Unequal-thickness heterogeneous dual-phase steel cold metal transition welding technology

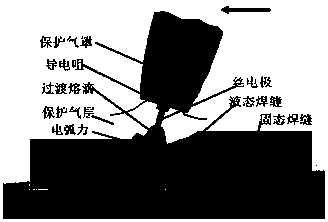

A cold metal transition and welding process technology, applied in metal processing equipment, welding equipment, manufacturing tools, etc., can solve problems such as difficult welding, large heat input, electrode wear, etc., to reduce welding heat input and good mechanical properties , Good effect of welding seam formation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

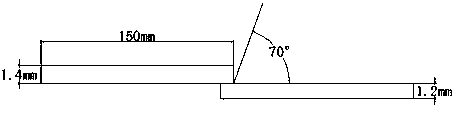

[0035] In this implementation case, the CMT (cold metal transition) welding process parameters are selected as: 1.4mm thick steel plate on top, 1.2mm thick steel plate on bottom, wire feeding speed: 3.0m / min, welding speed: 400mm / min. The welding torch is inclined at an angle of 70° to the steel plate in the direction perpendicular to the welding direction. The welding wire is a low-alloy welding wire with a diameter of 1.2mm, and the dry elongation of the welding wire is 10mm. The protective gas composition is 80%Ar+20%CO 2 A mixture of argon and carbon dioxide was used as the shielding gas.

[0036] The unequal-thickness heterogeneous dual-phase steel plates are used to form lap joints, and the width of the lap joints is 10mm. It is then welded using a CMT (cold metal transfer) welder.

[0037] In this example, the obtained weld is as Figure 4 As shown, the weld seam is uniform, and the welded lap joint is formed smoothly and beautifully; Figure 5 As shown, there is n...

Embodiment 2

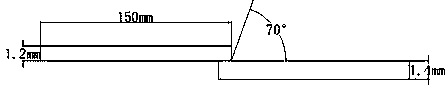

[0039]In this implementation case, the CMT (cold metal transition) welding process parameters are selected as: 1.4mm thick steel plate on top, 1.2mm thick steel plate on bottom, wire feeding speed: 3.0m / min, welding speed: 500mm / min. The welding torch is inclined at an angle of 70° to the steel plate in the direction perpendicular to the welding direction. The welding wire is a low-alloy welding wire with a diameter of 1.2mm, and the dry elongation of the welding wire is 10mm. The protective gas composition is 80%Ar+20%CO 2 A mixture of argon and carbon dioxide was used as the shielding gas.

[0040] The unequal-thickness heterogeneous dual-phase steel plates are used to form lap joints, and the width of the lap joints is 10mm. It is then welded using a CMT (cold metal transfer) welder.

[0041] In this example, the obtained weld is as Figure 7 As shown, the weld seam is uniform, and the welded lap joint is formed smoothly and beautifully; Figure 8 As shown, there is no...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com