Aluminum alloy 5052 having high corrosion resistance and manufacturing method thereof

An aluminum alloy, corrosive technology, applied in the field of alloy materials, can solve the problems that cannot fully meet the needs of ship applications, achieve the effects of improving heat resistance and toughness, improving metallographic structure, and reducing crack sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

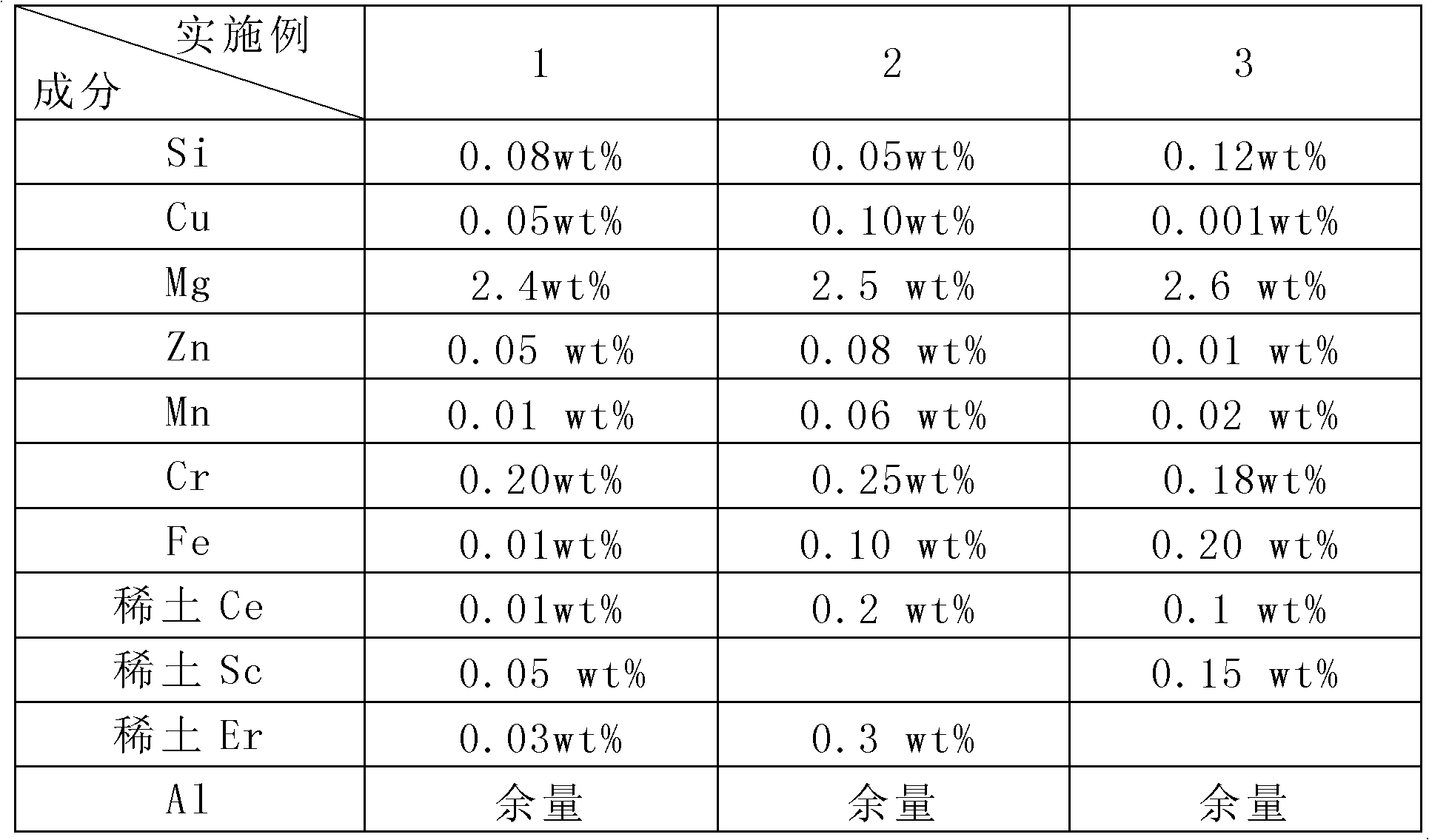

[0030] According to the mass percentage of Example 1 in Table 1, the ingredients were prepared to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4 and Al-rare earth, etc.

[0031] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted, add the intermediate alloy and stir; then add Mg and Zn, slag and refine; stir and stand still, pour into the cast iron mold; Aluminum alloy ingots are hot-rolled and cold-rolled into aluminum alloy coils, and the aluminum alloy coils are cold-rolled to a thickness of 3.0mm. The cold-rolled aluminum alloy coil is annealed at a temperature of 150° C., and the holding time is 8 hours.

Embodiment 2

[0033] According to the mass percentage of Example 2 in Table 1, the ingredients were prepared to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4 and Al-rare earth, etc.

[0034] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted, add the intermediate alloy and stir; then add Mg and Zn, slag and refine; stir and stand still, pour into the cast iron mold; The aluminum alloy ingot is hot-rolled and cold-rolled into an aluminum alloy plate, and the aluminum alloy plate is cold-rolled to a thickness of 2.0mm, and the cold-rolled aluminum alloy plate is annealed at a temperature of 160°C, and the holding time is 5 hours.

Embodiment 3

[0036] The batching was carried out according to the mass percentage of Example 3 in Table 1 to make aluminum ingots, master alloys AlCu50, AlMn10, AlCr4 and Al-rare earth, etc.

[0037] First put the aluminum ingot into the crucible resistance furnace, when the aluminum ingot is melted, add the intermediate alloy and stir; then add Mg and Zn, slag and refine; stir and stand still, pour into the cast iron mold; Aluminum alloy ingots are hot-rolled and cold-rolled into aluminum alloy coils, and the aluminum alloy coils are cold-rolled to a thickness of 1.0mm, and the cold-rolled aluminum alloy coils are annealed at a temperature of 120°C. The holding time is 10 hours.

[0038] The 5052 aluminum alloys prepared in Examples 1-3 and the existing common 5052 aluminum alloys were randomly selected for corrosion performance experiments, and the corrosion medium was 3.5% NaCl+0.05MgCl 2 (atomic percent) aqueous solution to simulate seawater. After 40 days of simulated seawater exper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com