Construction method for high-altitude section prefabricating, beam moving, beam storing and assembling of large concrete box beam

A concrete box girder, segmental prefabrication technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as cracks, achieve the effect of eliminating cracks and preventing cracks itself

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

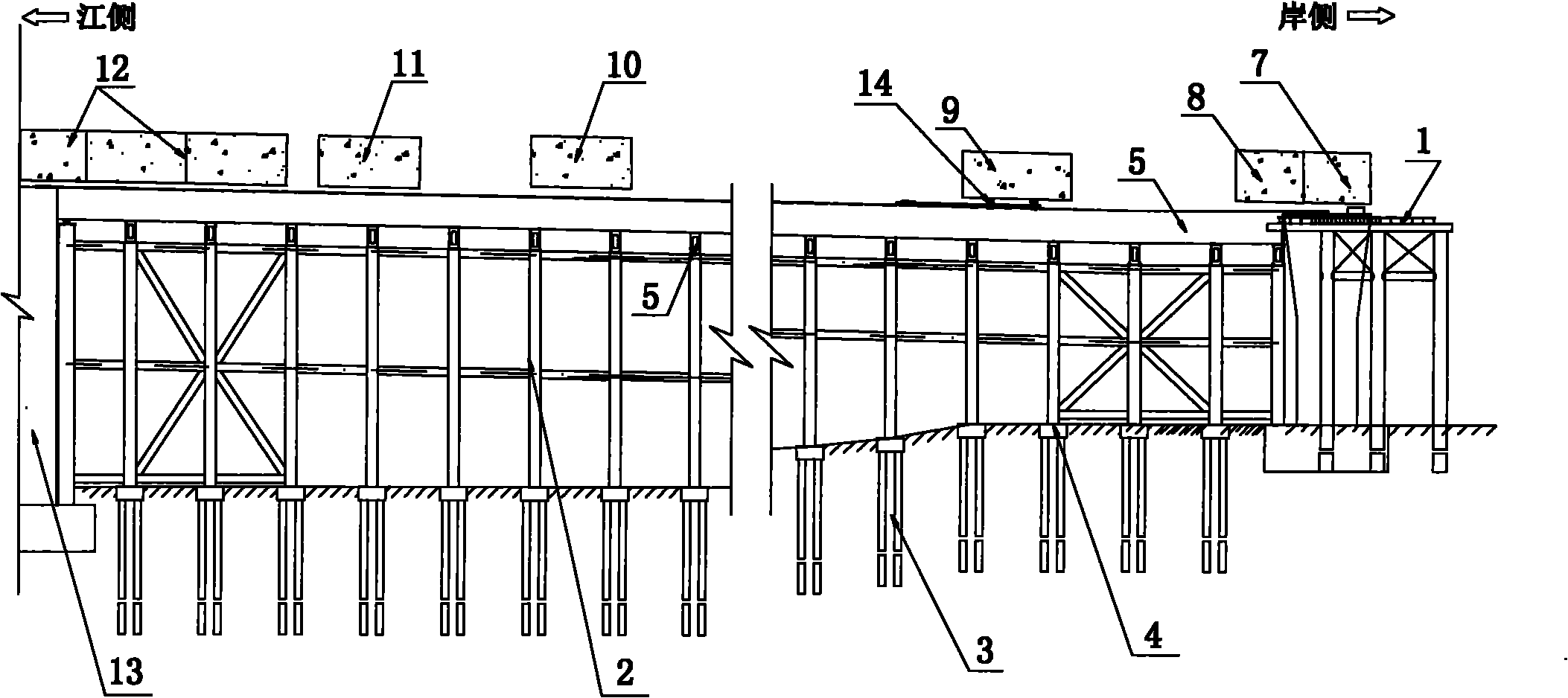

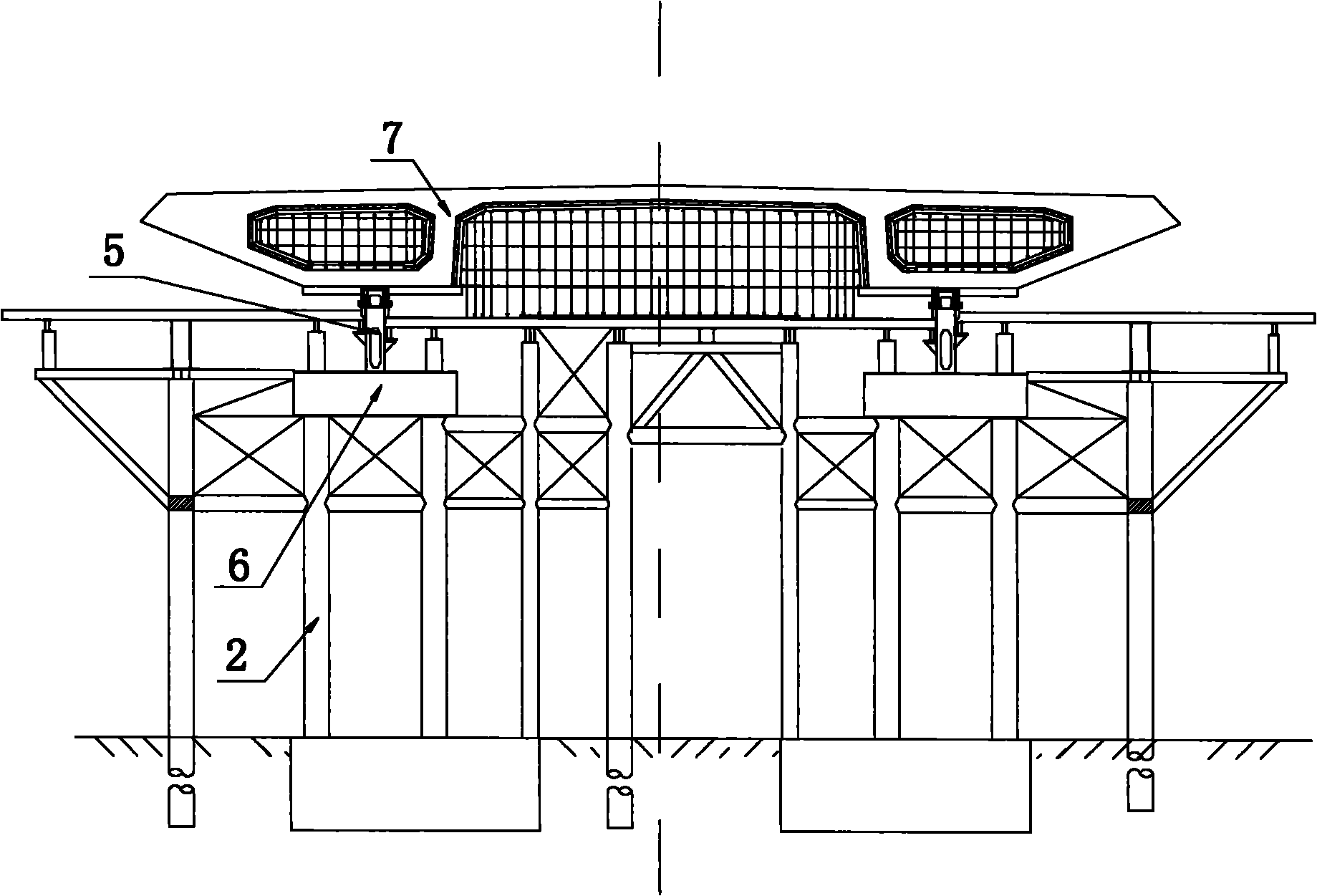

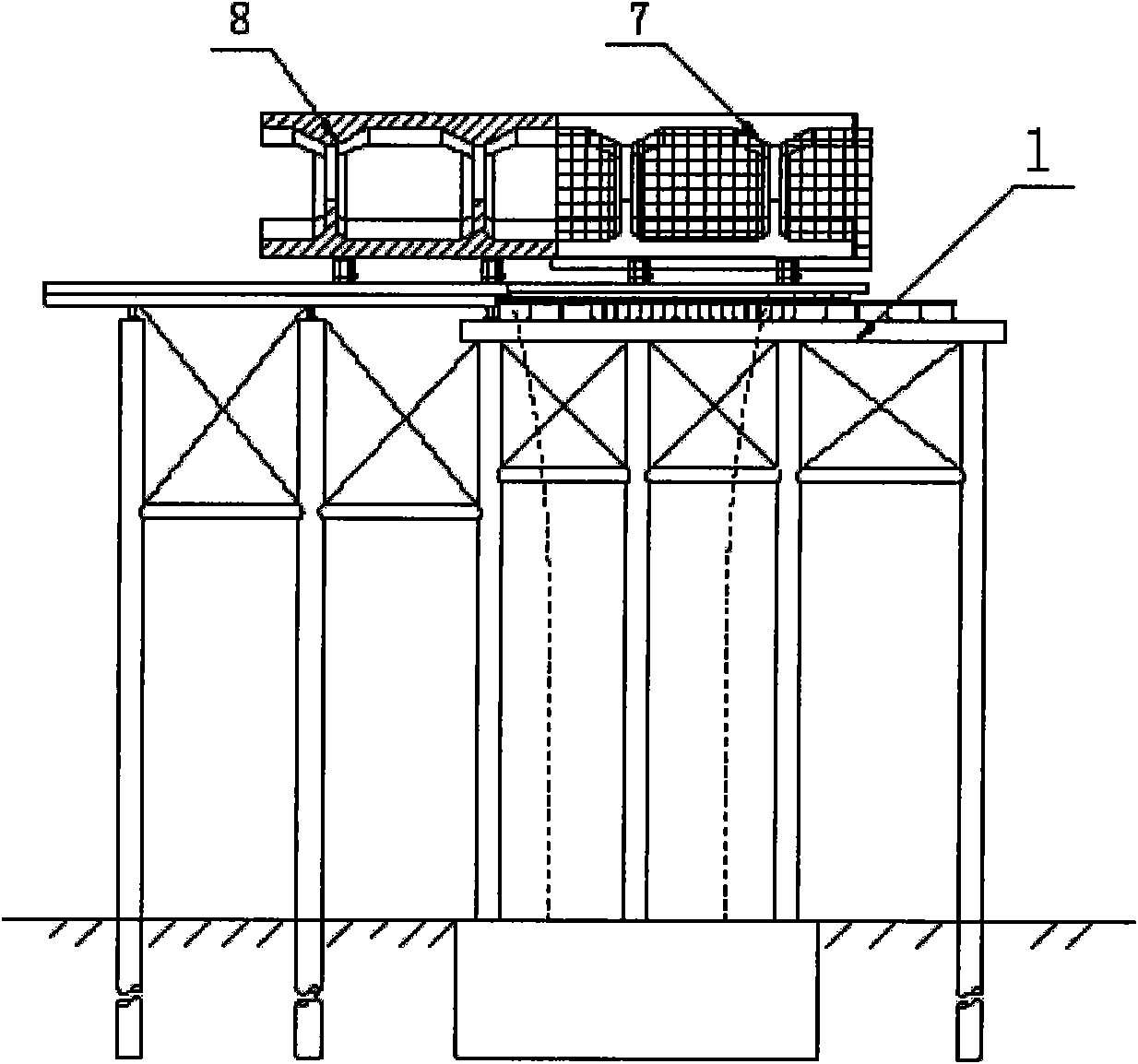

[0031] The inventive method comprises the following steps, see Figure 1 to Figure 9 :

[0032] 1. Set up a high-pile prefabricated platform 1 on the shore side (shore side) of the bridge. The high-pile prefabricated platform 1 adopts a steel pipe support structure, and arranges the formwork system required for the prefabricated beam section. See figure 1 , figure 2 ;

[0033] 2. Along the bridge direction, set up a beam-moving steel pipe support 2 between the high pile prefabricated platform 1 and the pier column 13 on the river side (river side) of the bridge. The beam-moving steel pipe support 2 is a load-bearing structure for the movement and storage of the beam section; Two parallel steel slide rails 5 are set on the beam-moving steel pipe support 2; Set cross braces and scissors braces to ensure the overall stability of the support; install distribution steel beams 6 in the cross bridge direction on the beam-moving steel pipe support 2, as the support of the load-bea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com