Side guide wheel of crane for preventing track biting of rim

A kind of technology of crane car and side guide wheel, which is applied in the directions of traveling mechanism, load hanging element, transportation and packaging, etc., can solve the problems of thinning of wheel rim wall, gnawing of rail, and wear of rail side.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

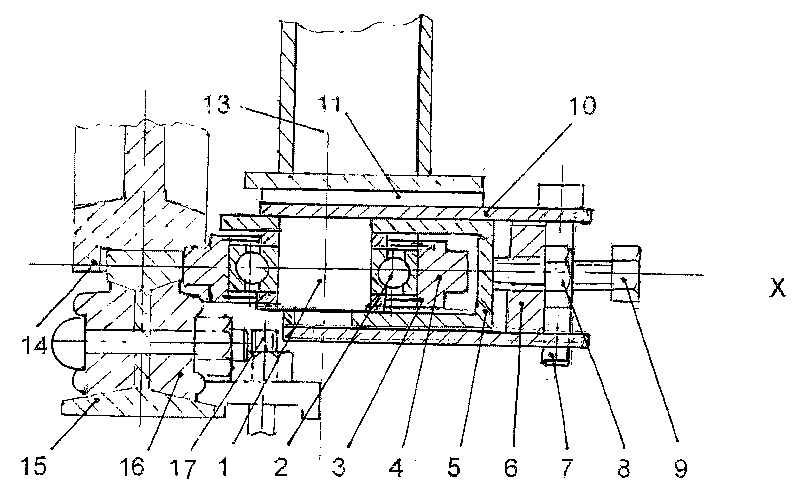

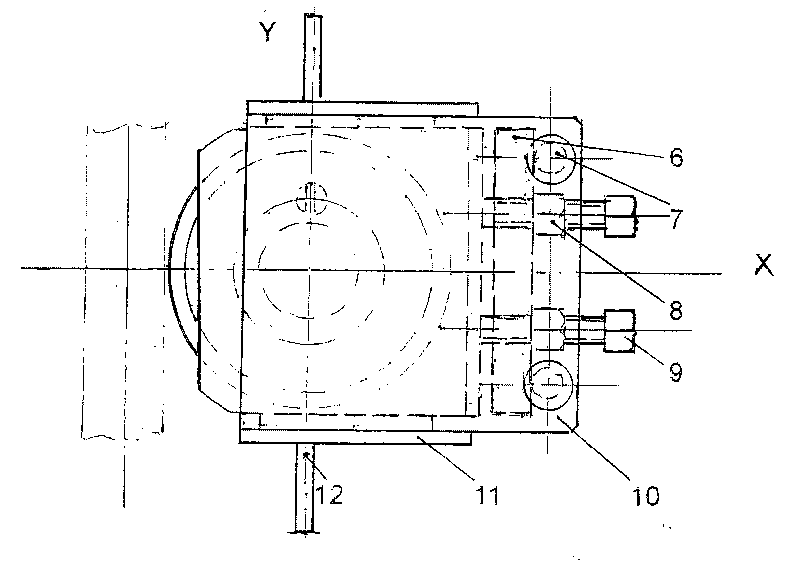

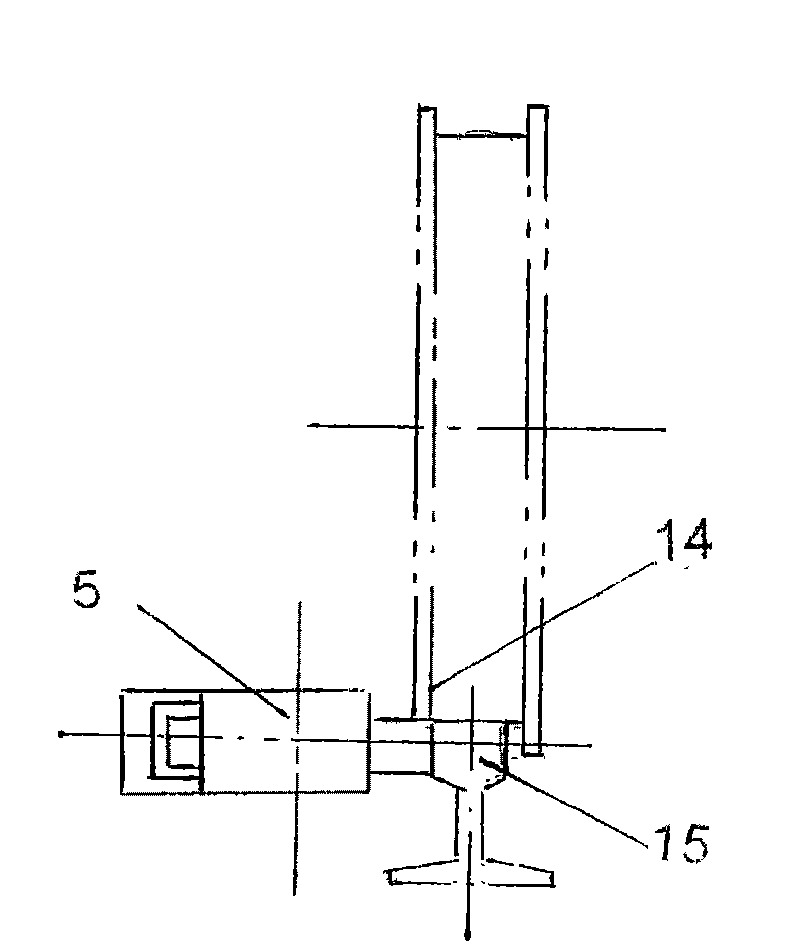

[0014] From figure 1 , figure 2 As can be seen from the implementation of the present invention shown, after the side guide wheel 4 bears on the upper side of the rail 15, there is a small gap between the wheel flange 14 and the side of the rail during operation of the crane, and there is no friction between the wheel flange and the side of the rail. , Effectively prevent the wheel rim from gnawing on the rail.

[0015] The force process is implemented, the side guide wheel 4 bears against the side of the rail, through the bearing 2, the guide wheel shaft 1, acts on the guide wheel frame 5, passes through the screw 9 to the screw hole stopper 6, and transmits to the blocking pin 7, and finally the force reaches On the chute combination box 10,11, the chute combination box is fixed on the bottom of the crane trolley by the steel structure 13.

[0016] The first advantage of the present invention is that when it is necessary to adjust the proper position of the side guide whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com