Novel high-strength foam concrete and preparation method for same

A foamed concrete and mixture technology, applied in the field of building materials, can solve the problems of poor durability of foamed concrete products, hinder the development of ultra-light foamed concrete, and high cost of special cement, achieve good cost performance and competitive advantages, good thermal insulation and thermal insulation functions, The effect of simplifying the roof structure and construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

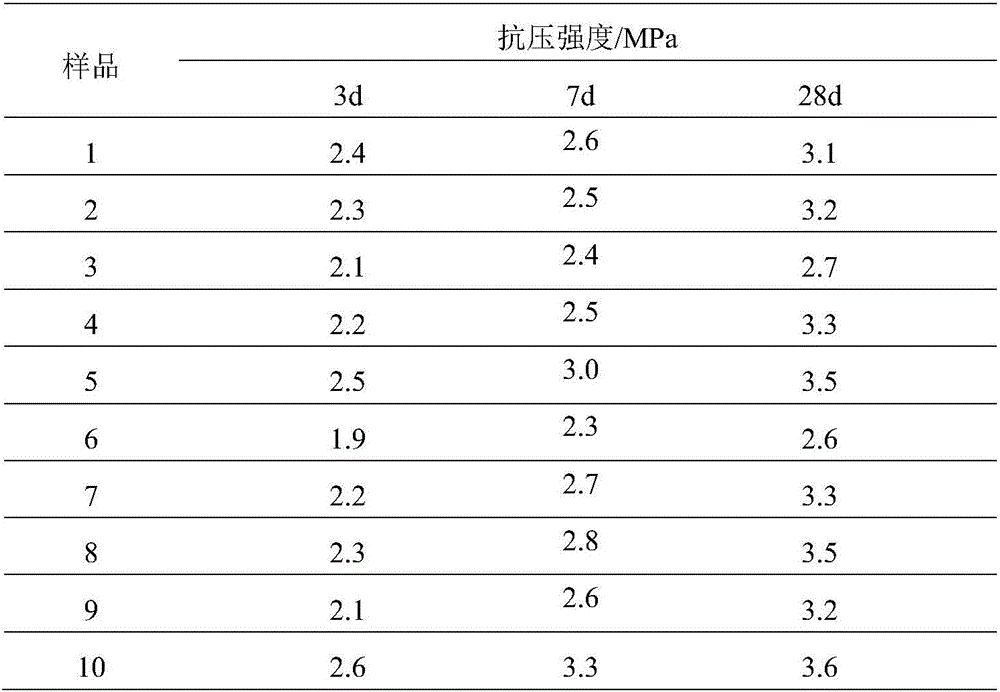

Examples

Embodiment 1

[0021] A kind of foam concrete material, described component is by mass parts:

[0022] Portland cement (42.5) 100 parts, fly ash 200 parts,

[0023] 250 parts of fine aggregate, the fineness modulus is 2.1,

[0024] 375 parts of coarse aggregate,

[0025] 8 parts of lignosulfonates,

[0026] 250 parts of water,

[0027] 20 parts of hexamethylene-1,6-diisocyanate,

[0028] 10 parts of polyacrylamide.

Embodiment 2

[0030] A kind of foam concrete material, described component is by mass parts:

[0031] 300 parts of aluminate cement (42.5), 100 parts of silica fume,

[0032] 550 parts of fine aggregate, the fineness modulus is 2.2,

[0033] 750 parts of coarse aggregate,

[0034] 7 parts of naphthalene series,

[0035] 850 parts of water,

[0036] 25 parts of tetramethylene-1,4-diisocyanate,

[0037] 15 parts of polyvinyl alcohol.

Embodiment 3

[0039] A kind of foam concrete material, described component is by mass parts:

[0040] Portland cement (42.5) 300 parts, mineral powder 400 parts,

[0041] 850 parts of fine aggregate, the fineness modulus is 2.3,

[0042] 1250 parts of coarse aggregate,

[0043] 8 parts of melamine series,

[0044] 850 parts of water,

[0045] 40 parts of 2,2,4-trimethylhexamethylene-1,6-diisocyanate,

[0046] 20 parts of polyvinyl alcohol.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com