Nanometer lubricating oil used for special coating welding wire not plated with copper and preparation method of nanometer lubricating oil

A technology without copper plating and lubricating oil, applied in welding equipment, lubricating composition, welding medium, etc., can solve the problems of wire feeding contact tip wear and easy wear of the contact tip, and achieve lower resistivity and good wire feeding performance. , the effect of reducing the coefficient of friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

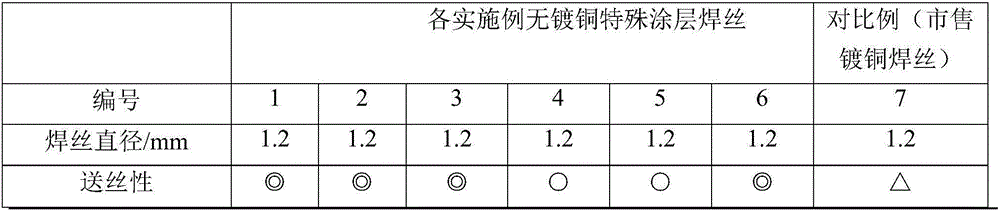

Embodiment 1

[0020] The nano lubricating oil for non-copper-plated special coated welding wire is made of the following components in mass percentage: 75% palm oil, 15% polytetrafluoroethylene, 4% carbon black, MoS 2 3.4%, nano CuO 0.4%, nano TiO 2 0.2%, graphene 2%.

[0021] The diameter of the nano-CuO is 45nm.

[0022] The nano-TiO 2 The diameter is 30nm.

[0023] The preparation method of the above-described embodiment without copper-plated special coating welding wire nano lubricating oil consists of the following steps:

[0024] Add the palm oil in the above mass percentage into the reaction kettle, stir at a constant temperature of 75° C. for 1 hour, and stop heating;

[0025] Then the polytetrafluoroethylene, carbon black, MoS 2 , Nano CuO, Nano TiO 2 and graphene were put into the reaction kettle respectively, heated to 50°C under the pressure of 0.4MPa, reacted for 1h, homogenized and degassed, and made into nano lubricating oil for non-copper-plated welding wire with spe...

Embodiment 2

[0027] The nano lubricating oil for non-copper-plated special coated welding wire is made of the following components in mass percentage: 70% palm oil, 10% polytetrafluoroethylene, 8% carbon black, MoS 2 6.5%, nano CuO1.5%, nano TiO 2 0.5%, graphene 3.5%.

[0028] The diameter of the nano-CuO is 80nm.

[0029] The nano-TiO 2 The diameter is 85nm.

[0030] The preparation method of the above-described embodiment without copper-plated special coating welding wire nano lubricating oil consists of the following steps:

[0031] Add the palm oil in the above mass percentage into the reaction kettle, stir at a constant temperature of 78° C. for 1 hour, and stop heating;

[0032] Then put the polytetrafluoroethylene, carbon black, MoS2, nano-CuO, nano-TiO2, and graphene in the above-mentioned mass percentages into the reaction kettle, heat to 54°C under the pressure of 0.5MPa, react for 1h, homogenize and degas, and prepare Nano lubricating oil for special coated welding wire w...

Embodiment 3

[0034] The nano lubricating oil for copper-free special coating welding wire is made of the following components in mass percentage: 68% palm oil, 12% polytetrafluoroethylene, 10% carbon black, MoS 2 2.7%, nano CuO 2.4%, nano TiO 2 0.6%, graphene 4.3%.

[0035] The diameter of the nano-CuO is 110nm.

[0036] The nano-TiO 2 The diameter is 135nm.

[0037] The preparation method of the above-described embodiment without copper-plated special coating welding wire nano lubricating oil consists of the following steps:

[0038] Add the palm oil in the above mass percentage into the reaction kettle, stir at a constant temperature of 81° C. for 1 hour, and stop heating;

[0039] Then the polytetrafluoroethylene, carbon black, MoS 2 , Nano CuO, Nano TiO 2 and graphene were put into the reaction kettle respectively, heated to 59° C. under a pressure of 0.7 MPa, reacted for 1 hour, homogenized and degassed, and made into nano lubricating oil for non-copper-plated special coating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com