Perfluoropolyether supermolecular gel composite nano-particle lubricant as well as preparation method and application thereof

A technology of composite nanoparticles and supramolecular gels, which can be used in lubricating compositions, petroleum industry, etc., and can solve problems such as poor dispersion stability of nanoparticles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] In the present invention, the preparation method of the gel factor preferably comprises the following steps:

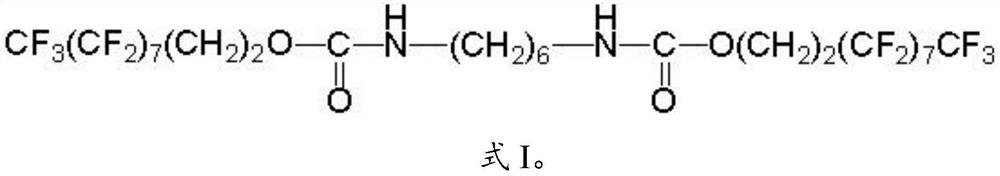

[0020] 1,1,2,2-tetrahydroperfluoro-1-decanol and 1,6-n-butyl hexamethylene diisocyanate are subjected to polyurethane reaction in a solvent to obtain the gel factor with the molecular formula shown in formula I.

[0021] In the present invention, the molar ratio of the 1,1,2,2-tetrahydroperfluoro-1-decanol to 1,6-n-butyl hexamethylene diisocyanate is preferably 2:1; the solvent is preferably Acetonitrile; the temperature of the polyurethane reaction is preferably 80-85°C, more preferably 82-83°C, and the time is preferably 12h; the polyurethane reaction is preferably carried out under reflux conditions.

[0022] In a specific embodiment of the present invention, it is preferred to first dissolve 1,1,2,2-tetrahydroperfluoro-1-decanol in a solvent, stir at room temperature for 10 minutes, and then dissolve 1,6-hexamethylene diisocyanate The n-butyl acid was adde...

Embodiment 1

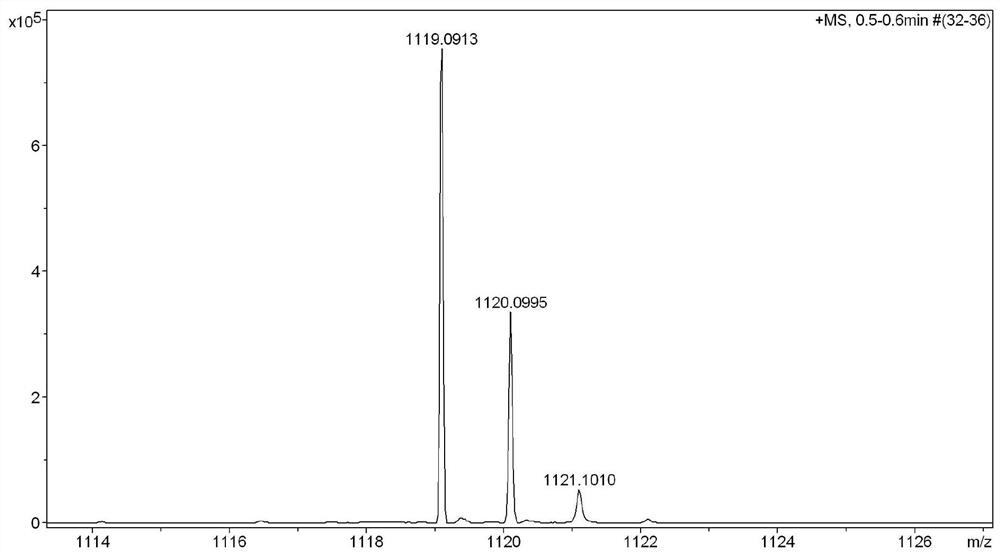

[0034] Add 0.02mol 1,1,2,2-tetrahydroperfluoro-1-decanol to a 250mL three-necked flask, and add 80mL acetonitrile as a solvent, and stir at room temperature for 10min to make 1,1,2,2-tetrahydroperfluoro -1-decanol was completely dissolved to obtain 1,1,2,2-tetrahydroperfluoro-1-decanol solution. Then take 0.01mol of 1,6-hexamethylene diisocyanate and add it dropwise to the 1,1,2,2-tetrahydroperfluoro-1-decanol solution obtained above while stirring, and then stir for 10 minutes to make the solution evenly mixed . Then, it was placed in an oil bath at 85°C and heated under reflux and stirred for 12 hours to obtain a milky white mixed solution, which was cooled to room temperature, filtered with suction and washed twice with acetonitrile, and finally dried in a vacuum oven at 80°C for 8 hours to obtain White powder gel factor. The mass spectrum of the obtained gel factor is as follows figure 1 As shown, it can be seen through mass spectrometry analysis that characteristic pea...

Embodiment 2

[0036] According to the mass concentration ratio of 1.5wt%, take the equivalent gel factor prepared in Example 1, and place the gel factor at a high temperature of 130°C to completely dissolve the gel factor in perfluoropolyether lubricating oil (purchased from Shenzhen Bomei Industrial Materials Co., Ltd. company). Then, add molybdenum disulfide nanoparticles (particle size 100nm, flake structure) in the proportion of 2.0wt%, 3.0wt%, and 4.0wt% respectively according to the mass concentration ratio, stir until the nanoparticles are mixed evenly, take out and cool to room temperature to obtain Perfluoropolyether supramolecular gel composite molybdenum disulfide nanoparticle lubricant, respectively denoted as GEL@2.0%MoS 2 、GEL@3.0%MoS 2 and GEL@4.0%MoS 2 .

[0037] Anti-friction performance test: The Optimol-SRV-IV friction and wear testing machine was used to evaluate the tribological performance of the prepared perfluoropolyether supramolecular gel composite molybdenum di...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com