Nano-material composite concrete with super high performance

An ultra-high-performance, nano-material technology, applied in climate sustainability, sustainable waste treatment, solid waste management, etc., can solve the problems of high price, can not achieve ultra-high performance, low cost, etc., to improve mechanical properties and durability, significant technical and economic significance, and the effect of major engineering practical value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

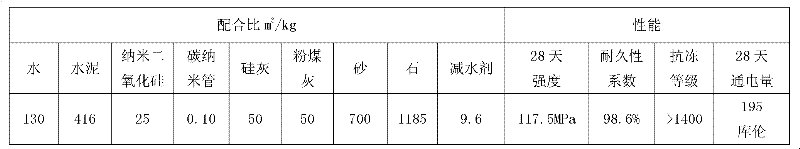

[0032] C100 high-performance concrete used in a sea-crossing bridge project, the raw materials and properties used are as follows:

[0033] Cement: P·I 42.5 Portland cement, produced by a cement factory, the 28-day compressive strength is 51.7MPa, and the 28-day flexural strength is 9.1MPa.

[0034] Fine aggregate: river sand with a fineness modulus of 2.74, which is medium sand in zone II; apparent density is 2.62g / cm 3 , the loose bulk density is 1520kg / m 3 , the tight packing density is 1670kg / m 3 . Rinse it with laboratory tap water and dry it before use, and its mud content and moisture content can be ignored.

[0035] Coarse aggregate: high-density limestone with a nominal particle size of 5-20mm and an apparent density of 2.85g / cm 3 , the loose bulk density is 1460kg / m 3 , the tap density is 1580kg / m 3 , the crush index is 3.45%. Rinse it with laboratory tap water and dry it before use, and its mud content and moisture content can be ignored.

[0036] Water: tap...

Embodiment 2

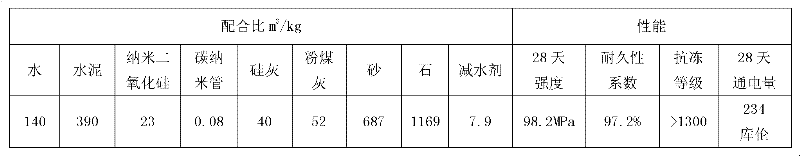

[0046] C90 self-compacting freeze-thaw resistant concrete is used in an oil production platform project, and the frost resistance grade is required to be F300.

[0047] Raw material used and performance are with embodiment 1.

[0048] Concrete mix ratio and properties are as follows:

[0049]

Embodiment 3

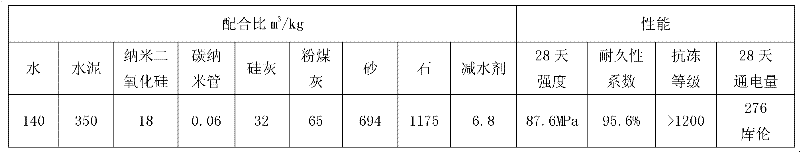

[0051] C80 self-compacting freeze-thaw resistant concrete is used in a seaport project, and the frost resistance grade is required to be F300.

[0052] Raw material used and performance are with embodiment 1.

[0053] Concrete mix ratio and properties are as follows:

[0054]

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com