Method for growing mullite crystals through floating-zone method

A technology of mullite and floating zone method, which is applied in the directions of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of difficulty in obtaining centimeter-level mullite crystals, lack of research on mullite crystals, etc., and achieve repeatable Strong performance, low cost and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

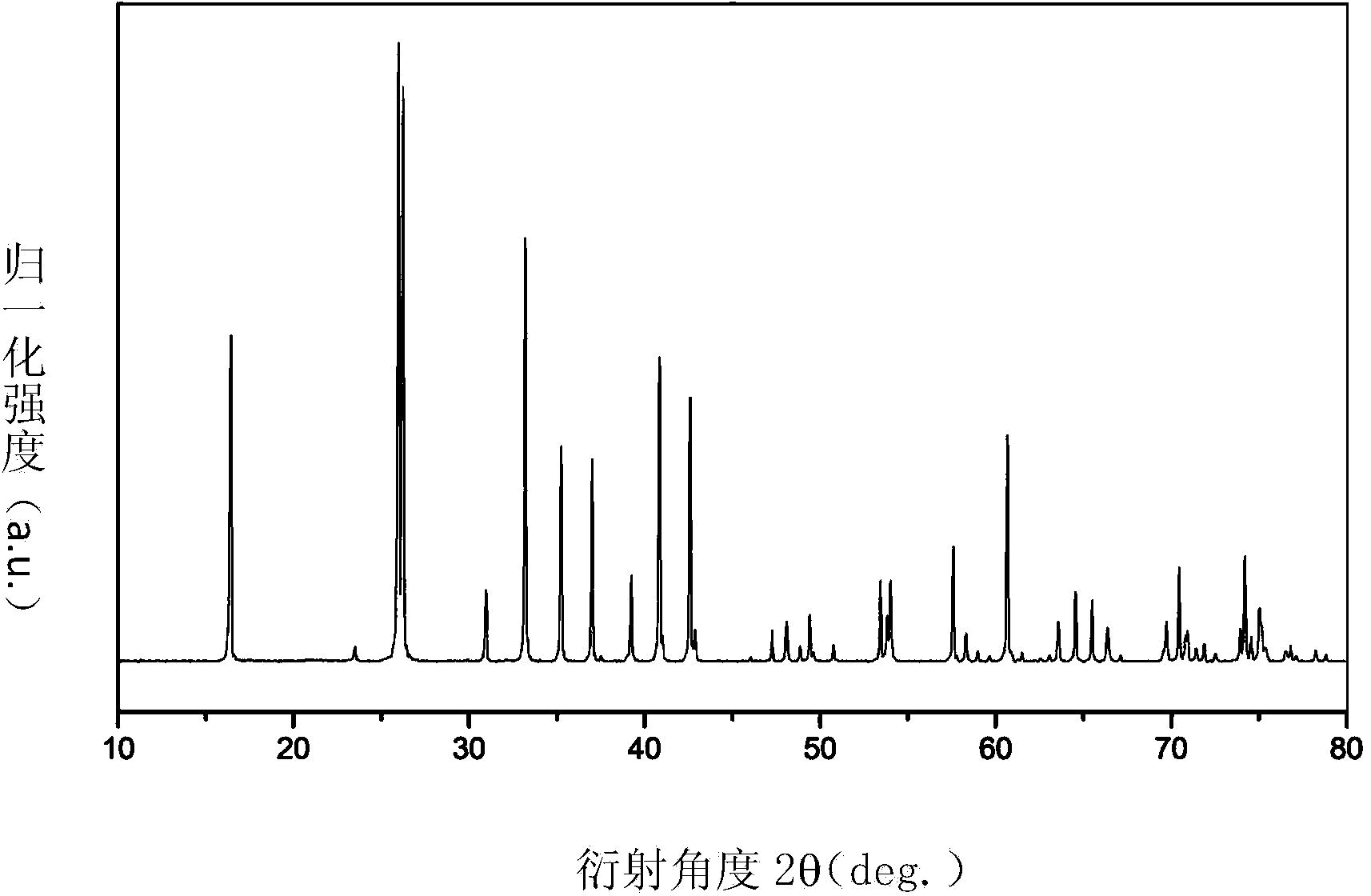

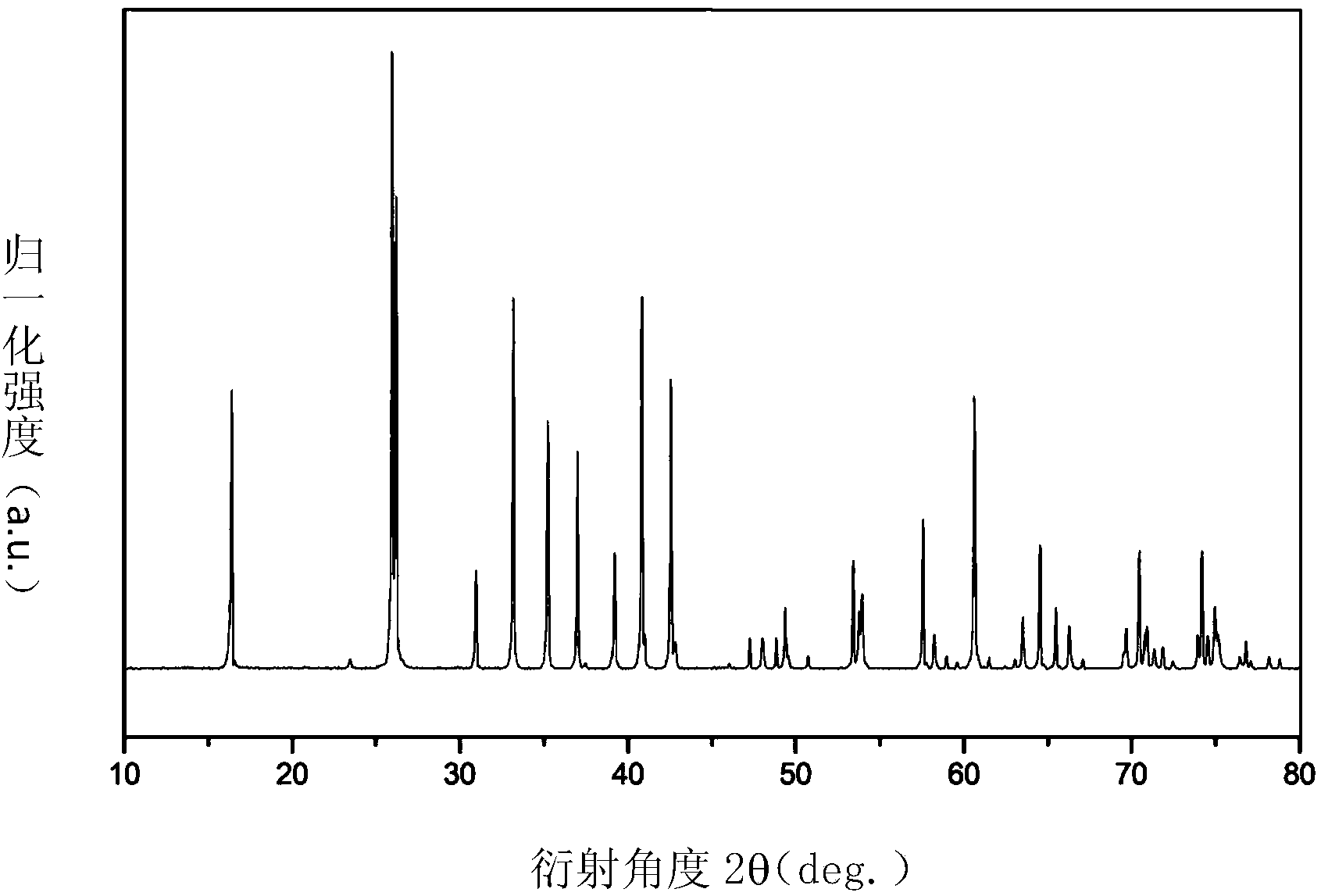

Image

Examples

Embodiment 1

[0023] (1) Powder Al with a purity of up to 99.99% 2 o 3 and SiO with a purity of up to 99.999% 2 Weigh the ingredients according to the stoichiometric ratio of 3:2, use absolute ethanol as the dispersant to dilute and mix evenly, ball mill and dry, sieve through 200 mesh, and put the powder into Al 2 o 3 Place the crucible in a muffle furnace to pre-fire at a temperature of 1450°C for 15 hours at a constant temperature, then grind and sieve through a 200-mesh second time;

[0024] (2) Put the powder sieved twice in step (1) into a strip-shaped rubber balloon, compact and seal it, vacuumize it for 10 minutes, and press it for 15 minutes under isostatic pressure of 70MPa to make it uniform in density vegetative body.

[0025] (3) Put the green body obtained in step (2) into the muffle furnace for sintering again, and sinter at a constant temperature for 30 hours at a temperature of 1550° C. to obtain a dense polycrystalline rod.

[0026] (4) Put the polycrystalline rod pre...

Embodiment 2

[0029] (1) Powder Al with a purity of up to 99.99% 2 o 3 and SiO with a purity of up to 99.999% 2 Weigh the ingredients according to the stoichiometric ratio of 3:2, use absolute ethanol as the dispersant to dilute and mix evenly, ball mill and dry, sieve through 200 mesh, and put the powder into Al 2 o 3 Place the crucible in a muffle furnace for pre-firing at a temperature of 1500°C for 20 hours at a constant temperature, then grind and sieve through a 200-mesh sieve for the second time;

[0030] (2) Put the powder that has been sieved twice in step (1) into a strip-shaped rubber balloon, compact it and seal it, vacuumize it for 15 minutes, and press it for 10 minutes under the pressure of isostatic pressure 70MPa to make it uniform in density vegetative body.

[0031] (3) Put the green body obtained in step (2) into the muffle furnace for sintering again, and sinter at a constant temperature for 24 hours at a temperature of 1550° C. to obtain a dense polycrystalline rod...

Embodiment 3

[0035] (1) Powder Al with a purity of up to 99.99% 2 o 3 and SiO with a purity of up to 99.999% 2 Weigh the ingredients according to the stoichiometric ratio of 3:2, use absolute ethanol as the dispersant to dilute and mix evenly, ball mill and dry, sieve through 200 mesh, and put the powder into Al 2 o 3 Place the crucible in a muffle furnace for pre-firing at a temperature of 1450°C for 20 hours at a constant temperature, then grind and sieve through a 200-mesh sieve for the second time;

[0036] (2) Put the powder that has been sieved twice in step (1) into a strip-shaped rubber balloon, compact and seal it, vacuumize it for 15 minutes, and press it for 20 minutes under isostatic pressure of 65MPa to make it uniform in density vegetative body.

[0037] (3) Put the green body obtained in step (2) into the muffle furnace for sintering again, and sinter at a constant temperature for 25 hours at a temperature of 1600° C. to obtain a dense polycrystalline rod.

[0038] (4) ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com