Modified composite material with recovered polypropylene as matrix and preparation method thereof

A technology of recycling polypropylene and matrix modification, which is applied in the field of polypropylene composite materials to achieve the effects of improving wear resistance and impact resistance, wide application range, and improving strength and rigidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

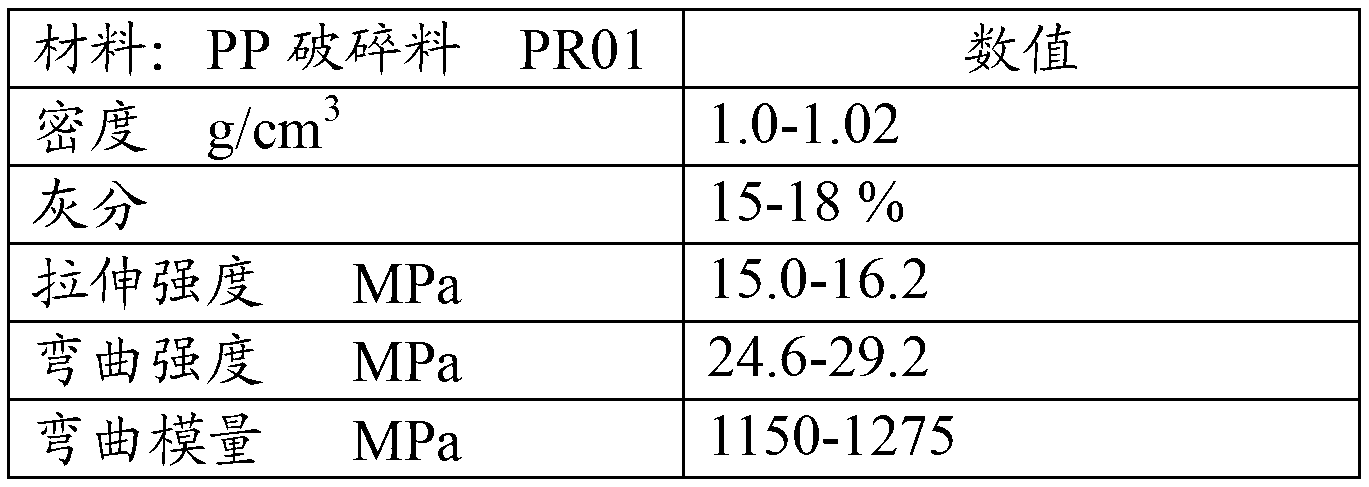

[0037] Applied to building materials (plastic interlocking floor tiles for gardens and municipal engineering, green belt grid panels), its appearance is shown in ZL201030203468.3 and ZL201030203469.8. In this example, polypropylene broken material PRO1 is used, and its physical properties are shown in Table 1 below. Since the interlocking floor tile is a large-scale product, a small amount of fly ash and calcium carbonate are added to improve or stabilize the fluidity of the material.

[0038] Table 1 Physical properties of polypropylene crushed material PR01

[0039]

[0040]

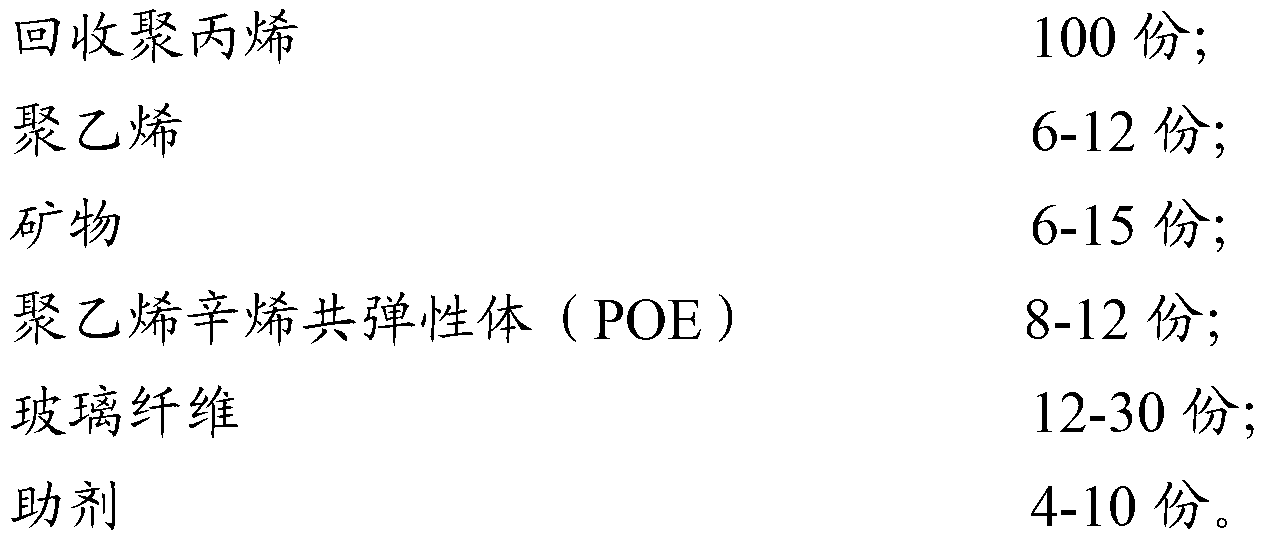

[0041] Raw materials:

[0042] POE, purchased from LG Chem, brand LC165;

[0043] Aluminate coupling agent, model DL-411, purchased from Nanjing Pinning Coupling Agent Co., Ltd.

[0044] Silane coupling agent, model KH-550, purchased from Jiangsu Chenguang Coupling Agent Co., Ltd.;

[0045] Glass fiber, commercially available; 508A chopped glass fiber

[0046] Use a single-screw extruder to m...

Embodiment 2

[0048] Modify the polypropylene broken material PRO1 shown in Table 1, the preparation method is as shown in Example 1, and the proportioning ratio is as shown in Table 2: 100 parts of PR01, 20-22 parts of glass fiber, 2-3 parts of calcium carbonate, 4 -6 parts of fly ash, 6 parts of LDPE, 10 parts of POE, 5 parts of PP-g-MAH, 0.3 parts of polyethylene wax, 0.1 parts of CaSt, 0.4 parts of aluminate coupling agent, 0.3 parts of antioxidant 1010, 0.1 Part of antioxidant 168, 0.1 part of antioxidant DLTP, 0.3 part of UV-531, 0.1 part of UV-327, appropriate amount of pigment. The pellets were tested, and the test results are shown in Table 3.

Embodiment 3

[0050] Modify the polypropylene crushing material PRO1 shown in Table 1, the preparation method is as shown in Example 1, and the proportioning ratio is as shown in Table 2: 100 parts of PR01, 29-30 parts of glass fiber, 3-5 parts of calcium carbonate, 6 -8 parts of fly ash, 10 parts of LDPE, 12 parts of POE, 6 parts of PP-g-MAH, 0.4 parts of polyethylene wax, 0.2 parts of CaSt, 0.1 parts of KH-550, 0.2 parts of aluminate coupling agent, 0.2 parts Antioxidant 1010, 0.1 part of antioxidant 168, 0.1 part of antioxidant DLTP, 0.3 part of UV-531, 0.1 part of UV-327, appropriate amount of pigment. The granulated material was tested, and the test results are shown in Table 3.

[0051] The ratio of each embodiment of table 2

[0052] Example 1 2 3 PR01 100 100 100 LDPE 6 6 10 POE 8 10 12 chopped glass fiber 13-15 20-22 29-30 calcium carbonate 2-3 2-3 3-5 fly ash 4-6 4-6 6-8 talcum powder - - - wollastonite - ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com