Main plate opposing connection welding method

A welding method and plate technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of light radiation pollution and little efficiency improvement, and achieve small droplet transition, fast melting speed, and deposition efficiency increased effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

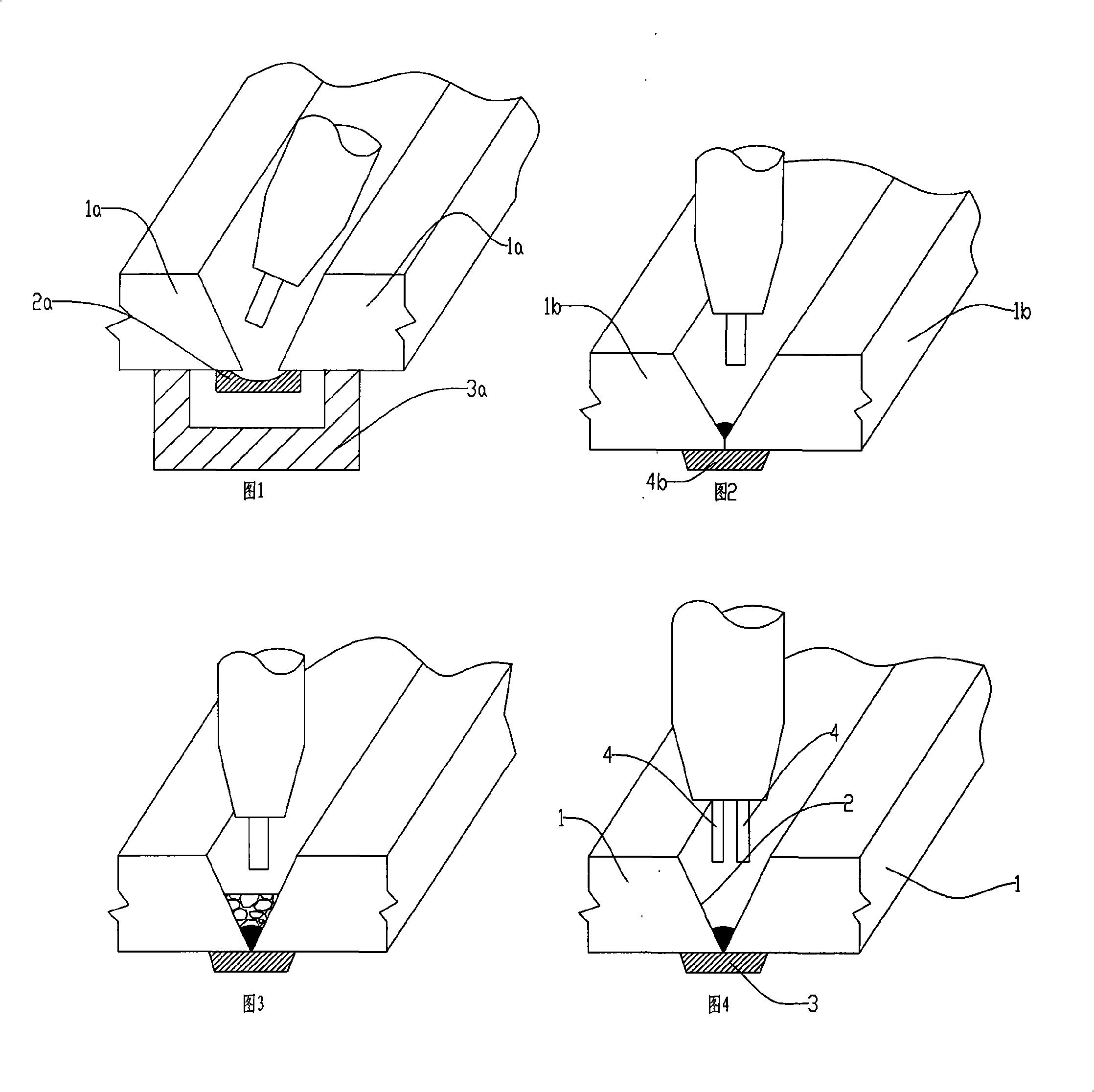

[0018] As shown in Figure 4, the two plates are butt welded. When welding, first closely butt the bottom of the welding groove 2 of the two plates 1 to be welded and fix them by spot welding in the groove; then, paste ceramics on the bottom of the joint through aluminum foil. Liner 3; Then, the thin welding wire 4 is simultaneously output to the two conductive tips of the welding torch through the wire feeder, so that the two thin welding wires are arranged side by side at a certain distance, and the two welding wires are energized and welded by submerged arc welding, and the weld seam is welded from bottom to top The whole weld is full.

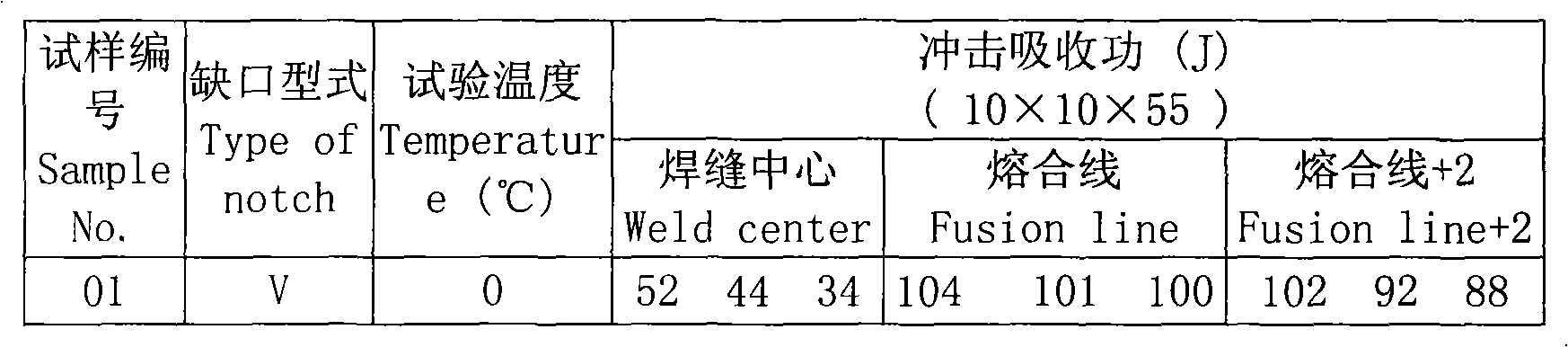

[0019] During welding, the weld seam is submerged arc welded by two thin welding wires with a certain transverse distance, which effectively shunts the welding current while maintaining a large heat input, and distributes the current evenly to the two welding wires, effectively It avoids the problem that the liner is easy to burn through bec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com