A kind of argon arc welding process of 1800mpa ultra-high strength hot forming steel plate

An ultra-high-strength, argon arc welding technology, applied in welding equipment, welding accessories, arc welding equipment, etc., can solve problems such as increasing the thickness of the plate, and achieve the effect of easy operation, high efficiency and maximum benefit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below with reference to the embodiments shown in the accompanying drawings.

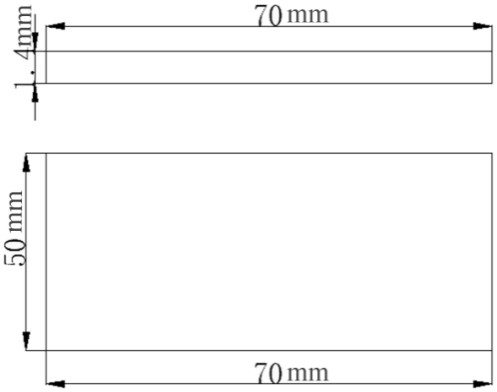

[0017] The invention provides an argon arc welding process for a 1800 MPa-grade ultra-high-strength hot-formed steel sheet, which uses a hot-formed steel sheet with a length of 70 mm, a width of 50 mm, and a thickness of 1.4 mm, and does not use welding wires for welding. The implementation process is as follows.

[0018] The hot-formed steel sheet is treated before welding: the rust layer after heat treatment on the surface of the steel plate is removed by pickling, the oxide layer is removed by grinding, and the parts to be welded are cleaned with acetone to ensure that the parts to be welded are clean.

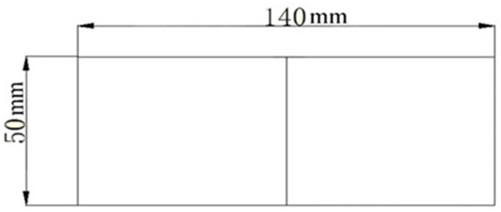

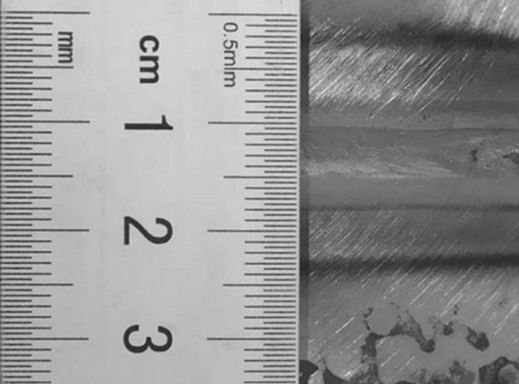

[0019] The ultra-high-strength hot-formed steel sheet is placed on the welding machine table in the form of a butt, and the size of the sheet is as follows figure 1 As shown, the docking form of the plate is as follows figure 2 shown. Tig...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com