1800 MPa ultrahigh-strength thermoforming steel plate resistance spot welding technique

A resistance spot welding, ultra-high-strength technology, applied in resistance welding equipment, resistance electrode bases, electrode features, etc., to achieve the effect of improving the process environment, good solder joint formation, and no macro defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be described in detail below in conjunction with examples.

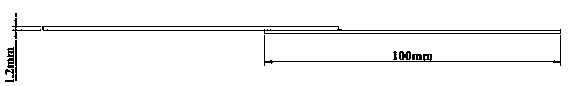

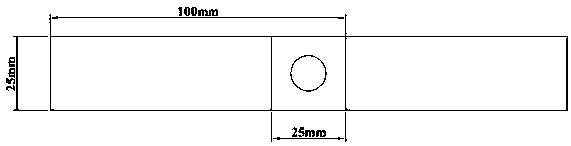

[0021] In the invention, two ultra-high-strength hot-formed steel plates are overlapped and placed on the working machine tool of the resistance spot welding robot, and the welding is performed after parameters are adjusted through a teaching panel. Ultra-high-strength hot-formed steel is the same steel grade and has the same thickness. The resistance spot welding robot uses the same type of electrode with the same end surface area. The specific method described is: lap two pieces of ultra-high-strength hot-formed steel together and tighten them with a clamp, use the resistance spot welding robot to teach the panel, set The path adjusts the position of the electrode so that the welding part is located at the center of the overlapping part. Add a welding command on the teaching panel and change the welding pressure. After adjusting the welding parameters through the welding machine, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com