Assistant coating TIG fusing-brazing method suitable for aluminum/steel dissimilar alloy butting

A brazing method, aluminum alloy technology, applied in the direction of welding/welding/cutting items, welding equipment, metal processing equipment, etc., to achieve the effect of good forming, strong adhesion, and stable welding process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

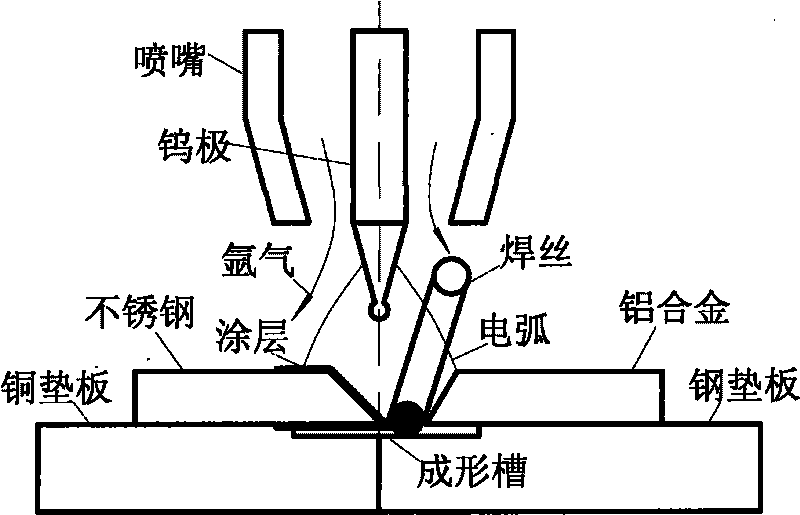

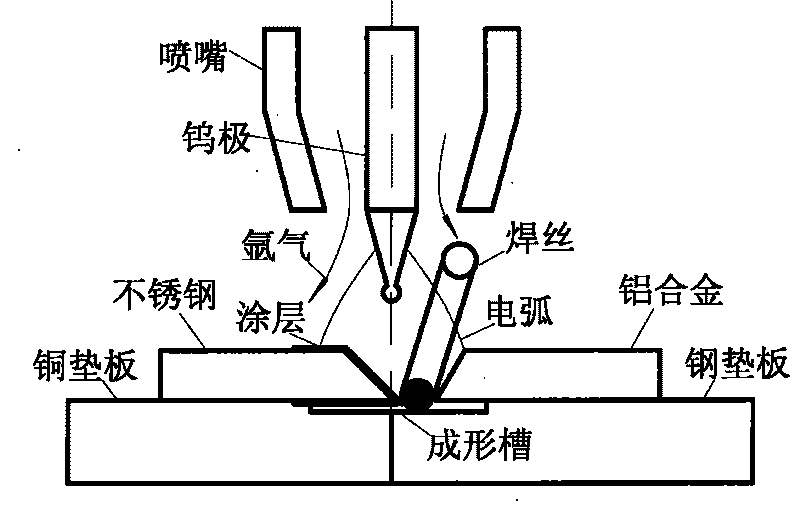

[0020] Example 1: Combining figure 1 , a kind of auxiliary coating TIG fusion-brazing method applicable to aluminum / steel dissimilar alloy butt joint of the present invention, method step is as follows:

[0021] Step 1: Asymmetric V-shaped grooves are made on the butt joint between aluminum and steel plates, the steel side groove angle is 20-50°, and the aluminum side groove angle is 0-30°;

[0022] Step 2: Mechanically grind the groove and the upper and lower surfaces of the aluminum and steel parts to remove the oxide film, and wipe with acetone to remove the surface oil, and then apply an auxiliary layer on the groove of the steel part and the upper and lower surfaces within the range of 5-20mm, auxiliary coating The thickness is 0.1~0.5mm;

[0023] Step 3: Fix the workpiece on the copper-steel composite backing plate, the backing plate is separated from the middle line, half of which is copper and half is steel, fix the steel parts on the copper backing plate, and fix the...

Embodiment 2

[0031]Example 2: 5A06 aluminum alloy and SUS321 stainless steel plate 3.0mm thick butt joint test piece, its auxiliary coating TIG fusion-brazing method is completed by the following steps: (1) The bevel angle of the stainless steel plate is 45 °, and the aluminum alloy plate The groove angle is 30°; (2) Mechanically grind the groove and the upper and lower surfaces of the aluminum alloy and stainless steel parts to remove the oxide film, and wipe with acetone to remove the surface oil, and then coat the auxiliary layer on the groove and the upper and lower surfaces of the stainless steel parts near 15mm , the thickness of the auxiliary coating is 0.3mm; (3) Fix the stainless steel parts on the copper backing plate, fix the aluminum alloy parts on the steel backing plate, and open a forming groove with a width of 8mm and a thickness of 0.5 mm in the middle of the backing plate ;(4) The butt gap of the joint is 2.0mm, the arc length is 4.0mm, and the arc heating position is 1mm ...

Embodiment 3

[0032] Example 3: In steps (1), (4) and (6) of this embodiment, the aluminum plate is pure aluminum or 6A02 aluminum alloy, the steel plate is low carbon steel, the plate thickness is 2.0mm, and the bevel angle of the steel plate is 40° , the groove angle of the aluminum alloy plate is 20°; the butt gap of the joint is 1.5mm, the arc length is 3.0mm, and the arc heating position is 0.5mm away from the steel side; aluminum-silicon welding wire is selected, and the diameter of the welding wire is 1.2mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com