Multilayered structure and multifunction pipeline and connecting device

A multi-layer structure, connecting device technology, applied in the direction of pipeline protection, protection of pipelines by thermal insulation, pipes/pipe joints/pipe fittings, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 2

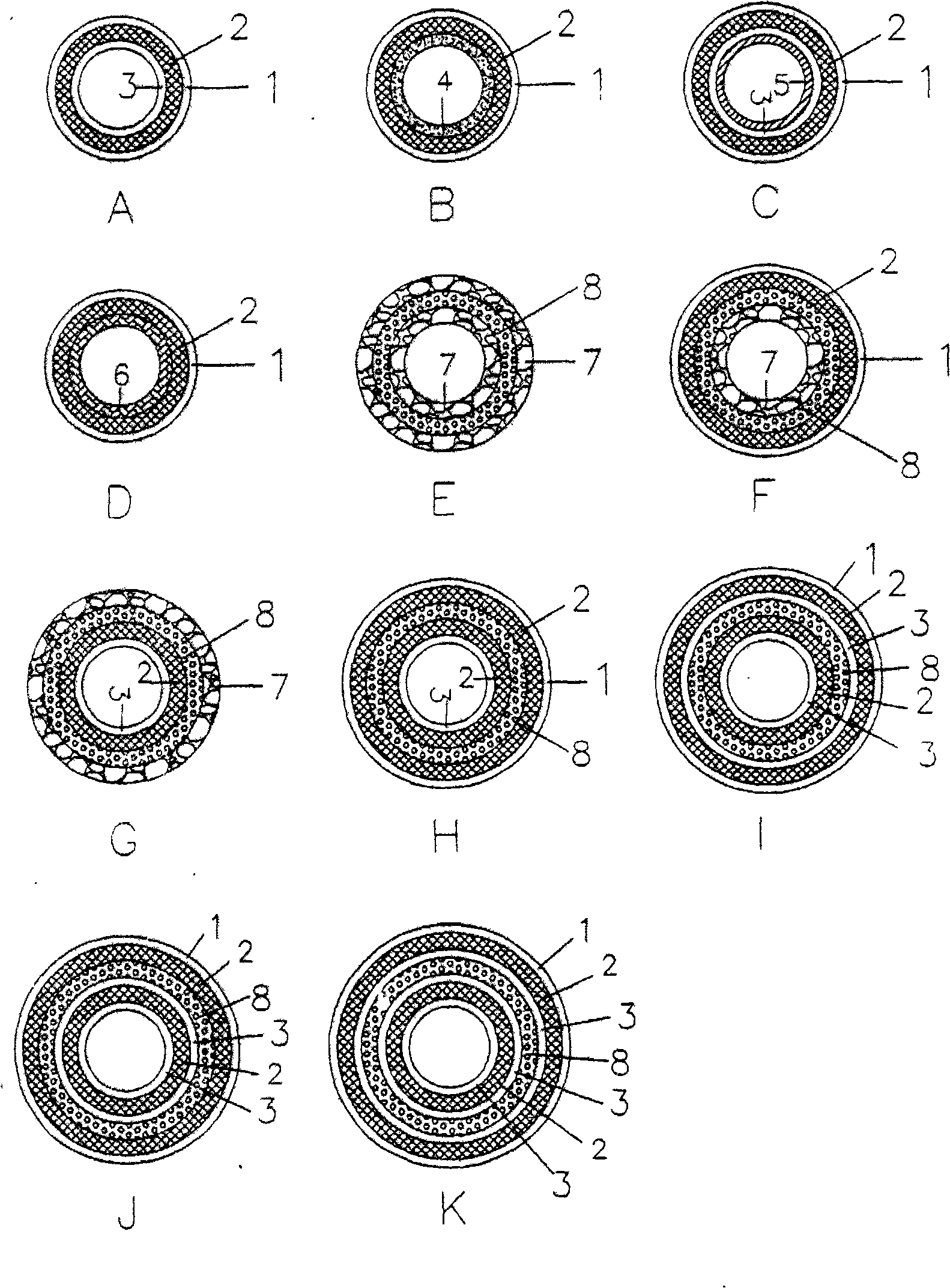

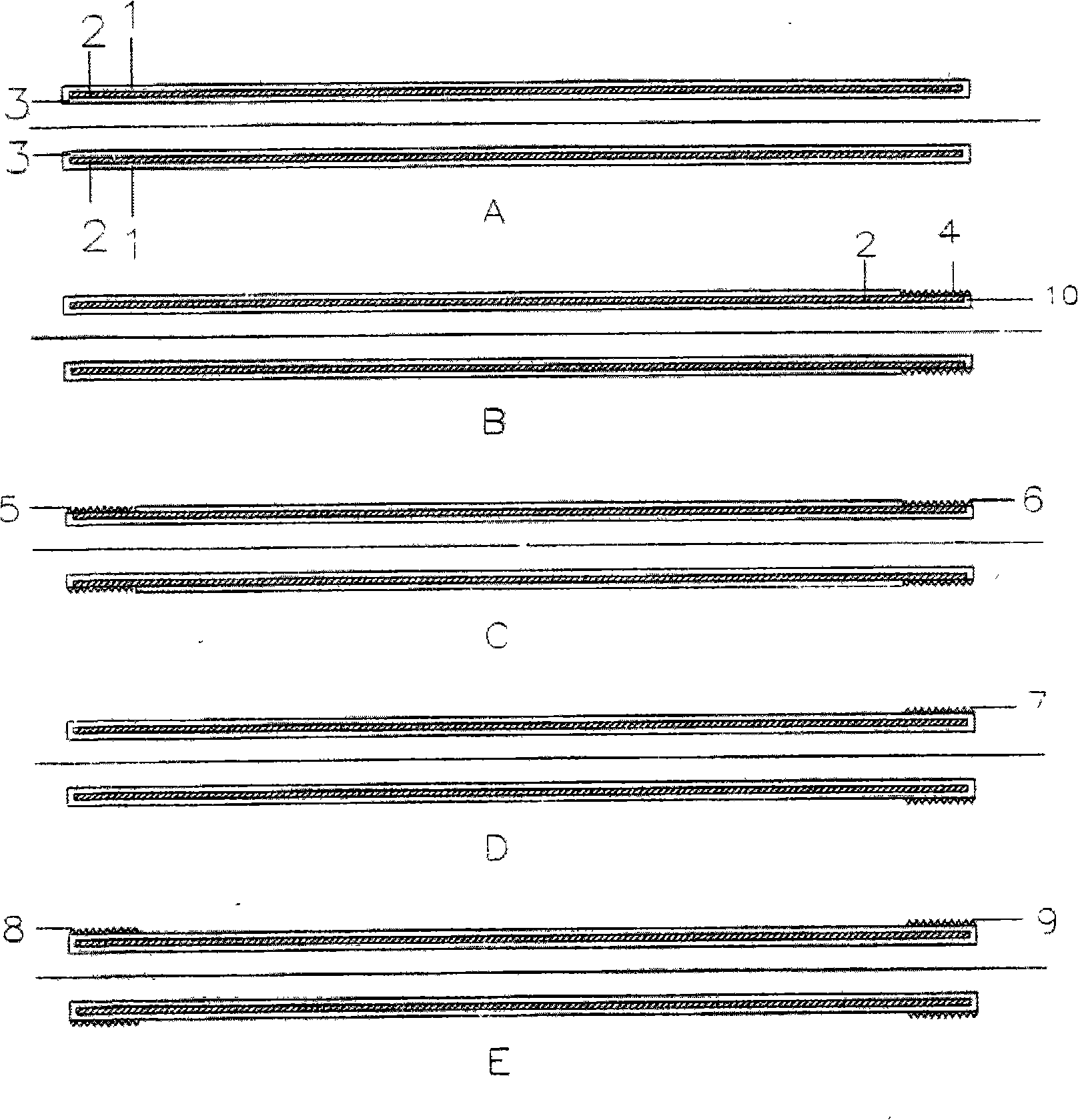

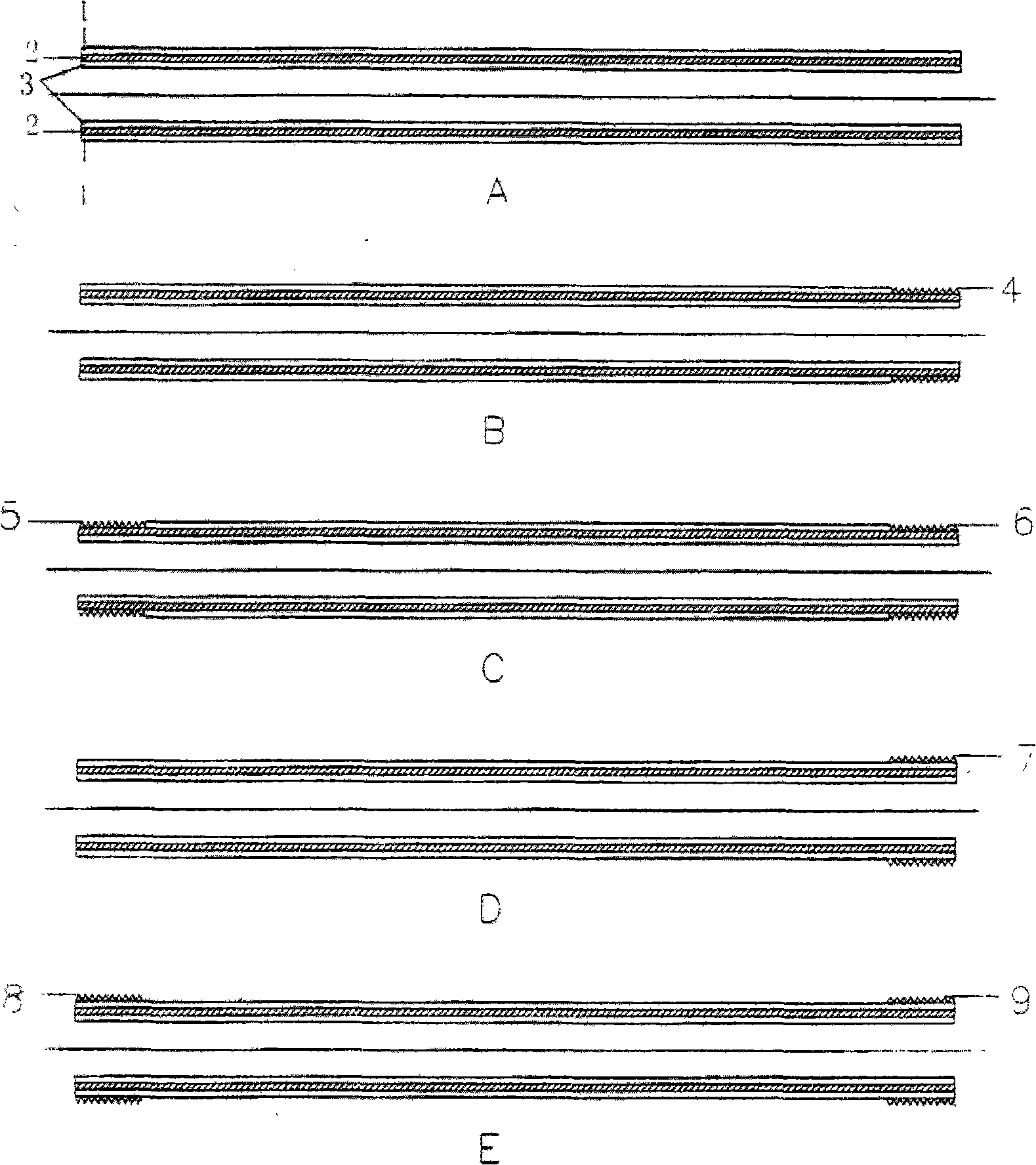

[0104] 1. The outer anti-corrosion layer and the inner anti-corrosion layer are made of plastic. The outer anti-corrosion layer is made into products with colors or patterns.

[0105] 2. The middle compression layer is iron pipe layer.

Embodiment approach 3

[0107] 1. Resins or their composites for outer anti-corrosion layer and inner anti-corrosion layer materials. The outer anti-corrosion layer is made into products with colors or patterns.

[0108] 2. The middle compression layer is a compound composed of steel mesh and other fibers.

Embodiment approach 4

[0110] 1. The outer anti-corrosion layer and the inner layer are made of plastic, resin, or rubber. The outer anti-corrosion layer is made into products with colors or patterns.

[0111] 2. The middle compressive layer is glass fiber cloth or glass fiber net, or its composite with cotton spinning fiber or other fiber cloth or fiber net.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com