Anion-exchange film, preparation method thereof and fuel cell

An anion exchange membrane and coating liquid technology, applied in anion exchange, ion exchange, fuel cell parts and other directions, can solve the problems of poor membrane structure uniformity, low mechanical strength, poor ion conductivity and mechanical properties, etc. The effect of good thermal stability, high mechanical strength and high OH-conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

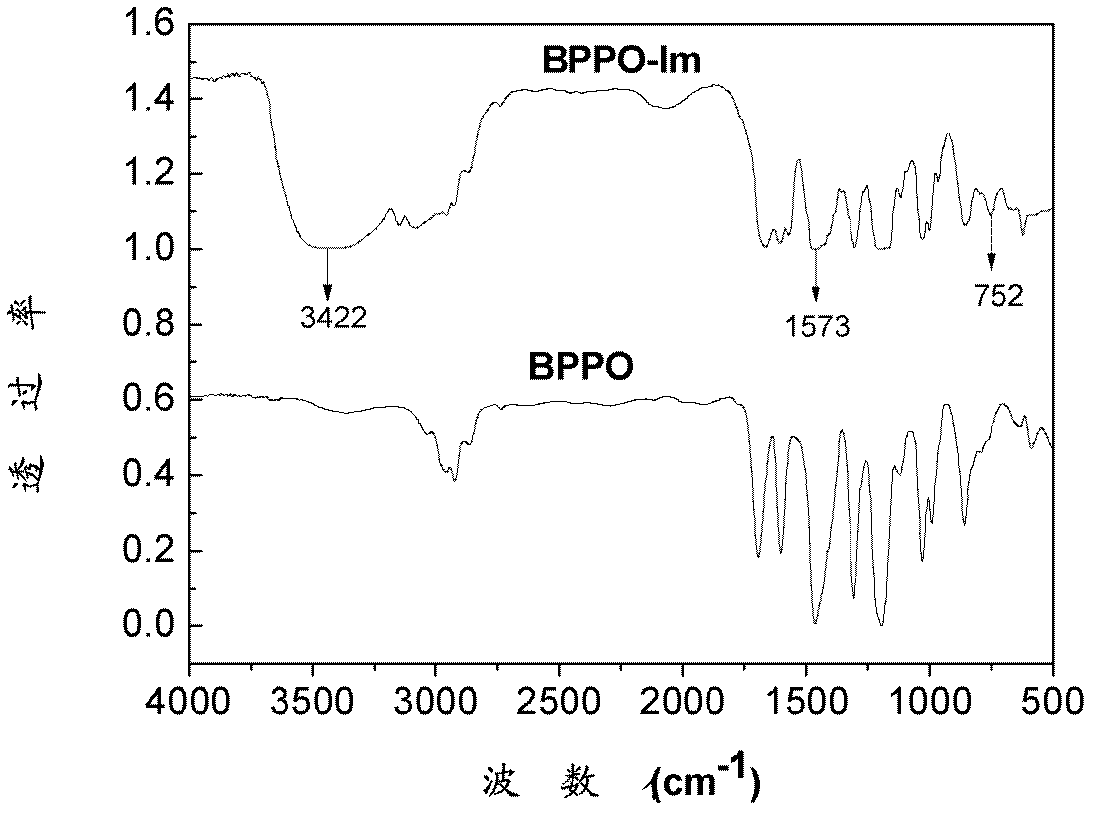

[0038] The preparation steps of the coating liquid include the following process: brominated poly(2,6-dimethyl-1,4-phenylene oxide) or brominated polyphenylene with a degree of methyl bromide of 10%-100% The ether is dissolved in an organic solvent and is configured as a polymer solution of 5%-25% (mass percentage), according to the brominated poly(2,6-dimethyl-1,4-phenylene oxide) containing bromomethyl 0.1-5 times the molar amount is added with N-substituted imidazole small molecules, and the reaction is stirred at 20-80°C for 4-50 h to obtain imidazole functionalized polyphenylene ether coating liquid.

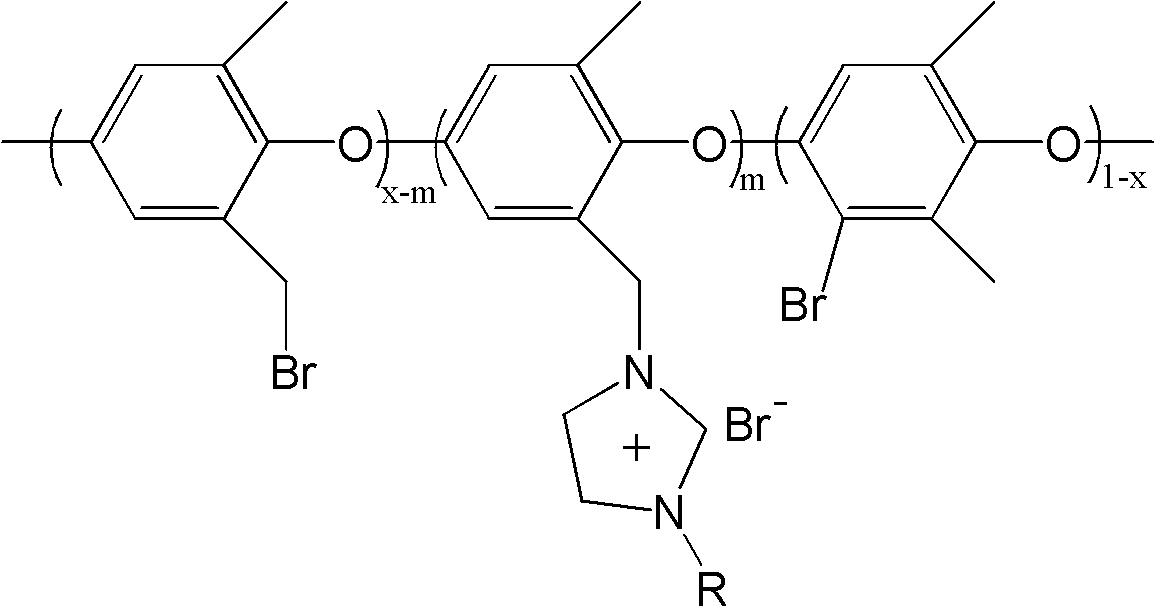

[0039] The brominated polyphenylene ether used in the present invention has the structural formula shown in the following formula (2):

[0040]

[0041] In the preparation method of the present invention, the organic solvent used is toluene, chlorobenzene, N-methylpyrrolidone (NMP), N,N-dimethylformamide (DMF) or N,N-dimethylacetamide (DMAc).

[0042] The structure formula of th...

Embodiment 1

[0056] 1. Preparation of coating liquid: 3g of brominated polyphenylene oxide (BPPO) (produced by Shandong Tianwei Membrane Technology Co., Ltd.) with a degree of bromination of 57.8% (produced by Shandong Tianwei Membrane Technology Co., Ltd.) was dissolved in 20 mL of N-methylpyrrolidone (NMP), After the polymer is completely dissolved, add 900 μL of N-methylimidazole (produced by Shanghai Demer Pharmaceutical Technology Co., Ltd.), where the ratio of the molar amount of bromomethyl contained in the N-methylimidazole to the brominated polyphenylene ether is 129.5 :100, magnetic stirring reaction at 30°C for 10h to obtain imidazole-functionalized brominated polyphenylene ether (BPPO-Im) coating liquid.

[0057] 2. Film forming steps:

[0058] The glass plate as the substrate is soaked in lye for one day, and then rinsed repeatedly with tap water and twice with distilled water after being taken out, and dried in an oven to obtain a clean glass plate.

[0059] The coating liquid obta...

Embodiment 2

[0085] The same operation process as in Example 1 was adopted, except that the amount of N-methylimidazole added was changed to 600 μL to obtain an anion exchange membrane with a similar structure.

[0086] Through the same performance measurement as shown in Example 1, it is measured that the moisture content of the obtained membrane is 58%, the ion exchange capacity is 2.21mmol / g dry membrane, and the OH at 20°C - Conductivity is 2.4×10 -2 S / cm. The thermal decomposition temperature is 185°C and the tensile strength is 21MPa. After soaking in 2mol / L NaOH for one week, at 20℃ OH - The conductivity drops only by 7%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Thermal decomposition temperature | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com