Honeycomb activated carbon, preparation method thereof, and air purifier prepared from honeycomb activated carbon

A honeycomb activated carbon, air purifier technology, applied in the directions of botanical equipment and methods, chemicals for biological control, separation methods, etc., can solve the problems of accelerated adsorption, air pollution, etc., and achieve accelerated adsorption and decomposition, forming rate High, simple production process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

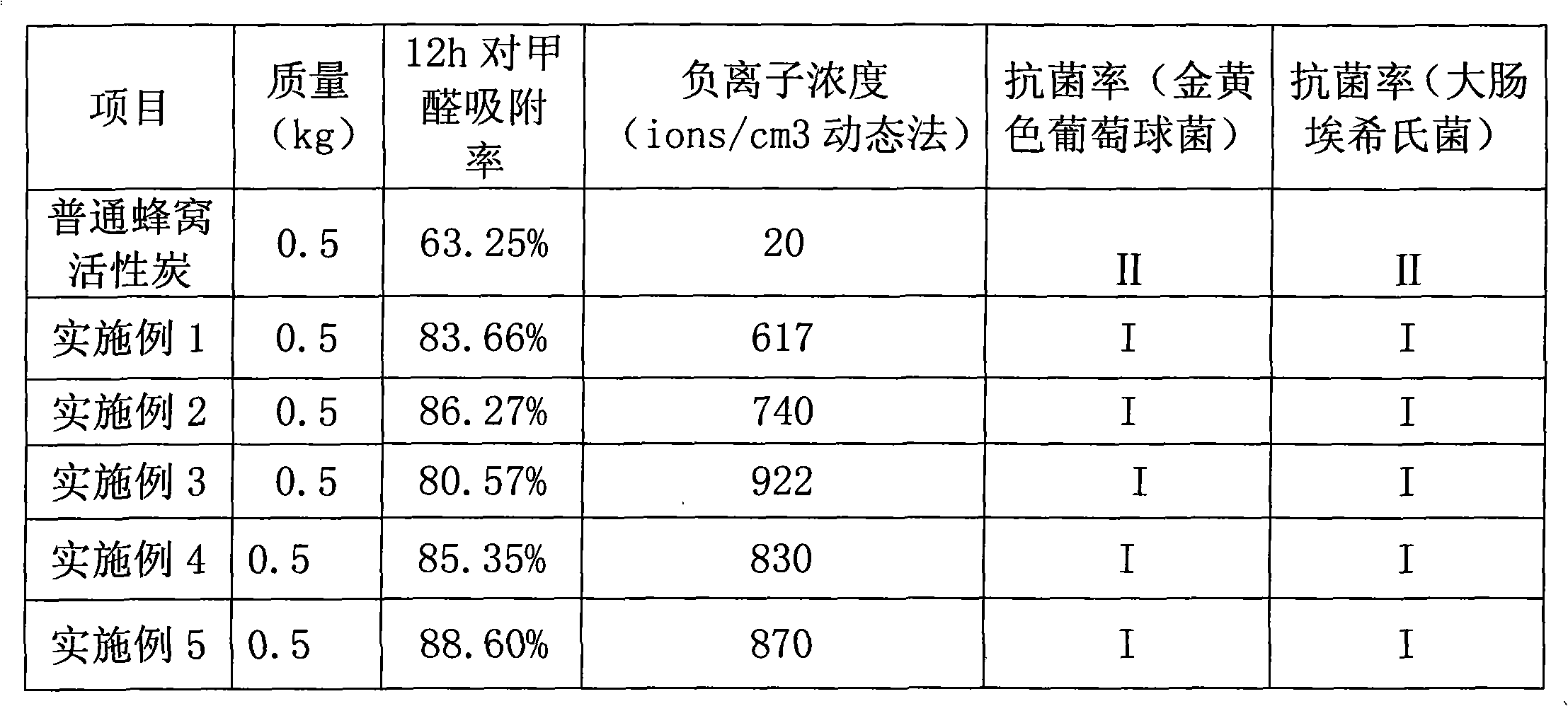

Embodiment 1

[0031] Step 1: Ingredients. 60kg of activated carbon above 300 mesh, 30kg of diatomite above 200 mesh, 10kg of negative ion powder, nano-TiO 2 Mix 2kg of powder, and fully stir in the blender for 15 minutes.

[0032] Step 2: Ball milling. Pour the homogeneously mixed raw materials in step 1 into a ball mill, and add 82kg of water into the ball mill for ball milling and mixing to prepare slurry. The ball milling time is 24 hours.

[0033] Step 3: Squeeze the mud. After the ball milled mud is fully stirred, it is pumped into the mud squeezer, filtered and squeezed dry.

[0034] Step 4: Practicing the mud, pour the mud cake after squeezing the mud into the vacuum mud refining machine for rough 2 times, and then finely practice 3-5 times.

[0035] Step 5: Extrusion molding, putting the refined mud section into the extruder barrel of the prepared mold to extrude the honeycomb activated carbon green body. The size of the mold is 100*100*100mm, and the extrusion pressure is 15 ton...

Embodiment 2

[0039] Step 1: Ingredients. 50kg of activated carbon above 300 mesh, 30kg of clay above 200 mesh, 15kg of negative ion powder, nano TiO 2 Mix 5kg of powder and fully stir in the blender for 15 minutes.

[0040] Step 2: Ball milling. Add the homogeneously mixed raw materials in step 1 into a ball mill, and add 75kg of water into the ball mill for ball milling and mixing to prepare a slurry. The ball milling time is 48 hours.

[0041] Step 3: Squeeze the mud. After the ball milled mud is fully stirred, it is pumped into the mud squeezer, filtered and squeezed dry.

[0042] Step 4: Practicing the mud, pour the mud cake after squeezing the mud into the vacuum mud refining machine for rough 2 times, and then finely practice 3-5 times.

[0043] Step 5: Step 5: Extrusion molding, putting the refined mud section into the extruder barrel of the prepared mold to extrude the honeycomb activated carbon green body. The size of the mold is 100*100*100mm, and the extrusion pressure is 17 ...

Embodiment 3

[0047] Step 1: Ingredients. 60kg of activated carbon above 300 mesh, 10kg of diatomite above 200 mesh, 10kg of perlite, 10kg of attapulgite, 5kg of negative ion powder, nano-TiO 2 Mix 5kg of powder and fully stir in the blender for 15 minutes.

[0048] Step 2: Ball milling. Add the homogeneously mixed raw materials in step 1 into a ball mill, and add 90 kg of water into the ball mill for ball milling and mixing to prepare a slurry. The ball milling time is 36 hours.

[0049] Step 3: Squeeze the mud. After the ball milled mud is fully stirred, it is pumped into the mud squeezer, filtered and squeezed dry.

[0050] Step 4: Practicing the mud, pour the mud cake after squeezing the mud into the vacuum mud refining machine for rough 2 times, and then finely practice 3-5 times.

[0051] Step 5: Extrusion molding, putting the refined mud section into the extruder barrel of the prepared mold to extrude the honeycomb activated carbon green body. The size of the mold is 100*100*100mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com