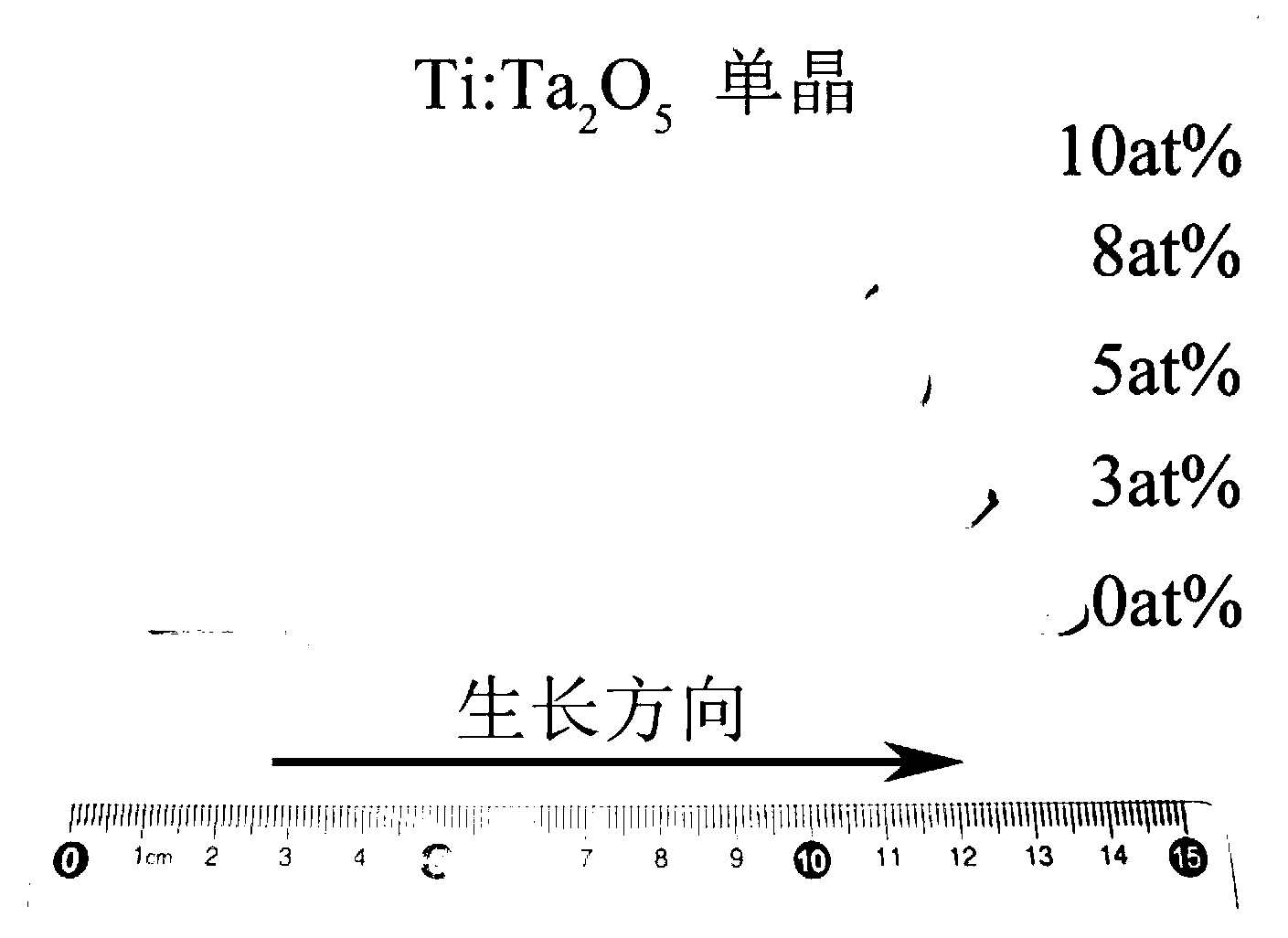

Method for crucible-free rapid growth of centimeter magnitude Ti:Ta2O5 crystals

A crucible-free, ta2o5 technology, applied in the direction of single crystal growth, crystal growth, single crystal growth, etc., can solve the problems of growth of high-melting point crystals, demanding experimental conditions, complicated equipment and other problems, to achieve no macroscopic defects, repeatable The effect of strong performance and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

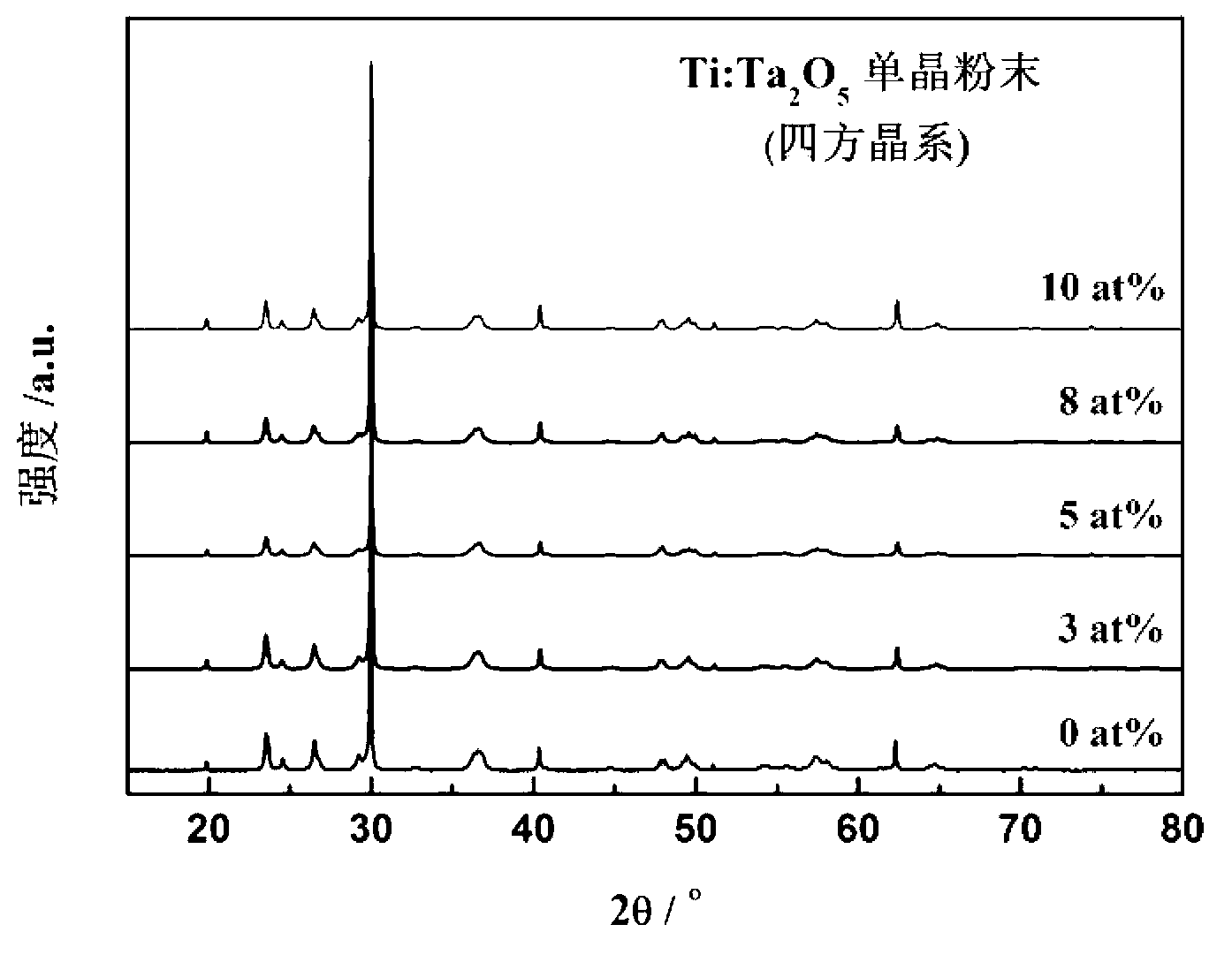

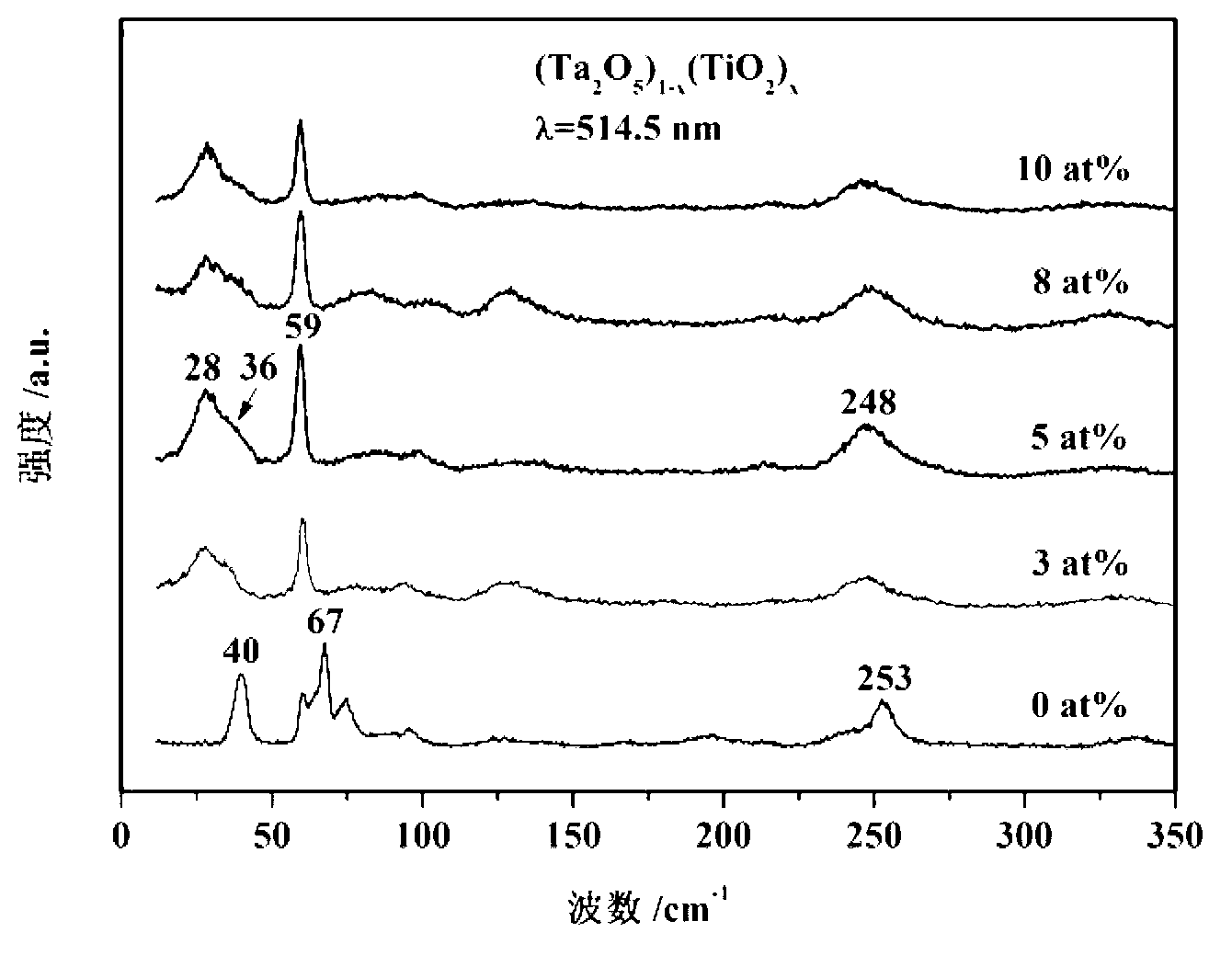

Embodiment 1

[0036] (1) Preparation of ingredients and rods: the high-purity raw material TiO 2 and Ta 2 o 5 The powder is mixed according to the stoichiometric ratio of 3at%, and then mechanically mixed; put into a high-temperature pre-calcination furnace with a pre-calcination temperature of 1350°C and a pre-calcination time of 14 hours to obtain polycrystalline powder. Put the pre-fired polycrystalline powder into a rubber tube, and then put it into a rod-shaped polycrystalline rod under isostatic pressure;

[0037] (2) Material rod and seed crystal installation: fix the pressed polycrystalline rod on the upper part of the central axis of the single crystal furnace as a material rod, and put the polycrystalline rod into the lower part of the central axis as a seed crystal. The crystal and the material rod form a straight line in the vertical direction, adjust the position of the material rod and the seed crystal to make them contact, and the contact point is on the same horizontal lin...

Embodiment 2

[0041] (1) Preparation of ingredients and rods: the high-purity raw material TiO 2 and Ta 2 o 5 The powder is mixed according to the stoichiometric ratio of 5 at%, and then mechanically mixed; put into a high-temperature pre-calcination furnace, the pre-calcination temperature is 1350 ° C, and the pre-calcination time is 16 hours to obtain polycrystalline powder. Put the pre-fired polycrystalline powder into a rubber tube, and then put it into a rod-shaped polycrystalline rod under isostatic pressure;

[0042] (2) Material rod and seed crystal installation: fix the pressed polycrystalline rod on the upper part of the central axis of the single crystal furnace as a material rod, and put the polycrystalline rod into the lower part of the central axis as a seed crystal. The crystal and the material rod form a straight line in the vertical direction, adjust the position of the material rod and the seed crystal to make them contact, and the contact point is on the same horizontal...

Embodiment 3

[0047] (1) Preparation of ingredients and rods: the high-purity raw material TiO 2 and Ta 2 o 5 The powder is mixed according to the stoichiometric ratio of 8at%, and then mechanically mixed; put into a high-temperature pre-calcination furnace, the pre-calcination temperature is 1350 ° C, and the pre-calcination time is 18 hours to obtain polycrystalline powder. Put the pre-fired polycrystalline powder into a rubber tube, and then put it into a rod-shaped polycrystalline rod under isostatic pressure;

[0048] (2) Material rod and seed crystal installation: fix the pressed polycrystalline rod on the upper part of the central axis of the single crystal furnace as a material rod, and put the polycrystalline rod into the lower part of the central axis as a seed crystal. The crystal and the material rod form a straight line in the vertical direction, adjust the position of the material rod and the seed crystal to make them contact, and the contact point is on the same horizontal ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com