Water-based light reflex industrial insulation coating and preparation method thereof

A thermal insulation coating and light reflection technology, applied in the direction of reflection/signal coating, anti-corrosion coating, coating, etc., can solve the problems of no heat conduction barrier effect, no anti-corrosion and weather resistance data, narrow application range, etc., to achieve Good thermal insulation and anti-corrosion functions, improved salt spray resistance, and improved application efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

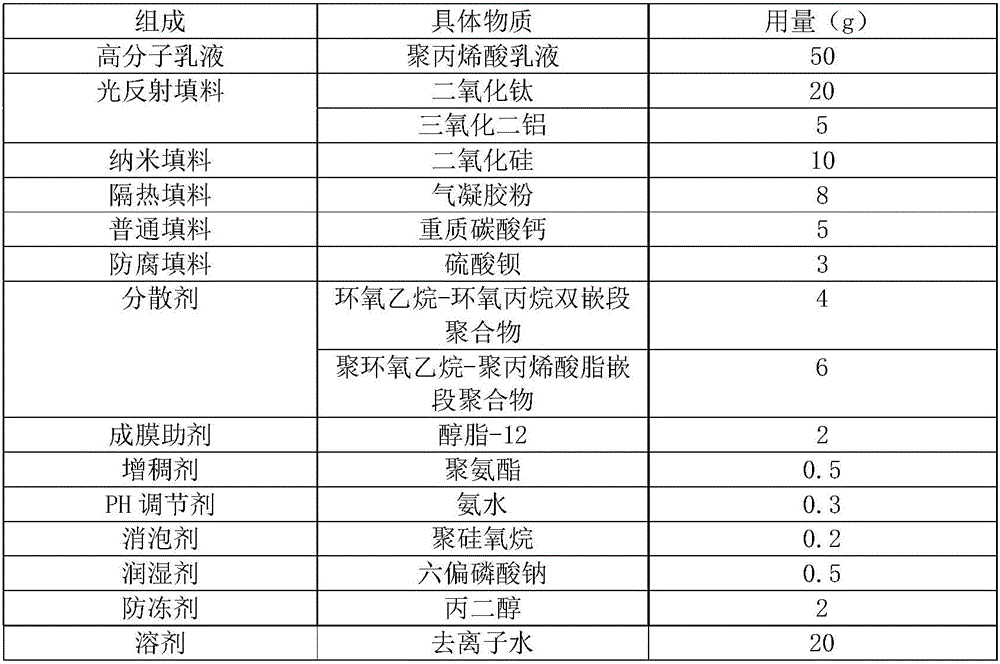

[0054] The formula composition of water-based industrial thermal insulation coatings is shown in the following table:

[0055]

[0056] The thermal conductivity of the airgel powder in the above table is 0.02w / (m k), and the density is 240kg / m 3 , the specific surface area is 220m 2 / g, the particle size is 3-8μm, the average particle size of silicon dioxide is 150nm, and the average particle size of titanium dioxide is 300nm.

[0057] Preparation of paint:

[0058] (1) Slurry mixing: Add deionized water, dispersant, antifreeze and a part of defoamer to the paint dispersion tank according to the above formula, and add light reflective fillers, heat insulation fillers, anti-corrosion fillers and ordinary fillers after mixing evenly , dispersed for 30 minutes at 1000 rev / min rotating speed to obtain a slurry;

[0059] (2) Slurry grinding: use a horizontal sand mill to grind the above energy-saving slurry, and mix the energy-saving slurry prepared in the above step (1) with...

Embodiment 2

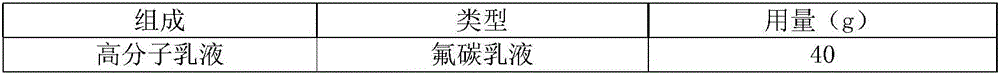

[0062] The formula composition of water-based industrial thermal insulation coatings is shown in the following table:

[0063]

[0064]

[0065] The particle size of tin antimony oxide in the above table is 70nm, and the average particle size of titanium dioxide is 300nm.

[0066] Preparation of paint:

[0067] (1) Slurry mixing: add water, dispersant, antifreeze and a part of defoamer to the paint dispersion tank according to the above formula, and add light reflective filler, anti-corrosion filler and ordinary filler after mixing evenly, at 1200 rpm Disperse for 30 minutes at a rotating speed to obtain a slurry;

[0068] (2) Slurry Grinding: Use a horizontal sand mill to grind the above energy-saving slurry, mix the energy-saving slurry prepared in the above step (1) with the grinding medium at a volume ratio of 1:1.1, and adjust the speed to 2000 Grind for 60 minutes after rev / min and filter the material;

[0069] (3) Preparation of water-based industrial thermal i...

Embodiment 3

[0071] The formula composition of water-based industrial thermal insulation coatings is shown in the following table:

[0072]

[0073]

[0074] The thermal conductivity of the airgel powder in the above table is 0.02w / (m k), and the density is 240kg / m 3 , the specific surface area is 220m 2 / g, the particle size is 3-8μm, the particle size of tin antimony oxide is 70nm, and the average particle size of titanium dioxide is 300nm.

[0075] Preparation of paint:

[0076] (1) Slurry preparation: add water, dispersant, antifreeze and a part of defoamer to the paint dispersion tank according to the above formula, and add light reflective filler, heat insulation filler, anti-corrosion filler and common filler after mixing evenly. Disperse for 30 minutes at 1200 rev / min rotating speed to obtain slurry;

[0077] (2) Slurry Grinding: Use a horizontal sand mill to grind the above energy-saving slurry, mix the energy-saving slurry prepared in the above step (1) with the grinding...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thermal conductivity | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com