Metal laser melting additive manufacturing method

A laser melting additive and manufacturing method technology, applied in the field of additive manufacturing, can solve problems such as easy to produce spheroidization and pores, difficult to completely change the continuous network distribution of thick-layer carbides, and difficult to transfer stress, so as to improve the forming quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

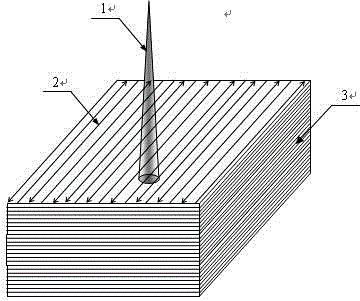

[0025] (1) For the forming of high-performance 316L stainless steel alloy parts, use 3D modeling software to design the 3D CAD model of the part, then process it with slicing software and save it as an STL file, and send the data information of the STL file to the laser additive manufacturing for rapid processing Forming equipment: use SLM to process the current slice layer, the powder feeding mechanism spreads a layer of 316L stainless steel powder with a thickness of about 0.05mm and a particle size of 10μm on the metal substrate, and the power of the fiber laser is 200W; figure 1 Among them, 1 is the laser beam; 2 is the path of the laser beam; 3 is the multi-layer entity.

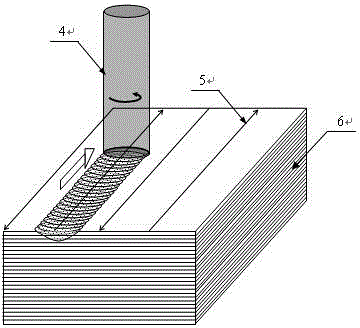

[0026] (2) After the current slice layer is processed by SLM, the cubic BN material is selected as the stirring head 4, and friction stir processing is performed on the laser melting area line by line. Among them, the diameter of the rotating shaft shoulder is 2mm, the rotating speed is 500rpm, the trav...

Embodiment 2

[0029] (1) For the forming of high-performance cobalt-based Co-27Cr-5Mo-0.5Ti alloy parts, use 3D modeling software to design the 3D CAD model of the part, and then process it with slicing software and save it as an STL file. The data of the STL file The information is sent to laser additive manufacturing rapid prototyping equipment; LENS is used to process the current slice layer, so that 500W YAG laser, 50g / min cobalt-based alloy powder, and Ar gas are simultaneously input to the substrate, and the layer thickness is 0.15mm;

[0030] (2) After the LENS finishes processing the current slice layer, the cubic BN material is selected as the stirring head 4, and the LENS area is subjected to row-by-row friction stir processing. Among them, the diameter of the rotating shaft shoulder is 2mm, the rotating speed is 500rpm, the traveling speed is 500mm / min, the FSP down pressure is 0.01mm, and the thickness of the FSP deformed layer is 0.3mm, so as to ensure that the thickness of the ...

Embodiment 3

[0033] (1) For the forming of high-performance Al-Si alloy parts, use 3D modeling software to design the 3D CAD model of the part, then process it with slicing software and save it as an STL file, and send the data information of the STL file to laser additive manufacturing Rapid prototyping equipment; SLM technology is used to process the current slice layer, the powder feeding mechanism spreads a layer of Al-Si alloy powder with a thickness of about 0.05mm and a particle size of 20μm on the metal substrate, and the fiber laser power is 150W;

[0034] (2) After the current slice layer is processed by SLM, the tool steel is selected as the stirring head 4 to perform friction stir processing on the laser melting area line by line. Among them, the diameter of the rotating shaft shoulder is 1mm, the rotating speed is 1000rpm, the traveling speed is 800mm / min, the FSP down pressure is 0.01mm, and the thickness of the FSP deformed layer is 0.2mm, so as to ensure that the thickness o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com