Method for growing zinc bismuth borate monocrystal through zone melting method

A technology of bismuth zinc borate, zone melting method, applied in the direction of self-zone melting method, single crystal growth, crystal growth, etc., can solve the problem of no relevant reports, and achieve the effect of high preparation efficiency, no macroscopic defects, and avoiding corrosion problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Synthetic bismuth zinc borate (Bi 2 ZnB 2 o 7 ) compound:

[0045] Sintering is carried out at a high temperature of 630°C by a solid-state synthesis method, and its chemical formula is: ZnCO 3 +B 2 o 3 +Bi 2 o 3 → Bi 2 ZnB 2 o 7 +CO 2 ↑;

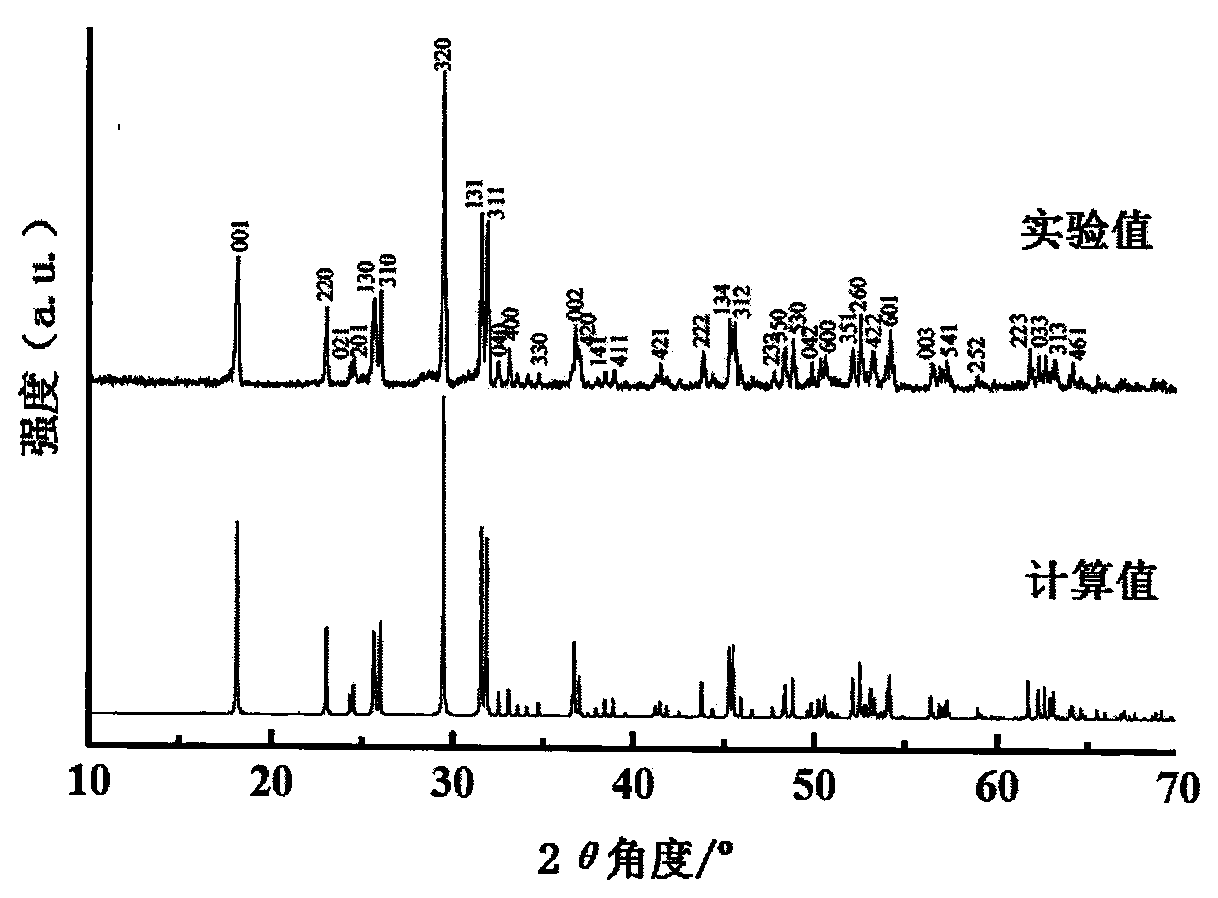

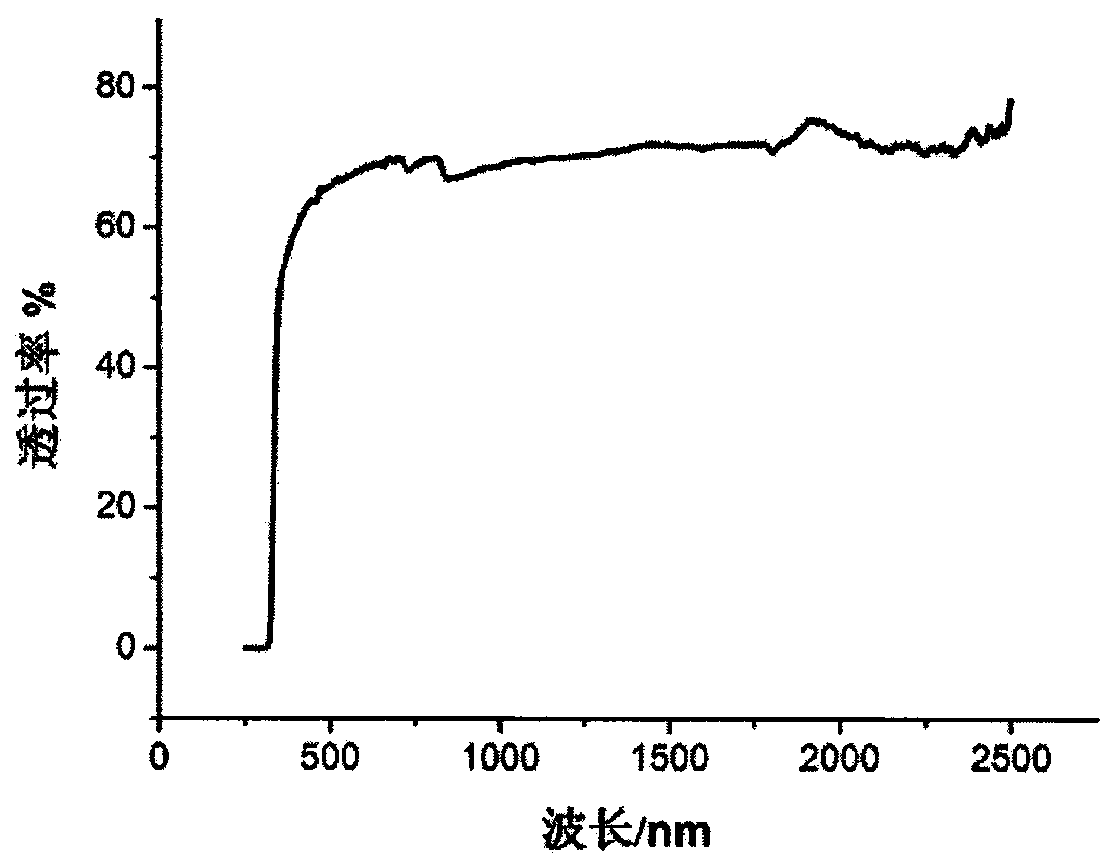

[0046] a. Pure phase synthesis of powder: ZnCO 3 , B 2 o 3 and Bi 2 o 3Weigh and put it into a mortar according to the metering ratio of 1:1:1, mix and grind carefully, then put it into a corundum crucible with an opening of Φ100mm×100mm, put it into a muffle furnace, slowly raise the temperature to 550°C, and keep the temperature constant for 24 hours. Cool to room temperature, take it out and put it into the muffle furnace after the second grinding, then raise the temperature to 630°C, keep the temperature for 48 hours, cool to room temperature, take out and grind to obtain the single-phase polycrystalline powder of bismuth zinc borate compound, and then the product Carry out powder X-ray analysis, gained powder X-...

Embodiment 2

[0054] Synthetic bismuth zinc borate (Bi 2 ZnB 2 o 7 ) compounds:

[0055] Sintering is carried out at a high temperature of 635°C by a solid-state synthesis method, and its chemical equation is: Zn(NO 3 ) 2 +B 2 o 3 +Bi 2 o 3 → Bi 2 ZnB 2 o 7 +2NO 2 ↑+0.5O 2 ↑;

[0056] a, pure phase synthesis of powder: Zn(NO 3 ) 2 , B 2 o 3 and Bi 2 o 3 Weigh and put it into a mortar according to the metering ratio of 1:1:1, mix and grind carefully, then put it into a corundum crucible with an opening of Φ100mm×100mm, put it into a muffle furnace, slowly raise the temperature to 550°C, and keep the temperature constant for 24 hours. Cool to room temperature, take it out and put it into a muffle furnace after the second grinding, then raise the temperature to 635°C, keep the temperature for 48 hours, cool to room temperature, take out and grind to obtain a single-phase polycrystalline powder of bismuth zinc borate compound, and then the product Carry out powder X-ray anal...

Embodiment 3

[0064] Synthetic bismuth zinc borate (Bi 2 ZnB 2 o 7 ) compounds:

[0065] Sintering is carried out at a high temperature of 630°C by a solid-state synthesis method, and its chemical formula is: ZnCO 3 +B 2 o 3 +2Bi(OH) 3 → Bi 2 ZnB 2 o 7 +CO 2 ↑+3H 2 O↑;

[0066] a. Pure phase synthesis of powder: ZnCO 3 , B 2 o3 and Bi(OH) 3 Weigh it into a mortar according to the metering ratio of 1:1:2, mix and grind it carefully, then put it into a corundum crucible with an opening of Φ100mm×100mm, put it into a muffle furnace, slowly raise the temperature to 550°C, and keep the temperature constant for 24 hours. Cool to room temperature, take it out and put it into the muffle furnace after the second grinding, then raise the temperature to 630°C, keep the temperature for 48 hours, cool to room temperature, take out and grind to obtain the single-phase polycrystalline powder of bismuth zinc borate compound, and then the product Carry out powder X-ray analysis, gained powder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com