Preparation method for carbon-coated silicon negative electrode material for lithium ion battery

A technology of lithium-ion batteries and carbon-coated materials, which is applied to battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering the development of new energy vehicles, unsafe costs, and short driving mileage, and achieves easy process realization, The effect of low cost and high conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

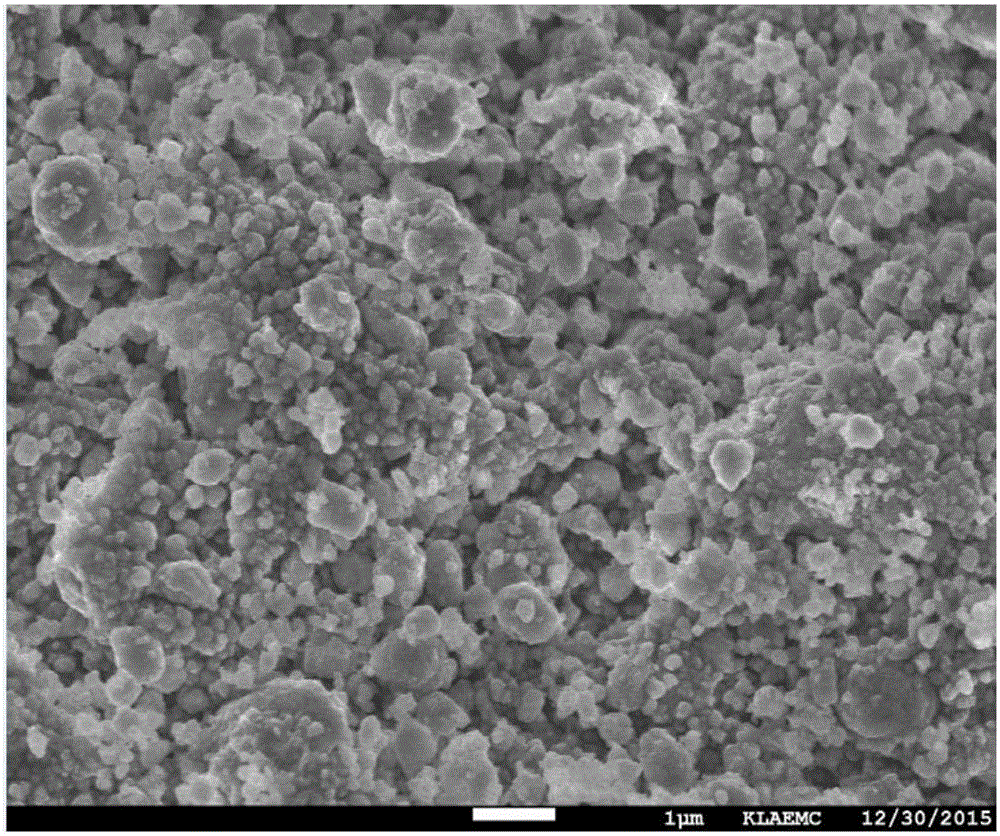

[0036] Embodiment 1 A kind of with sucrose as the first carbon coating, graphene is the preparation method of the silicon negative electrode material of the lithium ion battery of the second carbon coating, and its steps comprise:

[0037] 1) Put 80 grams of silicon powder with a particle size of 8 μm into the ball mill, add 160 ml of water, and ball mill for 6 hours;

[0038] 2) 20g of sucrose and 5g of polyvinyl alcohol were dissolved in 40ml of water to obtain the first carbon coating solution;

[0039] 3) adding the first carbon coating layer solution in step 2) to step 1), and continuing ball milling for 2 hours to obtain a dispersion of nano-sized silicon particles and the first carbon coating material;

[0040] 4) spray drying to remove the moisture of the dispersion liquid of the nano-silicon obtained in step 3) and the first carbon-coated material to obtain a solid;

[0041] 5) Carrying out high-temperature carbonization treatment of the solid in step 4) under a nitr...

Embodiment 2

[0048] A method for preparing a lithium-ion battery silicon negative electrode material with graphite as the first carbon coating and graphene oxide as the second coating, the steps comprising:

[0049] 1) Add 100 grams of silicon powder with a D50 of 25 μm into a ball mill, add 200 ml of water, and ball mill for 10 hours;

[0050] 2) ultrasonically disperse 10 g of graphite and 1.1 g of polyacrylic acid in 30 ml of water to obtain the first carbon coating layer dispersion;

[0051] 3) adding the first carbon coating layer dispersion in step 2) into step 1), and continuing ball milling for 3 hours to obtain nanometerized silicon particles uniformly dispersed in the first carbon coating layer;

[0052] 4) spray drying to remove the moisture in the product of step 3) to obtain a solid;

[0053] 5) Carrying out high-temperature carbonization treatment of the solid in step 4) under a nitrogen atmosphere at a heating rate of 10° C. / min, and maintaining at 700° C. for 3 hours to ob...

Embodiment 3

[0060] A method for preparing a lithium-ion battery silicon negative electrode material with starch as the first carbon coating and multi-layer graphene as the second coating, the steps comprising:

[0061] 1) Add 60 grams of silicon powder with a D50 of 15 μm into the ball mill, add 150 ml of water, and ball mill for 7 hours;

[0062] 2) ultrasonically disperse 6g of starch in 50ml of water to obtain the first carbon coating dispersion;

[0063] 3) adding the starch dispersion in step 2) to step 1), and continuing ball milling for 3 hours to obtain nano-sized silicon particles uniformly dispersed in the first carbon coating solution;

[0064] 4) spray drying to remove the moisture in the dispersion liquid of nano-silicon and starch obtained in step 3) to obtain a solid;

[0065] 5) Carrying out high-temperature carbonization treatment of the solid in step 4) under a nitrogen atmosphere at a heating rate of 6° C. / min, and maintaining at 850° C. for 5 hours to obtain a primary...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com