Polyurethane water-proof easy-to-paste heat-preserving composite board and method for producing the same

A polyurethane insulation board and polyurethane waterproof technology, which is applied in the direction of insulation, chemical instruments and methods, lamination devices, etc., can solve the problem that the thickness and uniformity of the polyurethane insulation layer cannot be guaranteed, and the waterproof quality and insulation effect cannot meet the design requirements. Insulation effect and other issues, to achieve the effect of superior insulation performance, good waterproof and heat preservation, high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

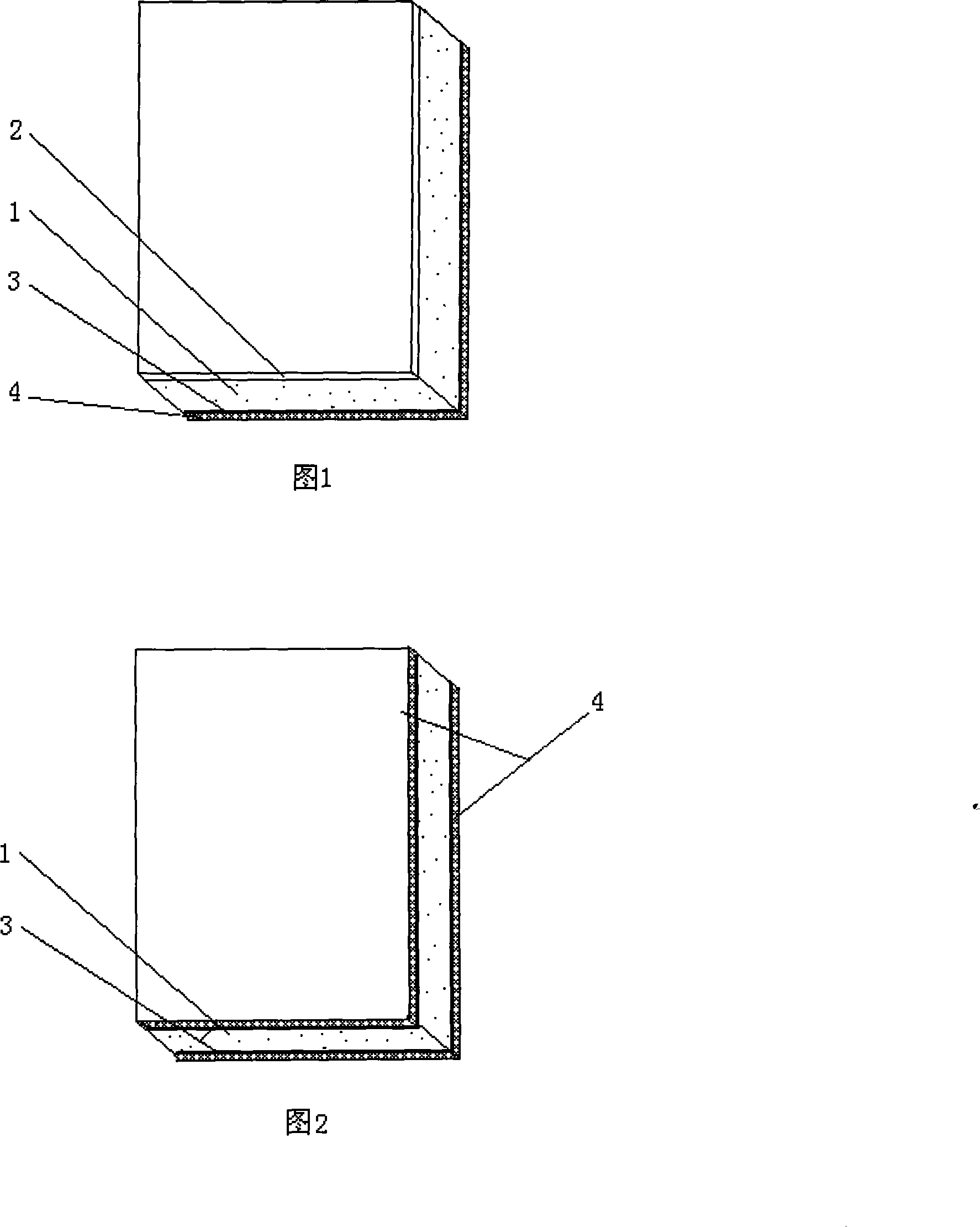

[0025] As shown in Figure 1, a waterproof layer 2 is provided on one side surface of the polyurethane insulation board 1, and a waterproof adhesive layer 3 and an easy-to-paste layer 4 are successively provided on the side surface, and the waterproof adhesive layer 3 is selected from VAE emulsion and Auxiliary materials (white cement, calcium carbonate, plasticizer and other materials) are used to make waterproof coatings. The easy-to-stick layer is made of non-woven fabric. The waterproof layer 2 is made of plastic waterproof coiled material.

[0026] The preparation process of polyurethane waterproof and easy-to-paste thermal insulation composite board is as follows:

[0027] (1) First apply a waterproof coating made of a waterproof adhesive layer VAE emulsion and auxiliary materials on the surface of the easy-to-stick layer, that is, one side of the non-woven fabric, to obtain a waterproof and easy-to-stick composite layer, and roll it on the shaft after drying;

[0028] ...

Embodiment 2

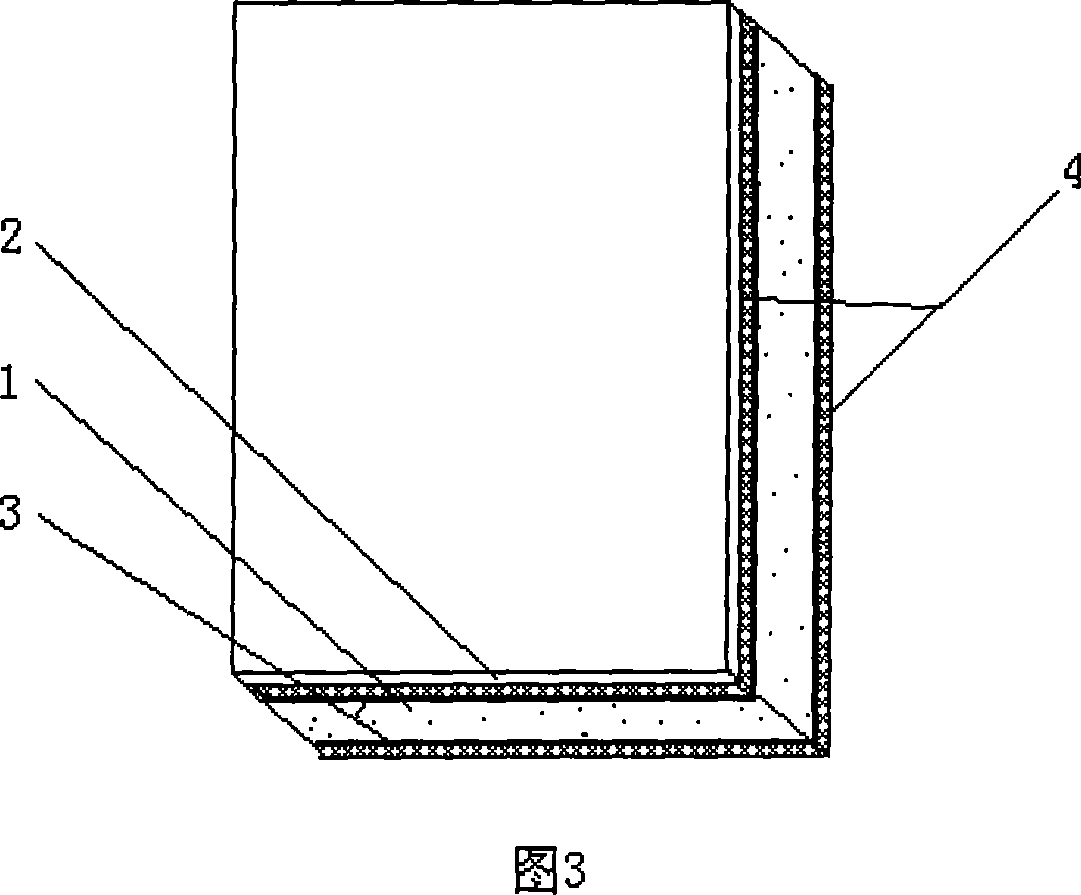

[0031] As shown in FIG. 2 , a waterproof adhesive layer 3 and an easy-to-stick layer 4 are sequentially arranged on both sides of the polyurethane insulation board 1 . The shaft roll of the waterproof and easy-to-paste composite layer obtained in step (1) in Example 1 is placed on the shelf at the inlet end of the foaming box, and the waterproof and easy-to-paste composite layer is pulled out (this side of the waterproof adhesive layer faces upwards) ), spread it flat on the walking plane at the inlet end of the foaming and curing box, and spray polyurethane material on the surface with a spray gun. All the other implementations are as in Example 1.

Embodiment 3

[0033] As shown in Figure 3, a waterproof adhesive layer 3 and an easy-to-stick layer 4 are sequentially provided on one side of the polyurethane insulation board 1, and a waterproof adhesive layer 3, an easy-to-stick layer 4, and a waterproof layer 2 are sequentially provided on the other side surface. . The double-side surfaces of the polyurethane thermal insulation board 1 obtained in Example 2 are successively provided with a waterproof adhesive layer 3, an easy-to-stick layer 4 and a heat-insulating composite board, and then one side of the easy-to-stick layer 4 is coated with a waterproof paint (VAE emulsion can be selected for use). Waterproof coating made with auxiliary materials) can be.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com