rate of 3°C / min, open the cover, add 0.4 kg of hydrogen peroxide with a volume concentration of 27.5%, cover and seal, heat up to 105°C at a rate of 1.5°C / min, keep warm for 10 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com