Composite material with high dielectric constant and preparation method for composite material

A technology of high dielectric constant and composite materials, which is applied in fixed capacitance parts, fixed capacitor dielectrics, etc., can solve the problems of damaging the flexibility and mechanical properties of polymers, low dielectric constant of composite materials, and agglomeration of nanoparticles. Achieve the effect of low cost, good flexibility and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

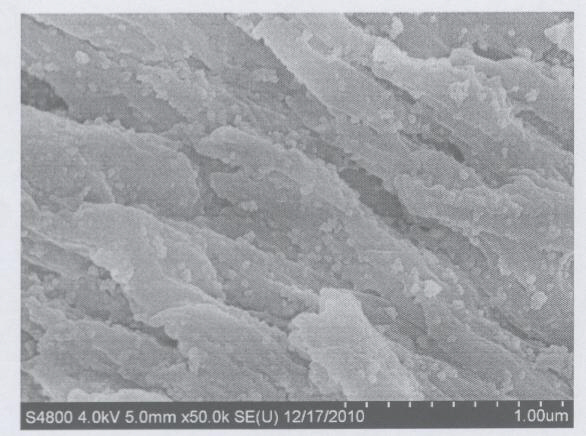

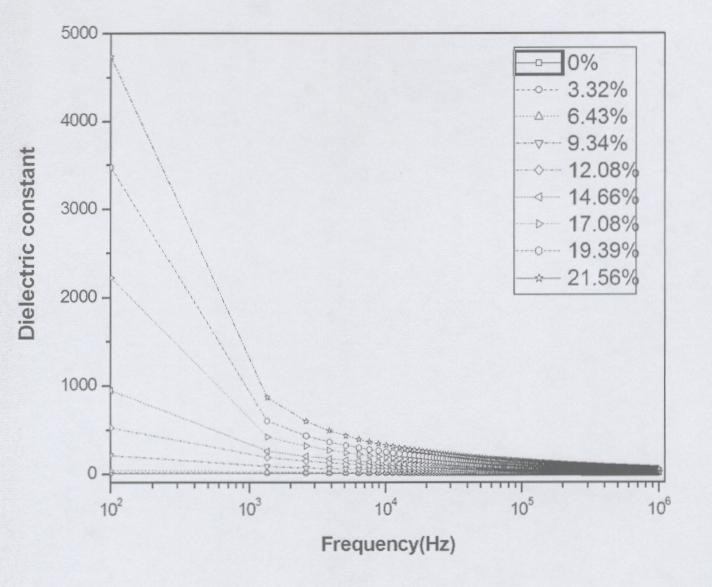

[0024] A kind of preparation method of high dielectric constant composite material, this high dielectric composite material comprises nanometer Fe 3 o 4 Granules and polyvinylidene fluoride powder are two components, and the preparation process is as follows:

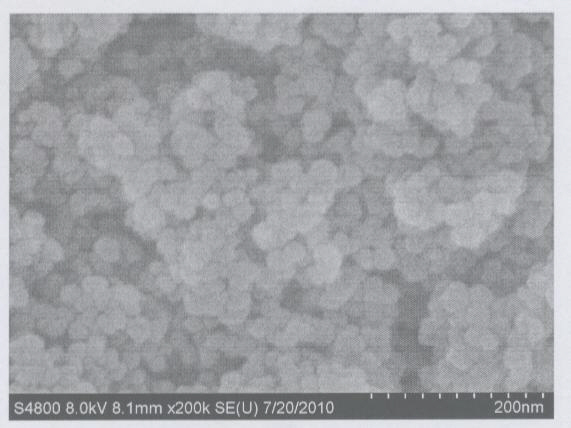

[0025] 1. Nano Fe 3 o 4 Preparation of particles: First, take 6.215g of FeCl 3 ·6H 2 O and 3.19 g FeSO 4 ·7H 2 O mixed well, dissolved in 75ml of deionized water, Fe 2+ / Fe 3+ The molar ratio of the solution is 1:2, the prepared mixed solution is placed in a three-necked flask, placed in a constant temperature water bath at 55°C, stirred rapidly, and NH 3 ·H 2 0 until the pH is 11-12, continue to stir and raise the temperature to 75°C for 2 hours, and the whole experiment process is carried out under the protective atmosphere of nitrogen. Then use a strong magnet to settle, s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com