Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

172results about How to "Increase insulation function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

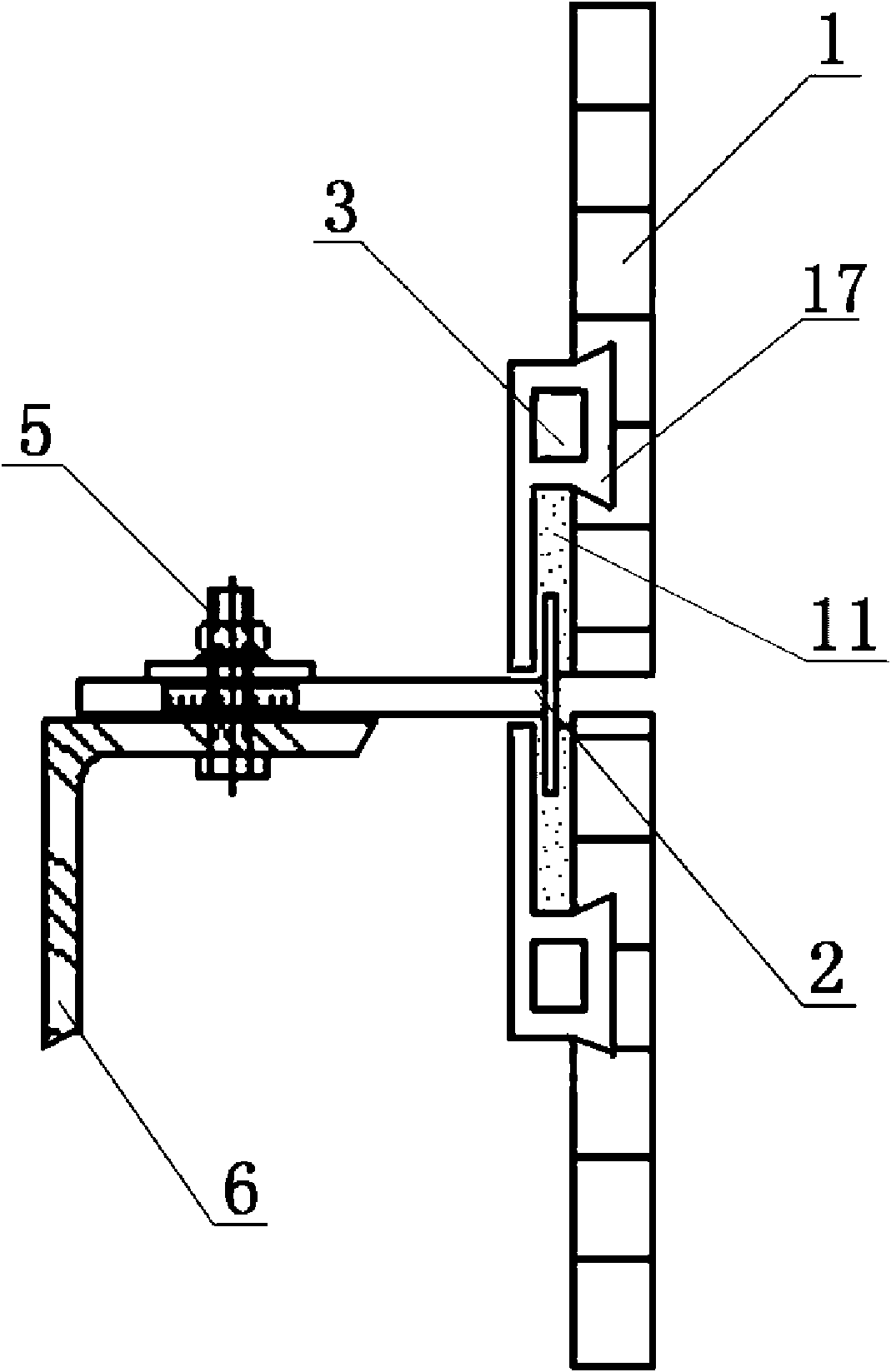

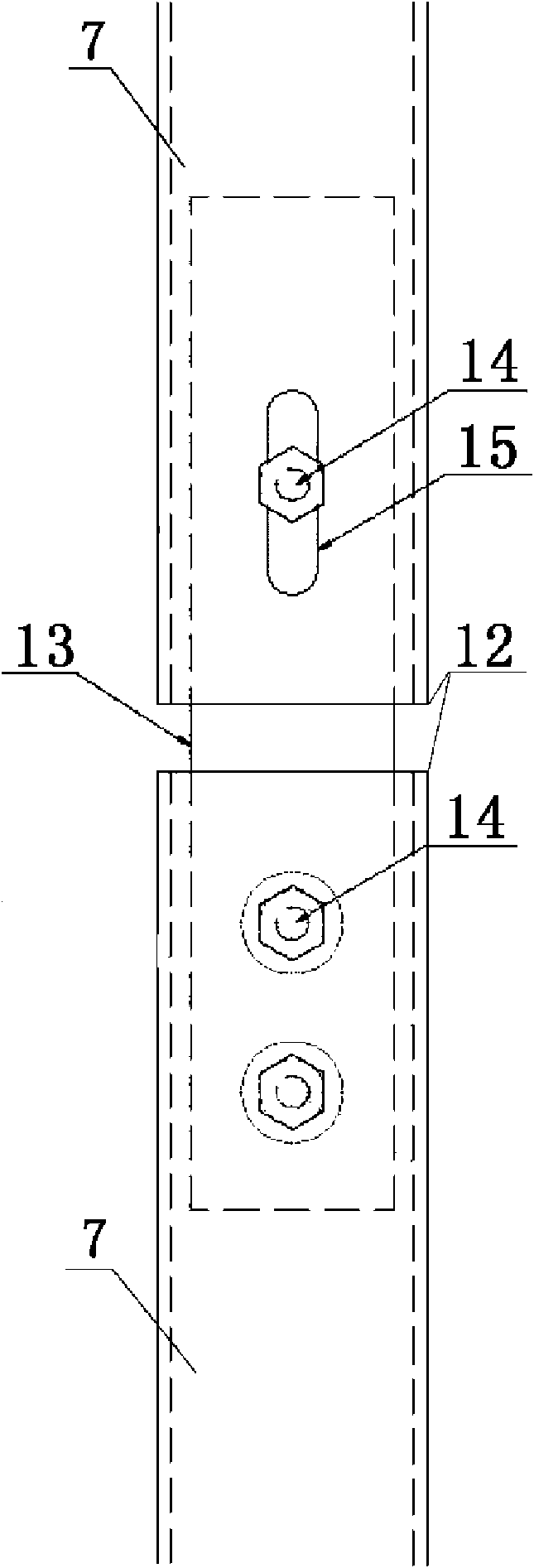

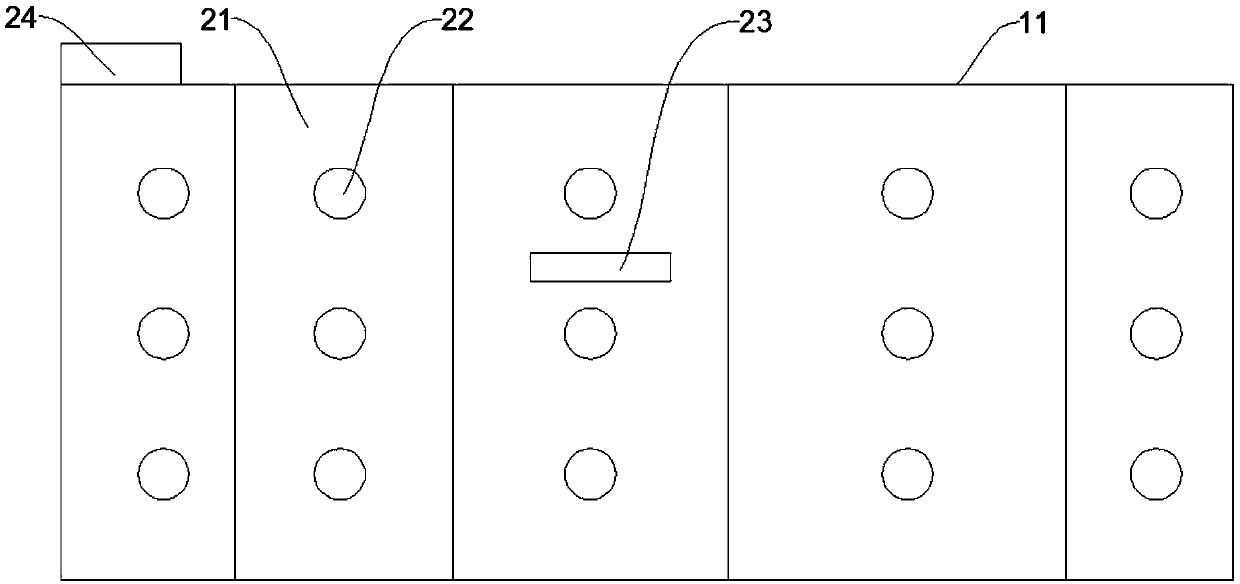

Drily hung vitrolite wall surface decoration system and construction method thereof

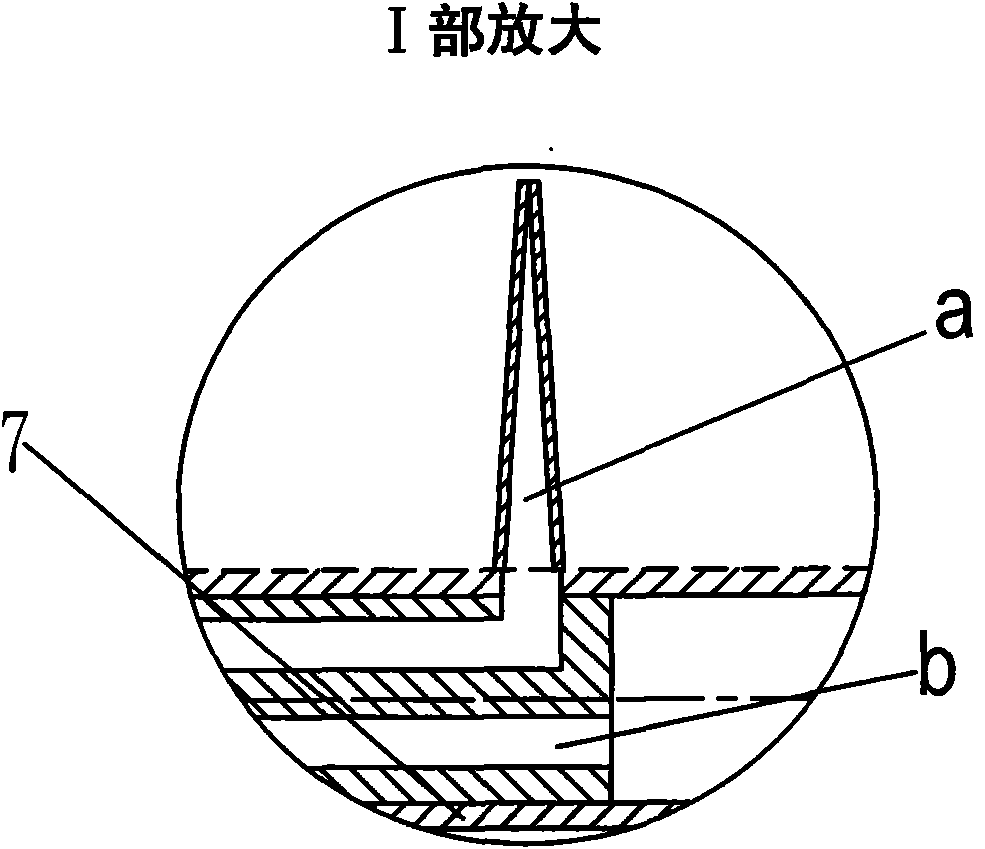

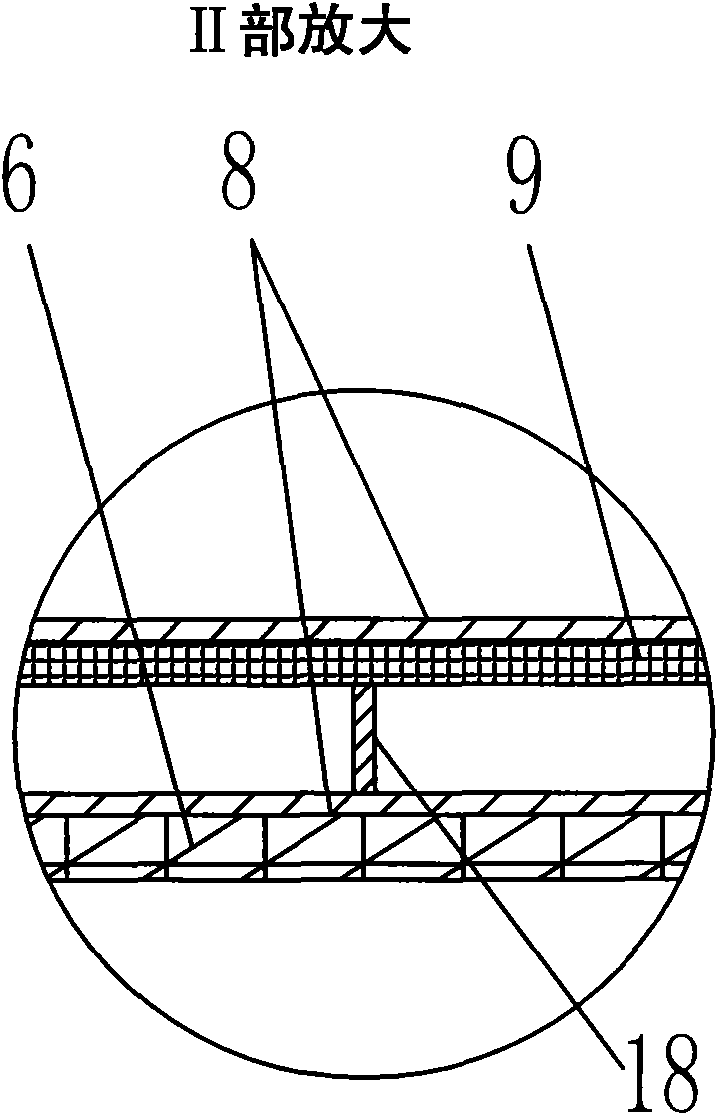

InactiveCN101824895ASatisfy self-expanding deformationFulfil requirementsCovering/liningsWallsKeelHigh rise

The invention relates to a drily hung vitrolite wall surface decoration system and a construction method thereof. A main building wall body is connected with a preembedded piece; the preembedded piece is connected with vertical keels through floor connecting pieces; the vertical keels are vertically connected with a transverse keel; the transverse keel is provided with a dilatation joint at each floor; a steel lock pin is inserted between the two vertical keels of the upper part and the lower part of the dilatation joint, one end of the steel lock pin is fixedly connected with a vertical keel through bolts, and the other end is in flexible connection with an oblong hole of the other vertical keel; the back of the vitrolite is provided with at least a pair of dovetail grooves; the dovetail grooves are connected with anchoring pieces in an embedded mode; the heads of the anchoring pieces are clamped into the dovetail grooves at the back of the vitrolite; a cavity for penetrating and anchoring the head of a T-shaped hanging piece is formed between an anchoring plate and the back of the vitrolite; the head of the T-shaped hanging piece extends to the cavity; the cavity is filled with epoxide resin anchoring glue; and a pectoral plate of the T-shaped hanging piece is fixedly connected with the transverse keel through a stainless steel bolt. The invention solves the problem of dry hanging vitrolite wall surface decoration systems on high rise buildings.

Owner:BEIJING CONSTR ENG GRP CO LTD

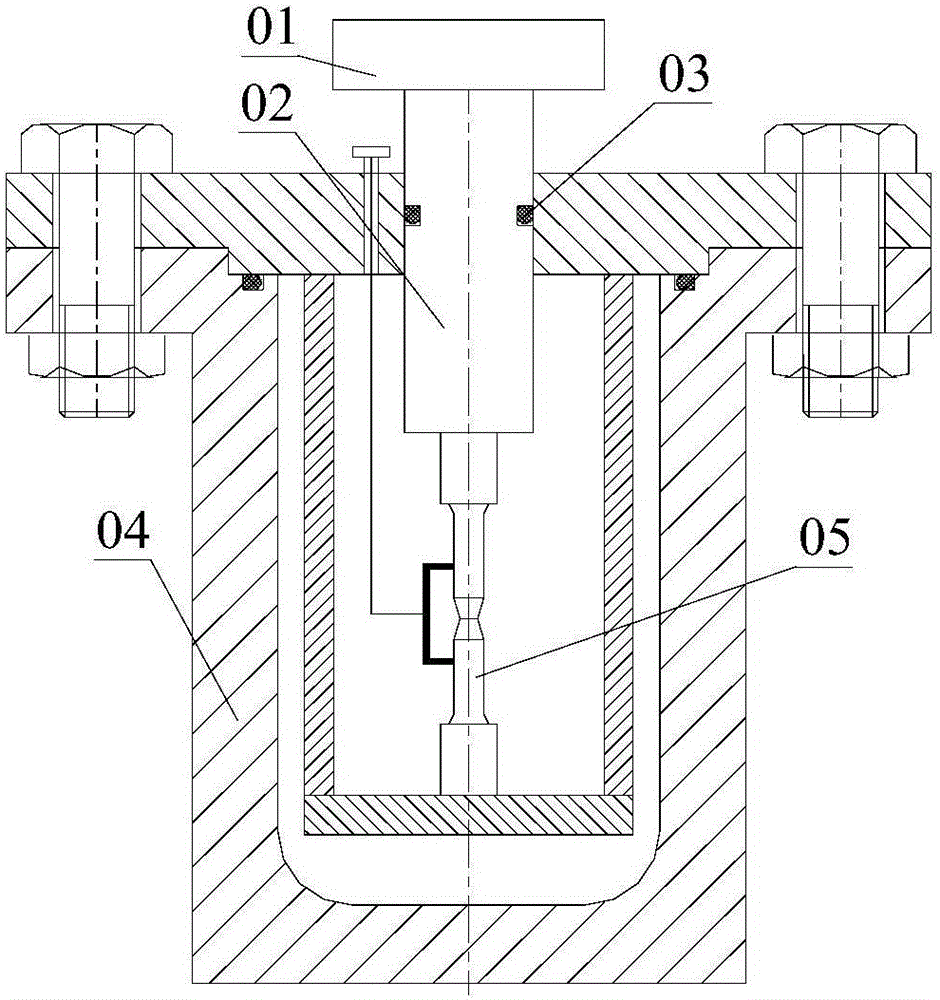

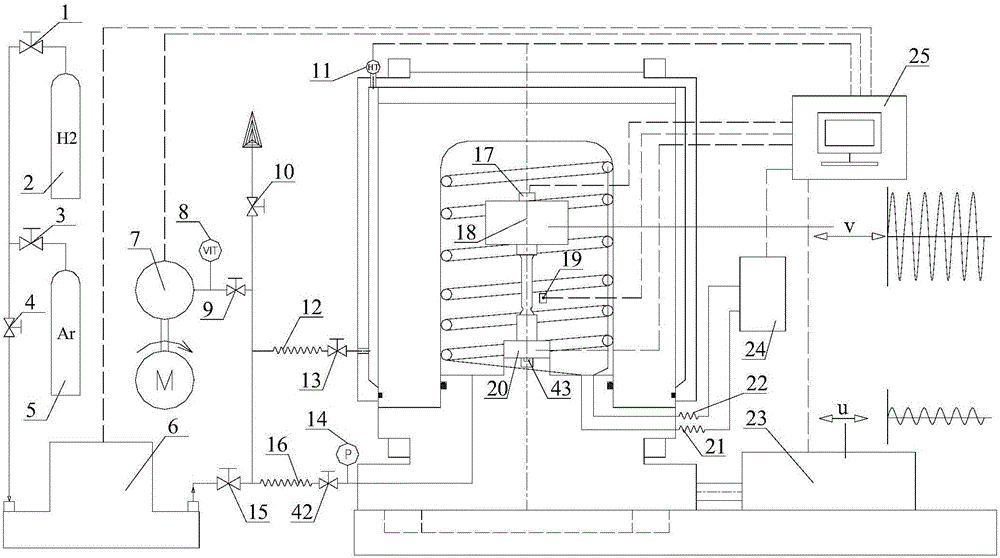

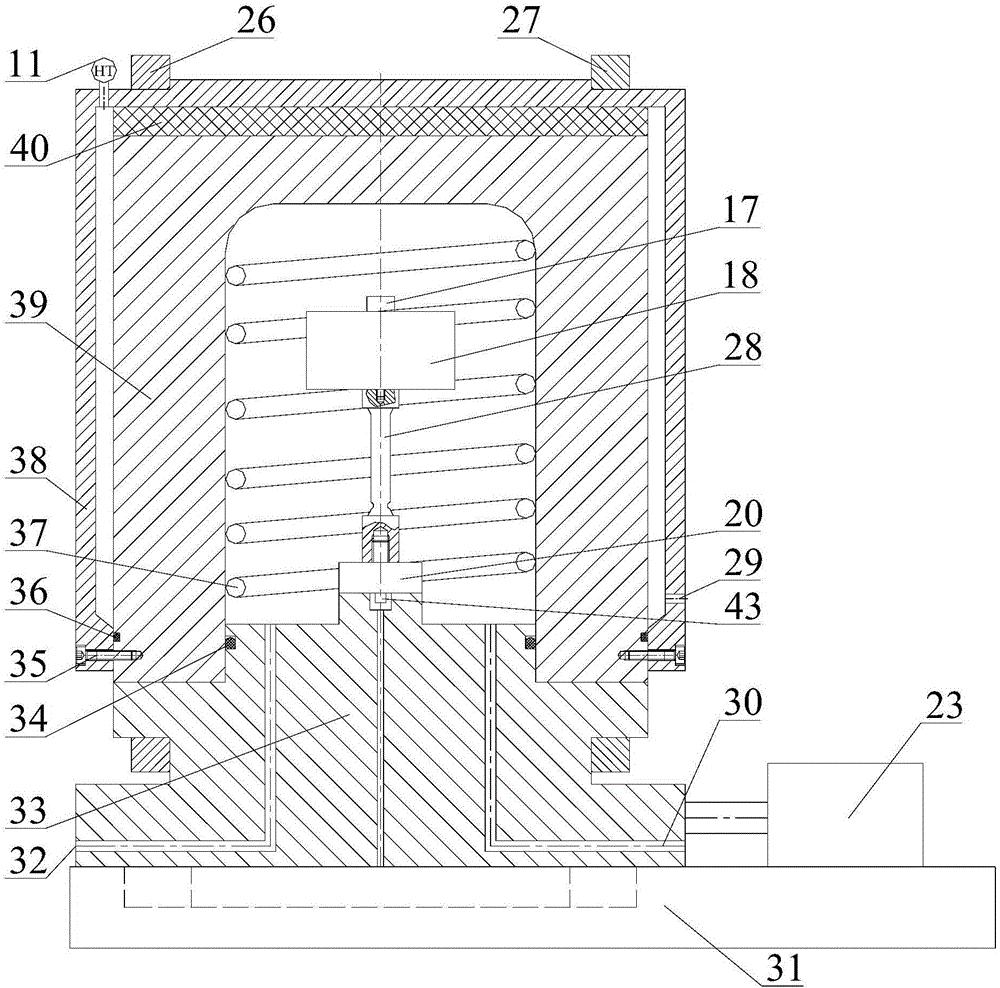

Non-dynamic sealing quick open type test device of material fatigue performance under high-pressure hydrogen environment

ActiveCN106018139AEliminate Hydrogen Leakage and Frictional Power LossIncrease test loading frequencyMaterial strength using repeated/pulsating forcesHigh pressure hydrogenMaterial fatigue

The invention discloses a non-dynamic sealing quick open type test device of a material fatigue performance under a high-pressure hydrogen environment. The test device mainly comprises an environmental box module, an air source module, a supercharger, a vacuum pump, a heat transfer module and an industrial personal computer. The test device of the material fatigue performance under the high-pressure hydrogen environment can be realized without a dynamic sealing structure, especially, a high-cycle or high-frequency fatigue test under the high-pressure hydrogen environment can be realized, the quick opening and closing of the test device and the real-time monitoring of health conditions of equipment can be realized, and the test device has high-efficiency and safe high and low temperature test function.

Owner:SOUTH CHINA UNIV OF TECH

Manufacturing method of inorganic insulating bearing building block

InactiveCN101637935AImprove insulation effectAvoid defectsSolid waste managementMixing operation control apparatusFoaming agentSlag

The invention discloses a manufacturing method of an inorganic insulating bearing building block, belonging to the technical field of the insulating building block and aiming at providing an inorganicinsulating bearing building block with good insulating performance and light weight; the adopted scheme is as follows: the manufacturing method of the inorganic insulating bearing building block comprises the following steps: grinding, mixing, casting, cutting and milling; the mixed materials are mixed according to the following parts by weight: composite light-bone admixture: cement:sand:stone:ceramsites:powdered coal ash:water:additive=(0.5-10):(6-25):(5-50):(0.1-45): (5-20):(1-30):(10-25):(0.1-35); the components and the parts by weight proportioning of the additive are as follows: 5 to 45 portions of silicon ash, 0.5 to 10 portions of air entraining agent, 0.1 to 30 portions of foaming agent, 3 to 30 portions of water-reducing agent, 10 to 35 portions of waste ore slag and 1 to 20 portions of polypropylene fiber. The manufacturing method can be applied to the technical field of buildings.

Owner:太原思科达科技发展有限公司

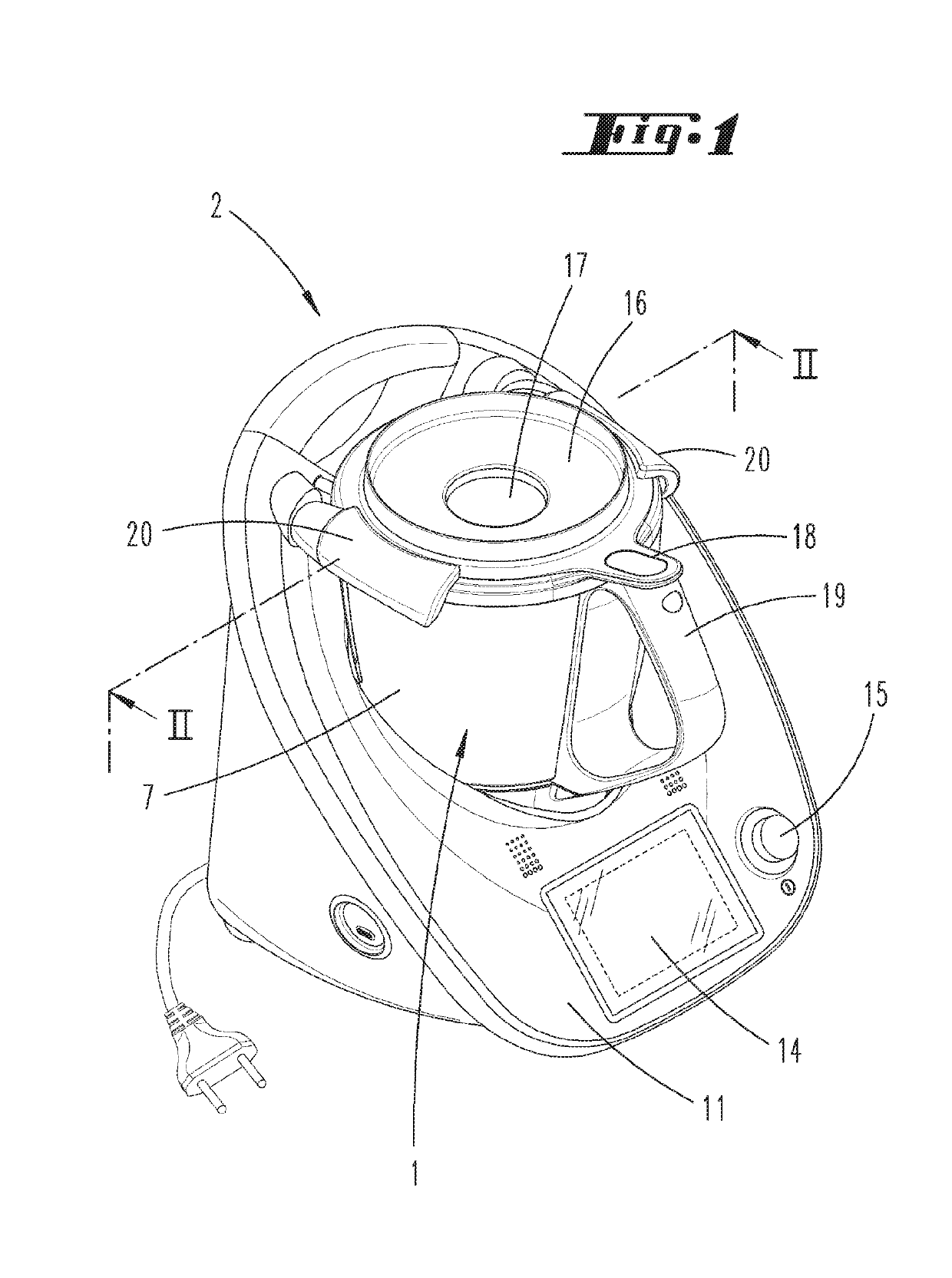

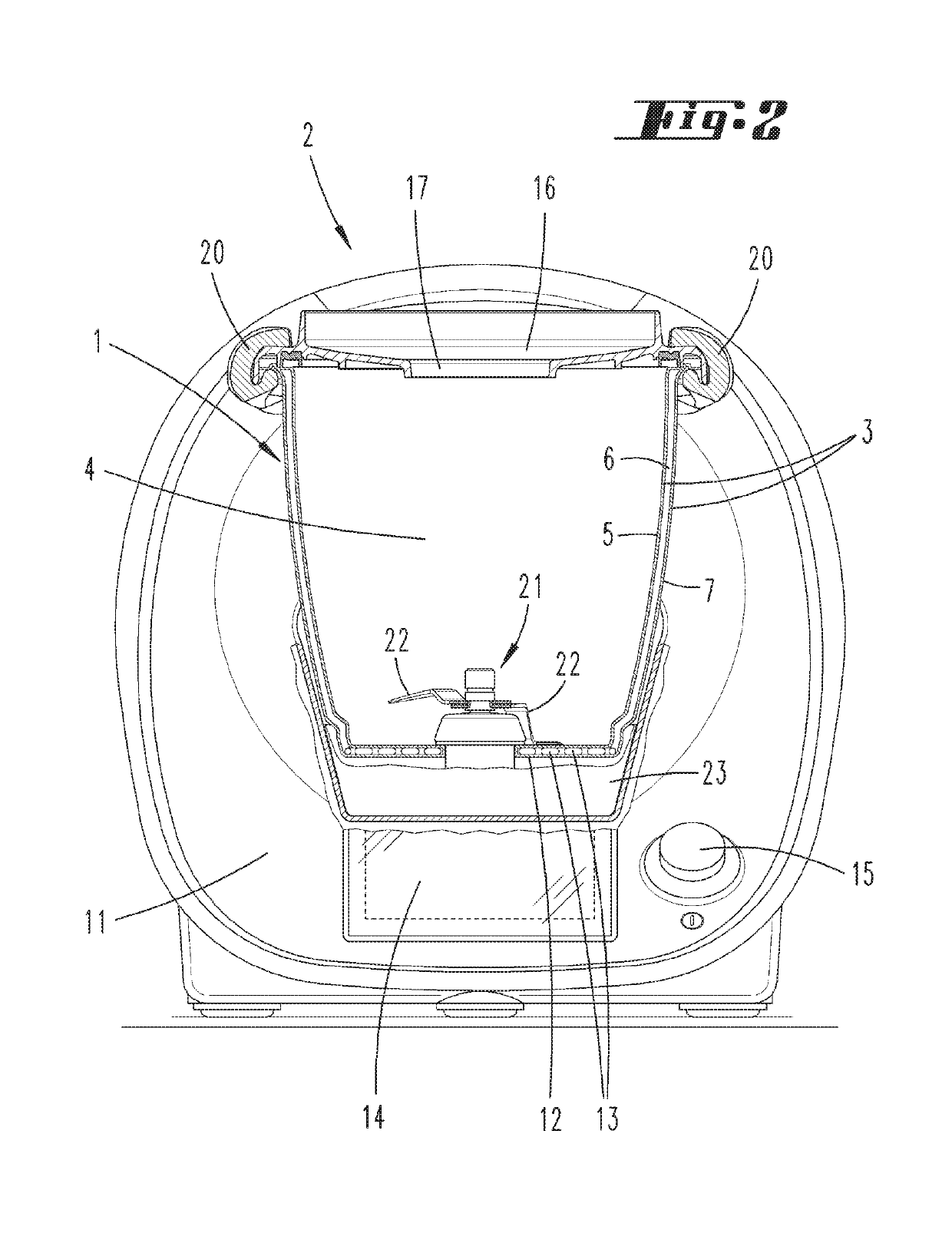

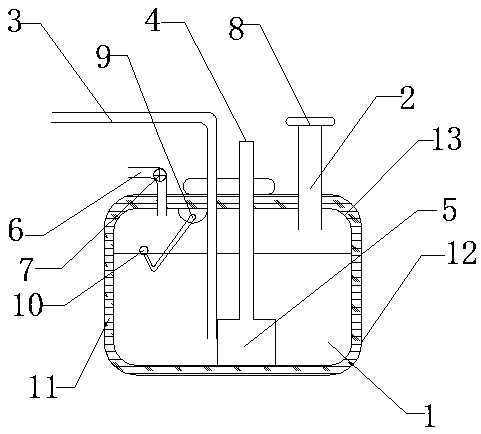

Preparation vessel for a food processor

InactiveUS20190174945A1Improve insulation performanceIncrease insulation functionSteam cooking vesselsVessels with intergral heatingDouble wallEngineering

A preparation vessel for a food processor has a vessel wall, at least a partial area of which has a double-wall configuration, with an inner wall that borders a preparation chamber of the preparation vessel and an outer wall designed separately from the latter and spaced apart from the inner wall by an intermediate space. In order to optimize such a preparation vessel with respect to both heating and / or heat retention as well as outward insulation, the intermediate space has a vacuum with a gas pressure of less than 300 mbar and / or an insulating material with a thermal conductivity of less than 0.02 W / (mK).

Owner:VORWERK & CO INTERHOLDING GMBH

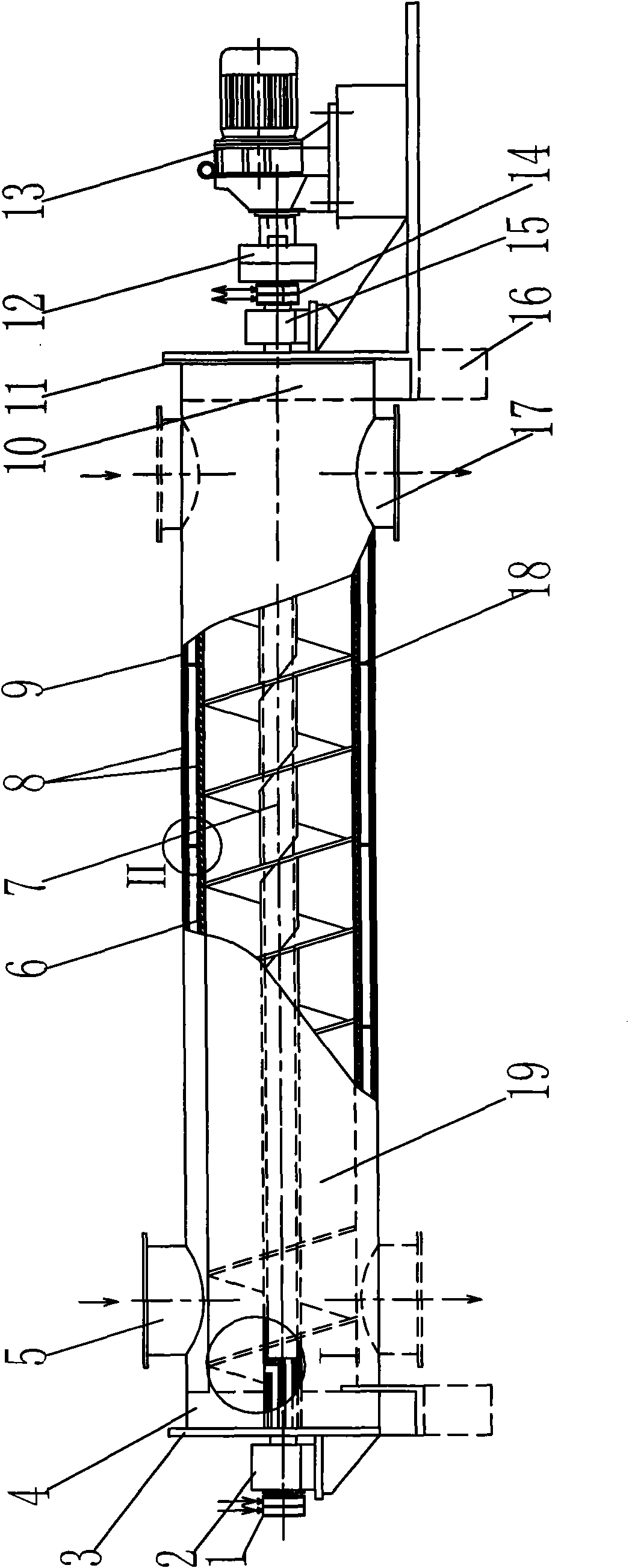

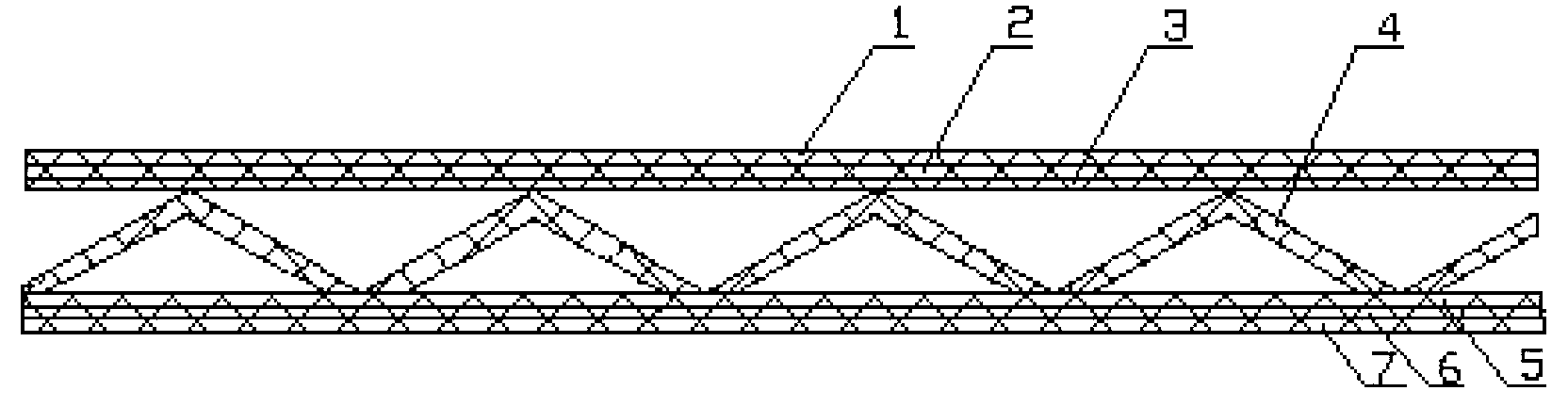

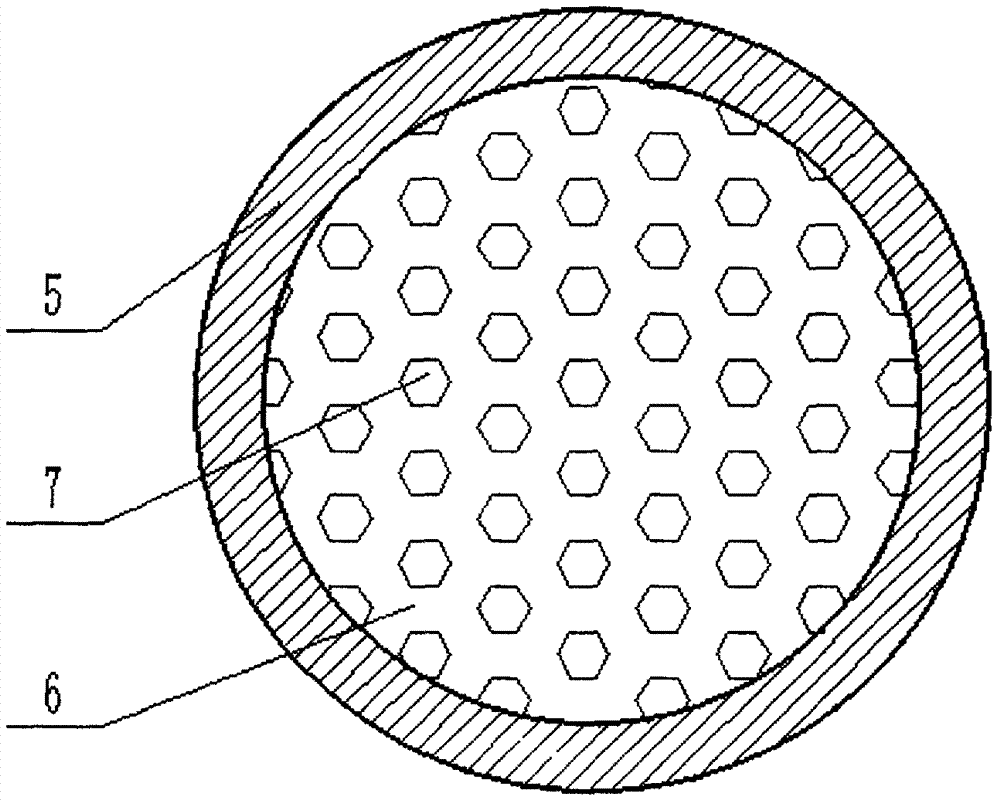

High temperature-keeping screw conveyor

The invention discloses a high temperature-keeping screw conveyor. A cylindrical shell (19) consists of a bushing (6) and two layers of stainless steel cylinder cavities (8), wherein the front end of the cylindrical shell (19) is welded with a front heat-isolating layer (4) and a front sealing plate (3); the rear end of the cylindrical shell (19) is welded with a rear sealing plate (11) and a rear heat-isolating layer (10); a central shaft of an auger (7) is connected with an output shaft with a motor speed reducer (13) through an elastic sleeve coupler (12); cooling water passages are formedin the central shaft and a blade of the auger (7); and a weighing module (16) is arranged on the lower part of the cylindrical shell (19). The high temperature-keeping screw conveyor has heat-isolating and protecting effects on a power transmission mechanism and prolongs the service life of the transmission mechanism. In order to achieve transfer control, the regularly and quantificationally conveying and blanking of high-temperature scattered materials are achieved through the arranged weighing module (16); and the high temperature materials can be sealed and subjected to heat preservation while being conveyed.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

Method for manufacturing plant fibre composite wall plate

InactiveCN101168263ALarge amount of resourcesExcellent flame retardantFlat articlesDomestic articlesPlant fibrePolystyrene

Provided is a process for preparing a plant fiber composite wall plate, belonging to wall material field. The invention resolves the shortages that the raw material of the existing architectural wall material is large in consumption, the manufacture cost is high and the distribution of the raw material is non-uniform. The process steps of the invention are that crop straw is cleaned and cut into pieces and is ground by a fiber re-chipper, and then is dried after dust and big lump material are screened. The prepared raw material is sent into a glue blend machine and is added with adhesive agent of 10-16%. After being uniformly stirred, the raw material and the added adhesive agent are taken out, added with fire retarding agent and paved, and then are cut in standard size after being pre-pressed, hot-press-molded and cooled. The plate in standard size is combined with polystyrene plates via different layers and thicknesses, the surfaces thereof are stuck with melamine fireproof plates, and then the plant fiber composite wall plate is formed via the combination. The product obtained by the process has the advantages of low density, light weight, perfect insulation, simple technology, large raw material source, low manufacture cost, waste utilization and environment protection. The invention can be used to produce building separating walls, framed wood structural buildings, mobile movable dwellings, and buildings in tourist spots and the like.

Owner:NORTHEAST FORESTRY UNIVERSITY

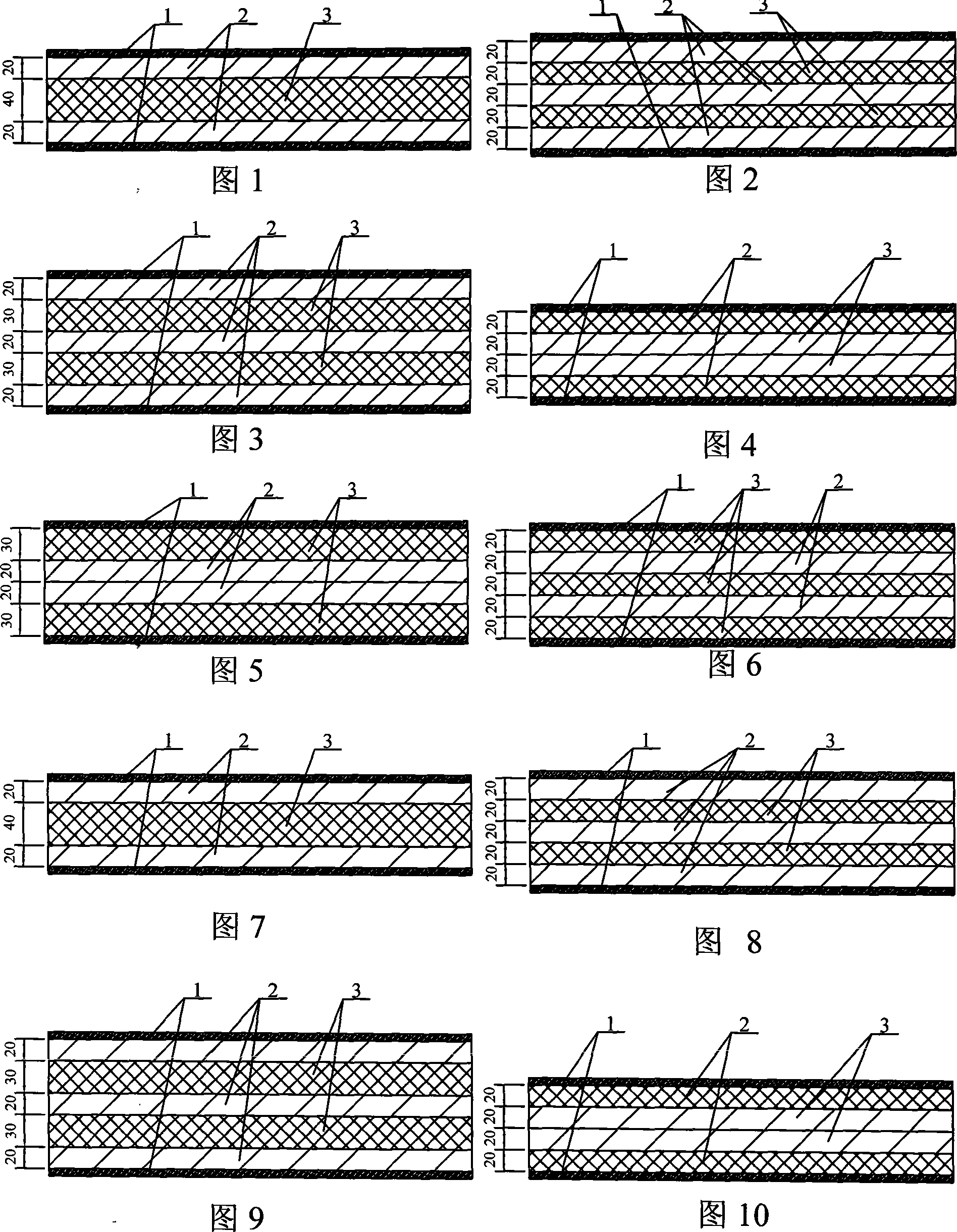

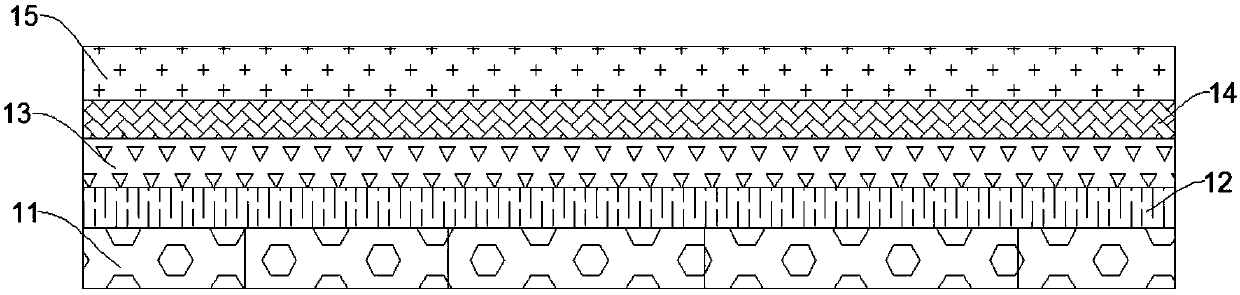

Heat insulating and fresh keeping waterproof paperboard carton

InactiveCN102700792AIncrease insulation functionInsulation function is efficient and cheapPaper/cardboard layered productsRigid containersPolypropyleneCardboard

The invention discloses a heat insulating and fresh keeping waterproof paperboard carton. A paperboard comprises the following layer structures: a first layer which is white synthetic paper or synthetic paper printed with patterns and provided with a waterproof layer, a second layer which is boxboard kraft paper or any selected payer, a third layer which is made of polyethylene or other spongy foaming coiled materials, a fourth layer which is single-layer or multi-layer bonded corrugated core paper consisting of corrugated payer, a fifth layer which is made of the polyethylene or other spongy foaming coiled materials, a sixth layer which is the boxboard kraft paper or any selected payer and the seventh layer which is the white synthetic paper or synthetic paper printed with patterns and provided with a waterproof layer. The waterproof made of polypropylene mixed polyethylene composite binding layer is respectively formed between every two layers. The heat insulating and fresh keeping waterproof paperboard carton can be used for solving the technical problem that the traditional paperboard carton does not have the functions of containing liquid, insulating heat and keeping fresh.

Owner:杨碧清

Warm and hot dual-function thermal-insulation mug capable of achieving rapid cooling and thermal insulating

InactiveCN105615518AIncrease insulation functionImprove insulation effectTravelling sacksDrinking vesselsWarm waterThermal insulation

The invention discloses a warm and hot dual-function thermal-insulation mug capable of achieving rapid cooling and thermal insulating. The thermal-insulation mug comprises a mug cover which comprises a mug cover inner wall and a mug cover outer wall, and a closed space is formed between the mug cover inner wall and the mug cover outer wall. The thermal-insulation mug further comprises a mug body which comprises a mug body inner wall and a mug body outer wall, and a closed space is formed between the mug body inner wall and the mug body outer wall; the closed space formed between the mug body inner wall and the mug body outer wall is vacuumized to form a vacuum layer. According to the thermal-insulation mug, a good thermal-insulation function is achieved, water with high temperature can be provided for a long time, boiled water can be rapidly cooled to warm water, and dual functions are achieved to meet different needs of people; the thermal-insulation mug is a split-type mug, one part of the thermal-insulation mug has the good thermal-insulation effect on hot water stored inside the part, the other part of the thermal-insulation mug has the rapid cooling function on hot water poured into the part, and water of 95 DEG C can be cooled to about 50 DEG C within 20 seconds at the soonest.

Owner:WEIFANG YUNBAO NETWORK TECH CO LTD

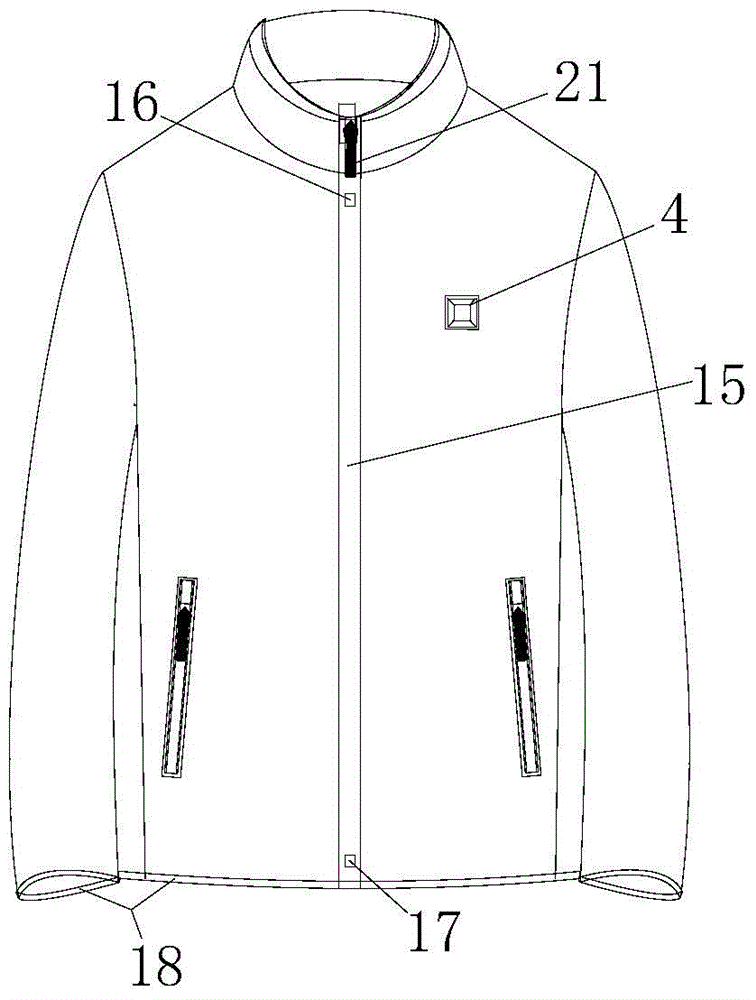

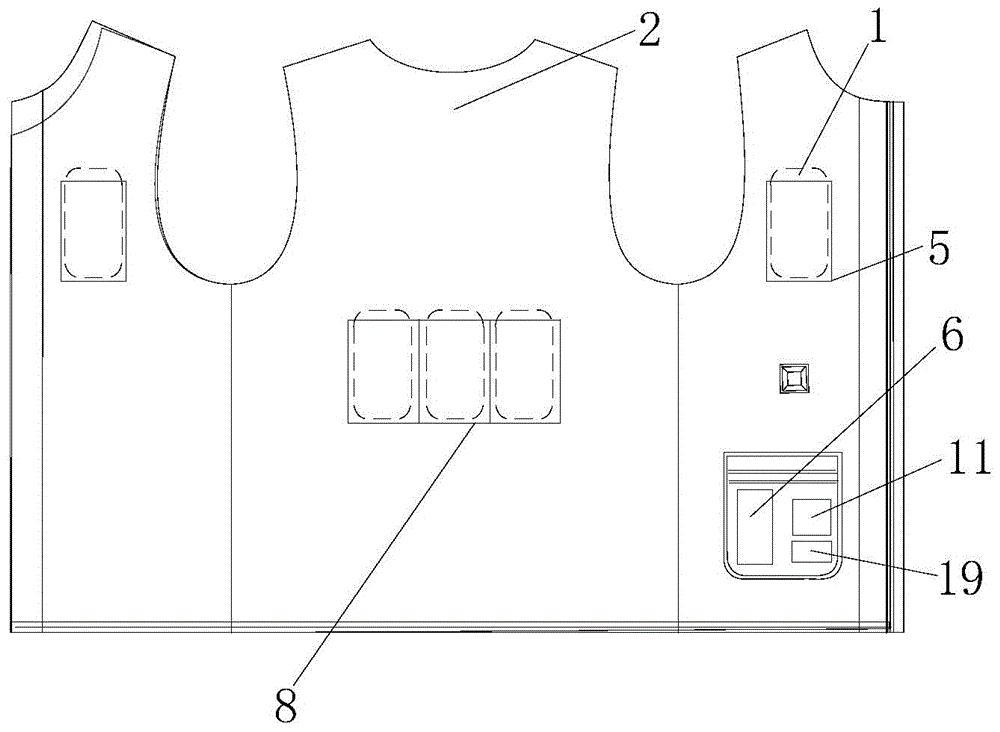

Clothes with heating temperature-adjusting function

InactiveCN104473338AHeats and keeps wellGood heating functionGarment special featuresProtective garmentAcupuncture pointEngineering

The invention discloses a piece of clothes with a heating temperature-adjusting function. The clothes comprises a plurality of temperature control chips and a temperature control switch, wherein the temperature control chips are arranged in the clothes; the temperature control switch is used for controlling the temperature control chips to heat; an interlayer is arranged in the clothes; a detachable or undetachable liner is arranged in the interlayer; the temperature control chips are arranged on the liner and respectively correspond to acupuncture points of a human body. According to the clothes, the temperature control chips respectively correspond to acupuncture points of the human body and are arranged on the liner of the clothes, so that better heating and heat-insulating functions of the clothes are achieved.

Owner:浙江鹰堡服饰有限公司

Novel fuel tank for automobile

The invention provides a novel fuel tank for an automobile. The fuel tank comprises a tank body, a fuel filler, a fuel return pipe, a fuel supply pipe, a fuel pump, a gasoline steam output pipe and a fuel level sensor, wherein the tank body comprises an inner layer and an outer layer, the fuel pump is mounted at the lower part in the tank body and connected with the fuel supply pipe, the fuel level sensor is mounted at the top in the tank body, the fuel return pipe is mounted on the left side of the fuel supply pipe, the gasoline steam output pipe is mounted on the left side of the fuel return pipe, a check valve is mounted in the gasoline steam output pipe, the fuel filler is mounted on the right side of the fuel supply pipe, a fuel tank cover is mounted at the top of the fuel filler, and the fuel filler is mounted at the top of the tank body. The fuel tank has the benefits as follows: a vacuum interlayer is arranged between the outer layer and the inner layer, has insulation and heat isolation functions, can prevent fuel from freezing and can play roles in preventing burning of the fuel tank and explosives due to fuel temperature rise; the fuel tank is simple in structure, convenient to use, higher in safety, convenient to mount and capable of reducing environmental pollution.

Owner:CHONGQING ZHONGKE SCI & TECH

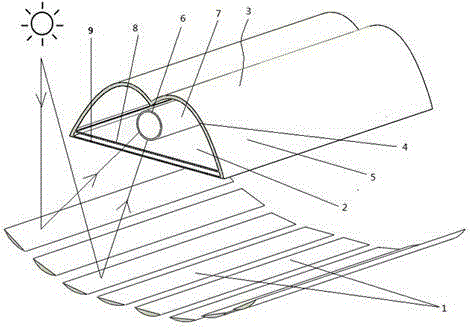

Composite paraboloid solar collector

InactiveCN104990286AEffective absorptionImprove efficiencySolar heating energySolar heat devicesCollector deviceEngineering

The invention relates to a composite paraboloid solar collector. The solar collector comprises a Fresnel reflection collecting mirror array and a solar collector body. The Fresnel reflection collecting mirror array is arranged under the solar collector body. A collector part of the solar collector body is a collector pipe, the outer wall face of the collector pipe is coated with an absorption coating, and the upper wall face of the collector pipe is a composite paraboloid composed of a heat-isolation protective layer and a secondary reflection mirror. The lower wall face of the solar collector body is composed of two layers of glass faces. The upper wall face and the lower wall face of the solar collector body define a closed cavity to form a layer of air wall. The two-layer glass design is adopted, and advantages of a composite paraboloid solar collector without heat-isolation measures and advantages of a composite paraboloid solar collector with a vacuum glass pipe are combined; under the situation that heat losses are not reduced, integration complexity of a system is effectively reduced, the structure is simple, manufacturing and operation cost is low, and safety and stability of the solar collector are improved.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

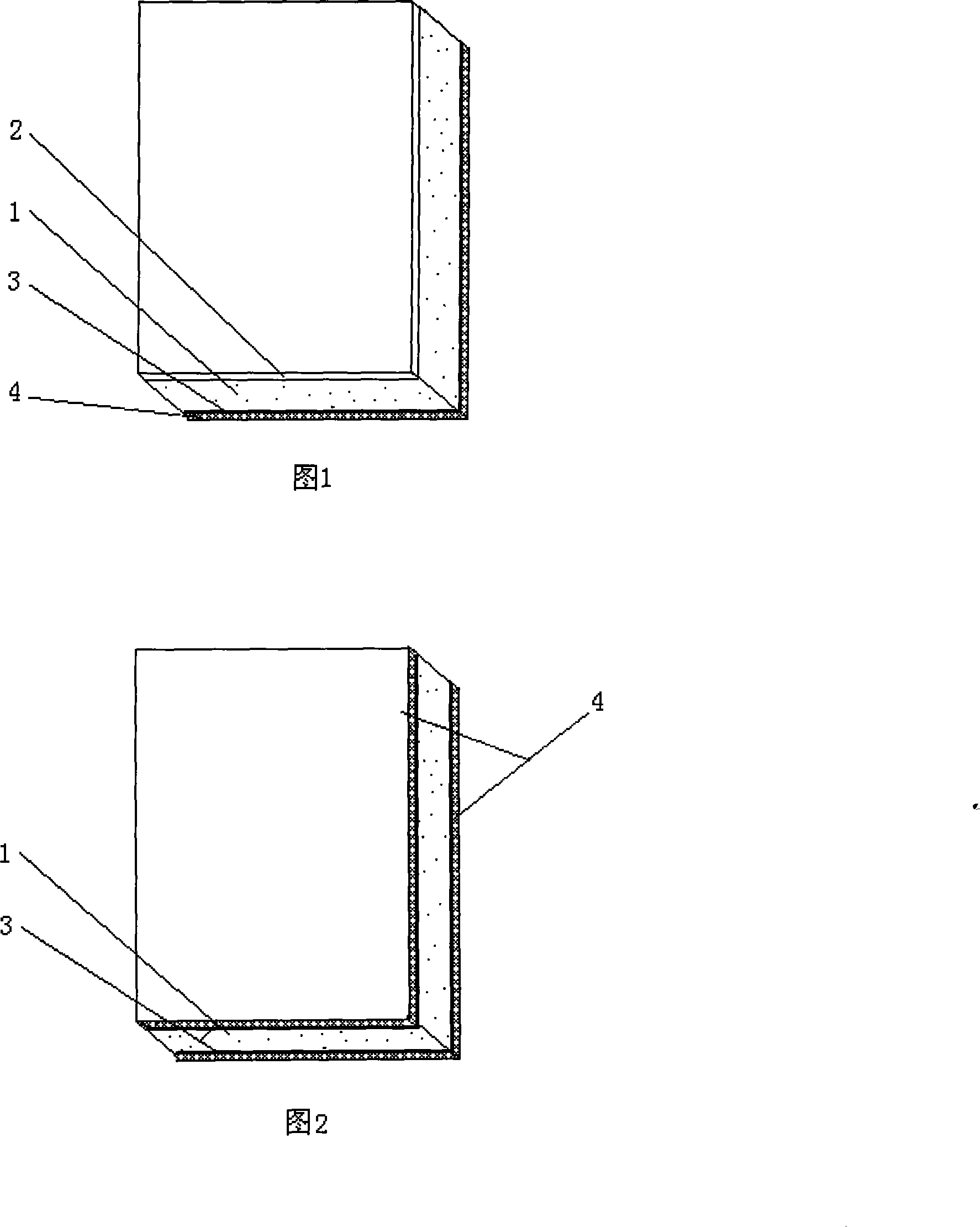

Polyurethane water-proof easy-to-paste heat-preserving composite board and method for producing the same

InactiveCN101220696AGood qualityExcellent insulation performanceLaminationLamination apparatusCohesive strengthEngineering

The invention discloses a polyurethane waterproof adhesive heat-insulating composite board and the manufacturing method thereof, which includes a polyurethane heated board, wherein the surfaces at both sides of the polyurethane heated board are sequentially provided with a waterproof binding course and an adhesive course; or the surface of one side is sequentially provided with a waterproof binding course and an adhesive course while the surface of another side is sequentially provided with a waterproof course; or the surface of one side is sequentially provided with a waterproof binding course and an adhesive course while the surface of another side is sequentially provided with a waterproof binding course, an adhesive course and a waterproof course. The invention is manufactured in serials through the factory, and the foaming and aging of the polyurethane heated board are both finished in a thermostatic equipment, furthermore, the bonding and compositing of the waterproof course and the adhesive course at both sides are also finished simultaneously during the process. The invention has excellent heat-insulating property, high cohesive strength with the wall and is simple and convenient for construction.

Owner:赵金法

Low-dielectric-constant heat-conducting silica gel sheet and preparation method thereof

InactiveCN111378284AThe overall impact is smallLow dielectric constantHeat-exchange elementsLow-k dielectricSilane coupling

The invention discloses a low-dielectric-constant heat-conducting silica gel sheet, which comprises low-dielectric-constant heat-conducting powder, vinyl silicone oil, hydrogen-containing silicone oil, a silicone rubber reinforcing agent, a platinum catalyst, an inhibitor and a silane coupling agent. The low-dielectric-constant heat-conducting powder accounts for 40%-90% of the total mass; the vinyl silicone oil accounts for 4-59% of the total mass; wherein the hydrogen-containing silicone oil accounts for 0.4%-1% of the total mass of the silicone oil, the silicone rubber reinforcing agent accounts for 1%-4% of the total mass of the silicone oil, the platinum catalyst accounts for 0.2%-1% of the total mass of the silicone oil, the inhibitor accounts for 0.01%-0.03% of the total mass of thesilicone oil, and the silane coupling agent accounts for 0.1%-0.6% of the total mass of the heat conduction powder; and the dielectric constant of the low-dielectric-constant heat-conducting powder is less than or equal to 4. The invention further discloses a preparation method of the low-dielectric-constant heat-conducting silica gel sheet. The low-dielectric-constant heat-conducting silica gelsheet not only has the characteristics of high heat conductivity coefficient, low hardness and high insulating strength of a common heat-conducting sheet, but also can be used for thermal interface filling, and has low interference to signals, which is not possessed by the common heat-conducting sheet.

Owner:SUZHOU TIANMAI THERMAL TECH

Novel high-strength foam concrete and preparation method for same

InactiveCN106186954ASimple production processProduction process safetyCeramicwareFoam concreteUltimate tensile strength

The invention discloses novel high-strength foam concrete and a preparation method for the same. The novel high-strength foam concrete is characterized in that the novel high-strength foam concrete is prepared from the following raw materials in parts by weight: 300 to 800 parts of a gel material, 250 to 850 parts of a fine aggregate, 375 to 1,250 parts of a coarse aggregate, 4 to 8 parts of a water reducing agent, 250 to 850 parts of water, 20 to 40 parts of a foaming agent and 10 to 20 parts of a foam stabilizer, wherein the foaming agent is an isocyanate derivative. According to the novel high-strength foam concrete and the preparation method for the same, the following principle is utilized: isocyanate adopted as the foaming agent is reacted with the water to generate unstable carbamic acid at first, the unstable carbamic acid is rapidly decomposed into amine and carbon dioxide, and the discharged carbon dioxide acts for foaming to generate a foam body; a prepared foam concrete material is favorable for making a heat insulation, soundproof and high-strength foam concrete building block on one hand, and on the other hand, the construction engineering cost is reduced, and the high-strength foam concrete can be widely applied to construction engineering.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

Foam concrete

ActiveCN102503284AIncreased load-bearing capacityIncrease the use of spaceCeramicwareFoam concreteFoaming agent

Foam concrete is produced by mixing the following raw materials in parts by weight: 200-300 parts of cement, 250-850 parts of fine sand, 20-40 parts of foaming agent and 10-20 parts of compensating agent. The foam concrete has the advantages that: the foam concrete is light in weight and attractive in appearance; closed holes exist in the foam concrete, so that the volume weight of the foam concrete is 500-1200 kg / m3; the foam concrete is cast in site and integrally formed and is light in weight and high in hardness; the foam concrete is closely connected with a base course, so that the bearing capability of a heat insulating layer is greatly improved; and the original raised heat insulating layer is changed into an attractive, flat and practical garden, or an entertainment place or the like, so that the using space of a building is increased.

Owner:CHINA CONSTR SEVENTH ENG DIVISION CORP LTD

EPDM (ethylene-propylene-diene monomer) rubber for air conditioners and preparation technique thereof

The invention relates to an EPDM (ethylene-propylene-diene monomer) rubber for air conditioners and a preparation technique thereof. The rubber is prepared from the following components in parts by weight: 100 parts of EPDM unvulcanized rubber, 60-80 parts of carbon black N550, 30 parts of silica, 80-100 parts of paraffin oil, 6-8 parts of zinc oxide, 1-2 parts of stearic acid, 1-3 parts of PEG 4000, 5-8 parts of ointment, 5-8 parts of calcium oxide, 1-2 parts of BZ-80, 1-2 parts of MBT-80, 1-2 parts of CBS-80, 1-2 parts of TDEC-75, 2-5 parts of AC-75, 7-10 parts of OBSH and 1-2 parts of sulfur. The EPDM rubber for air conditioners has favorable formula; the product has excellent weather aging resistance; the formed product has closed foaming pores, and thus, has favorable thermal insulation function, shock absorptivity and energy saving property; and the preparation technique is simple.

Owner:TAICANG RONGNAN SEAL TECH

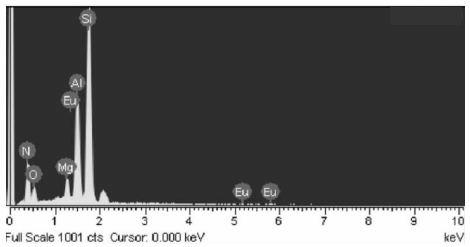

Manufacturing method of flourescent material taking mg-alpha-sialo<n> as host lattice

InactiveCN102321473AImprove glow qualitySlow heatingLuminescent compositionsPhysical chemistryNitrogen source

The invention relates to a manufacturing method of a flourescent material, comprising the steps of supplying a spindle-shaped object which comprises a magnesium source, a silicon source, an aluminum source, an oxygen source, a solid state nitrogen source, an ammonium halide salt and an activator ion source; wrapping an ignition agent on the spindle-shaped object to obtain a reactive spindle; placing the reactive spindle in an adiabatic apparatus and filling ceramic powder between the adiabatic apparatus and the reactive spindle; and igniting the spindle-shaped object by burning the ignition agent to obtain a flourescent material taking Mg-alpha-SiAlO<n> as a host lattice. Therefore, the purposes are achieved that the manufacturing process is simple, time is not consumed and the flourescent material can be manufactured without needing high temperature and high pressure conditions.

Owner:钟贤龙

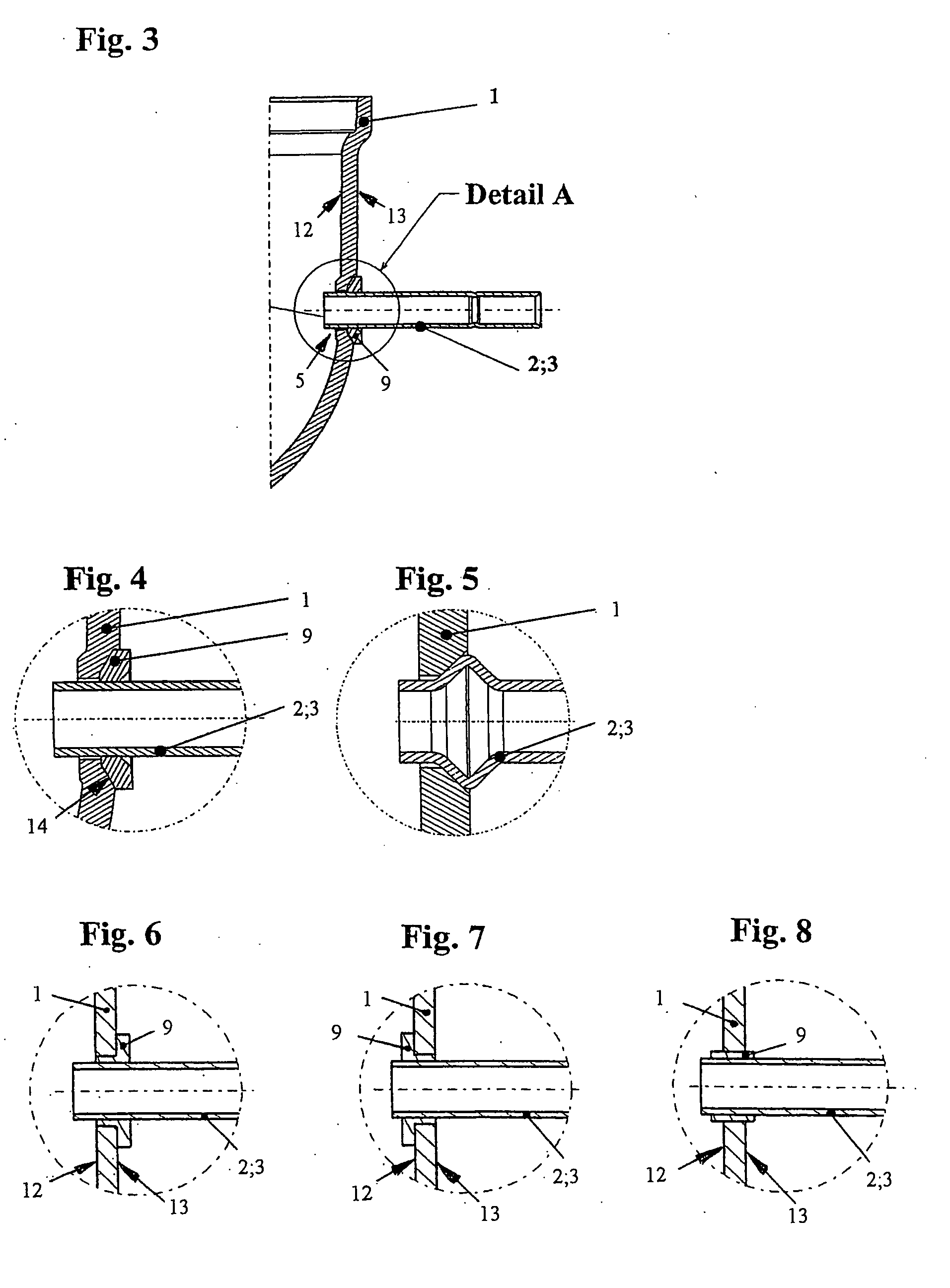

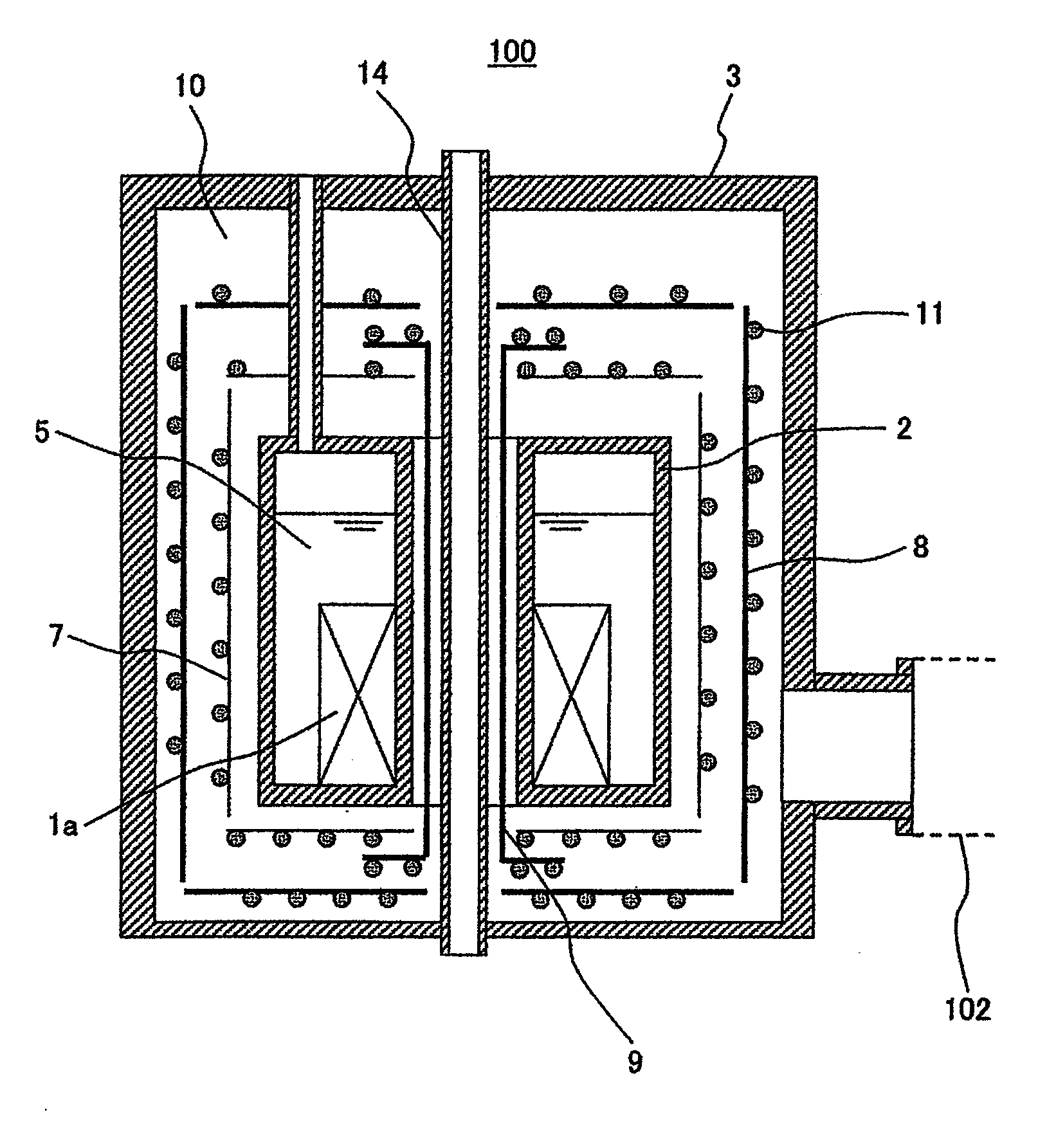

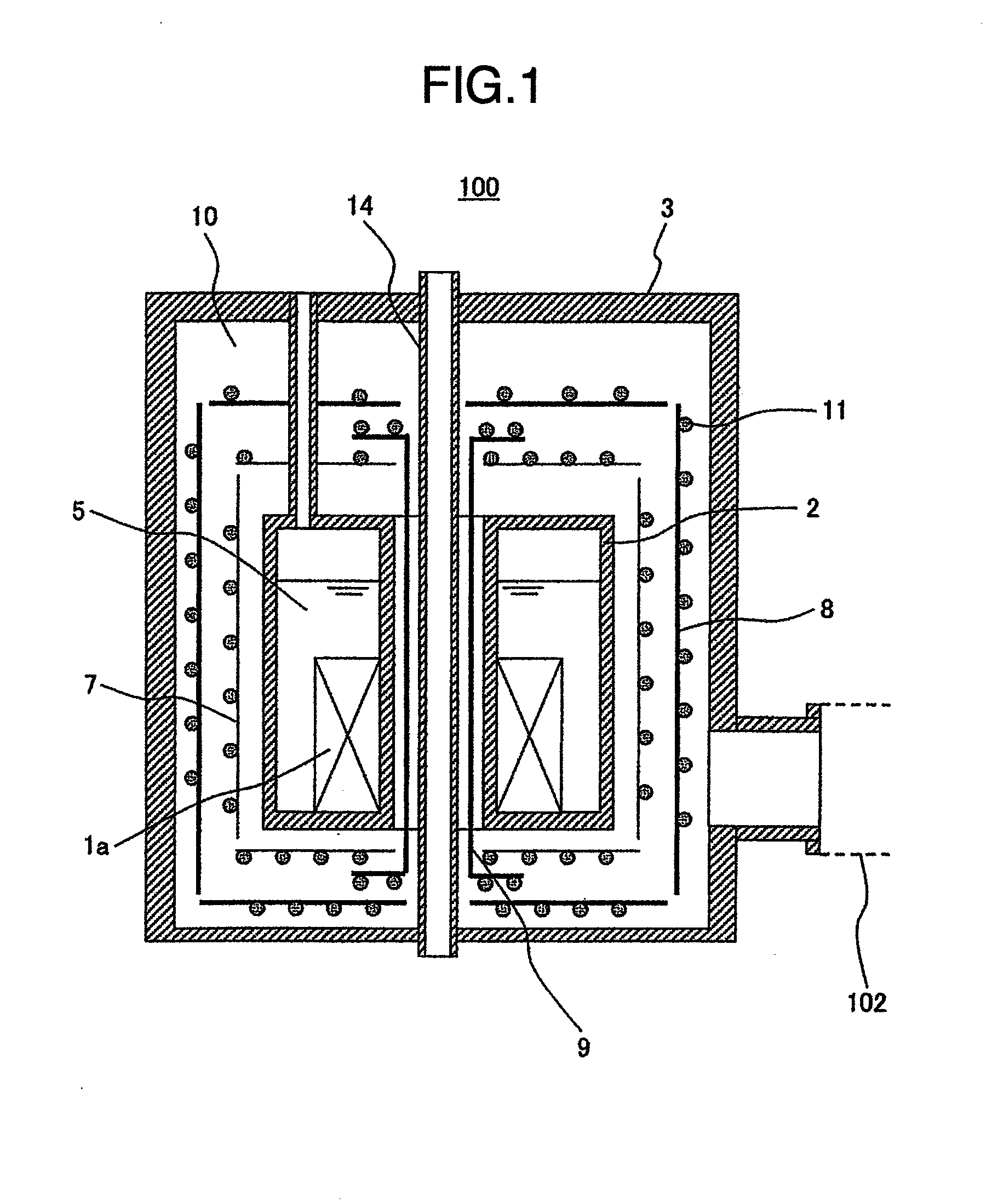

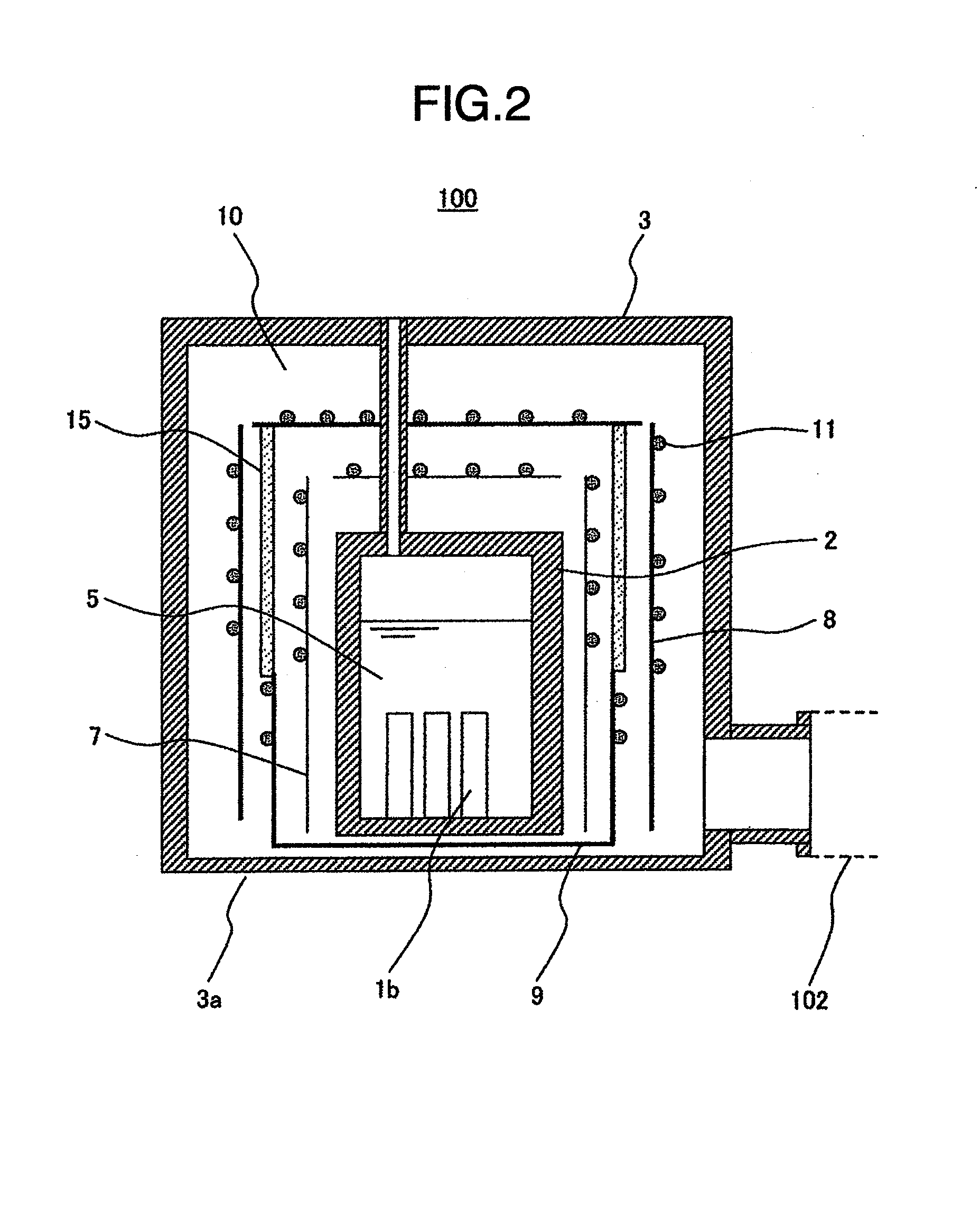

Refrigerant compressor

InactiveUS20090110586A1Reduce efficiency lossImprove efficiencyRotary/oscillating piston combinations for elastic fluidsOscillating piston enginesHermetic sealRefrigerant

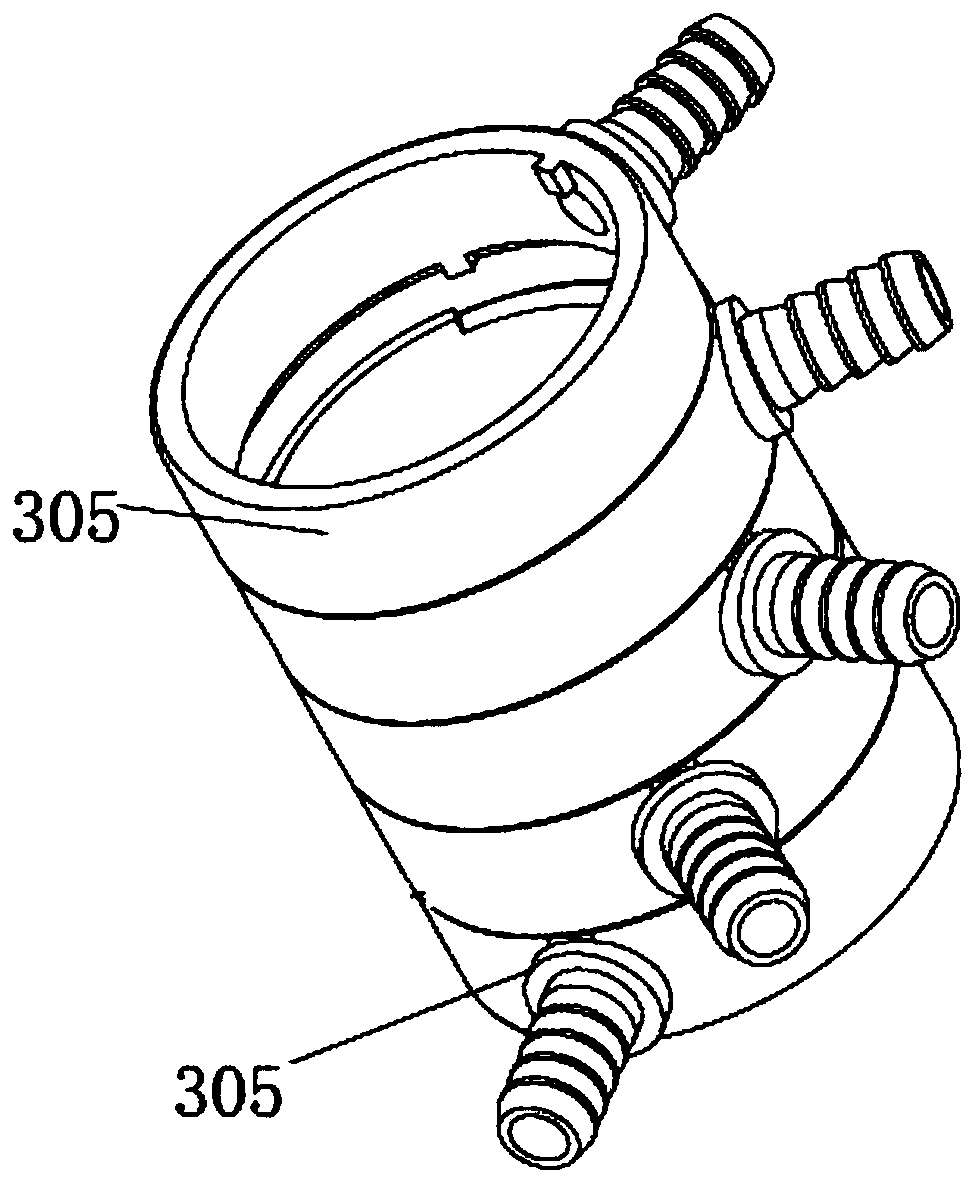

A hermetically encapsulated refrigerant compressor which comprises a hermetically sealed compressor housing (1), in the interior of which a piston-cylinder unit which compresses a refrigerant and a suction pipe (2) and a pressure pipe (3) are provided, with refrigerant flowing via the suction pipe (2) to the piston-cylinder unit and the refrigerant compressed by the piston-cylinder unit being conveyed out of the compressor housing (1) via the pressure pipe (3), with connection openings (5) for the suction pipe (2) and the pressure pipe (3) being provided on the compressor housing (1), with the connection of the suction pipe (2) and pressure pipe (3) to the connection openings (5) occurring in a hermetically tight manner by means of a connection apparatus (9) and with the connection apparatus (9) comprising a preferably sleeve-like body element (8) and at least one spacer element (7) which spaces the body element (8) from the suction pipe (2) / pressure pipe (3). It is provided in accordance with the invention that the body element (8) is attached to an outside (13) of the compressor housing (1) outside of the connection opening (5) by enclosing the same in a hermetically sealing manner.

Owner:ACC AUSTRIA GMBH

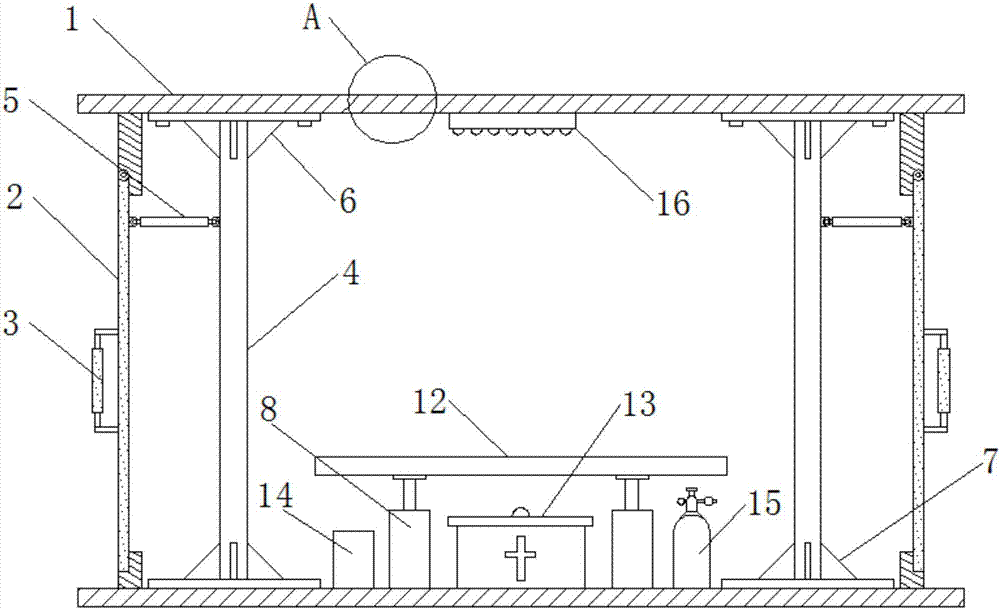

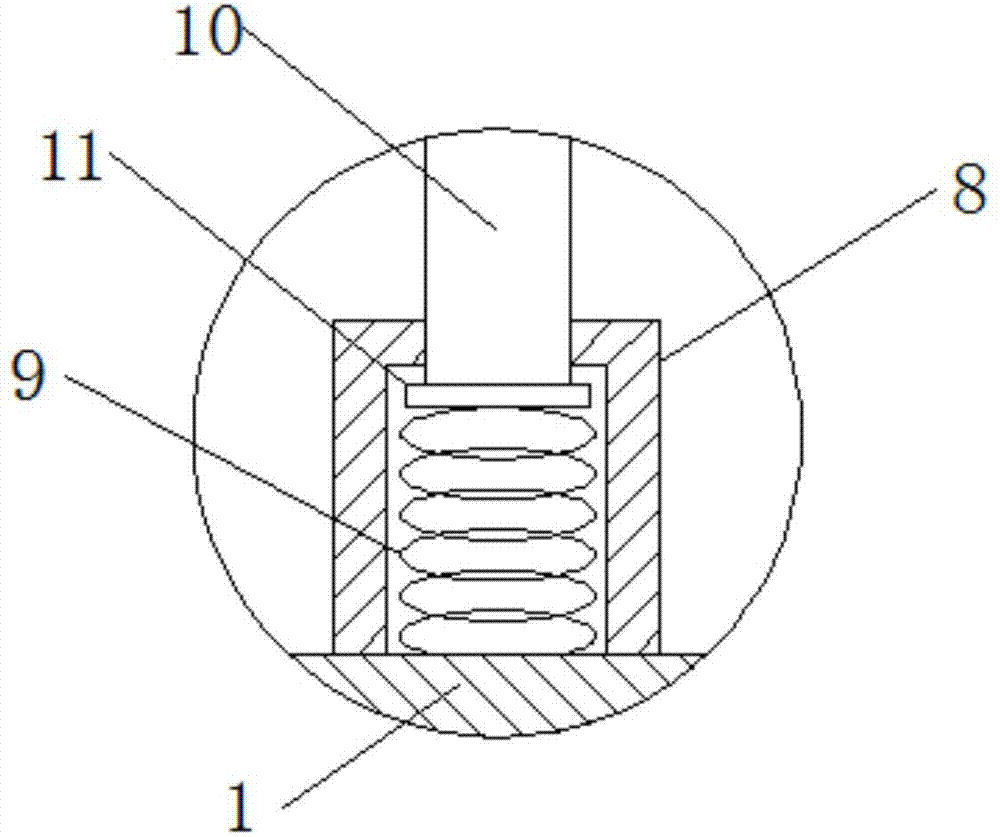

Rescue capsule for coal mining

InactiveCN107882588ANovel structureImprove usabilitySynthetic resin layered productsPower-operated mechanismHydraulic cylinderEngineering

The invention discloses a rescue cabin for coal mine development, which includes a cabin body, side doors are hinged on the left and right side walls of the cabin body, handles are connected to the side doors, and supports are longitudinally arranged inside the cabin body Beam, the top of the support beam is provided with a first reinforcement rib, the bottom end of the support beam is provided with a second reinforcement rib, a hydraulic cylinder is provided between the support beam and the side door, and the two ends of the hydraulic cylinder are respectively It is connected to the support beam and the side door through the rotation of the pin shaft. A sleeve is uniformly arranged in the middle of the bottom of the cabin, and the top of the sleeve is opened. The inside of the sleeve is provided with a spring, and the top of the spring is connected with a A guide column, the top of the guide column is fixedly connected with a bed body, a first aid box is provided at the bottom of the bed body, a battery pack is provided on the left side of the first aid box, and an oxygen cylinder is provided on the right side of the first aid box , an LED light is installed in the middle of the top of the cabin, which is suitable for widespread promotion.

Owner:成都千里之行科技有限公司

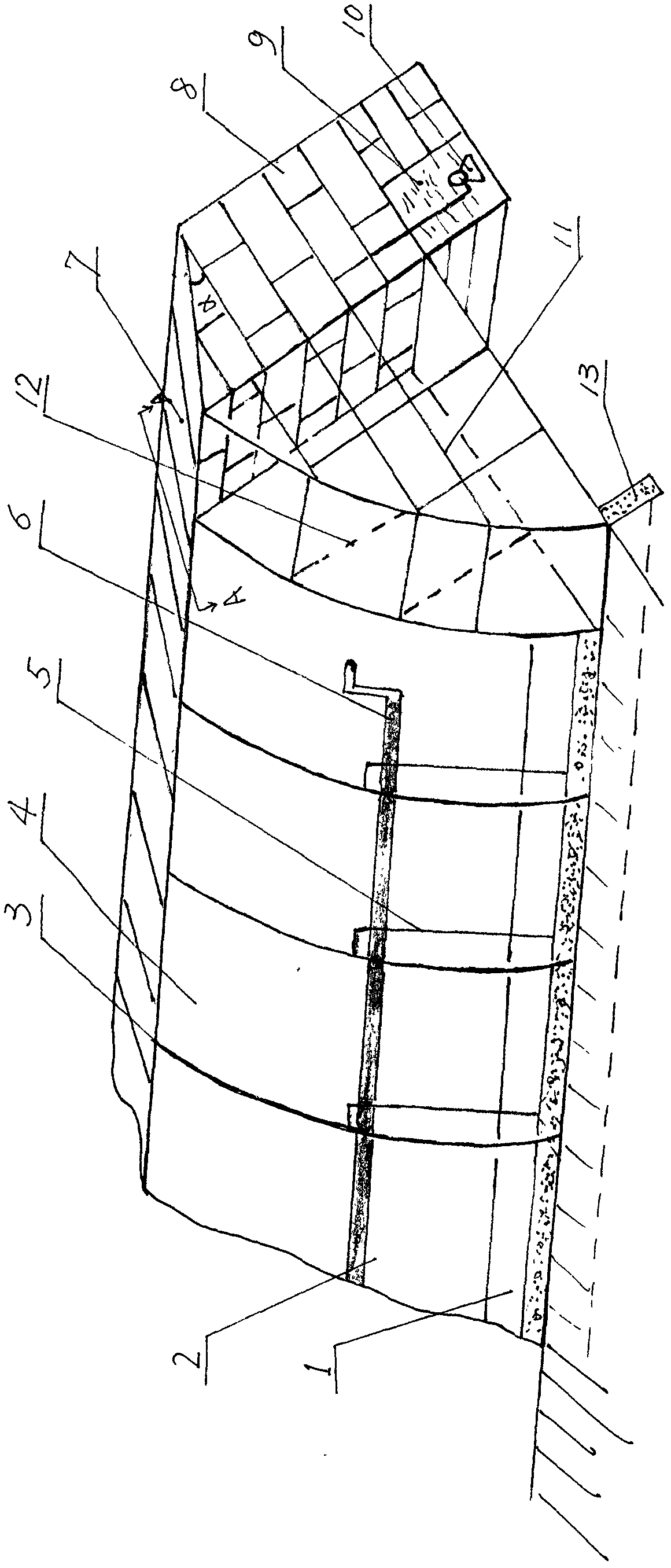

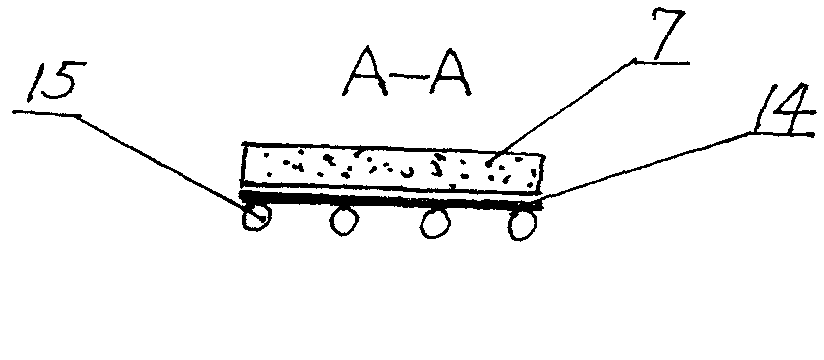

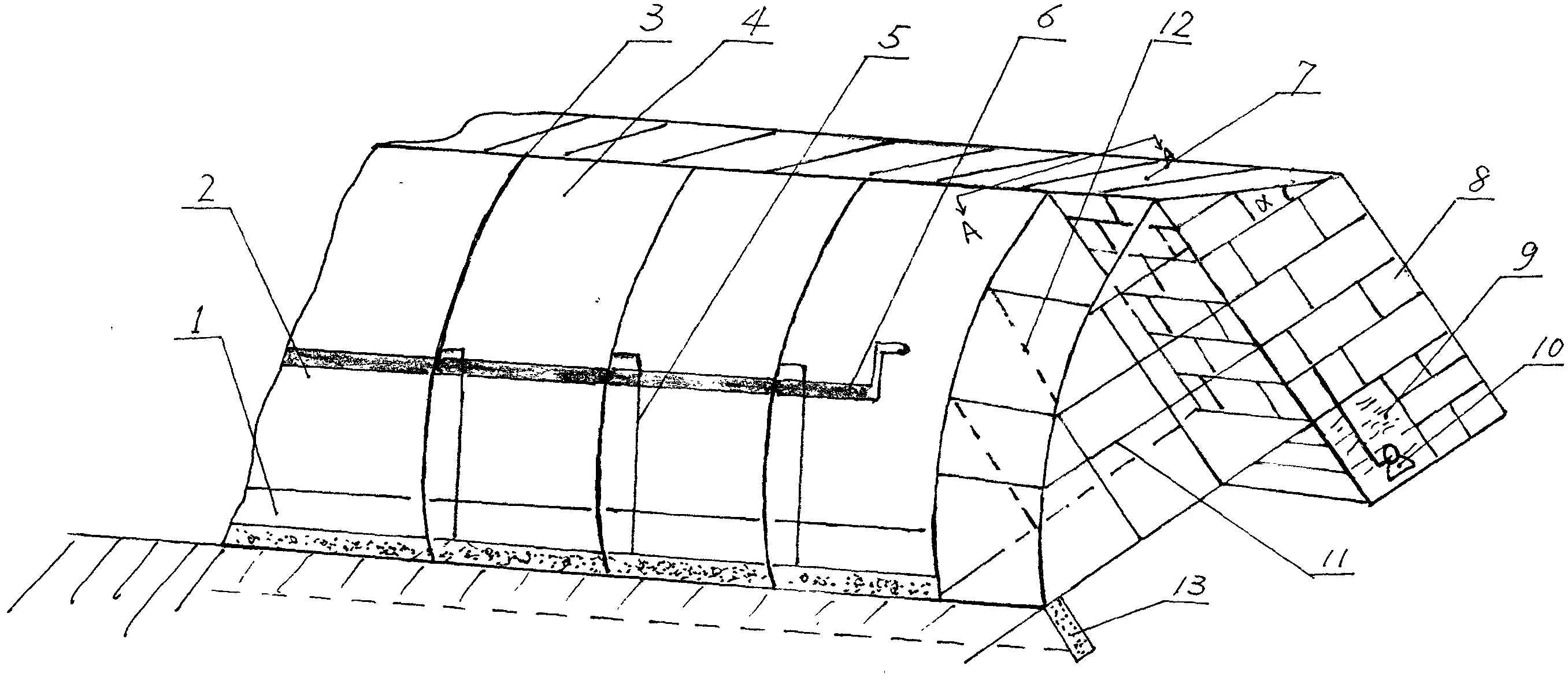

One-wall energy-saving sunlight greenhouse

InactiveCN102613028AIncrease insulation functionSolve the shade problemClimate change adaptationGreenhouse cultivationBrickDaylight

The invention discloses a one-wall energy-saving sunlight greenhouse which is characterized in that both gable walls are light-transmission gable walls which are internal and external light-transmission layers composed of light-transmission films and support grids; the grids between the internal light-transmission layers and external light-transmission layers are connected and fixed with a framework by lacing bars; a reservoir is arranged at the bottom of a rear wall; a thermal storage tube nest communicated with the reservoir to form a circulation loop is arranged below a rear slope above the rear wall; and a reflective film is placed between the rear slope and the thermal storage tube nest. In the greenhouse, the light-transmission gable walls replace the original cob walls or brick walls; shading of the gable walls is avoided; the land utilization rate is increased; photosynthesis of plants is improved, so that output of planted crops can be significantly increased; compared with the existing greenhouse, the temperature is increased by 3-5 DEG C, and the benefit is increased by more than 10%; with the adoption of an arc greenhouse body, the highest point moves forward, and the best lighting angle is increased by 5-10 DEG; with the adoption of 1 million mu greenhouse, the greenhouse land area available is increased by 95.95 thousand mu, and the greenhouse utilization rate of the original 1 mu of land is as high as 109.59%; and the greenhouse is good in heat preservation, is windproof and rain-proof, and is high in stability.

Owner:黄文永

Heat insulation magnesium oxide board and production method of same

InactiveCN103242056AIncrease insulation functionImprove heat preservation functionCeramicwareCalcium silicateFiber

The invention discloses a heat insulation magnesium oxide board, which is formed by mixing the following raw materials in parts by weight: 70-100 parts of magnesium oxide, 50-75 parts of magnesium chloride, 35-50 parts of expanded granules, 20-30 parts of calcium silicate, 20-30 parts of aluminum silicate fiber, 10-20 parts of cotton fiber, 2-5 parts of foaming agent and 10-20 parts of water. In the heat insulation magnesium oxide board, the expanded perlite, calcium silicate and the aluminum silicate fiber all have excellent heat insulation performance; and with the foaming agent, combination among the expanded perlite, calcium silicate and the aluminum silicate fiber is facilitated, so that the heat insulation performance of the heat insulation magnesium oxide board is enhanced.

Owner:ZHANGJIAGANG EVERNICE BUILDING MATERIALS

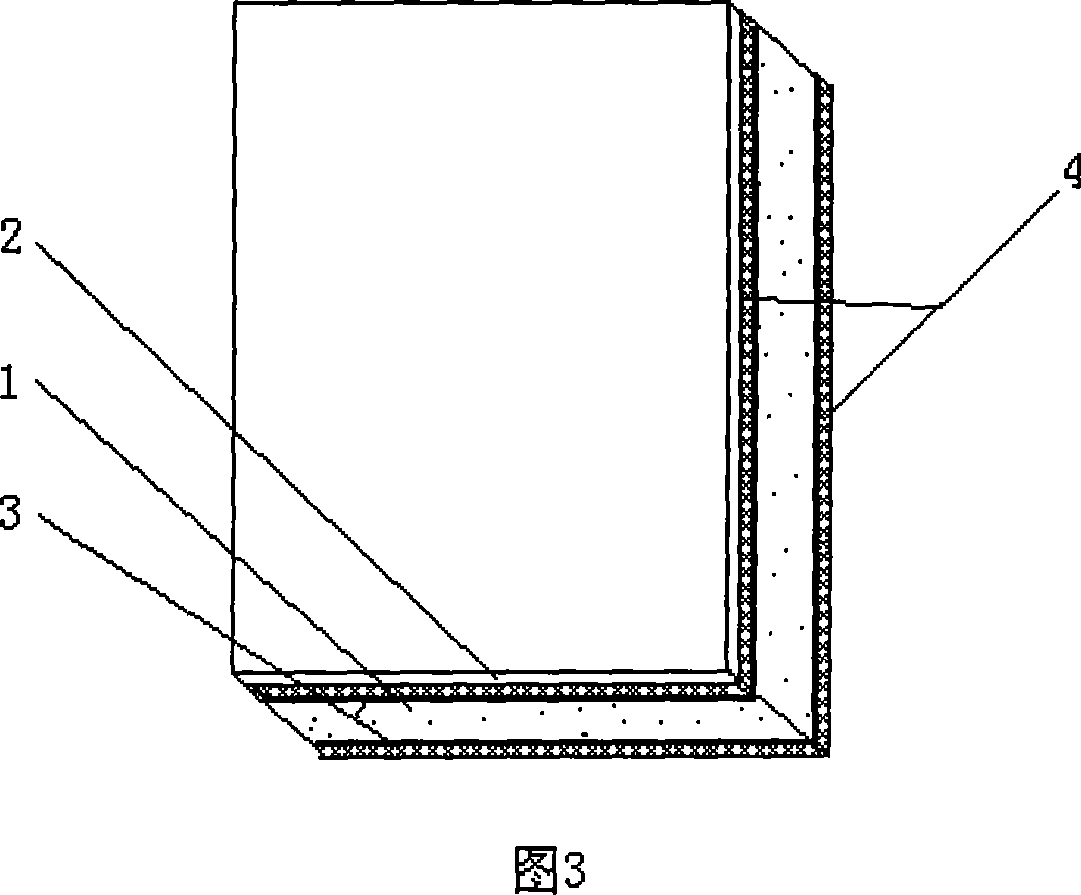

Renewable-aggregate industrial mortar and preparation method thereof

InactiveCN103420655AExcellent heat preservation functionImprove thermal insulation function and building energy-saving levelSolid waste managementThermal insulationCoal

The invention discloses an industrial mortar using renewable aggregates as a main filling raw material and a preparation method of the industrial mortar. The production formula of the industrial mortar is that 10-30 percent of silicate cement, 10-20 percent of calcium oxide, 10-15 percent of renewable concrete aggregate of which particle size is smaller than or equal to 5 mm, 5-10 percent of renewable clay brick aggregate of which particle size is smaller than or equal to 5 mm, 2-3 percent of renewable glass aggregate of which particle size is smaller than or equal to 5 mm, 10-20 percent of natural yellow sand, 15-25 percent of coal ash, 4-6 percent of water-reducing agent and a proper quantity of water are adopted, wherein the water-reducing rate of the water-reducing agent is required to be greater than 12 percent; preferably, the formula does not contain other components. Through the process of the method, the cost is effectively reduced; the mortar can be used in building surfaces and wall surfaces for plastering, is conducive to improving thermal insulation performance and energy-saving level of buildings, and has higher pressure resistance and tensile strength compared with existing similar products.

Owner:LANGFANG RONGSHENG CONCRETE

Intelligent electric blanket

InactiveCN108684090AEasy to fold and carryAutomatic temperature adjustmentOhmic-resistance heating circuitsOhmic-resistance waterproof/air-tight sealsEngineeringFar infrared

The invention relates to the technical field of electric blankets, in particular to an intelligent electric blanket comprising an electric blanket body, a blanket surface, a heating device, a heat insulating layer, a waterproof layer and a touch screen. The electric blanket body is divided into at least two heating zones. The blanket surface is arranged over the electric blanket body. The heatingdevice comprises a heating controller, a far-infrared cloth and a heating film. Heating films are disposed in the heating zones. The far-infrared cloth is arranged between the electric blanket body and the blanket surface. A first temperature sensor and a pressure sensor are arranged in the electric blanket body. The touch screen is in communication connection with the heating controller. The touch screen is provided with a second temperature sensor. By means of simple structure, the intelligent electric blanket not only can separately generate heat in different zones, but also can generate heat by the combination of the heating films and far-infrared rays, can adjust temperature as required, has physiotherapy and steaming functions, has a sleep detection function, can automatically adjusttemperature, has an energy-saving function, is automatically powered off when nobody is present, and has good waterproof and heat preservation effects.

Owner:张健

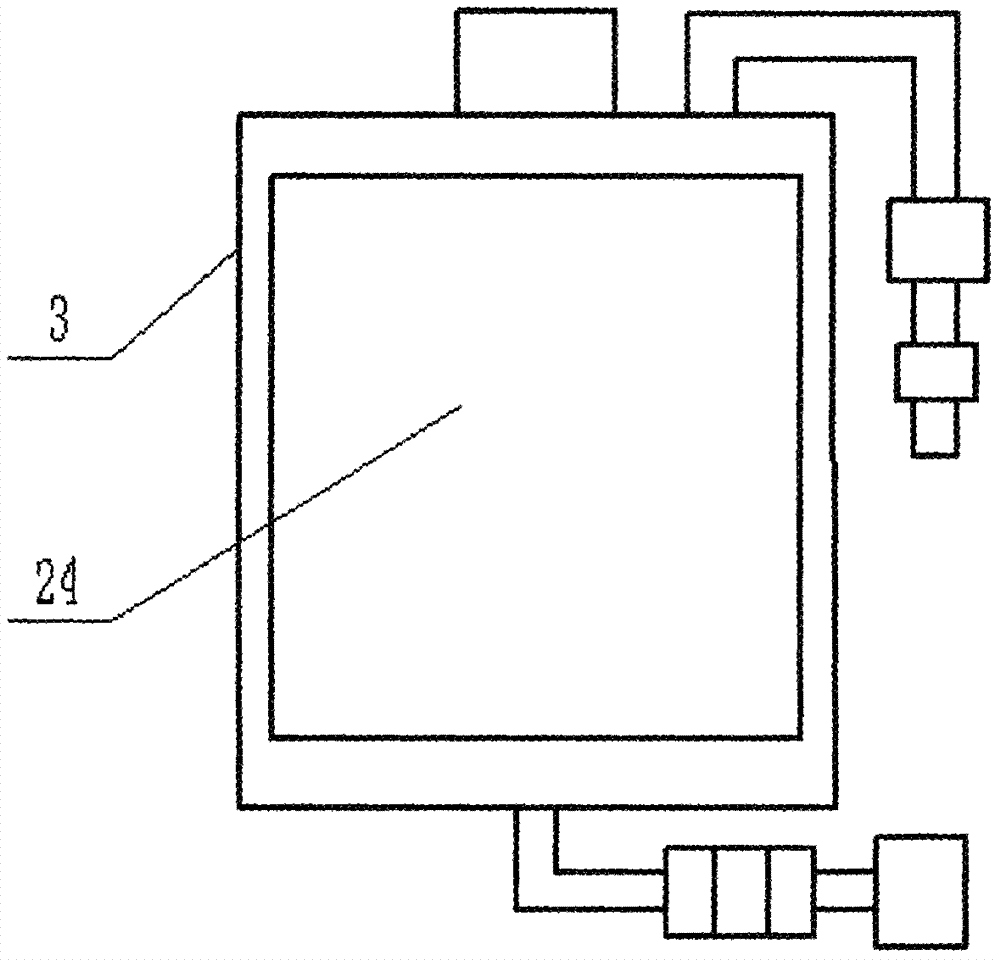

Cooling system for cryogenic storage container and operating method therefor

InactiveUS20080307801A1Prevent evaporationIncrease insulation functionMagnetic measurementsMachines using refrigerant evaporationProcess engineeringPiping

A cryogenic storage container is provided with a storage container, a vacuum container containing the storage container, and a heat shield. The cryogenic storage container is coupled to a cooling source equipped with a cryogenic freezer via transport piping so that the vibration of the cryogenic freezer cannot be directly delivered to the cryogenic storage container. The vibration can be further reduced by providing a bellows unit for transport piping.

Owner:HITACHI LTD

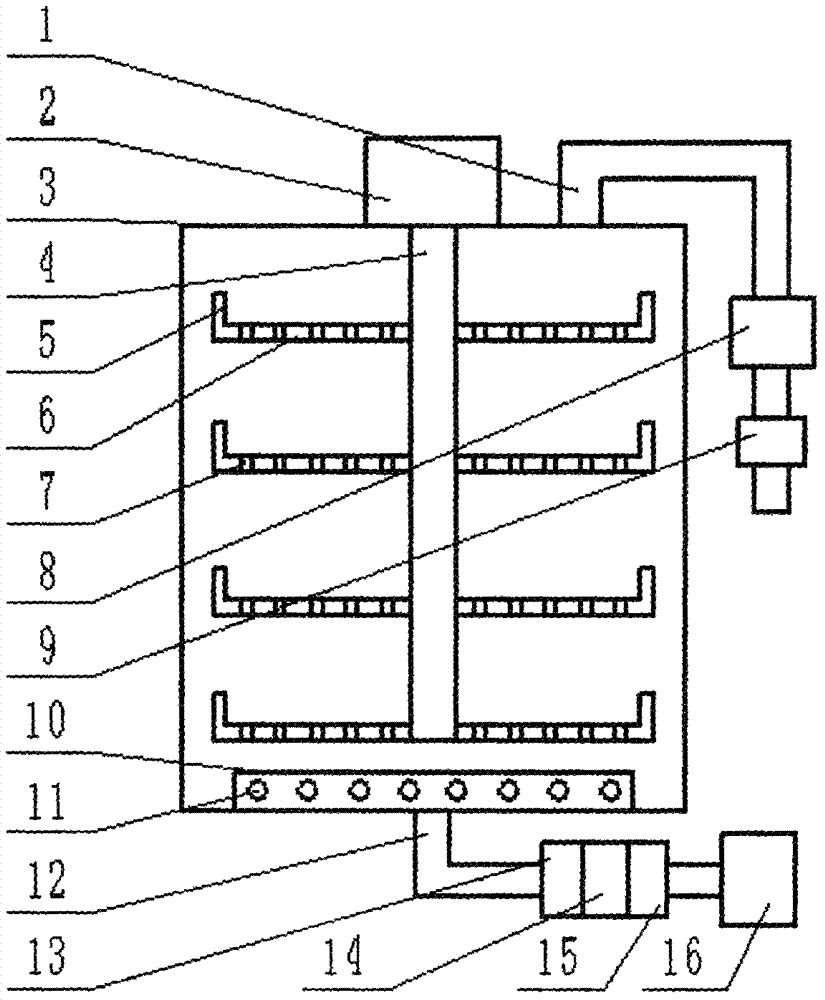

Efficient tea dryer

InactiveCN107289774AAvoid scatterHigh strengthTea dryingDrying gas arrangementsAir purifiersAgricultural engineering

The invention discloses a high-efficiency tea drying machine, which comprises a casing, a motor and a heating and purifying device. A motor is fixedly installed in the middle of the upper end of the casing, and the output shaft of the motor is connected with a rotating shaft, which is arranged vertically. In the inside of the housing, a plurality of support discs are fixedly installed on the rotating shaft, and a plurality of ventilation holes are opened on the support discs. An air distribution pipe is fixedly installed on the inner side of the bottom end of the housing, and the air distribution pipe is connected with the air intake pipe outside the housing. The air intake pipe is provided with a heating and purifying device and a blower, the top of the housing is connected with an air outlet pipe, the outlet pipe is provided with a second air cleaner, and the end of the air outlet pipe is provided with a suction fan. The trachea is connected, the invention has a simple structure and a reasonable design, which can greatly improve the drying efficiency of tea leaves, and can remove waste gas generated during the drying process, and the shell has strong strength and a long service life.

Owner:桐乡市大麻杰匠电子产品经营部

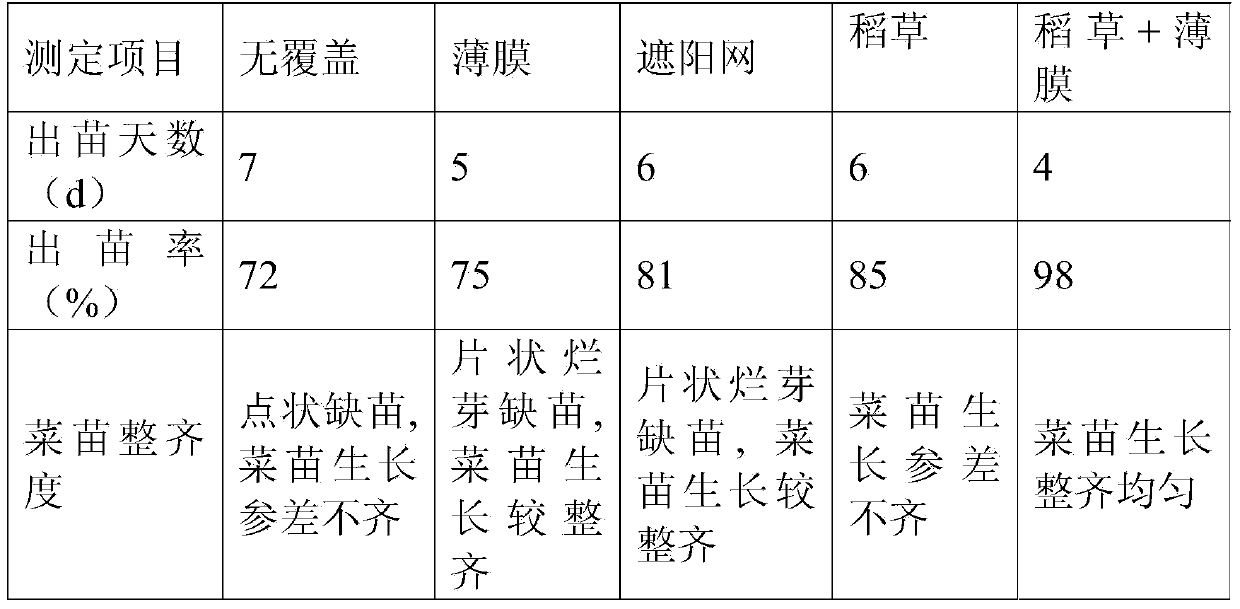

Method for improving germination quality of blanket seedlings of rapes

InactiveCN103766130AGood water retention and moisturizing functionIncrease insulation functionPlant protective coveringsPlastic filmSeedling

The invention relates to a method for improving germination quality of blanket seedlings of rapes and belongs to the field of the agricultural technologies. The method comprises the steps of overlapping a rice straw curtain on a plate opening of a seedling plate, enabling the rice straw curtain to be not directly contacted with bed soil, an overlapping a layer of plastic film on the grass curtain; and watering through the grass curtain. According to the method, the water retention and humidity preservation function of the rice straw is used; the heat preservation function of the plastic film is used; reasonable temperature, humidity and ventilation conditions are provided for the seedling plate; rot sprouts and dead seedlings can be avoided; and an obvious effect of improving the germination quality of blanket seedlings is achieved.

Owner:YANGZHOU UNIV

Antioxidation anticorrosion transformer oil containing multiple nanoparticles and preparation method thereof

ActiveCN104130829AImprove insulation performanceSmall dielectric coefficientAdditivesButylated hydroxytolueneOxidation resistant

Disclosed antioxidation anticorrosion transformer oil containing multiple nanoparticles is characterized by being prepared from the following raw materials in parts by weight: 1000-1500 parts of cycloalkyl base oil, 2-4 parts of aluminium nitride, 0.2-0.5 parts of molybdenum disulfide, 0.3-0.5 parts of polyisobutylene, 0.5-1.0 parts of active alumina micro powder, 0.2-0.5 parts of resorcinol, 0.2-0.5 parts of nanometer tantalum carbide powder, 0.2-0.5 parts of butylated hydroxytoluene, 2-4 parts of boron phosphide, and 0.5-1.0 parts of an auxiliary agent. The nanoparticles are prepared by utilizing an absolute-ethanol ball milling method, and employed equipment is simple and easy to operate. The added multiple nanoparticles help the transformer oil to improve insulating property and heat conduction property and enable the dielectric coefficient to be small. The added auxiliary agent improves the anti-oxidation, anti-corrosion and insulating properties of the transformer oil. The problems that transformer oil is easy to oxidize and corrode, is not long in service life and the like are effectively solved, and the safety coefficient of the transformer oil is substantially improved.

Owner:桐乡市华宇电力设备股份有限公司

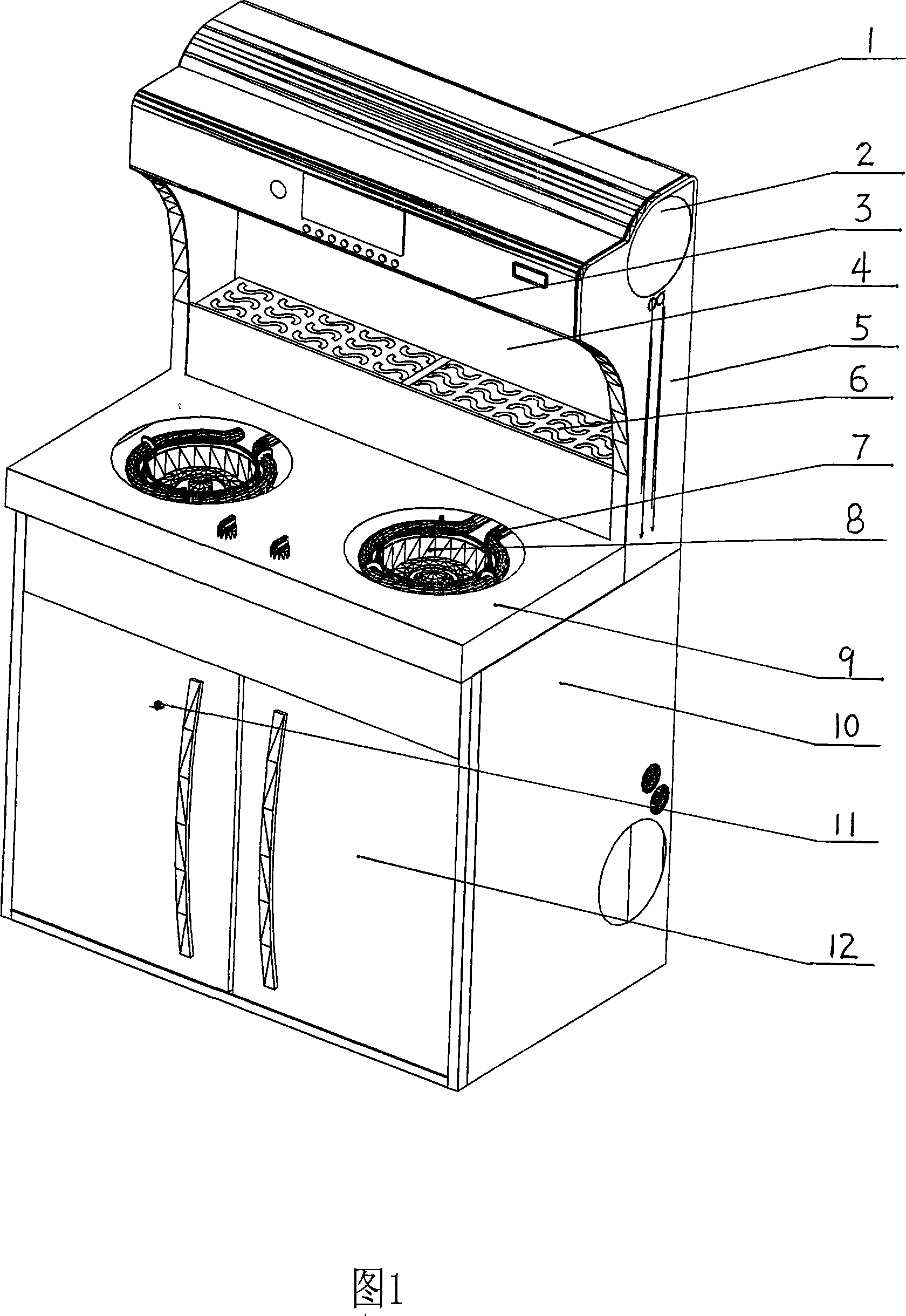

Energy-saving kitchen tool

InactiveCN101209186ATake advantage ofGood electric heating functionLighting and heating apparatusWater heating stoves/rangesWater storageEngineering

The invention discloses an energy-saving kitchen utensil, including a kitchen table (10) and a gas stove (9), the gas stove is arranged on the kitchen table, the gas stove is provided with a burner (8), the invention is characterized in that: the energy-saving kitchen utensil further includes a water storage device, the periphery of the burner of the gas stove is provided with an annular hollow tube (7), the both ends of the annular hollow tube are respectively connected with two interfaces of the water storage device, and the installation height of the water storage device is higher than the installation height of the annular hollow tube. The energy-saving kitchen utensil is characterized by utilization of residual heat and the energy conservation.

Owner:林忠生 +1

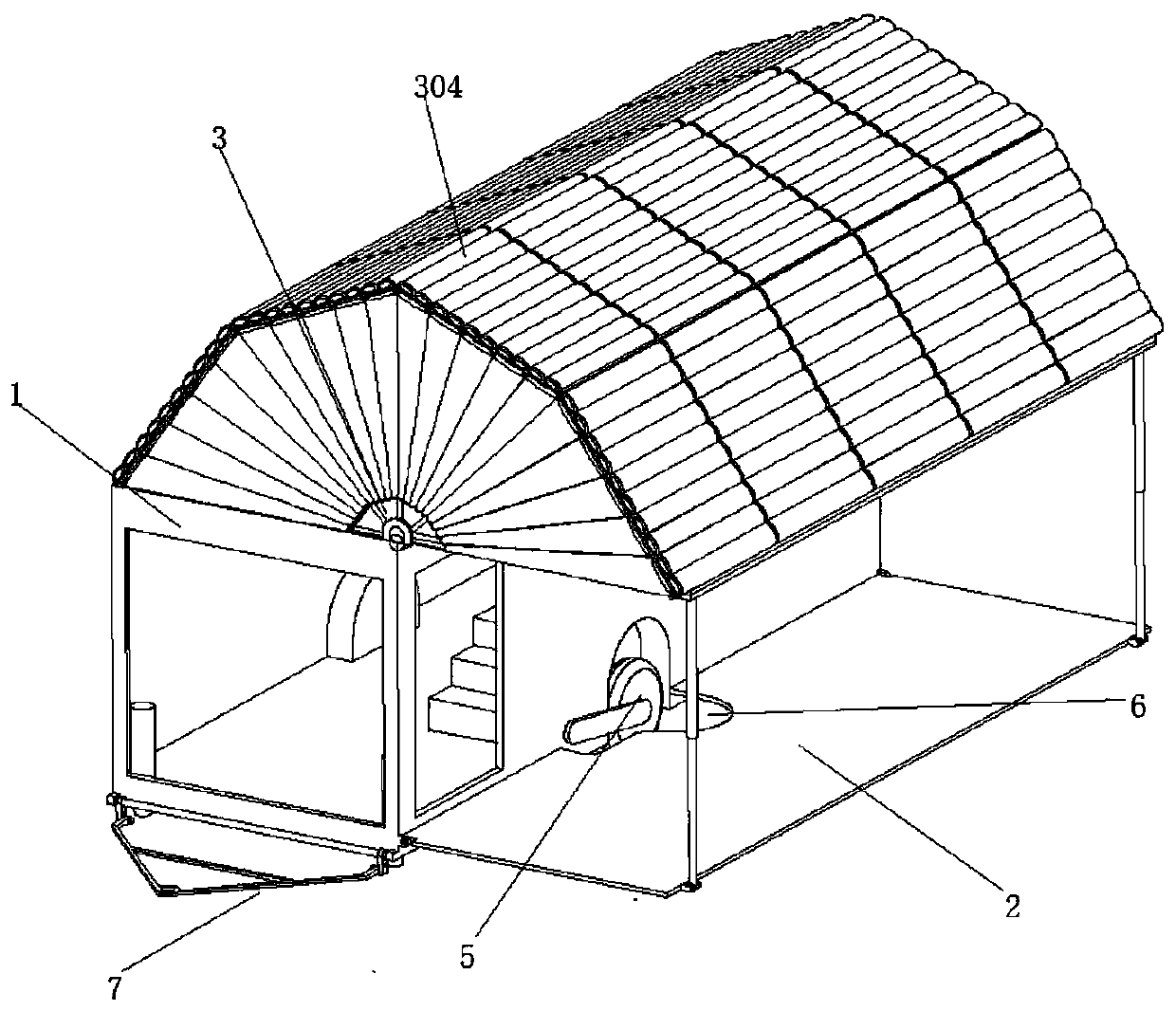

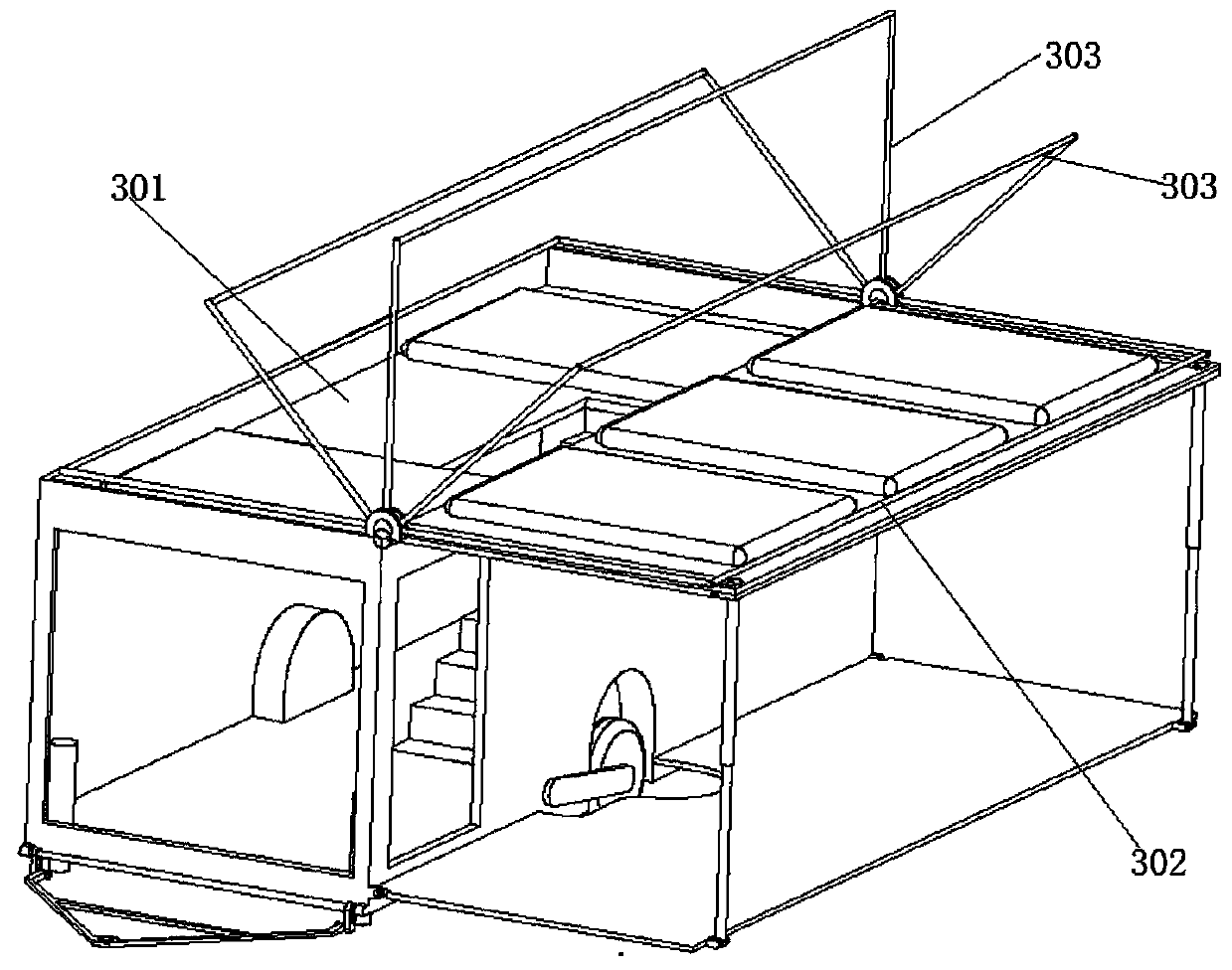

Convenient-to-move folding cabin and using method thereof

ActiveCN111319552AImprove wind strengthHigh standardVehicle with living accommodationItem transportation vehiclesStructural engineeringThermal water

The invention discloses a convenient-to-move folding cabin and a using method thereof and belongs to the technical field of folding cabins. The folding cabin comprises a box body, a foldable ceiling installed at the top of the box body and a moving assembly installed at the bottom of the box body and used for driving the box body to move; the foldable ceiling comprises a bottom plate fixed to thetop of the box body, a hinge assembly installed on the bottom plate and located on the same side as an expansion table, a rotating plate connected to the hinge assembly in a transmission mode, n cabintop keels arranged between the bottom plate and the rotating plate and hinged to the hinge assembly, and air bags. The convenient-to-move folding cabin is convenient to use and transport and can be unfolded in a short time on site; after being unfolded, the use space of the folding cabin is large enough. With the convenient-to-move folding cabin and the using method thereof life of the inventionadopted, conditions are rich and perfect, and the level of outdoor life is improved; energy-saving and environment-friendly performance can be realized; electric power and hot water can be provided for the washing for users; the wind-resistant strength of the unique inflatable foldable ceiling is higher than that of a traditional tent and has an excellent heat preservation or heat insulation function.

Owner:NANJING ZUHANG AVIATION TECH CO LTD

Novel aluminum steel continuous casting tundish covering agent and application thereof

The invention relates to a novel aluminum steel continuous casting tundish covering agent and the application thereof and belongs to the technical field of steel continuous casting. The tundish covering agent comprises components, by mass, 26-35% of CaO, 26-13% of SiO, 22-32% of Al2O3, 5-12% of MgO, 8-15% of (Na2O+Li2O) and 2-8% of B2O3. The tundish covering agent has the low viscosity of 0.5-1.2 Pa.s at the temperature of 1300 DEG C and has the low melting temperature of 1180 DEG C-1300 DEG C, can effectively absorb impurities in aluminum steel, improve the cleanness of molten steel in a tundish, well prevent the molten steel from being oxidized for the second time, and improve the quality of a casting blank, and has the advantages of being good in heat preserving property and the like. The designed covering agent can be well applied to the aluminum steel continuous casting process with the Al mass percentage within the range of 0.3-3%.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com