Large-lead nut turning device

A large lead and nut technology, applied in the direction of tangent devices, metal processing equipment, manufacturing tools, etc., can solve the problems of poor consistency and low thread accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

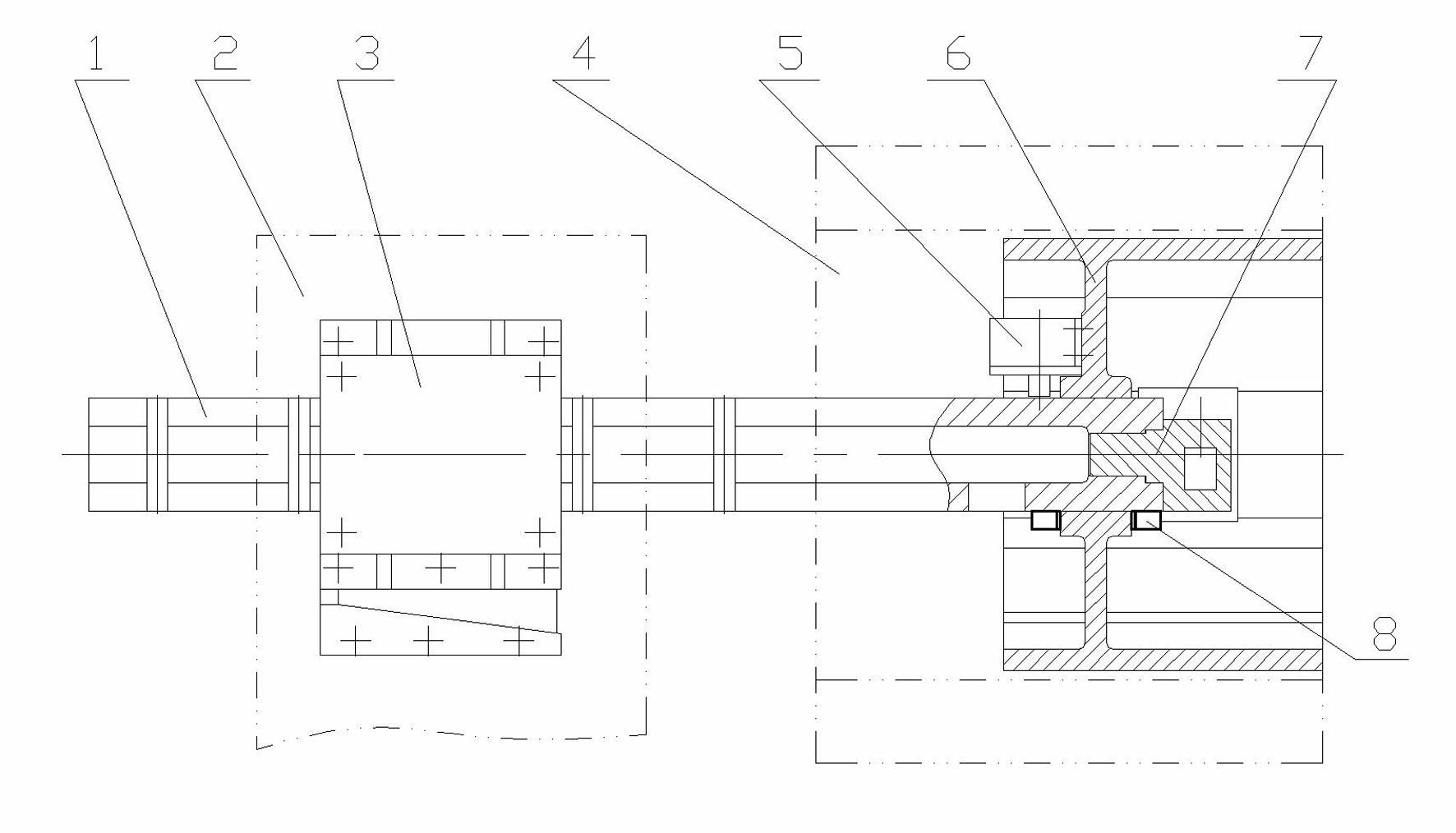

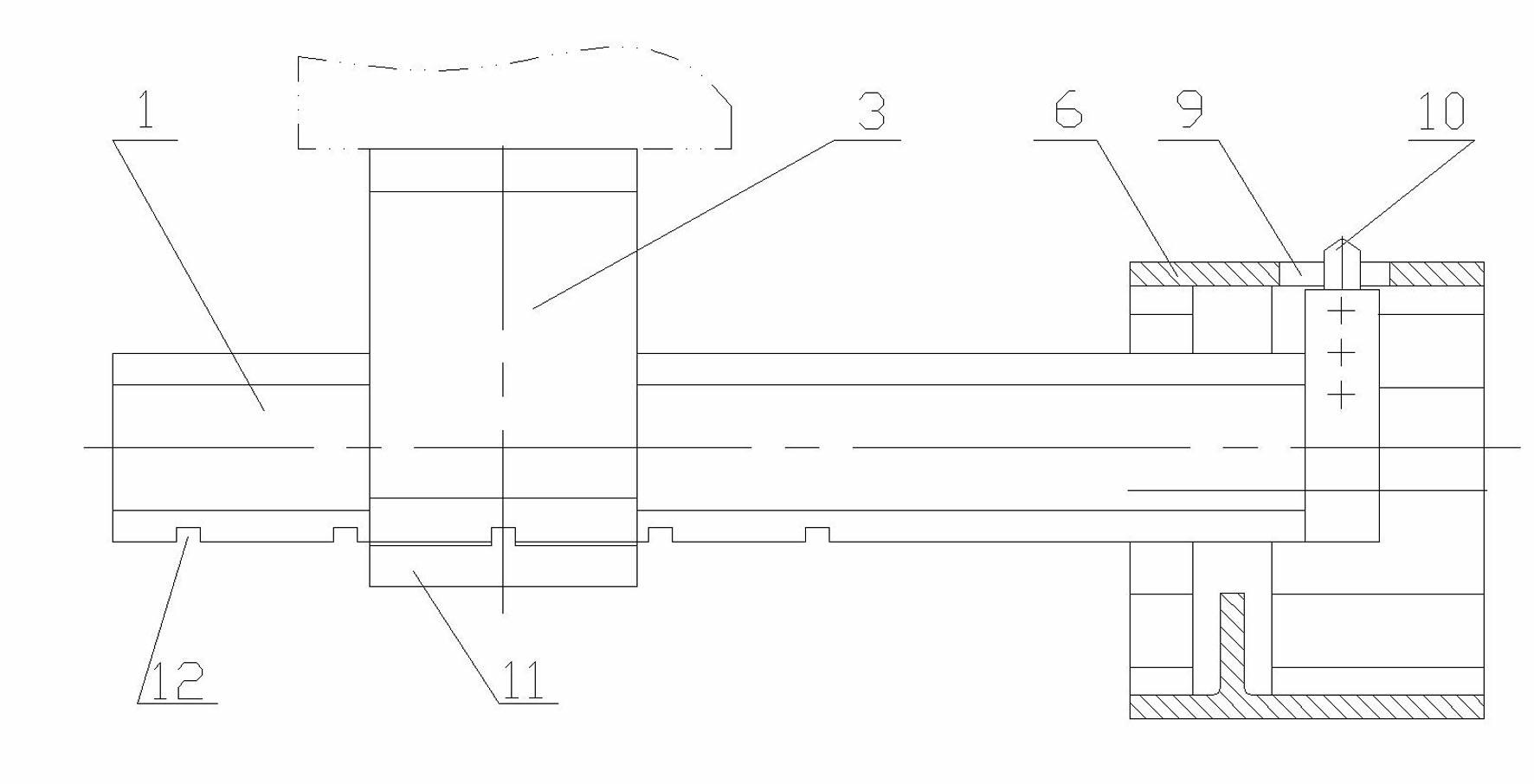

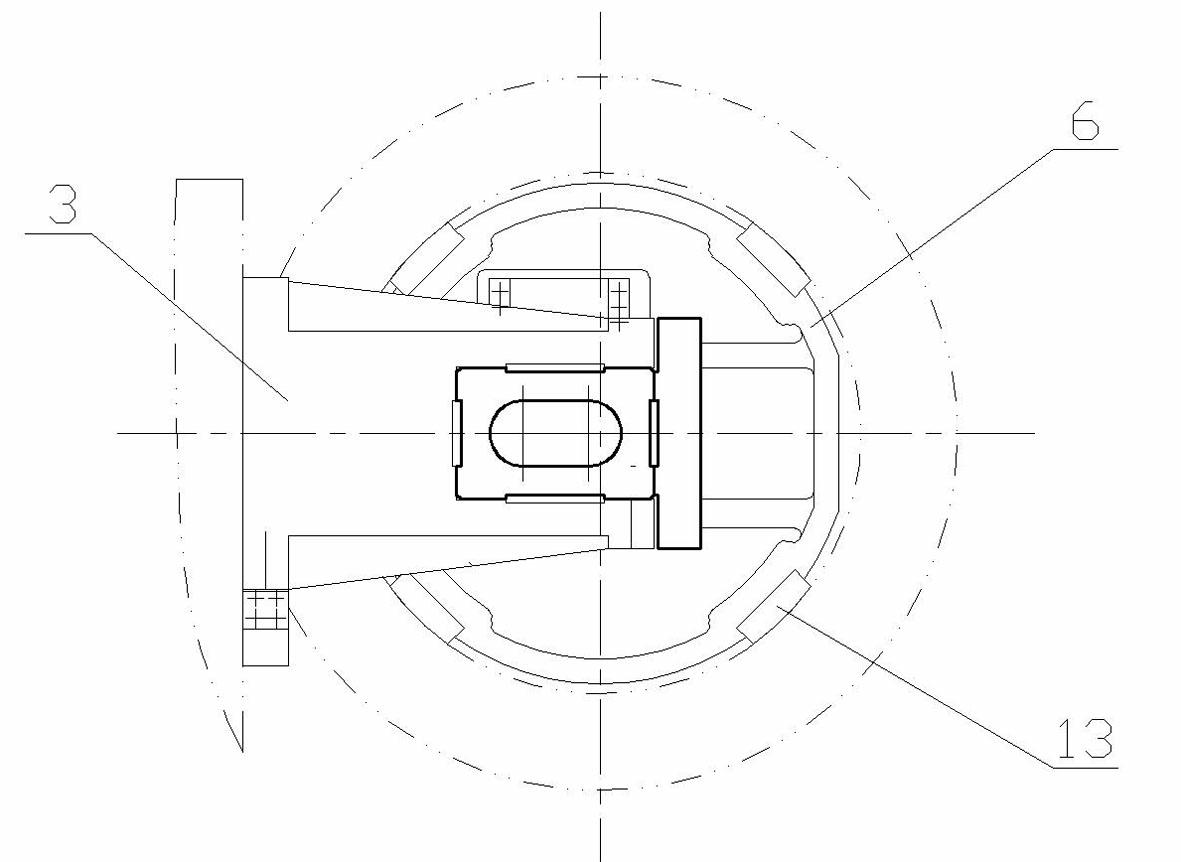

[0031] Refer to the attached figure 1 with 2 The high lead nut turning unit shown, figure 1 The double dotted line on the right shows the nut 4, and the left double dotted line shows the tool holder end face 2 for installing the tool holder 3. The basic structure of the large lead nut turning device is that it includes:

[0032] The tool holder 3 has a connecting structure connected to the tool rest of the lathe;

[0033] The tool bar 1 is fixedly mounted on the tool seat, and is used to overhang into the prefabricated hole of the nut 4 to be turned;

[0034] The turning tool 10 is fixed on the part of the tool bar that is used to hang into the nut 4;

[0035] It also includes:

[0036] The guide sleeve 6 is connected to the cutter bar, and is used to cooperate with the prefabricated hole of the nut 4 to form a shaft hole to form an auxiliary support.

[0037] Based on the above-mentioned structure, the installation of the tool bar 1 will not be negatively affected by the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com