Method for preparing surface composite sinterer grate bars

A technology of surface compounding and machine furnace, which is applied in the direction of furnace, furnace type, manufacturing tools, etc., can solve the problem of service life affecting the production efficiency and production cost of sintering materials, affecting the production efficiency and production cost of sintering materials, and large consumption, etc. problem, to achieve the effect of improving service life, excellent wear resistance and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

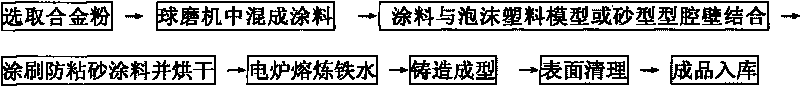

Embodiment 1

[0018] Take 15% of 20-35 mesh SiC powder, 35% of 100-150 mesh alumina powder, and 50% of 150-200 mesh high-carbon ferrochrome powder according to weight percentage, mix the above materials and put them in 4% vol polyvinyl alcohol aqueous solution Mix in a ball mill for 1.5 hours to make an alloy powder coating. Coat the mixed alloy powder coating on the foamed plastic model of the sintering machine grate bar with a thickness of 4mm, and then hang 1.5-2mm thick magnesia powder anti-sticking sand coating on the outside. Before use, it needs to be dried in an oven at ≤50°C for 24 hours, or it can be fully dried in a natural environment.

[0019] The foamed plastic model and gating system of the sintering machine grate coated with alloy powder coating and anti-sticking sand coating were placed in a vacuum lost foam (EPC) sandbox and filled with dry quartz sand. Then place it on a vibrating table and vibrate it tightly. The upper part of the sand box is covered with a plastic fil...

Embodiment 2

[0023] Take 20% of 20-35 mesh SiC powder, 40% of 100-150 mesh alumina powder, 40% of 150-200 mesh high-carbon ferrochrome powder, mix the above materials with 5% vol polyvinyl alcohol aqueous solution, and put them into a ball mill for mixing 2 hours, made alloy powder coating. The mixed alloy powder paint is brushed, sprayed or pressed into a paste block and bonded to the upper working part of the grate bar of the sand mold cavity wall of the sintering machine grate bar, and the coating thickness is 5mm. The alloy powder coating should be fully baked with a blowtorch before use.

[0024] The molten iron is smelted in an electric arc furnace, slag is removed after deoxidation, and then the temperature is measured and cast into shape. After the casting is cooled to room temperature, the casting is turned out of the sand mold, the nozzle is cut off, and the sticky sand and coating on the surface of the casting are cleaned with a roller to make a qualified Al alloy. 2 o 3 +SiC...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com