Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

50results about How to "Realize flexible clamping" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

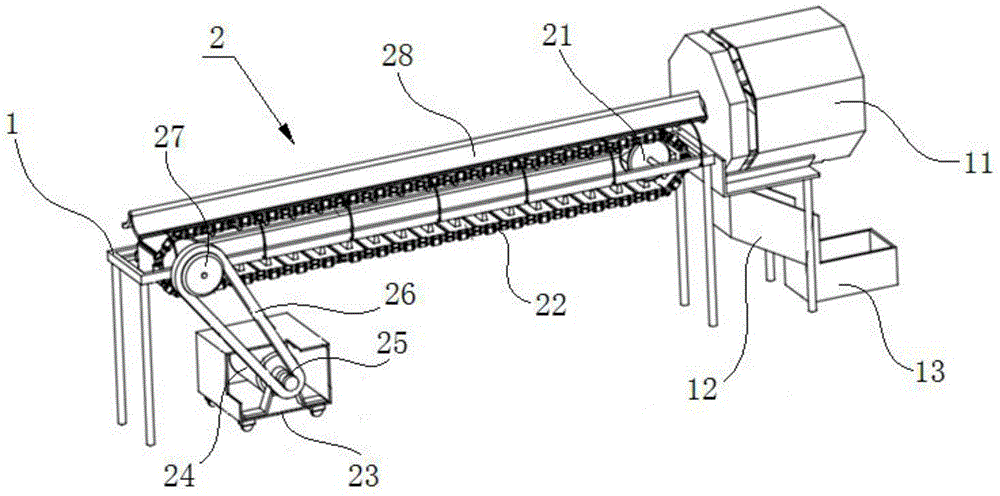

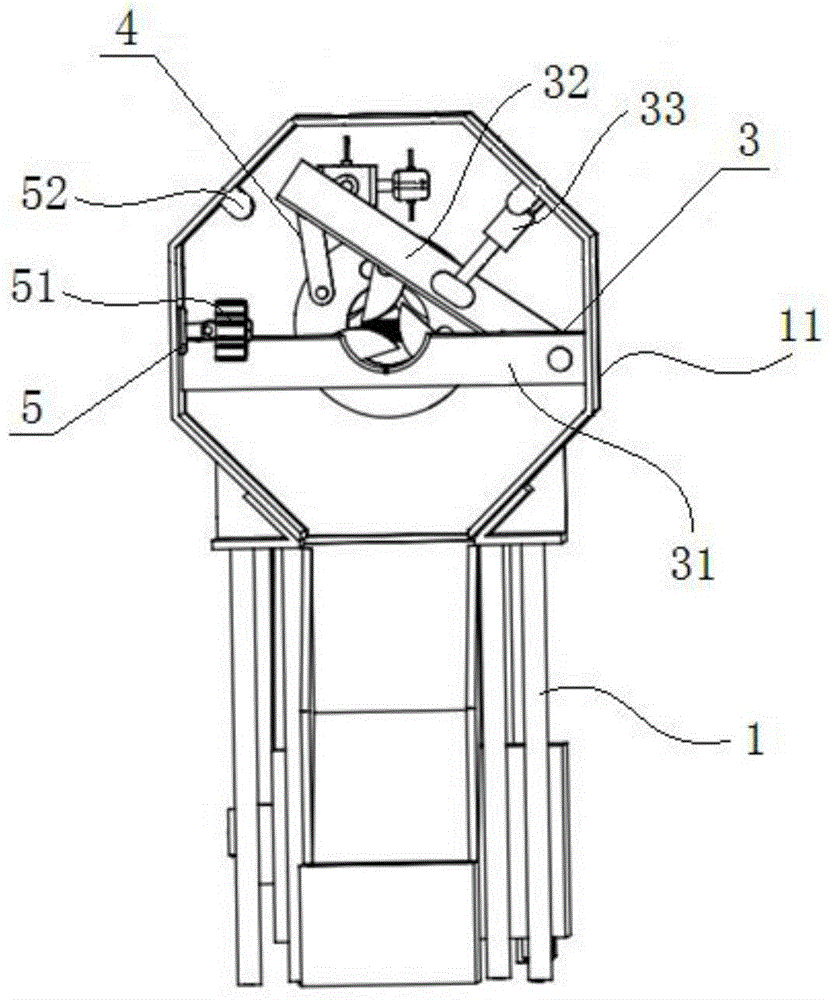

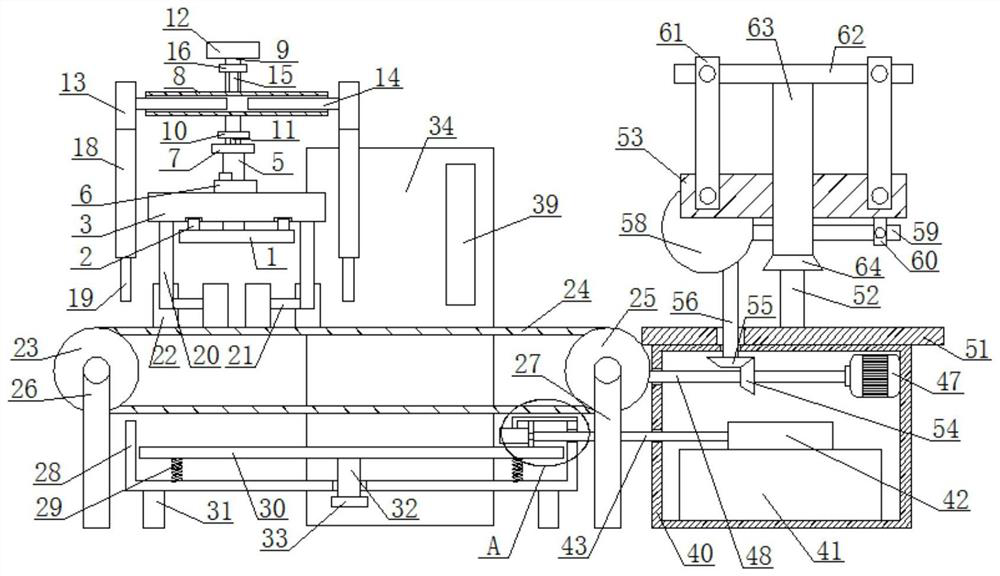

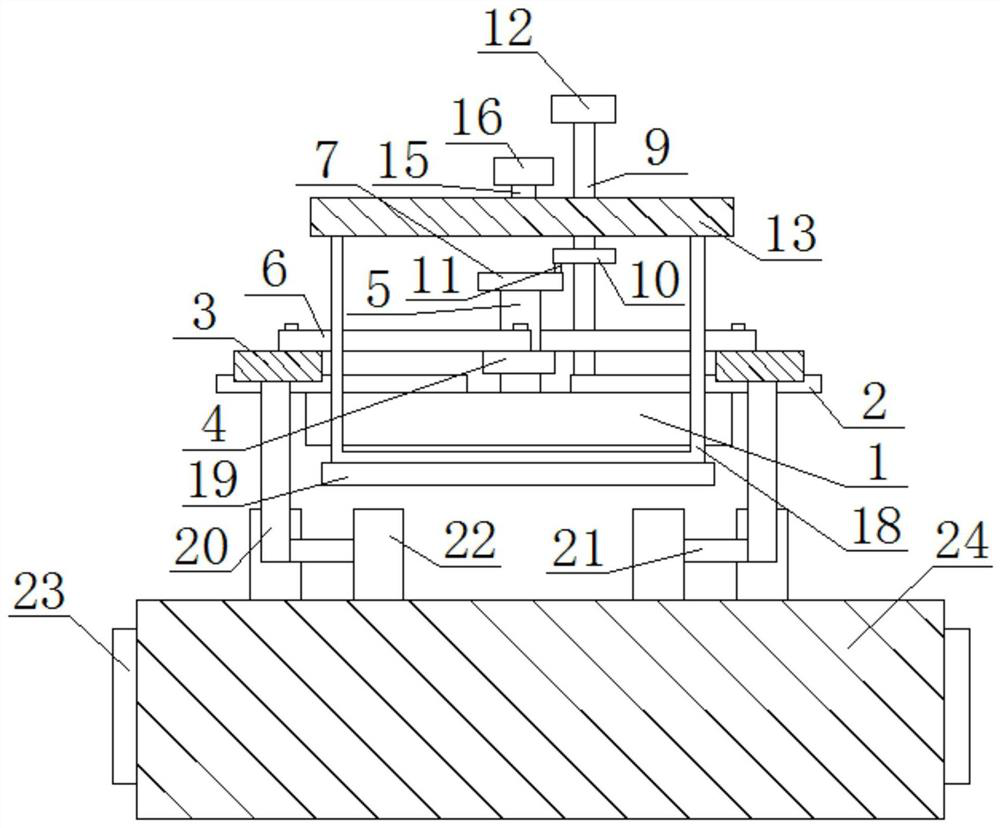

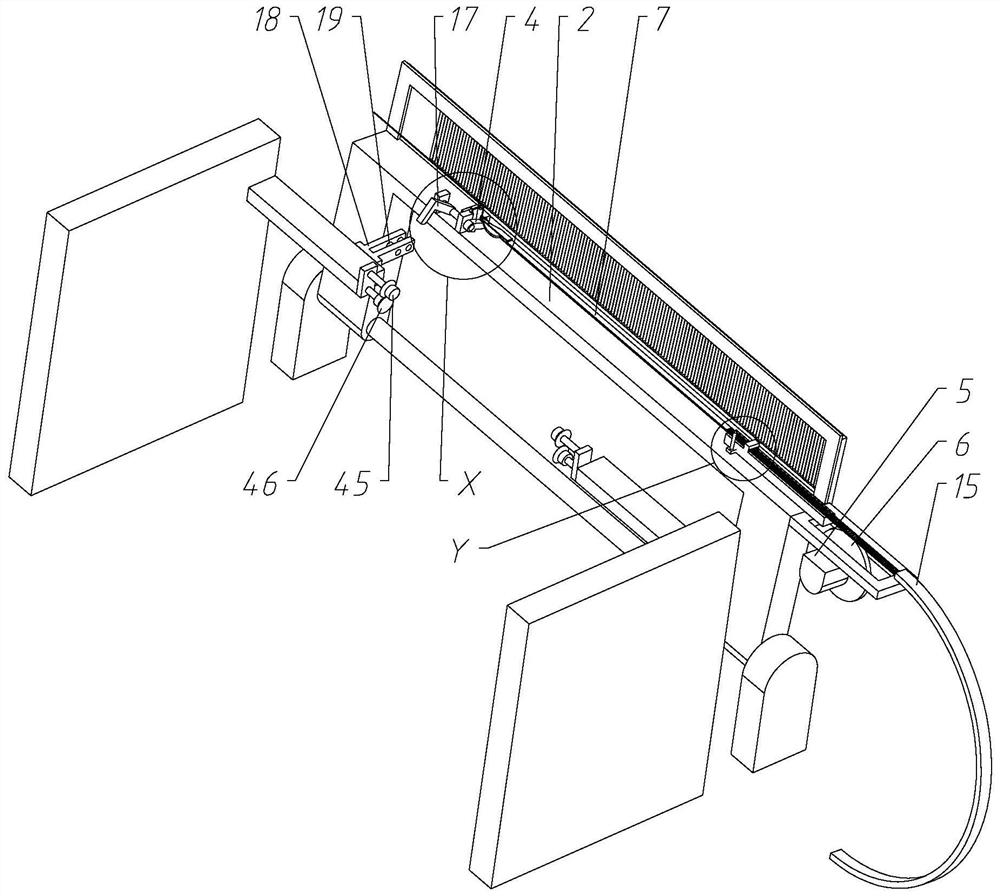

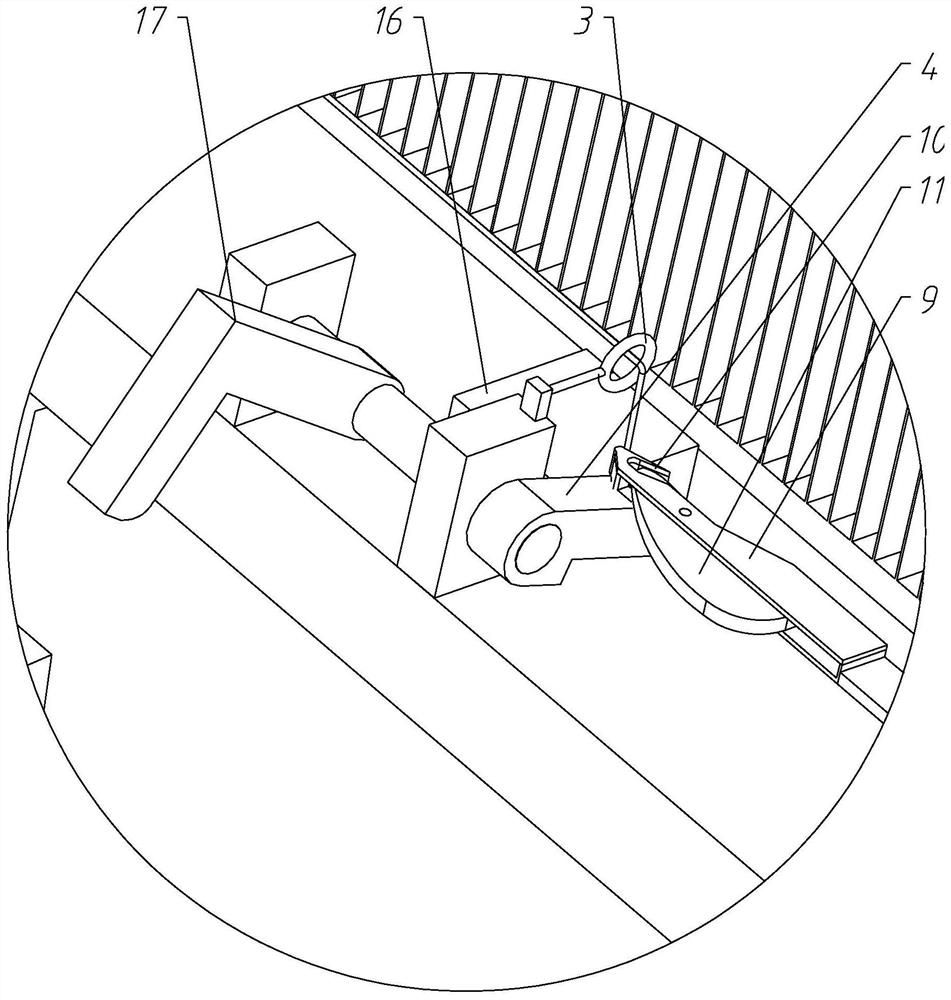

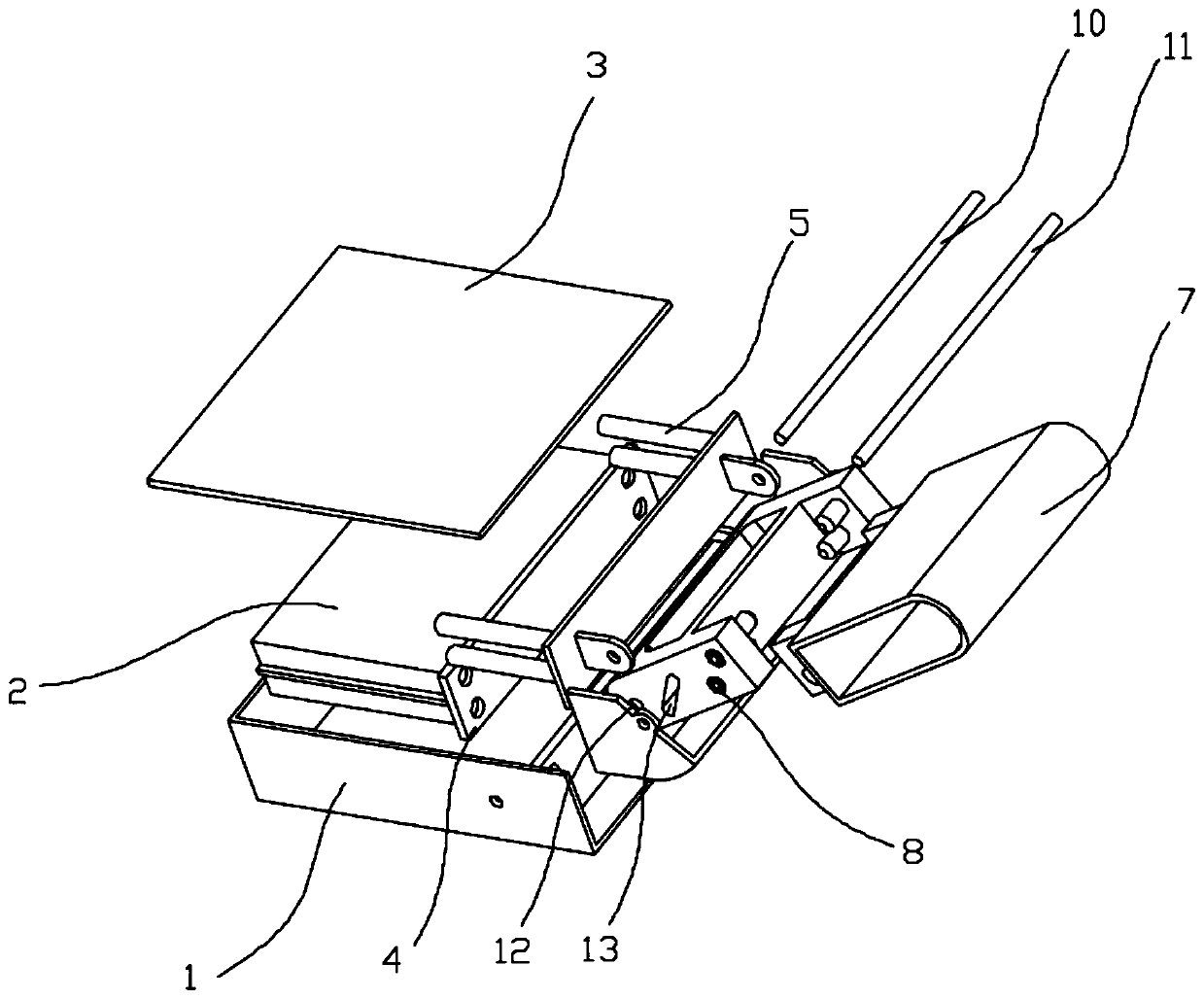

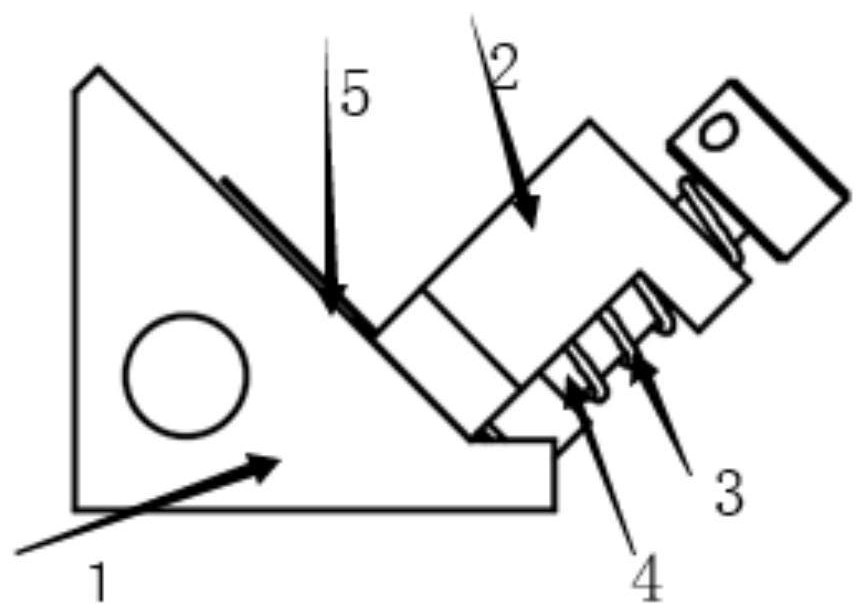

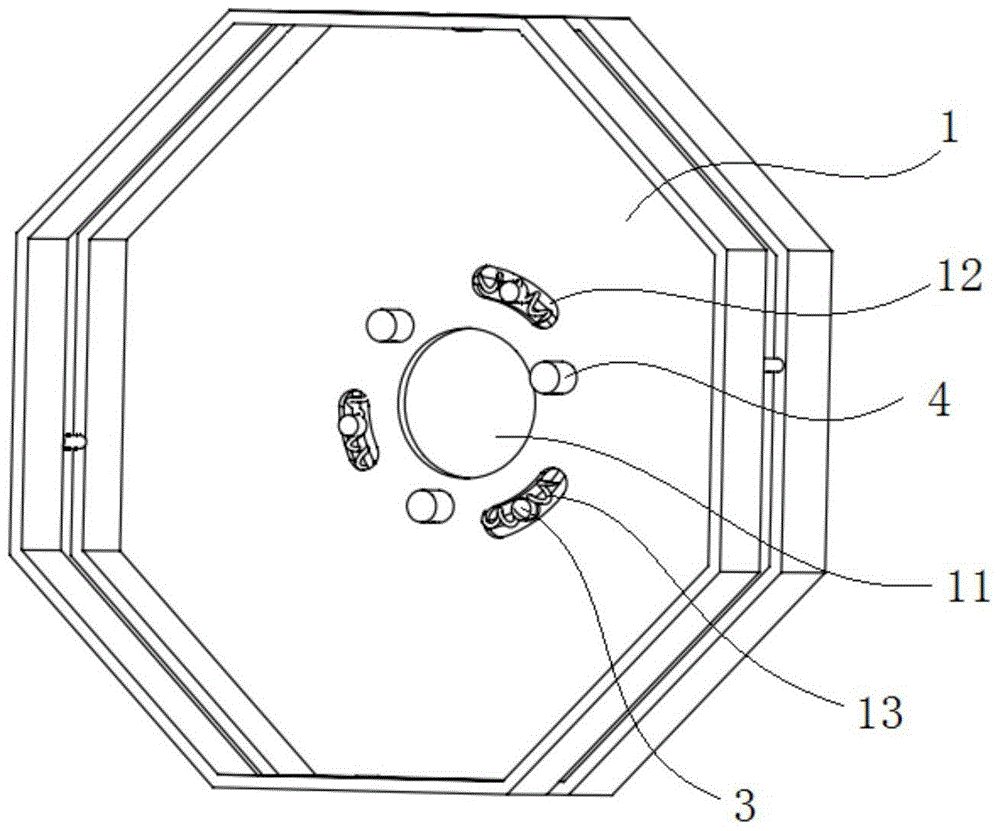

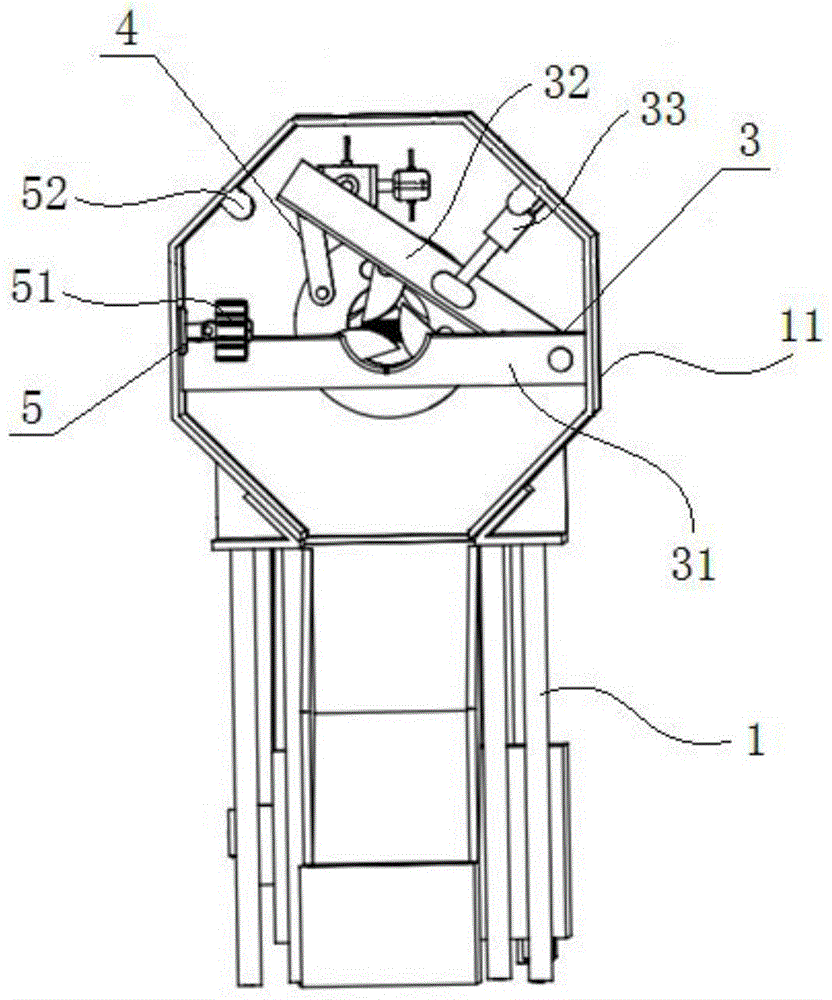

Sugarcane cutter device based on seed bud image identification

ActiveCN104798614AHigh degree of automationReduce labor intensityCuttersCutting implementsCell buddingImage identification

The invention discloses a sugarcane cutter device based on seed bud image identification. The device comprises a rack, a cutting device, a clamping device and an image identification device, wherein the rack is provided with a conveying device; a cutting box is arranged on the front end of the conveying device on the rack; the cutting device is arranged in the cutting box and is used for cutting off sugarcanes; the clamping device is arranged in the cutting box, is located behind the cutting device, and is used for clamping or releasing the sugarcanes; the image identification device is arranged in the cutting box and is capable of identifying seed buds on the sugarcanes through image forming; the number of the seed buds contained by the sugarcanes passing the cutting device is counted. According to the invention, the seed buds of the sugarcanes are counted by the image forming, a control system can control the cutting device to cut off the sugarcanes by virtue of the number of the seed buds, each section of sugarcanes can contain a proper number of seed buds, the degree of automation is high, the labor intensity is reduced, and the production efficiency is improved.

Owner:GUANGXI UNIV

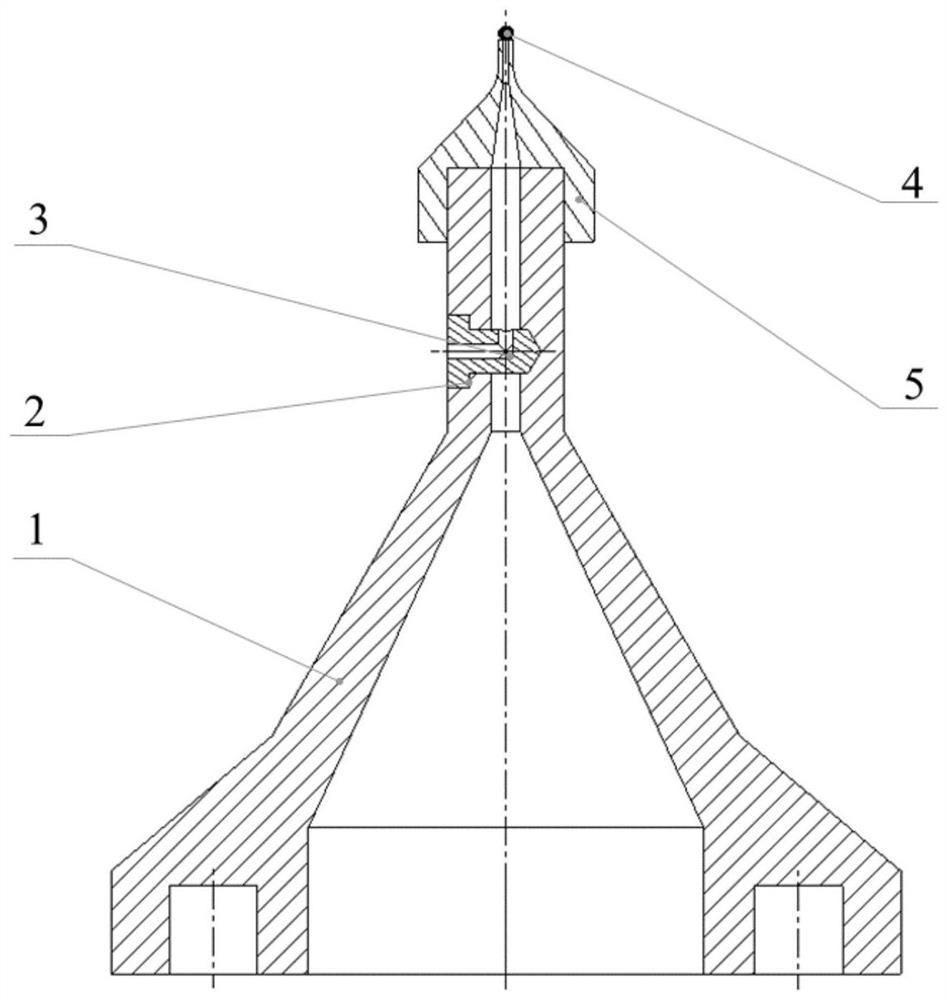

Air bag clamping device used for lossless clamping of low-rigidity framework type part

ActiveCN107414448APrecise and non-destructive clampingAvoid clampingProgramme-controlled manipulatorGripping headsButt jointEngineering

The invention discloses an air bag clamping device used for lossless clamping of a low-rigidity framework type part and belongs to the technical field of microoperation and micro electro mechanical systems. The air bag clamping device comprises an air cavity seat, a holding frame, an air bag and an air way assembly. The air bag is of a structure with one end opened and one end closed, wherein the closed end of the air bag is provided with a cylindrical cavity concave inwards and a circular-ring-shaped cavity coaxial with the cylindrical cavity, the circular-ring-shaped cavity is used for being matched with a ring-shaped face of a framework type part, and the cylindrical cavity is used for being in shaft fit with the assembling position. The shape of the holding frame and the shape of the air bag are consistent, and one or more openings are machined in each of the two opposite circumferential faces of a circular-ring-shaped cavity of the holding frame. The opening end of the air cavity seat is in butt joint with the opening end of the air bag. The holding frame is arranged on the outer surface of the air bag in a sleeving manner and is fixed to the end face of the opening end of the air cavity seat. The air way assembly communicates with a cavity of the air cavity seat through an air pipe connector and is used for inflating and deflating of the air bag. By means of the air bag clamping device, the low-rigidity framework type to-be-assembled part can be extruded in double directions accurately in a lossless manner.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

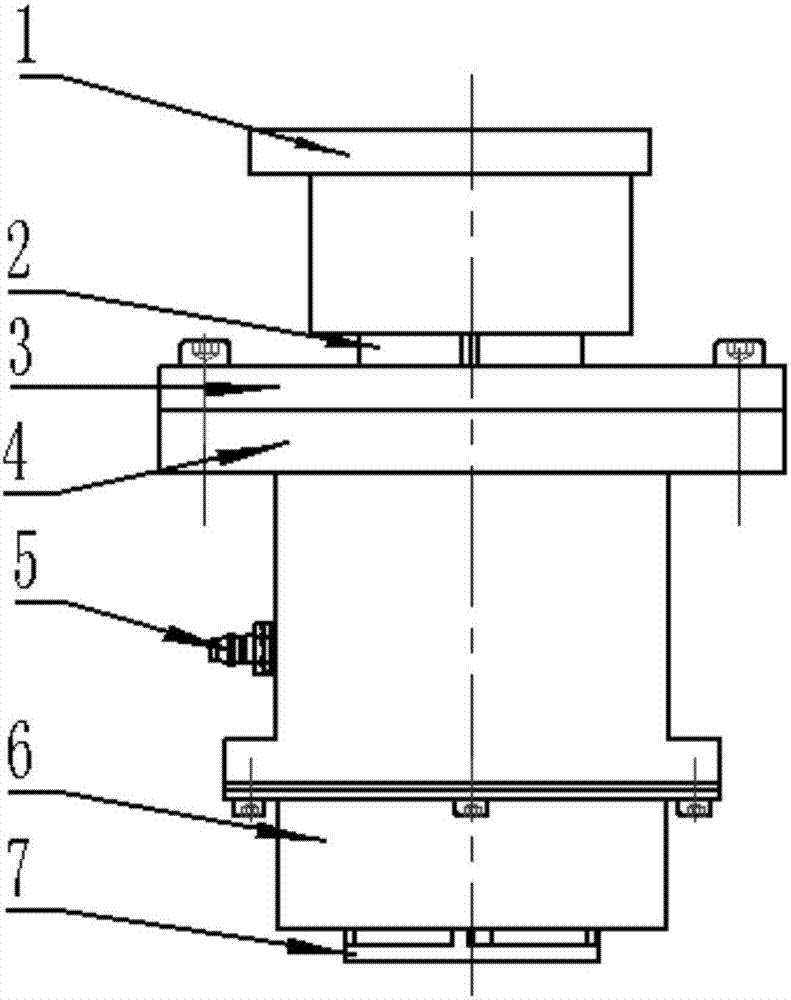

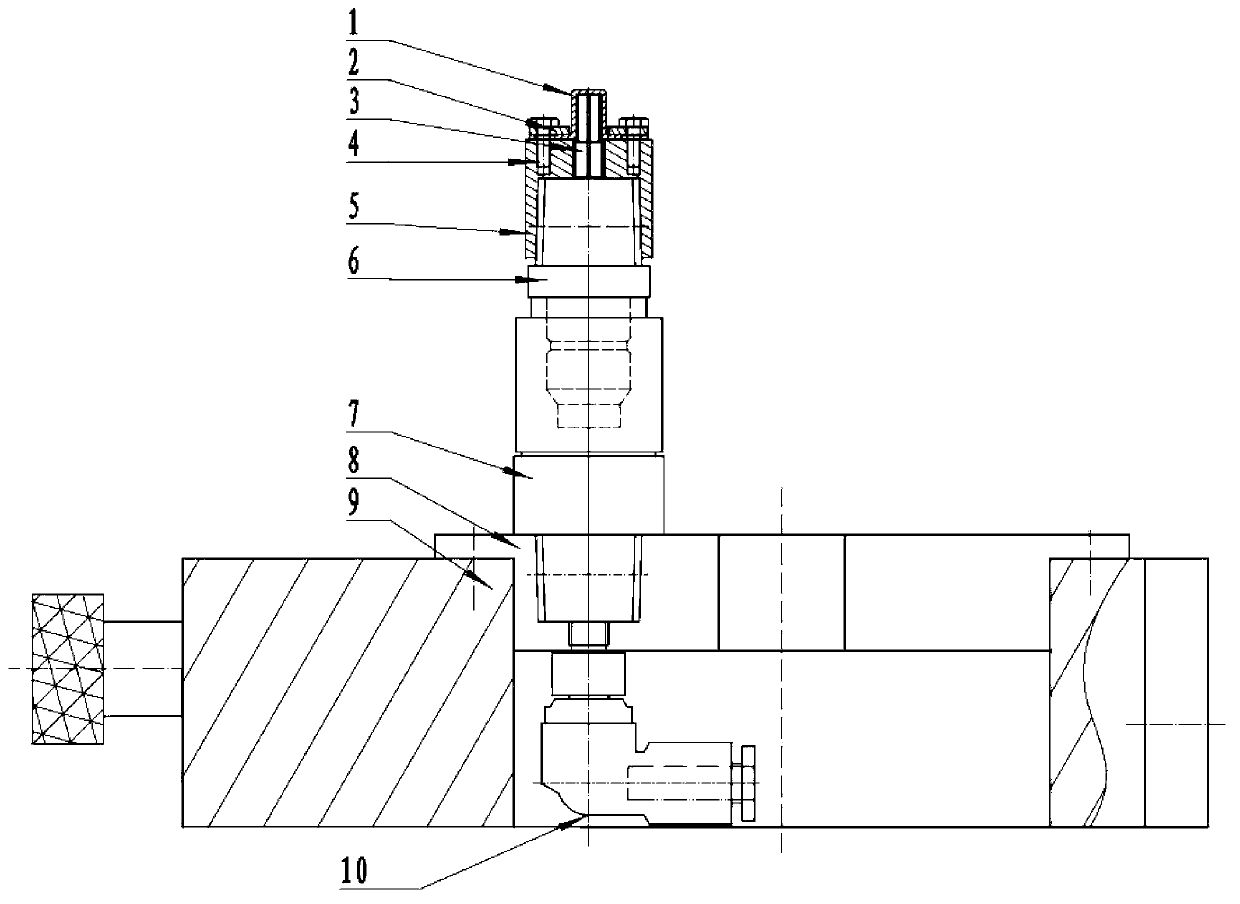

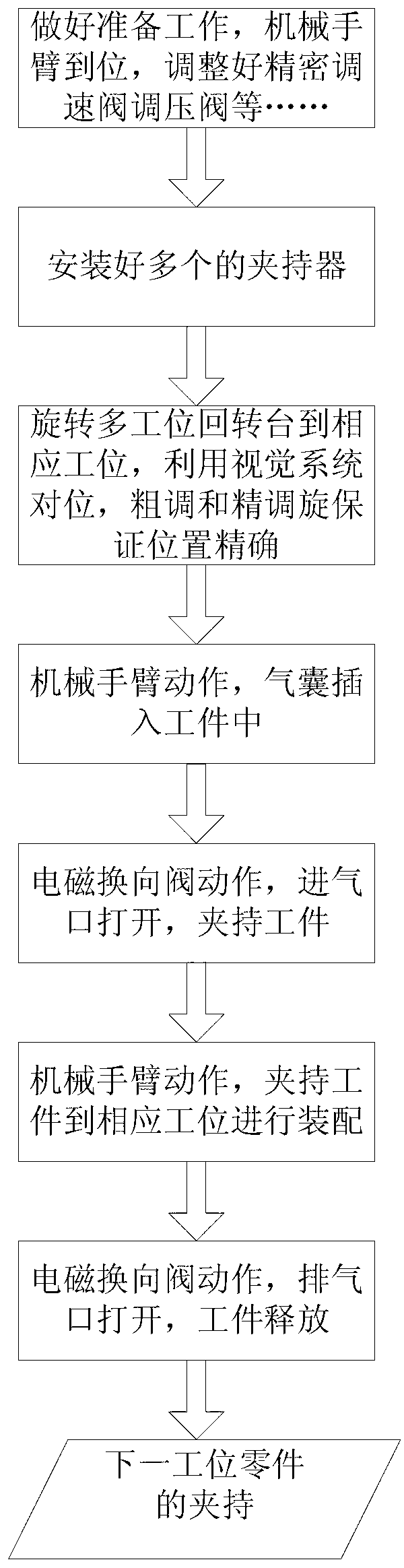

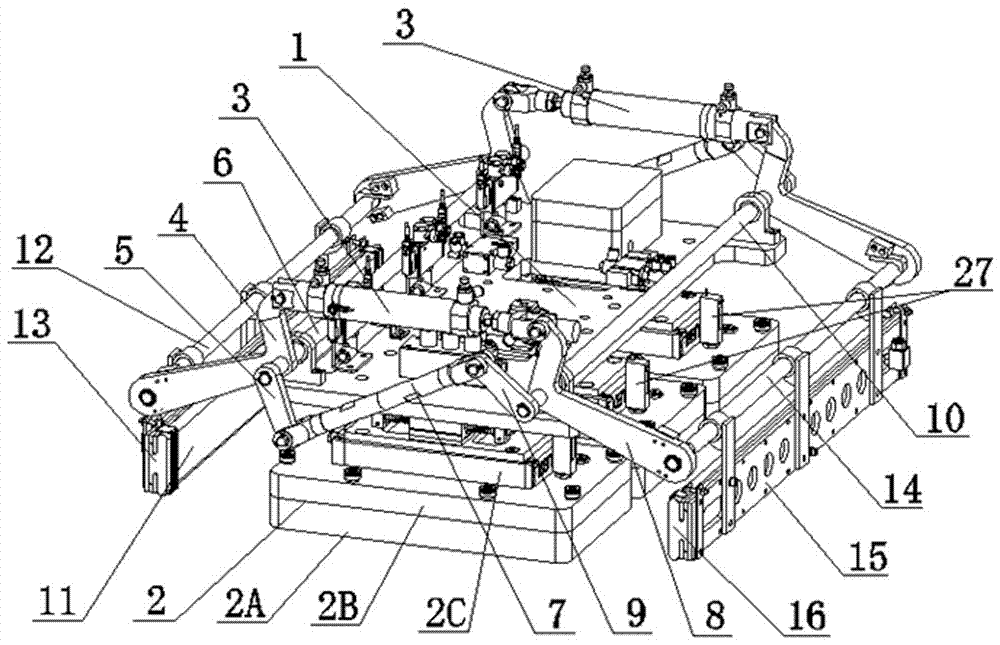

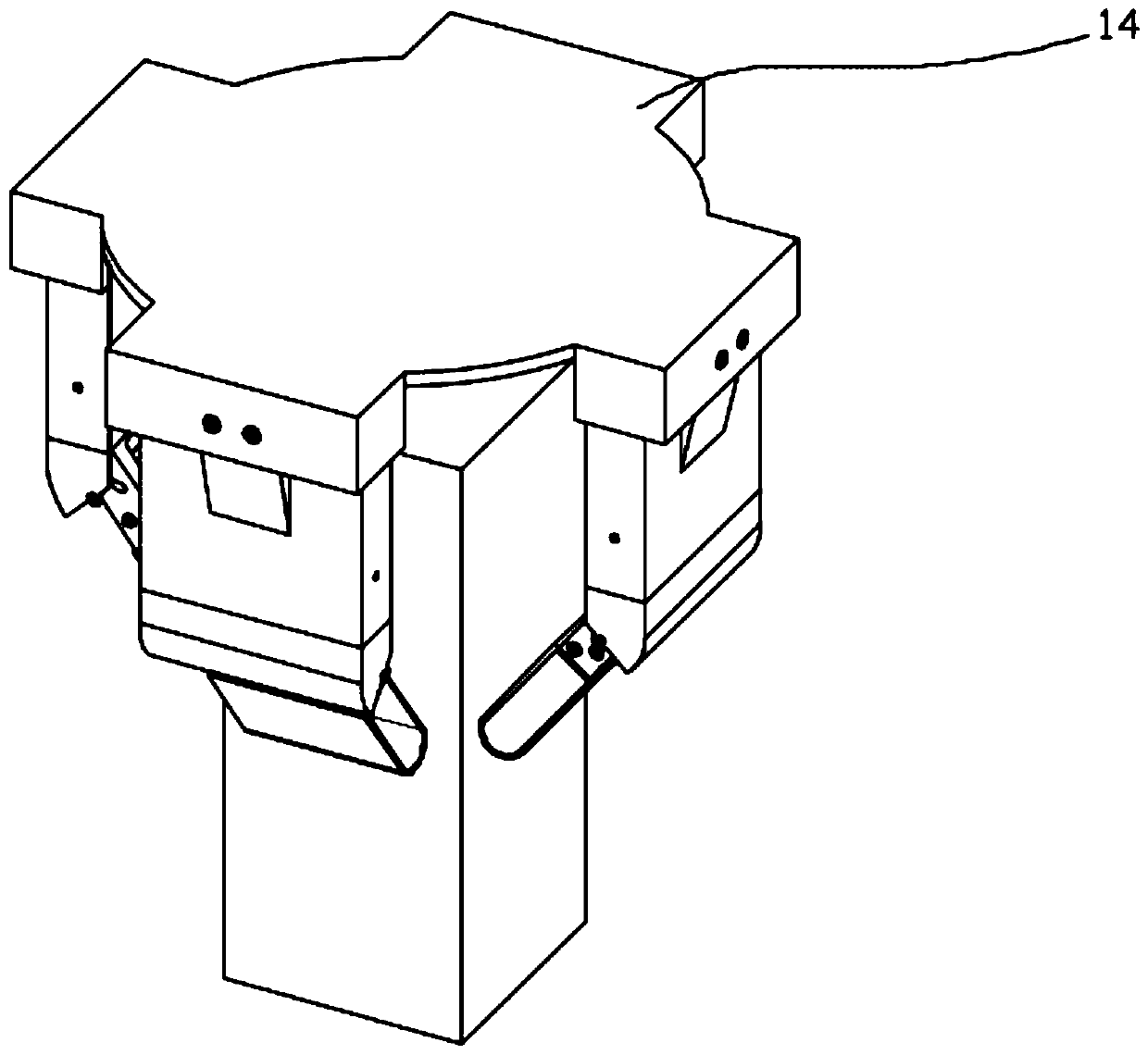

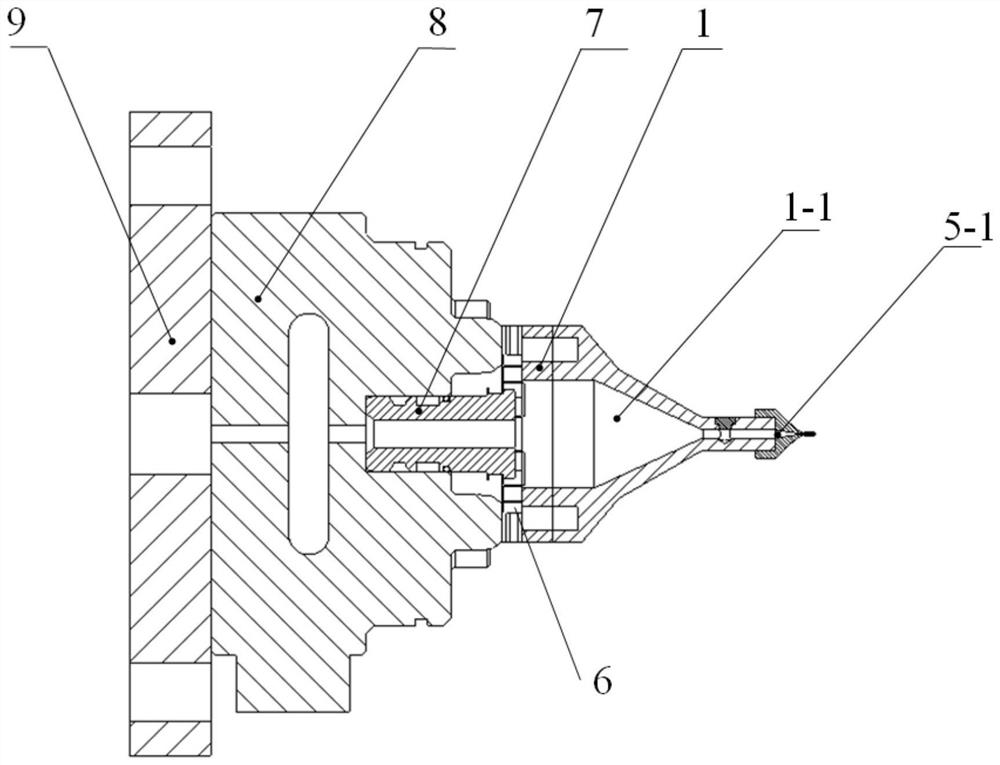

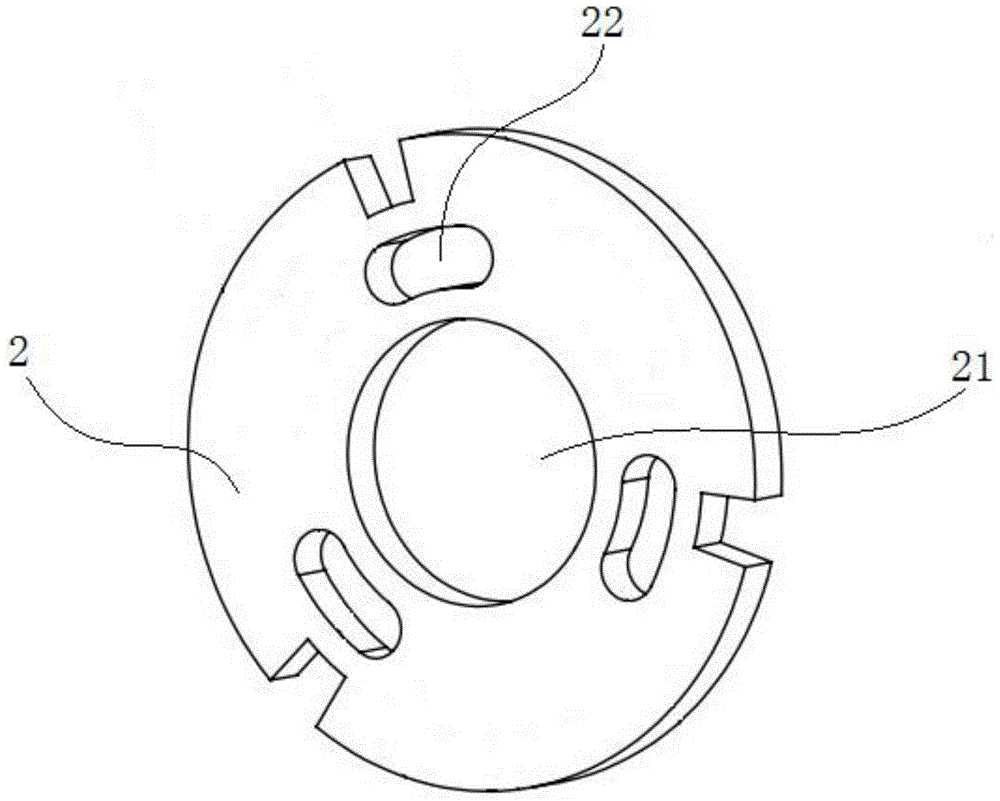

Multi-station silica gel air bag clamping device for clamping ultrathin wall deep cylinder part

ActiveCN103341861ARealize flexible clampingImprove clamping efficiencyGripping headsMetal working apparatusMagnetic exchangeEngineering

The invention relates to a multi-station silica gel air bag clamping device for clamping an ultrathin wall deep cylinder part and belongs to the field of microoperation and the micro electromechanical technology. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part particularly comprises an air bag clamping head, a conical surface quick-insertion connector, a multi-station rotary table and a gas circuit system. The air bag clamping head comprises an air bag, a center retainer, a ring fastening gasket and a connection transition part. The conical surface quick-insertion connector comprises a quick-change connector plug and a quick-change connector socket. The multi-station rotary table comprises a 360-degree manual rotary table and a pinboard. The gas circuit system comprises a gas source, a filter, a pressure regulating valve, a speed controlling valve, a magnetic exchange valve and a gas pipe connector. The multi-station silica gel air bag clamping device for clamping the ultrathin wall deep cylinder part solves the problems that clamping of thin-wall parts is small in strength, poor in intensity, and deformation, invalidation and even damage are prone happening. Use of the quick-change connector and the multi-station rotary table can effectively achieve quick and flexible clamping and assembling of parts of different sizes and the same kind, facilitate operation and improve assembling precision and assembling efficiency.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

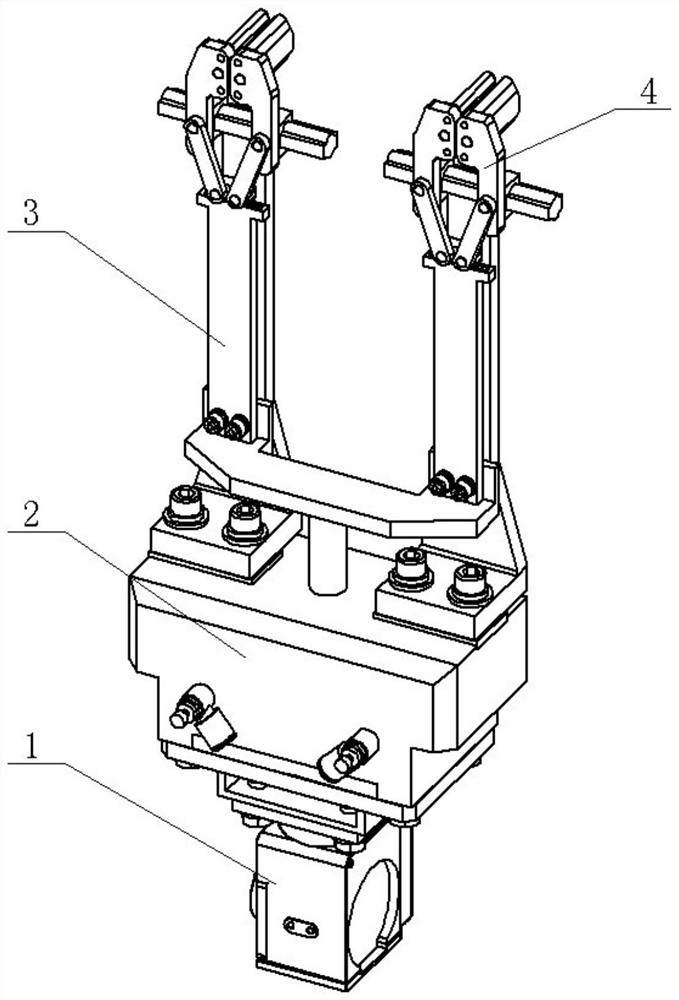

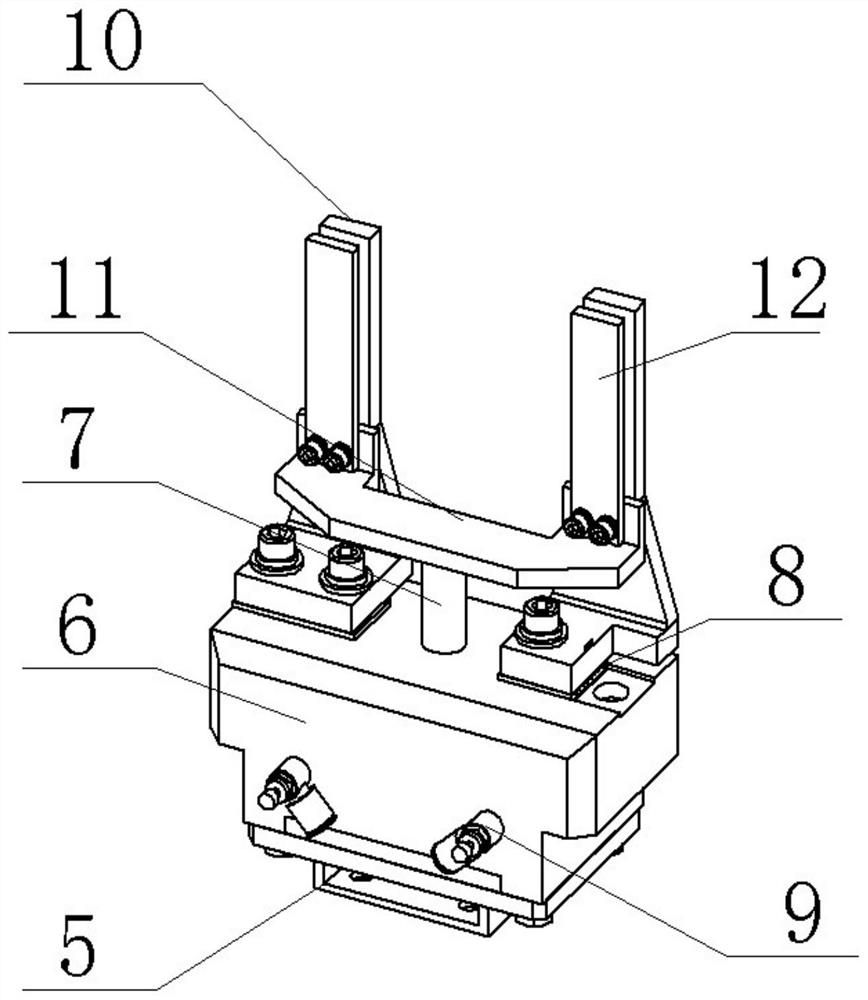

Robot paw clamp with flexible clamping and fixing function

PendingCN107953354AIncrease static frictionAvoid graspingGripping headsClassical mechanicsStructural engineering

The invention discloses a robot paw clamp with flexible clamping and fixing functions. The bottom of a mounting plate is connected with a sucker device whose working surface is downward. The top of the mounting plate is parallelly screwed with a left connecting shaft and a right connecting shaft. Two ends of the left connecting shaft are respectively vertically and fixedly connected with the middle parts of two parallel left connecting rods, and are respectively vertically and fixedly connected with ends of left connecting plates. Two ends of the right connecting shaft are respectively vertically and fixedly connected with the middle parts of two right connecting rods, and are vertically and fixedly connected with ends of right connecting plates. Top ends of the left connecting rod and theright connecting rod are respectively hinged with two ends of a linear driving device. The other ends of the left connecting plates and the right connecting plates are hinged with pull rods. A left air bag shaft which is parallel with the left connecting shaft is arranged between the bottom ends of the two left connecting rods. One side of the left air bag plate is fixedly connected with the leftair bag shaft, and one surface is fixedly provided with a left clamping air bag. A right air bag shaft which is parallel with the right connecting shaft is arranged between the bottom ends of the tworight connecting rods. One side of the right air bag plate is fixedly connected with the right air bag shaft, and is parallel with the left air bag plate. The robot paw clamp is characterized by compact structure, stable and reliable clamping, good adaptive capacity, and accurate positioning.

Owner:云南柔控科技有限公司

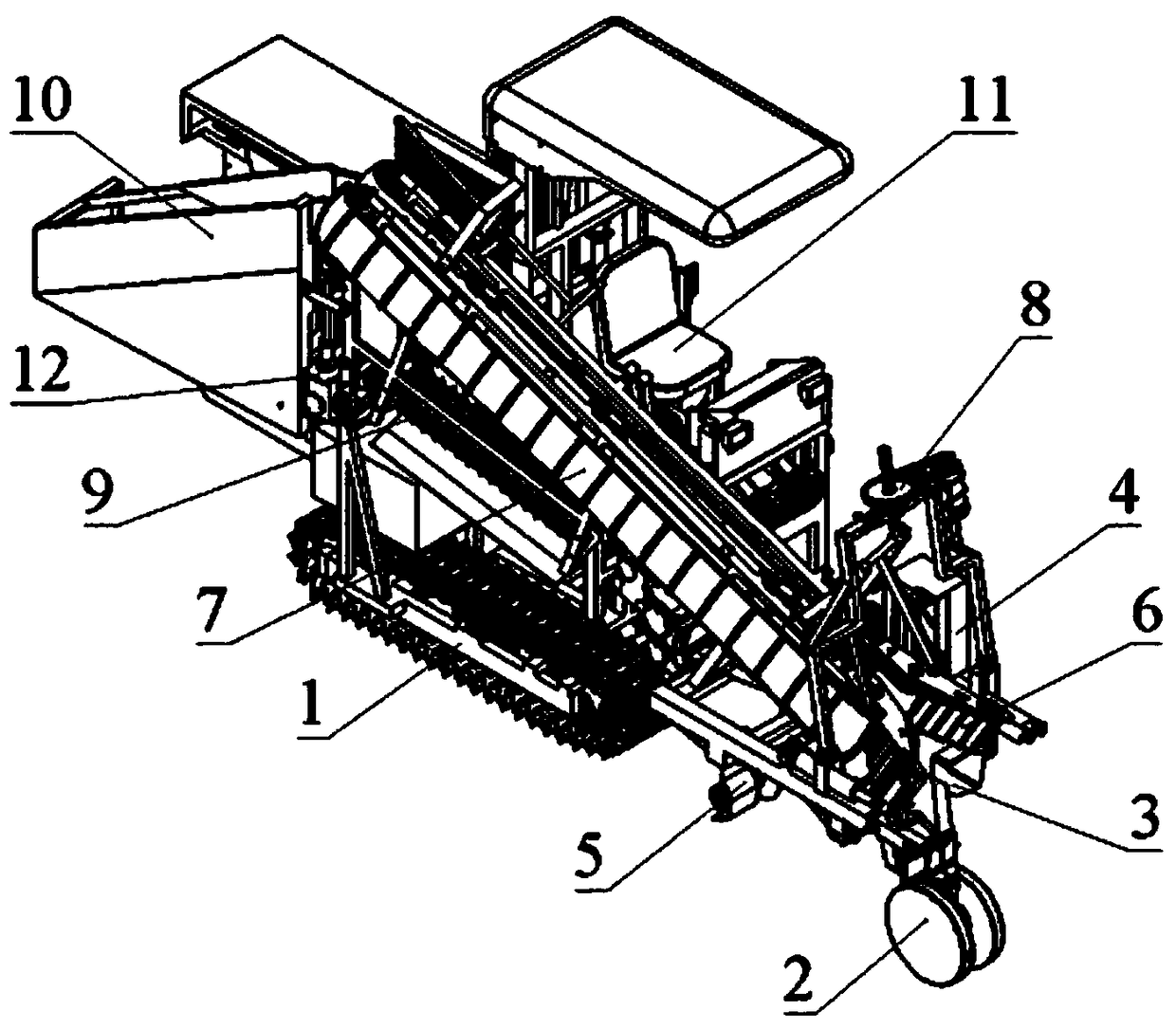

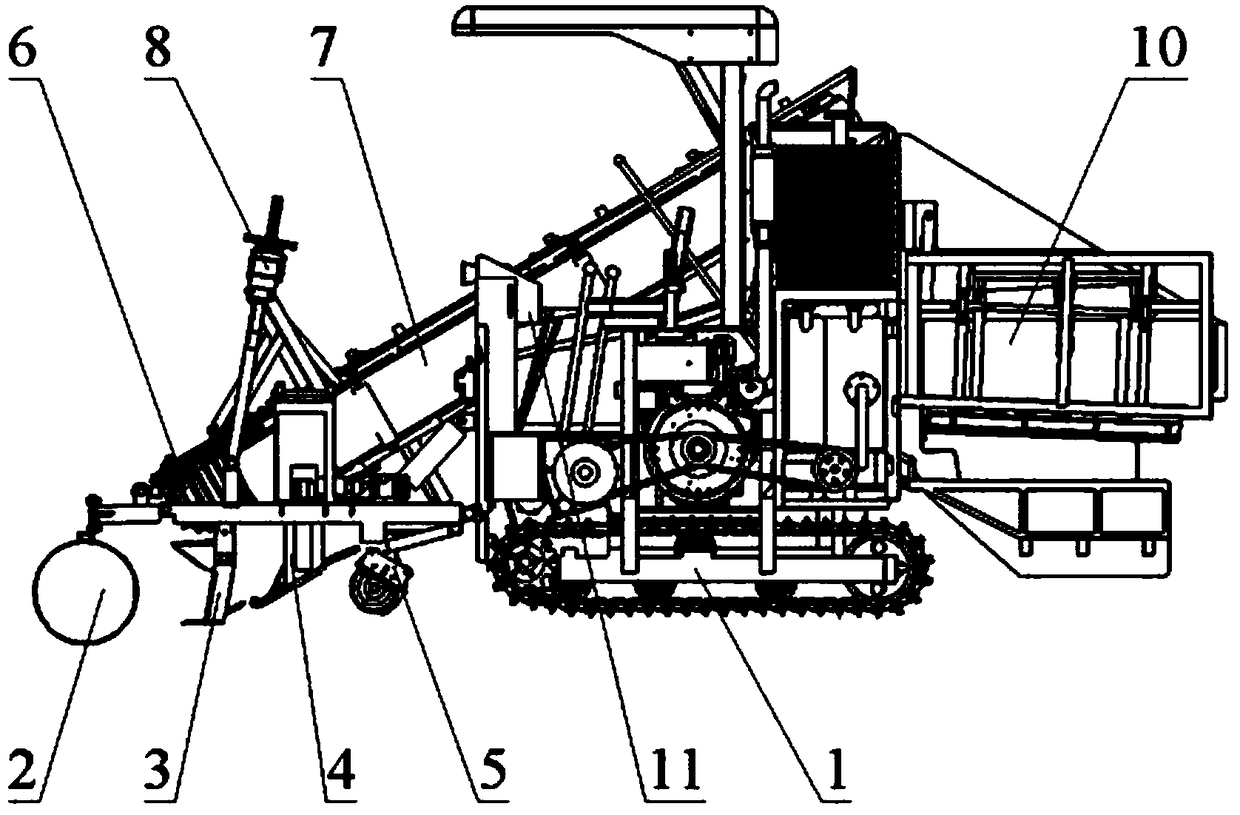

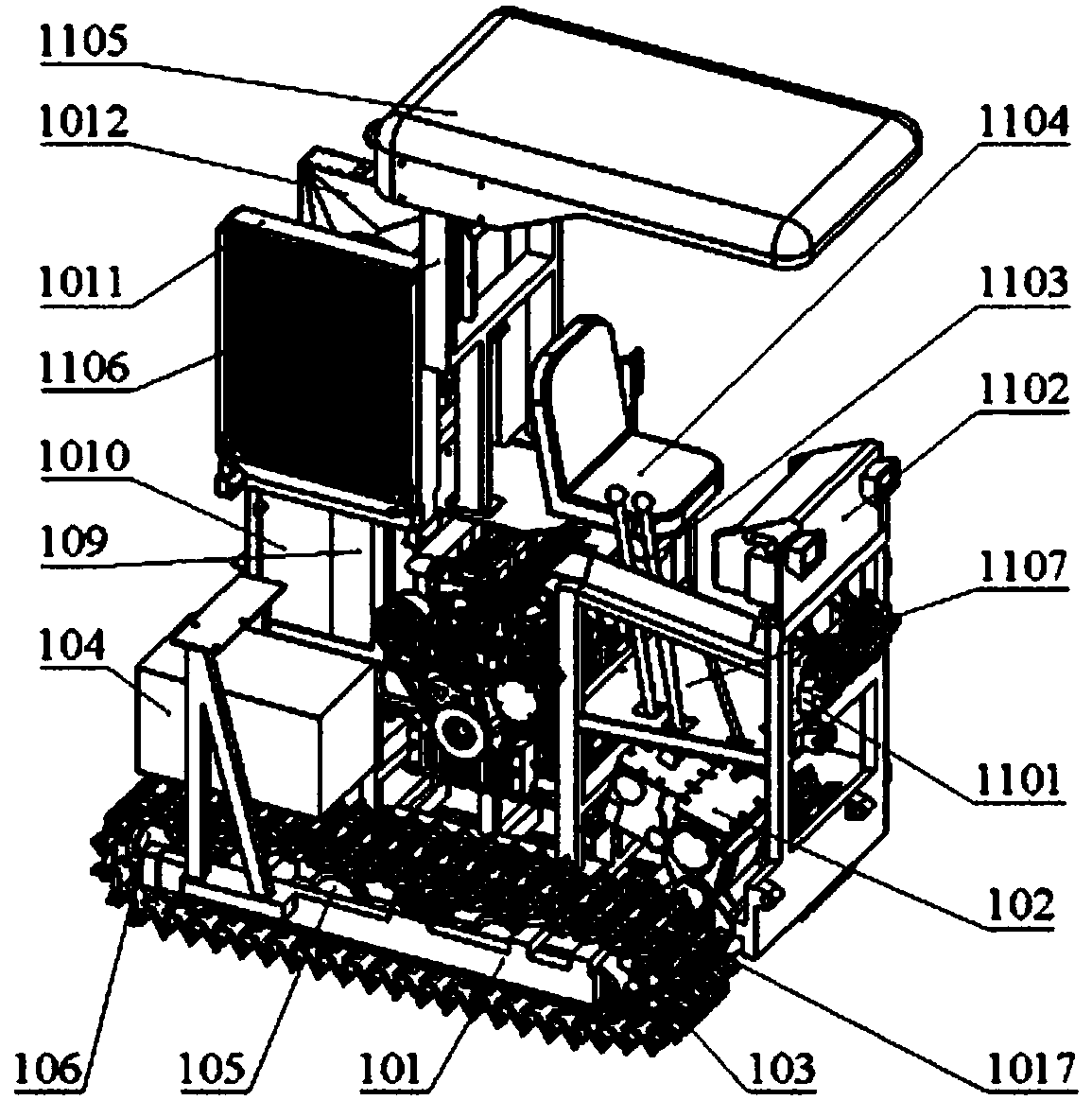

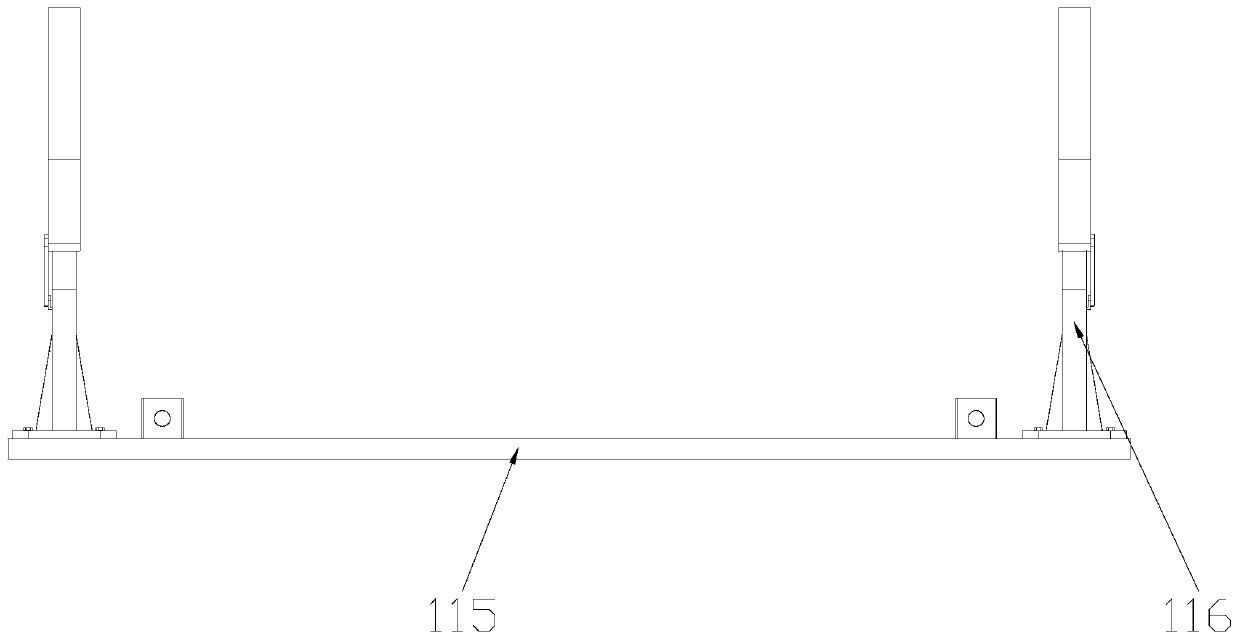

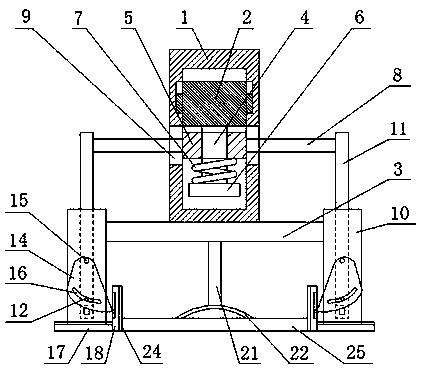

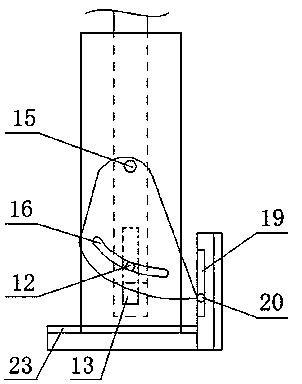

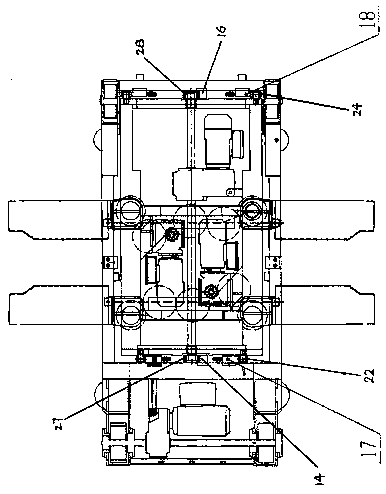

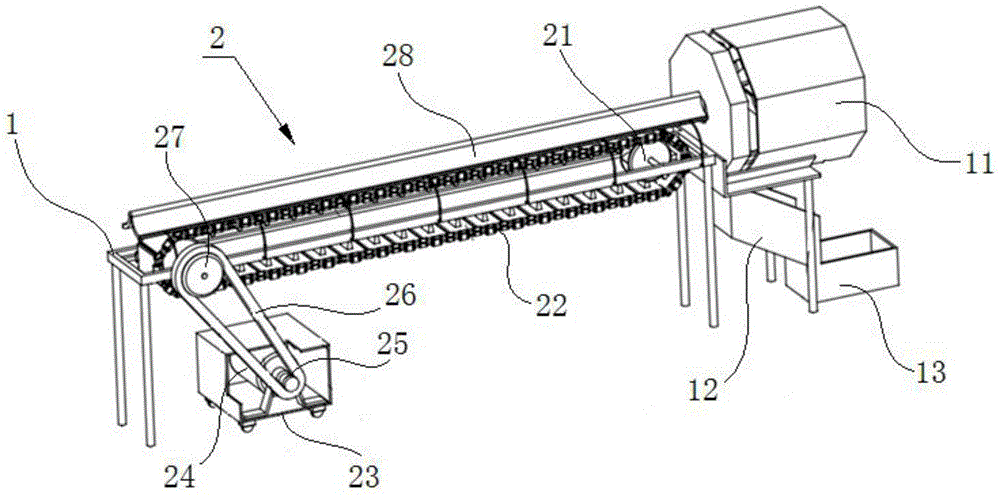

Single-row self-propelled scallion combine harvester

PendingCN109429667ASatisfy the Harvest RequirementsHigh clean land rateSpadesPloughsHydraulic cylinderEngineering

The invention relates to a single-row self-propelled scallion combine harvester, which comprises a chassis provided with a power system, an excavating device and a clamping and conveying device, wherein the excavating device and the clamping and conveying device are arranged on a chassis main frame; the chassis main frame is further provided with a collecting and discharging device positioned at the discharging end of the clamping and conveying device; the excavating device comprises a excavating support frame hinged with the chassis main frame, and a excavating shovel fixedly connected with the excavating support frame; the excavating support frame is connected with the chassis main frame through a lifting hydraulic cylinder. According to the single-row self-propelled shallot combine harvester, the excavating, soil shaking, clamping and conveying, collecting and stacking of the single-row scallion can be completed at one time, so that the harvesting requirements of various scallion can be met; a soil shaking device and an impurity cleaning device finish the twice soil removal treatment of the scallion, and the clean soil rate of the scallion is higher; the clamping and conveying device achieves flexible clamping and nondestructive conveying of the scallion; the collecting and discharging device is used for stacking and laying the scallion, so that manual bundling and collection can be facilitated, and the strength of manual operation can be reduced.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

Flexible seedling clamping machine

ActiveCN105109998ARealize flexible clampingAvoid damageConveyor partsHorticultureEngineeringGraft survival

The invention relates to a flexible seedling clamping machine. The flexible seedling clamping machine comprises a movable clamp splice with a cavity, a gas bag communicated with the cavity and sealing the cavity in a surrounding manner, a gas bag fixing sleeve, a positioning clamp splice, an air charging system, a gas pressure sensor, a gas pressure release valve and a power source, wherein the gas bag fixing sleeve is used for fixing the gas bag placed in the gas bag fixing sleeve onto the end part of the movable clamp splice; the gas bag fixing sleeve and the positioning clamp splice can form a notch for allowing a seedling to be placed in; and the movable clamp splice is provided with an end opening communicated with the cavity and used for air charging. The flexible seedling clamping machine can realize flexible clamping of seedlings, greatly reduces the stalk damage rate of the seedlings, improves the graft survival rate and belongs to the field of gardening and vegetable grafting machinery.

Owner:SOUTH CHINA AGRI UNIV

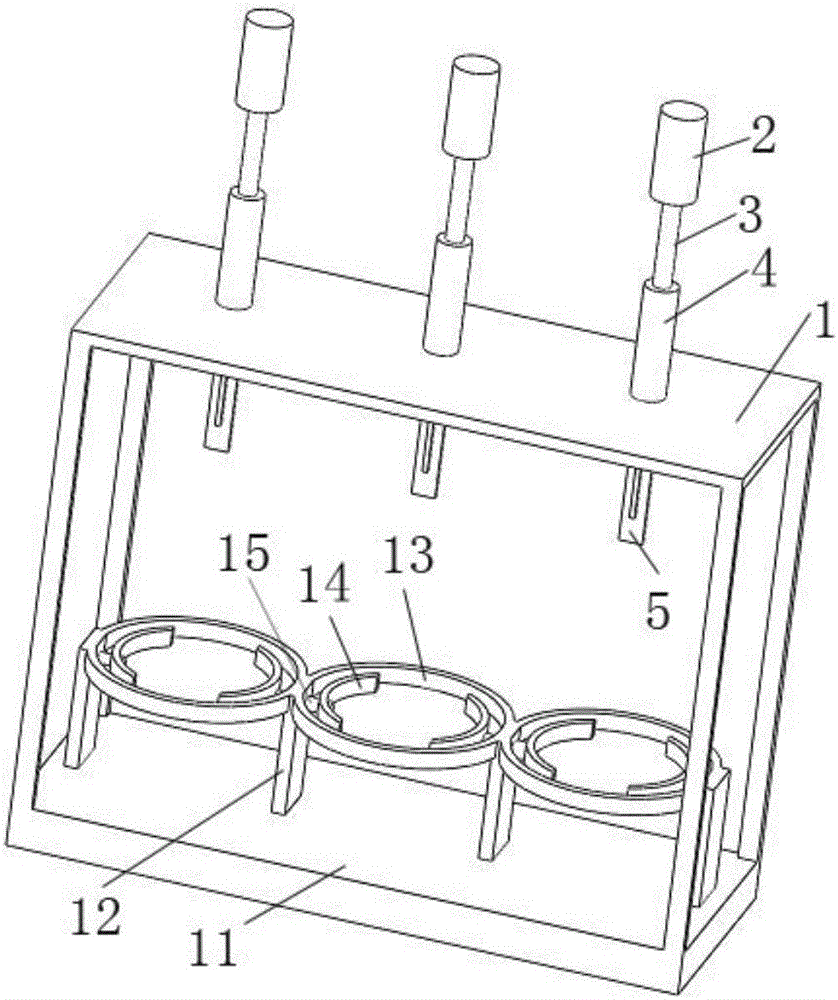

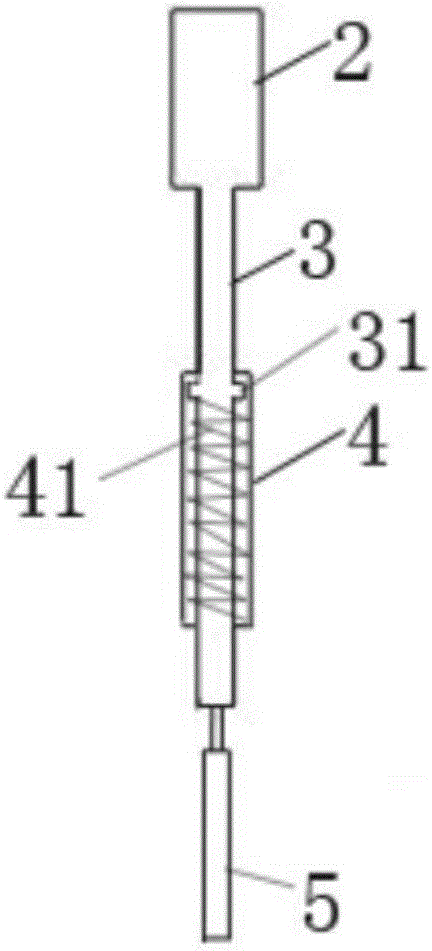

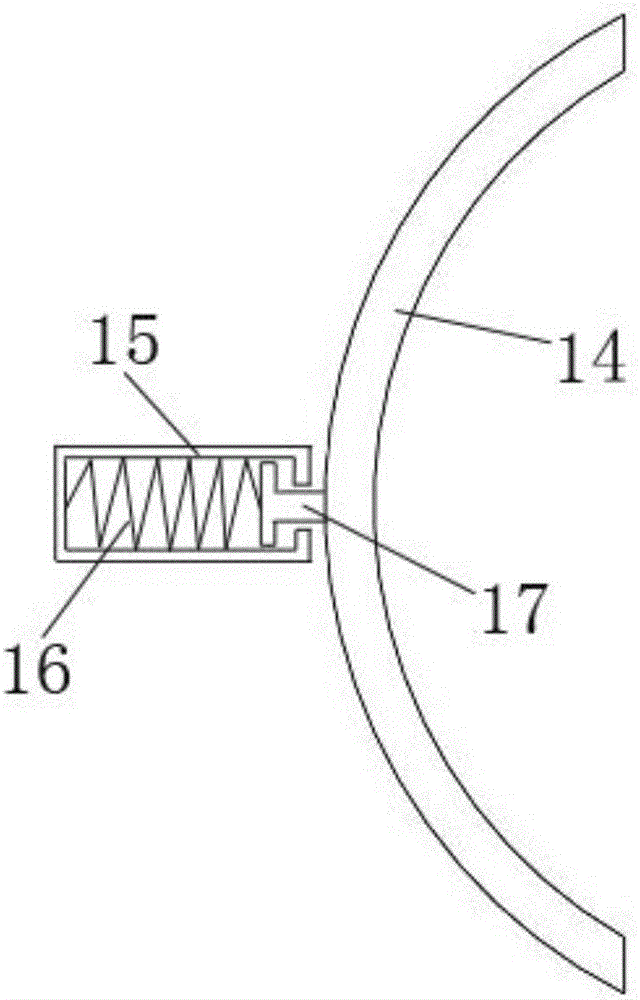

Rinsing device used for filling beverage bottles

The invention discloses a rinsing device used for filling beverage bottles. The rinsing device comprises a mounting frame, clamping assemblies and rinsing assemblies. Four supporting plates are distributed on a bottom plate of the mounting frame, and one clamping assembly is arranged between every two adjacent supporting plates. Each clamping assembly comprises an outer ring and two arc-shaped plates, wherein the outer ring is transversely arranged at the top ends of the two adjacent supporting plates, and limiting pipes protrude from the two opposite sides of the inner wall of the outer ring and internally provided with first springs; and connecting rods on the outer walls of the two arc-shaped plates are located in the corresponding limiting pipes and connected with the outer ends of the first springs in the limiting pipes. The rinsing assemblies in one-to-one correspondence with the clamping assemblies are arranged on a top plate of the mounting frame. Each rinsing assembly comprises a guiding pipe, a guiding rod, a handle and a rinsing brush, wherein the guiding pipe is arranged on the top plate of the mounting frame, the guiding rod is inserted into the guiding pipe, a limiting plate protrudes from the middle of the guiding rod, and the portion, located between the limiting plate and the bottom face of the guiding pipe, of the guiding rod is sleeved with a second spring; and the lower end of the guiding rod extends downwards and is longitudinally connected with the rinsing brush. The rinsing device can be used for quickly rinsing the beverage bottles.

Owner:HEFEI ZHONGCHEN LIGHT IND MACHINERY

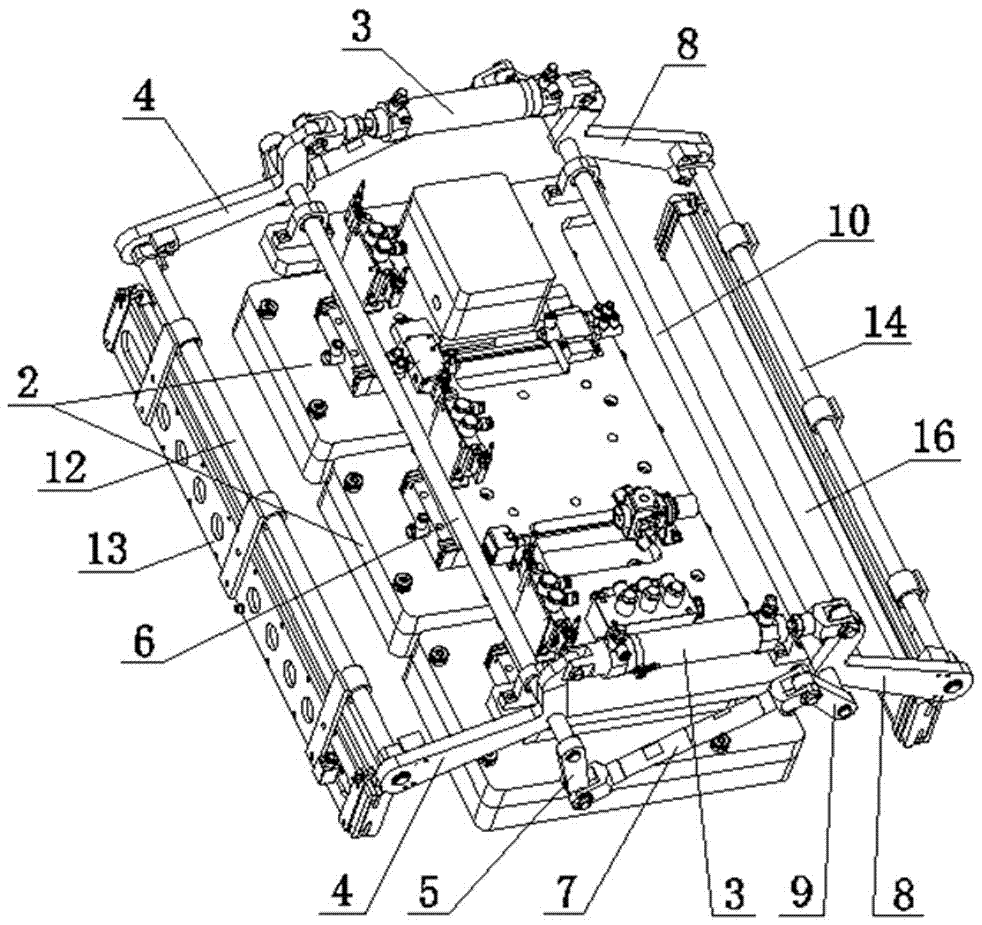

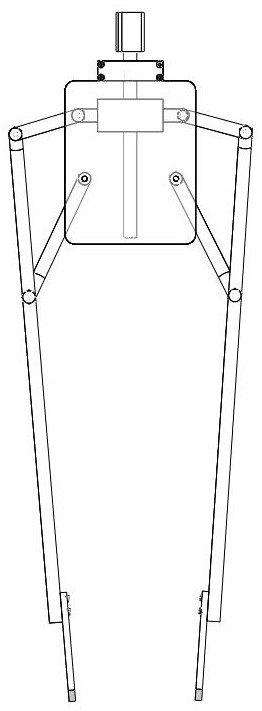

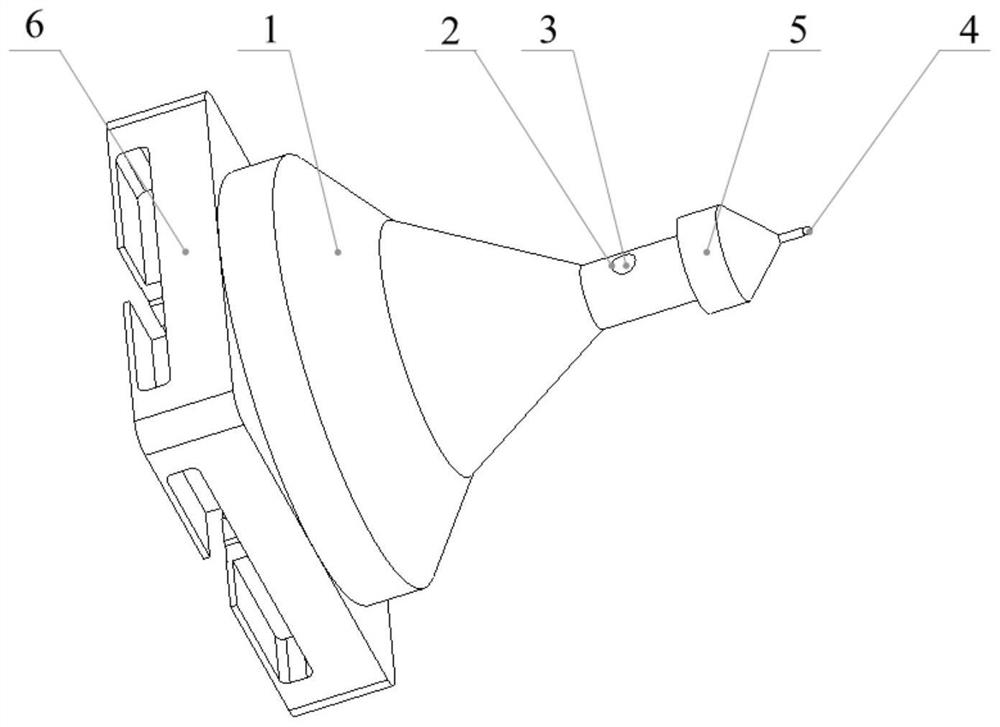

Plug seedling taking device driven by motor

PendingCN111955116ARealize flexible clampingAvoid damageTransplantingElectric machineAgricultural engineering

The invention relates to a plug seedling taking device driven by a motor, which can accurately control the opening and closing angle and the clamping force and is suitable for end effectors of seedling taking mechanisms of various transplanters. The plug seedling taking device comprises a driving motor, a screw rod, a rack, a front mounting plate, a rear mounting plate, a screw rod nut seat, connecting rods, connection rods, rocking rods and seedling claws. The motor provides driving force, the lead screw drives the lead screw nut seat to move up and down, and then the connecting rods are driven to control opening and closing of the seedling claws to realize opening and closing of the seedling claws; the mechanism is simplified to the maximum extent, the machining and manufacturing difficulty is reduced, the seedling taking efficiency is guaranteed, the hole entering angle and the clamping force are further controlled by accurately controlling the rotating speed of the motor, flexibleclamping of a pot seedling clamping mechanism on a pot seedling matrix is achieved, damage to the pot seedling matrix is reduced, and meanwhile the real-time performance of control is guaranteed. Theproblem that labor wastes time and labor is solved, and high-speed low-loss seedling taking is achieved.

Owner:SHIHEZI UNIVERSITY

Automatic clamping mechanical hand with buffer damping function

InactiveCN106393099AStable and accurate operationEasy to operateProgramme-controlled manipulatorGripping headsDamping functionCoupling

The invention discloses an automatic clamping mechanical hand with a buffer damping function and mainly relates to the technical field of mechanical hands. The automatic clamping mechanical hand comprises a machine body, a first joint shaft, a second joint shaft, a buffer mechanism and a clamping finger. The two ends of the first joint shaft are in matched connection with the machine body and the second joint shaft correspondingly. The first joint shaft, the second joint shaft and the clamping finger are all driven by a servo motor arranged in the machine body. The upper end of a piston rod is in matched connection with an air cylinder through the buffer mechanism, the lower portion of the piston rod penetrates through the second joint shaft and is embedded in a connection pipe in a sleeved mode, and the bottom of the piston rod is fixedly connected with a coupling. The clamping finger is in matched connection with the piston rod through the coupling, and V-shaped blocks are fixedly connected to the inner sides of the two ends of the clamping finger. The machine body is connected with an external controller. According to the automatic clamping mechanical hand with the buffer damping function, the damage to a workpiece is small, a worker can operate the mechanical hand easily, and the joint shafts can be precisely and stably operated for a long time; and moreover, the mechanical hand is small in redundant structure, very convenient to assemble, disassemble and maintain and low in manufacturing and operating cost.

Owner:苏州塞默机械有限公司

Flexible clamping claw

ActiveCN104786230AGuaranteed success rateSimple device structureGripping headsHorticultureEngineeringMechanical engineering

The invention provides a flexible clamping claw which comprises a base, a perpendicular fixed shaft penetrating through the base, a clamping device arranged on the fixed shaft in a sleeving mode, and a push device for opening and closing the clamping device. The clamping device comprises a left clamping body, a right clamping body and a tension spring, wherein the tail portion of the left clamping body and the tail portion of the right clamping body are arranged on the fixed shaft in a crossed and sleeving mode and rotate in the axial direction of the fixed shaft, and the two ends of the tension spring are fixedly connected with the arm portion of the left clamping body and the arm portion of the right clamping body respectively. The push device comprises a push rod and a limiting rod, wherein a slide groove which is through and extends in the length direction of the push rod is formed in the push rod, and the fixed shaft perpendicularly penetrates through the slide groove. The first end of the push rod is fixedly provided with the limiting rod which is parallel to the fixed shaft, the limiting rod is clamped in a space outside the crossed point of the tail portion of the left clamping body and the tail portion of the right clamping body, the slide groove is used for making the push rod reciprocate within the stroke range of the slide groove, the limiting rod is separated from or clamped in the crossed space of the tail portion of the left clamping body and the tail portion of the right clamping body, and therefore the left clamping body and the right clamping body can be opened and closed.

Owner:北京市农林科学院智能装备技术研究中心

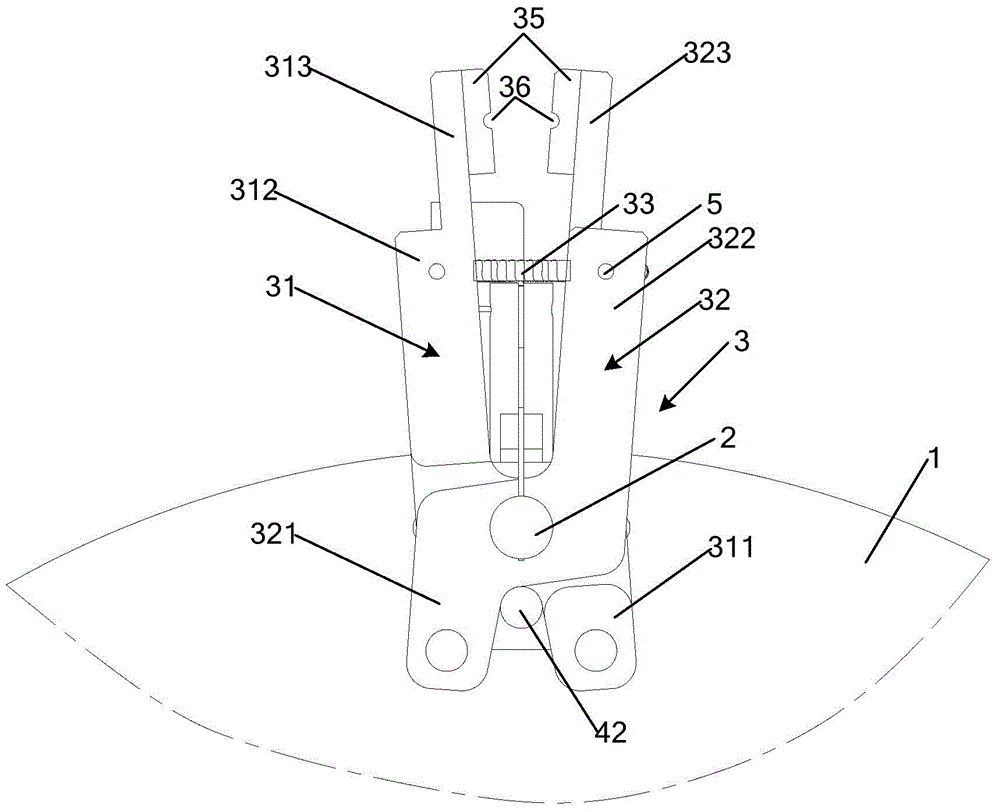

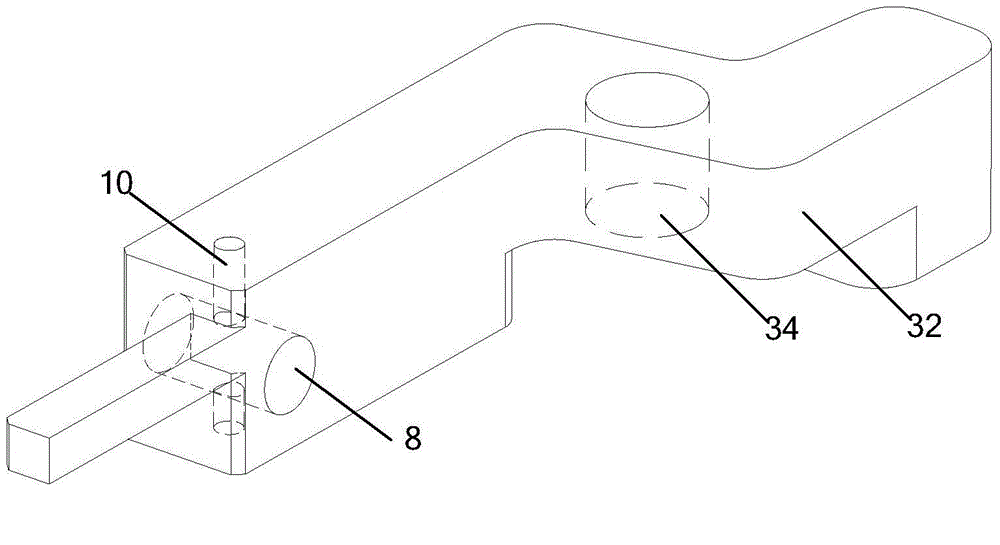

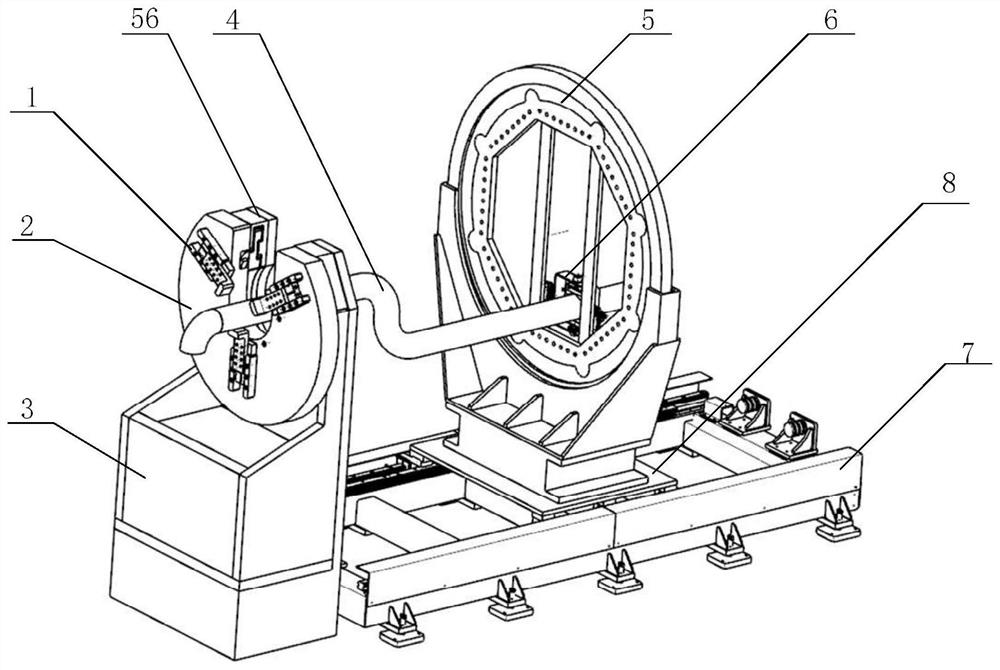

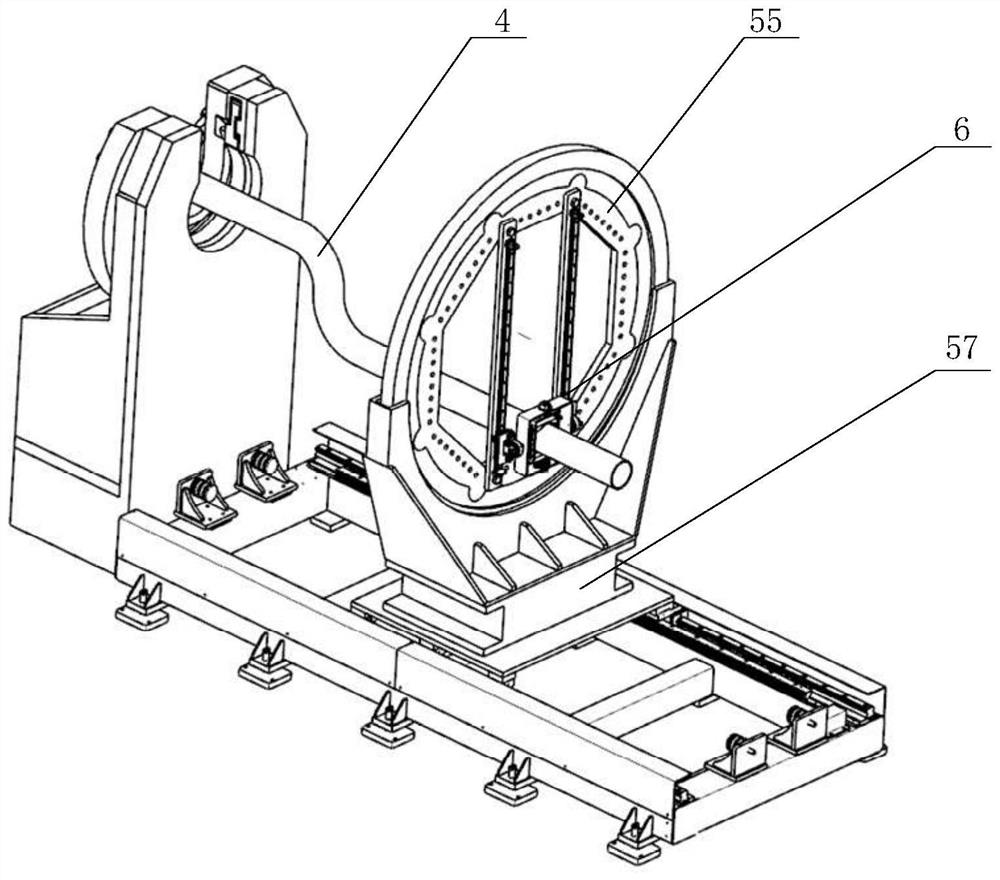

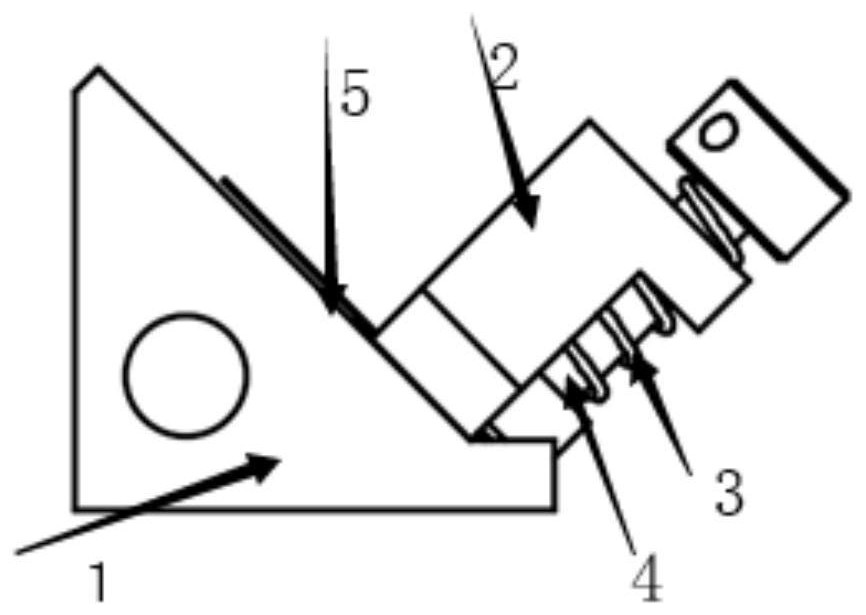

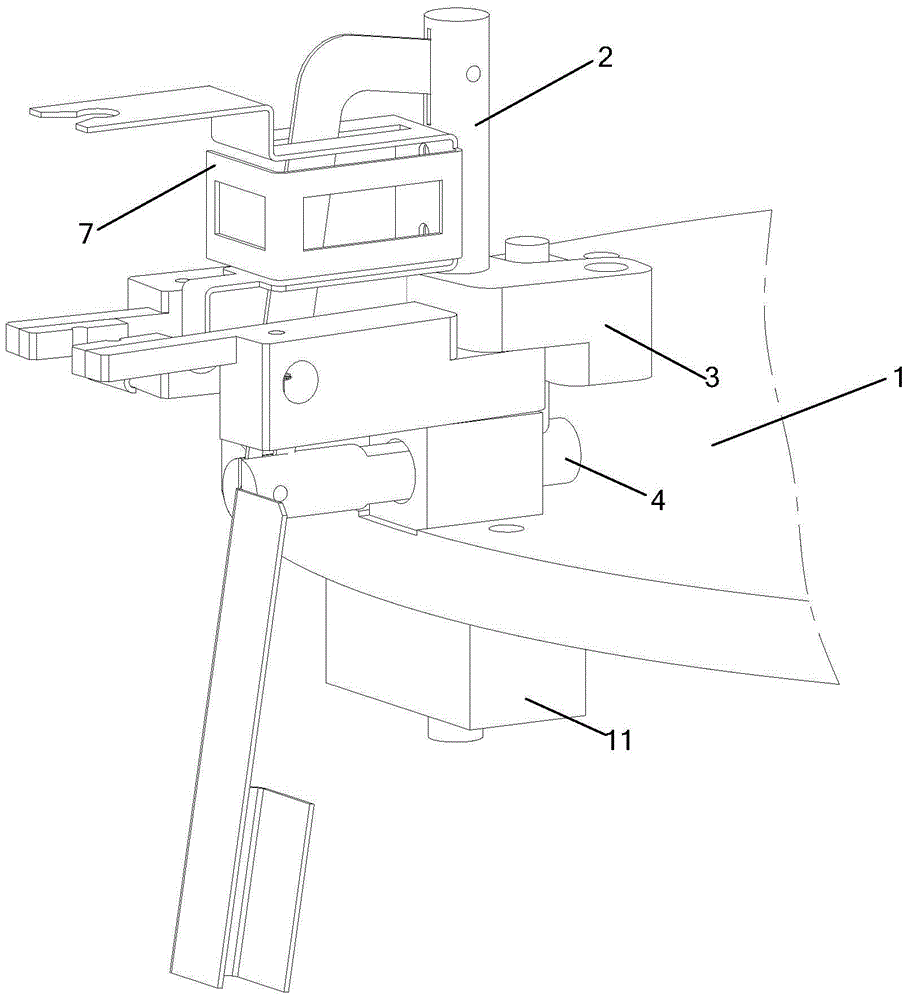

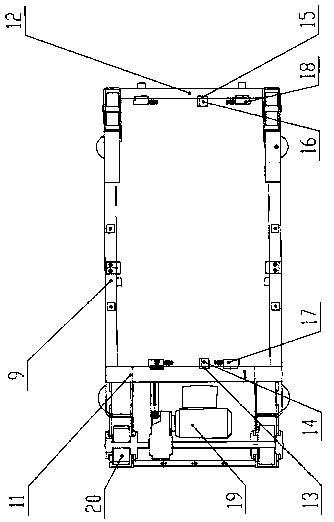

Flexible clamping tool for rotary positioning of bent pipe

ActiveCN112605601ANo torsionRealize flexible clampingWelding/cutting auxillary devicesAuxillary welding devicesEngineeringSlide plate

The invention discloses a flexible clamping tool for rotary positioning of a bent pipe. The flexible clamping tool comprises an open type positioner, an R-shaped positioner, a clamping tool and a rail. The open type positioner is used for clamping the to-be-welded nearby area of the bent pipe and conducting rotary positioning. The R-shaped positioner is used for clamping the other end of the bent pipe and carrying out rotary positioning. The clamping tool is flexibly adjusted on the R-shaped positioner and clamps the bent pipe. The R-shaped positioner is installed on the top of the rail through a sliding plate, freely slides and can adapt to the bent pipes with different lengths. By means of the flexible clamping tool for rotary positioning of the bent pipe, flexible clamping and automatic rotary positioning of the multi-bend bent pipe can be achieved, and the automation level of welding of the multi-bend bent pipe is improved.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP +1

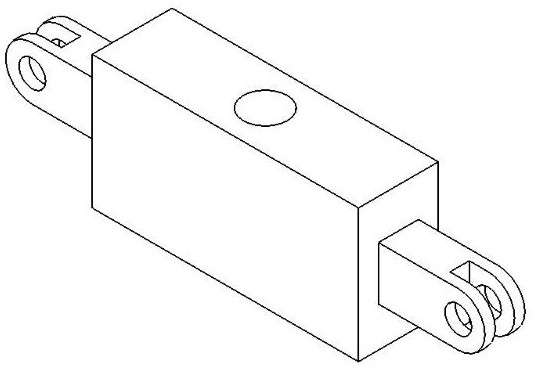

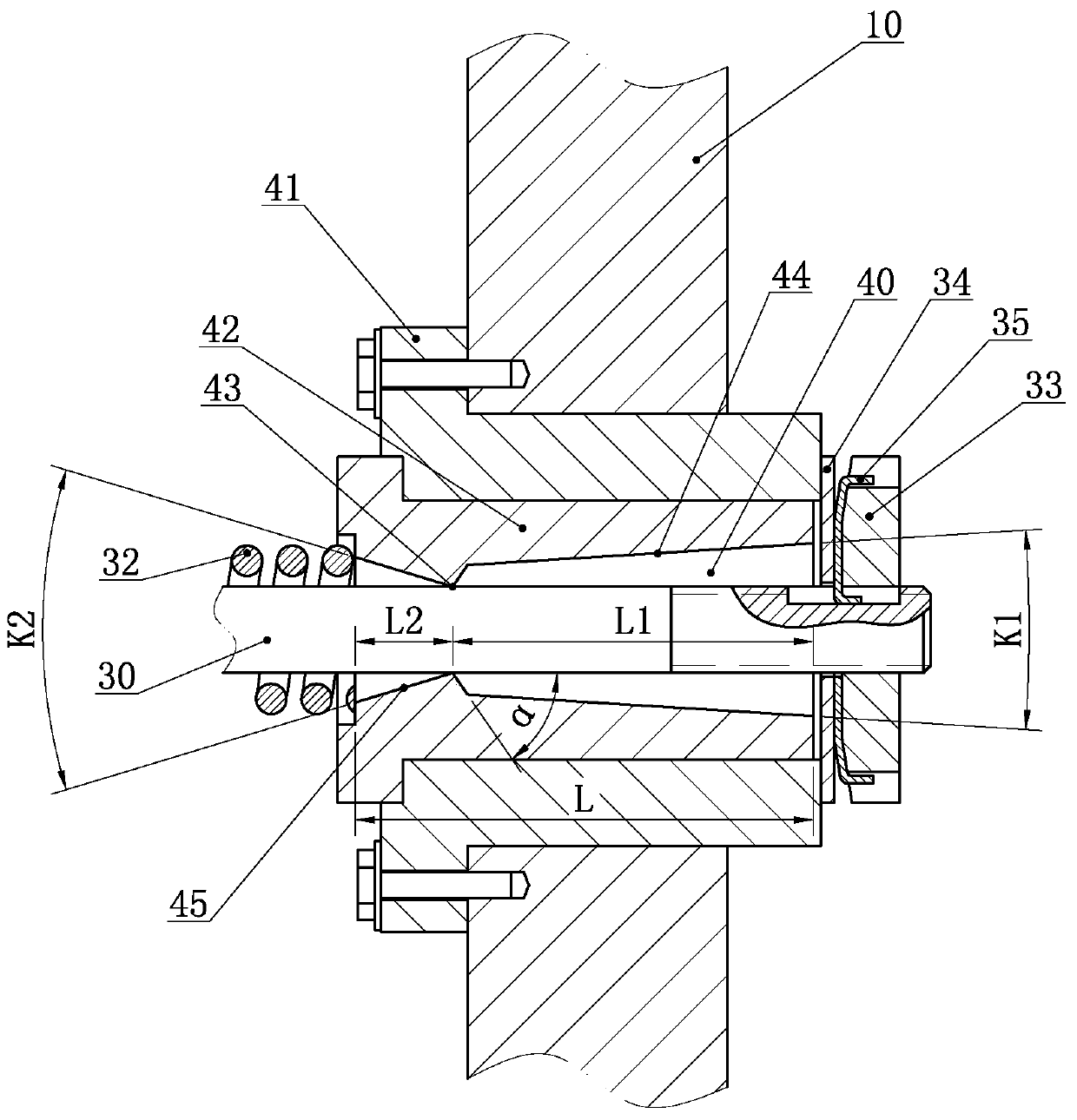

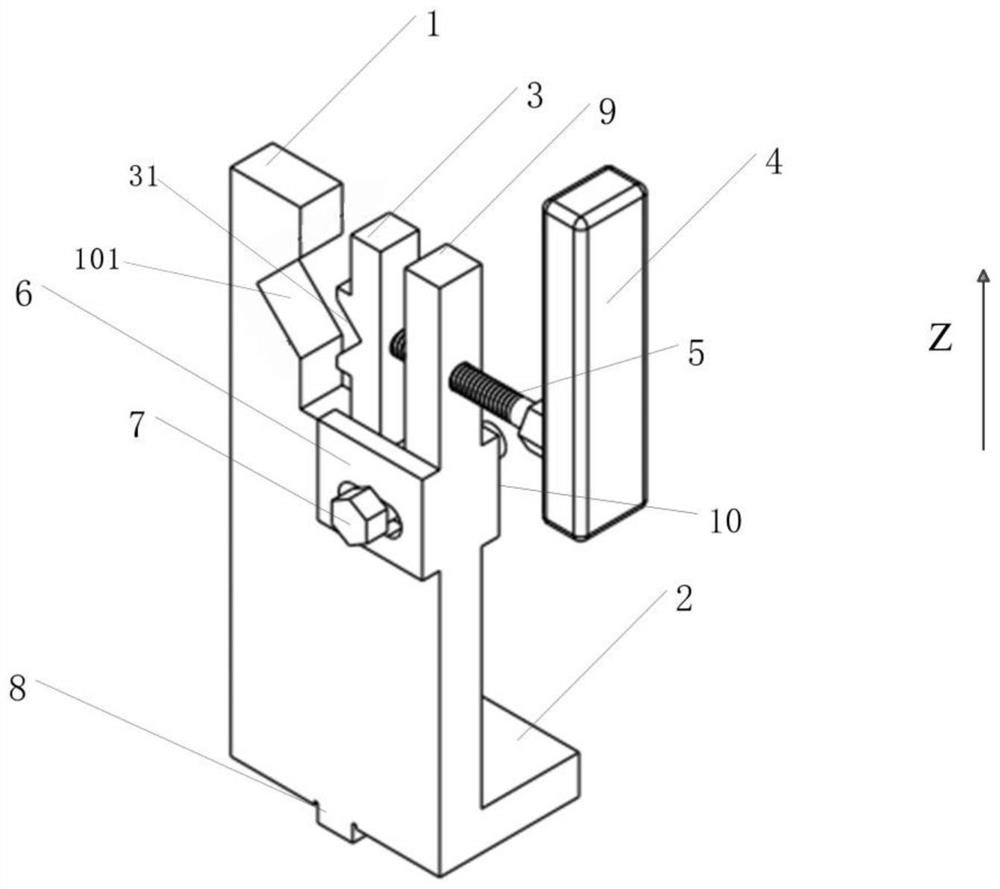

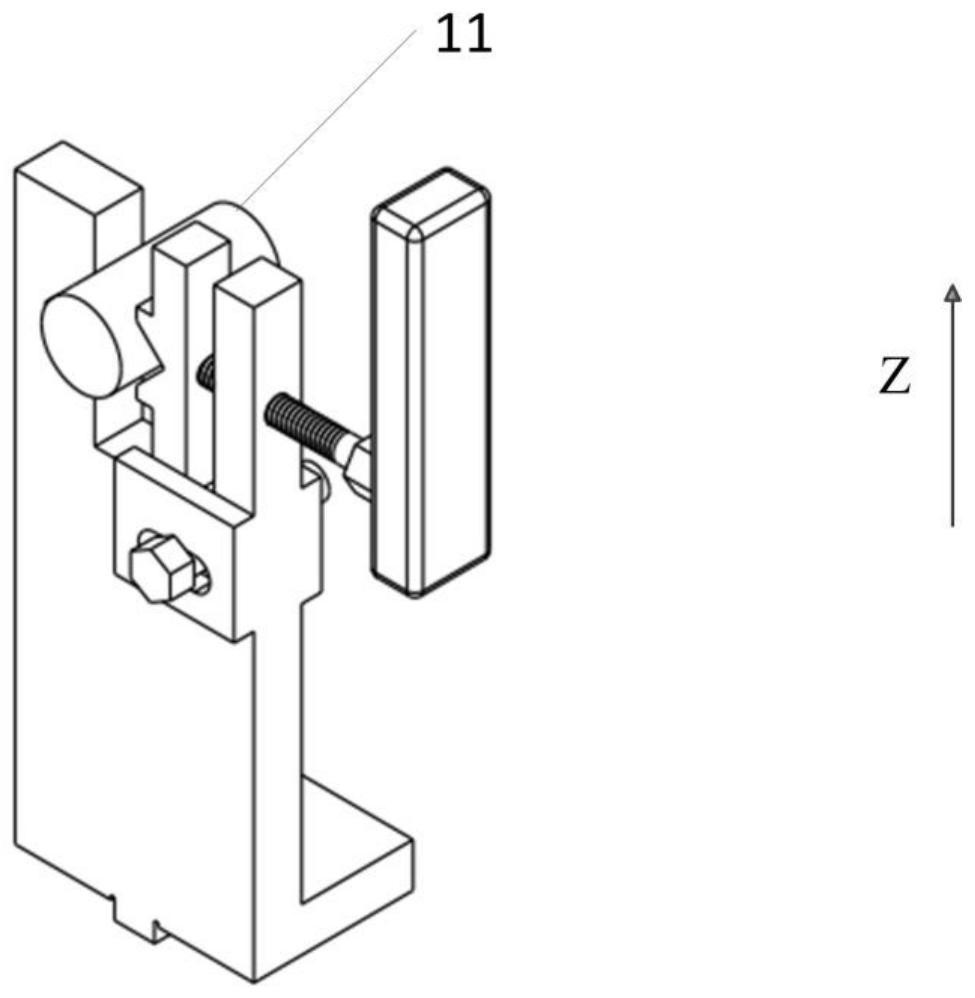

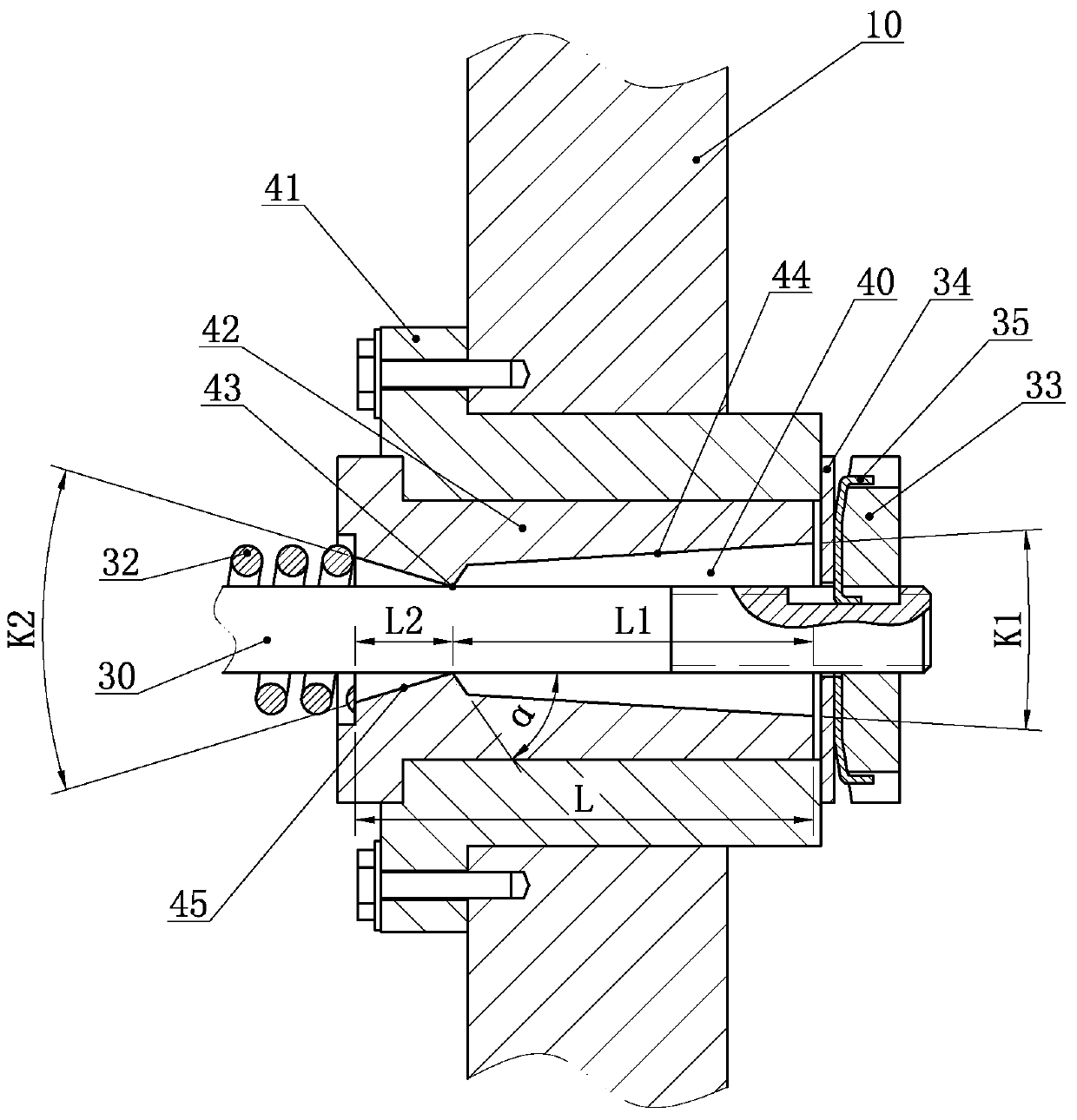

Follower fixture for shaft products, and fixture unit thereof

ActiveCN110340696APrevent circumferential rotationImprove accuracy and efficiencyPositioning apparatusMetal working apparatusEngineeringMechanical engineering

Owner:CHONGQING UNIV

Burr shearing device for paper printing

InactiveCN112894922ARealize flexible clampingEasy to fixUsing liquid separation agentMetal working apparatusPaper sheetKnife blades

The invention discloses a burr shearing device for paper printing. The device comprises a bottom plate, wherein two first limiting rods are fixedly connected to the position, close to the front side, of the top of the bottom plate, two first limiting rods are fixedly connected to the position, close to the rear side, of the top of the bottom plate, the four first limiting rods are arranged in bilateral symmetry, first moving plates are arranged at the positions, close to the front side and the rear side, of the top of the bottom plate respectively, and first sliding grooves are formed in the positions, close to the front sides and the rear sides, of the bottoms of the two first moving plates respectively. Through mutual cooperation of a second rotary knob, a second transmission rod, a second limiting rod, second movable blocks, a first transverse plate, third connecting rods, first vertical plates, blades and other mechanisms, paper of different sizes can be cut by adjusting the range correspondingly; and through mutual cooperation of the bottom plate, the first limiting rods, first movable blocks, a first connecting rod, a first transmission rod, second connecting rods, a first circular plate, vertical rods, L-shaped rods, rollers and other mechanisms, the paper can be flexibly clamped, and meanwhile the paper is fixed more firmly and is not prone to deviation.

Owner:吴红艳

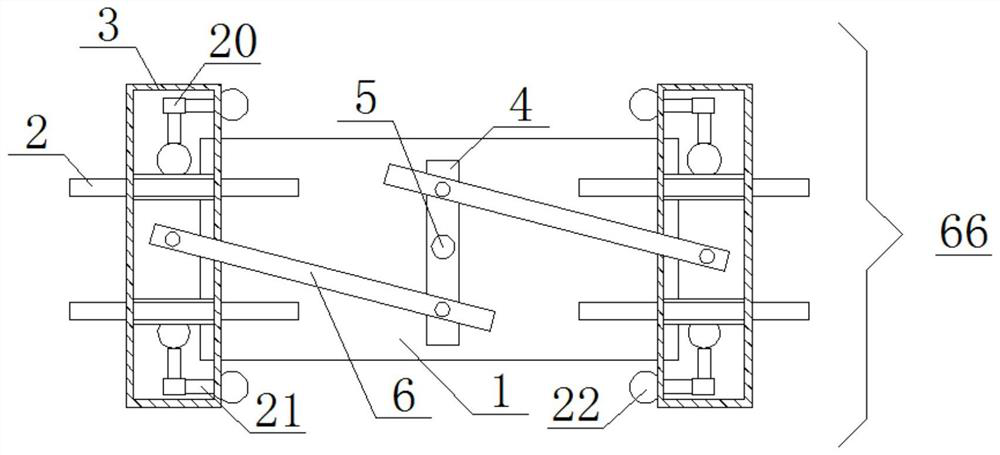

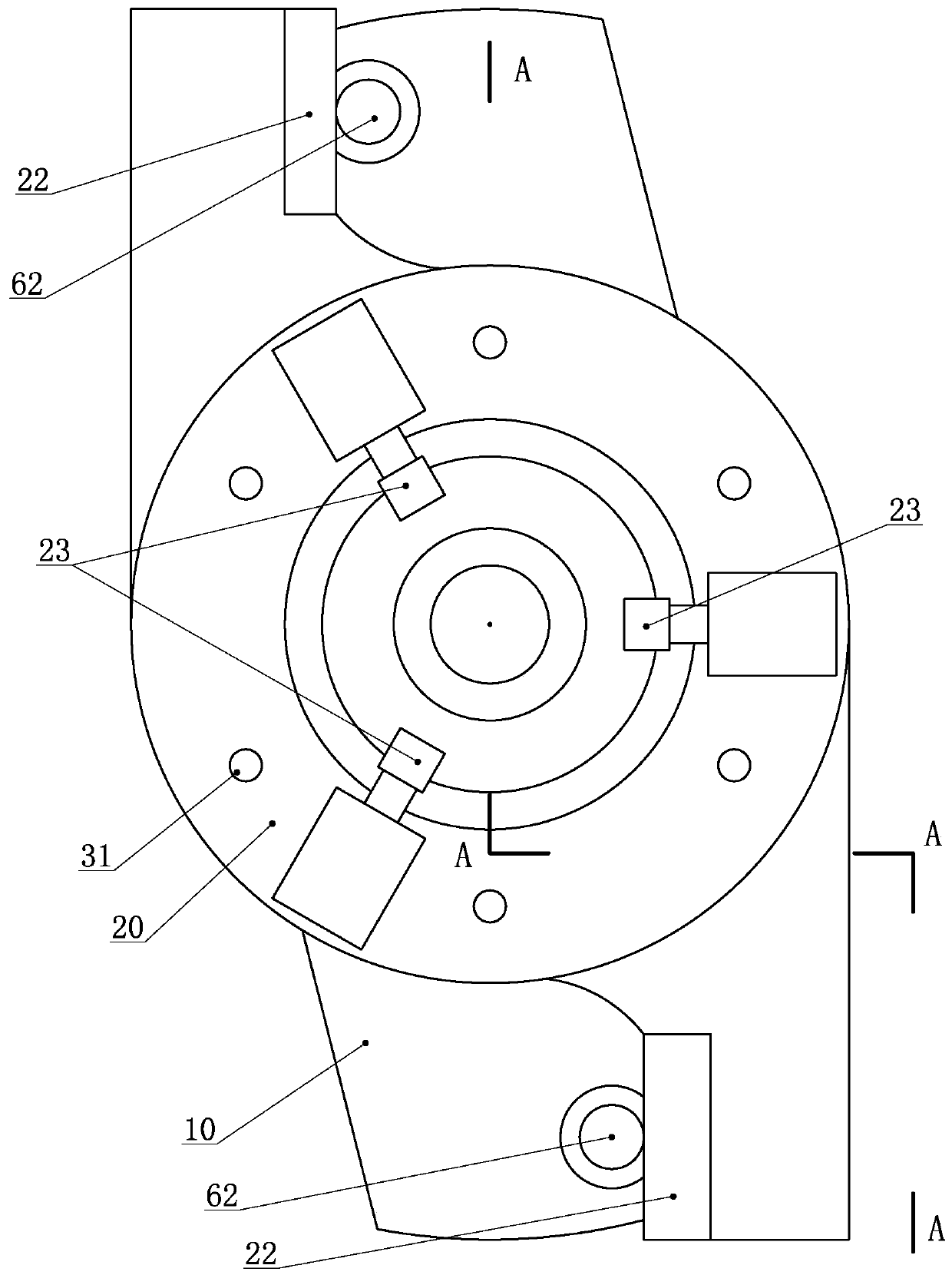

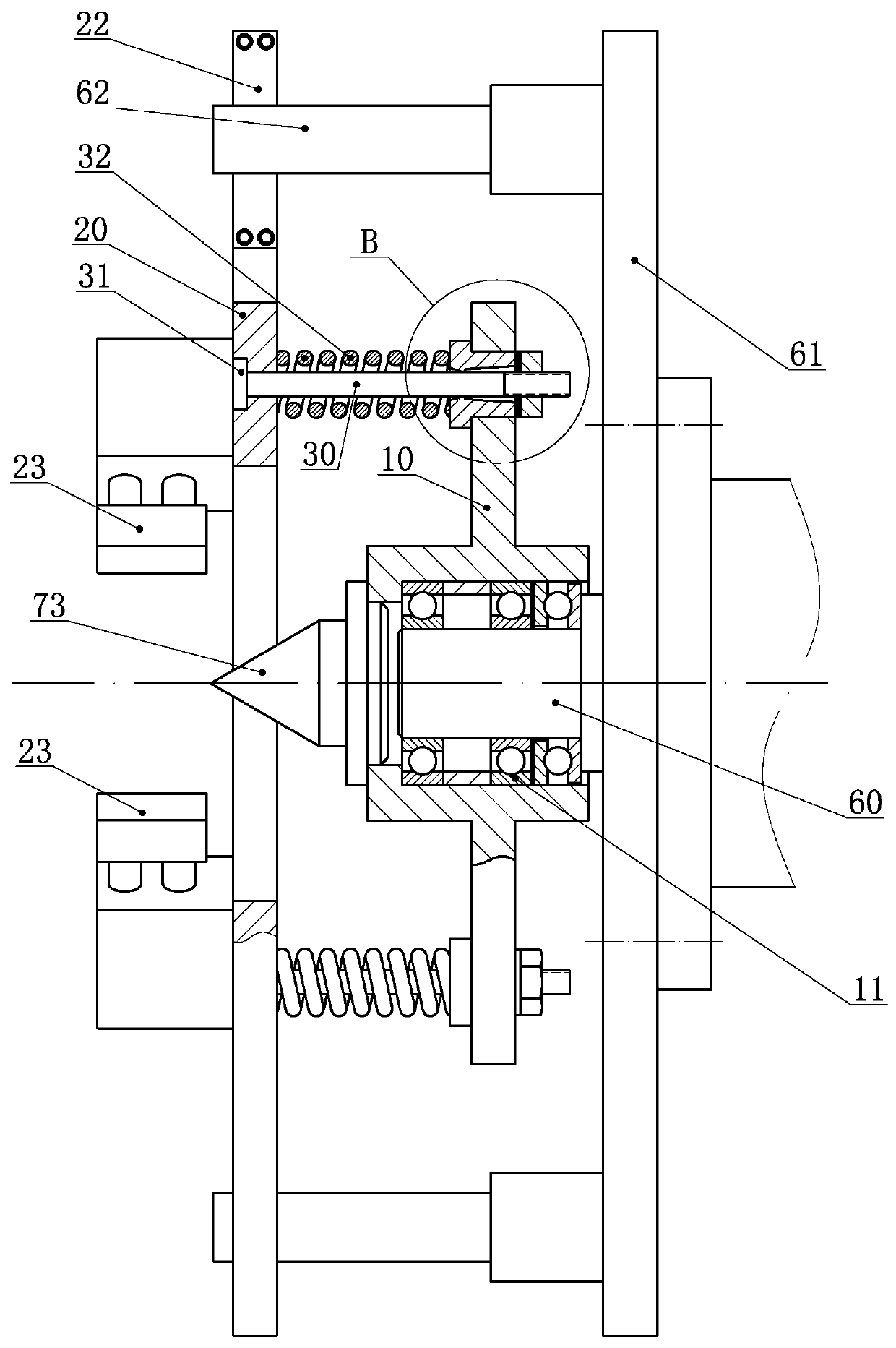

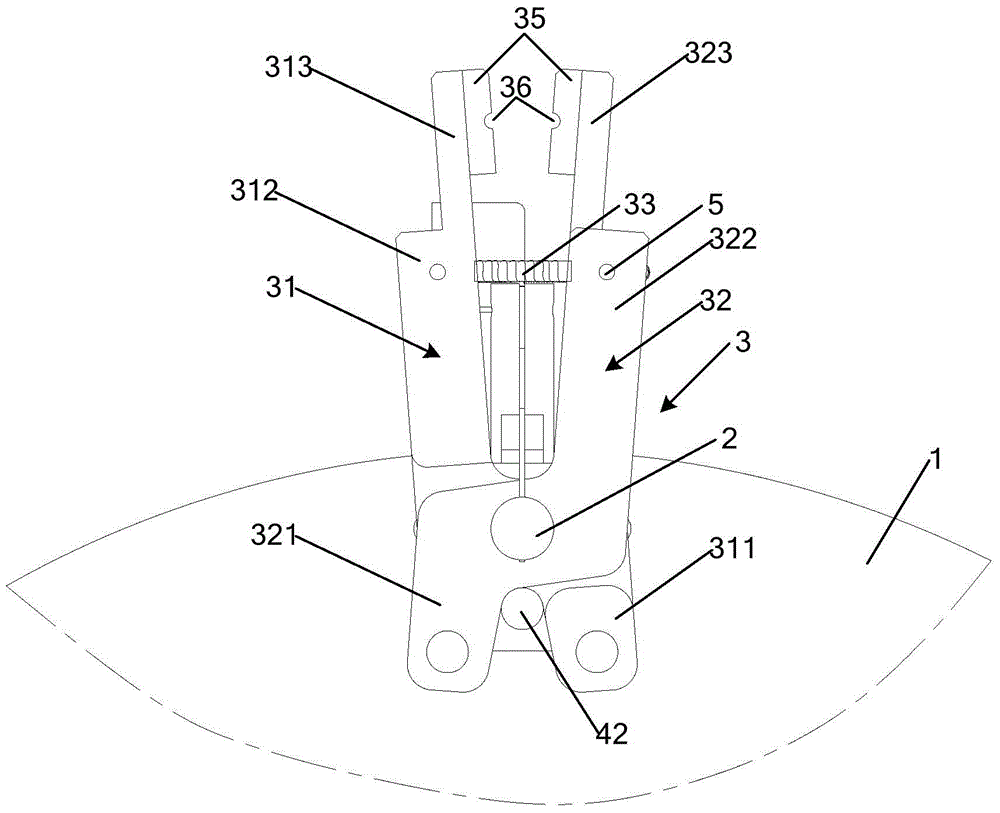

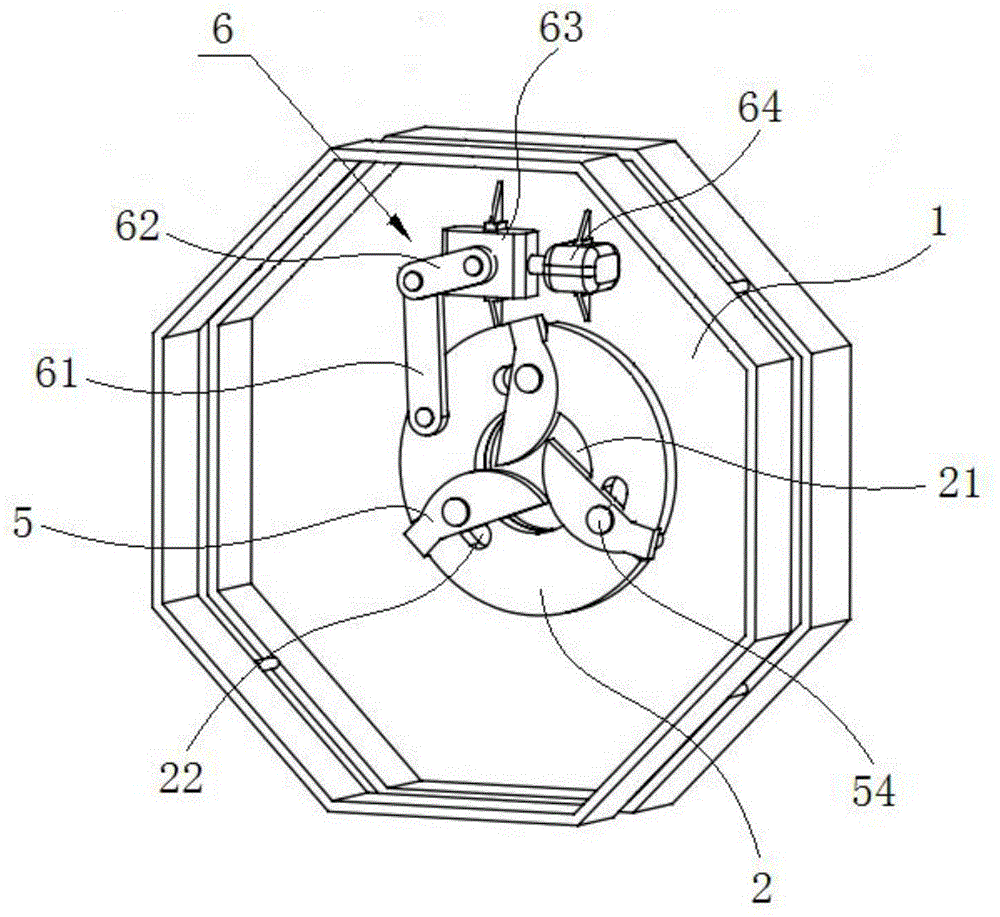

Rotary workpiece flexible driving fixture

ActiveCN110052871ARealize flexible clampingHigh structural precisionPositioning apparatusMetal-working holdersEngineeringMachining process

The invention relates to a rotary workpiece flexible driving fixture which comprises a rotary chassis ad a flexible chuck, wherein the rotary chassis is mounted on a machine tool spindle and coaxiallyand freely rotates relative to the machine tool spindle; the flexible chuck is mounted on the rotary chassis through a flexible connecting rod; and a flexible connecting spring is arranged on the flexible connecting rod in a sleeving manner. The rotary workpiece flexible driving fixture has the following benefits: flexible clamping and fixing of a rotary workpiece are realized through adopting the flexible connecting rod, a flexible connecting hole and a flexible connecting spring, so that stress and elastic deformation generated during the clamping process of a cylindrical workpiece can be avoided, the machining precision and quality can be ensured, the defects that the roundness error, the taper error and the cylindricality error are excessively large, a shaking line and a feeding lineare generated on the machining surface during the finish machining process of the cylindrical workpiece are eliminated, and the structural precision and the degree of finish of the workpiece can be remarkably improved.

Owner:廊坊市钦纵机电产品制造有限公司

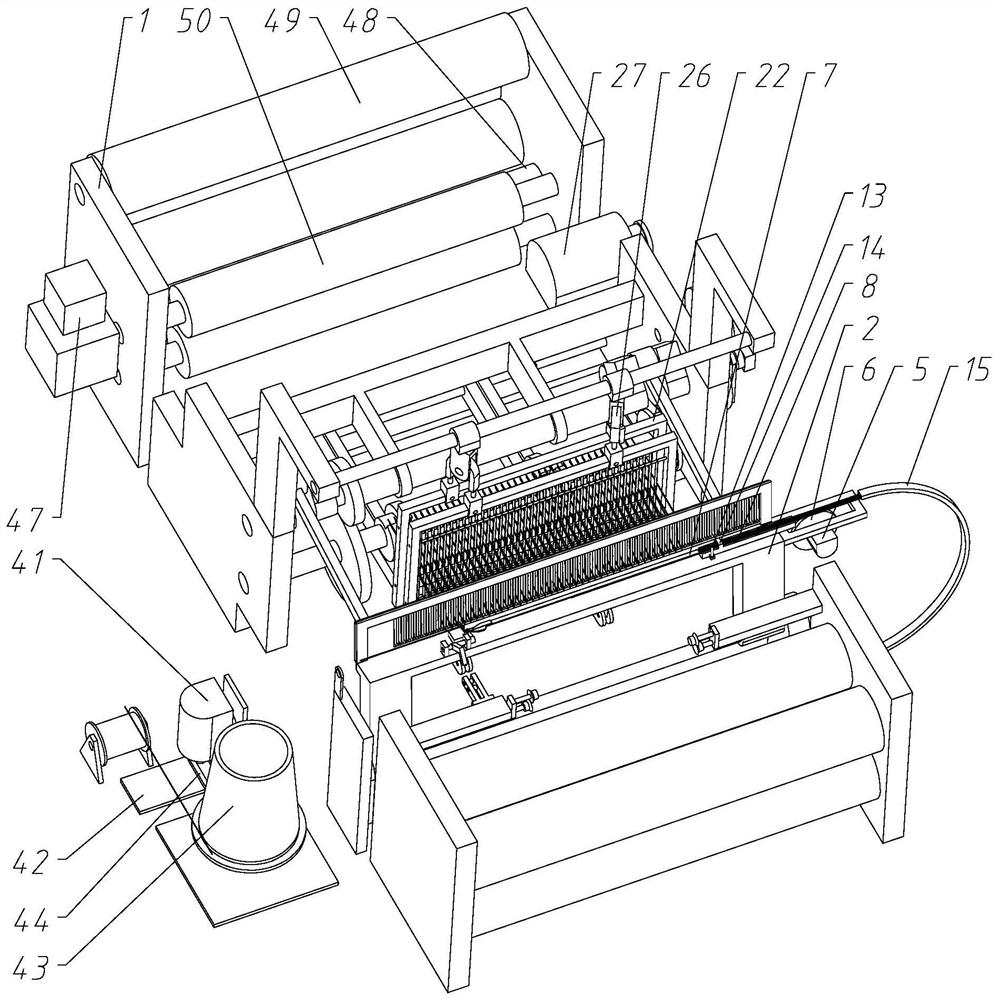

Weaving machine for wire mesh and weaving method

ActiveCN114850355APrevent disengagementStable clampingWire networkElectric machineryStructural engineering

The invention relates to the technical field of metal mesh weaving equipment, and provides a metal mesh weaving machine which comprises a rack, and a feeding mechanism, a wire guiding mechanism, a weaving mechanism, a receiving mechanism and a power unit are arranged on the rack. The weaving mechanism comprises a swing frame, a guide ring, a positioning assembly and a clamping assembly, wherein the clamping assembly comprises a clamping motor, a rapier belt, a rapier head, a clamping plate and a clamping spring; wherein the clamping motor is fixedly arranged on the swing frame, and a first transmission wheel is arranged at the output end of the clamping motor; the sword belt is movably arranged on the swing frame by means of a clamping motor, a tooth groove is formed in the sword belt, and the tooth groove is in meshed connection with teeth on the first transmission wheel; the rapier head is arranged on the rapier belt, and a clamping head is arranged on the rapier head; the clamping plate is rotationally arranged on the rapier head; by means of the technical scheme, the problem that knitting fails due to the fact that weft yarn clamping stability is poor in the silk screen knitting process in the prior art is solved.

Owner:河北康利达金属网有限公司

Form and position measurement flexible clamp and form and position measurement method for columnar part

PendingCN114734392AAvoid Duplicate PositioningImprove flexibilityMeasurement devicesWork holdersStructural engineeringMechanical engineering

Owner:CHANGSHU INSTITUTE OF TECHNOLOGY

A positioning jig for positioning dentures

ActiveCN107984334BRealize multi-point positioning installationAvoid deformationArtificial teethGrinding machinesDenturesEngineering

The invention relates to the field of denture processing and repair equipment, and in particular to a positioning fixture for positioning dentures. The bottom of the denture is provided with a positioning hole. The positioning fixture for positioning dentures includes a base, an expansion support device and a telescopic clamping device. ; The expansion support device is installed on the base, which is suitable for inserting into the positioning hole to support the denture; the telescopic clamping device is installed on the base, which is suitable for clamping the outer surface of the denture. The positioning fixture for positioning dentures of the present invention clamps the dentures from multiple directions through the cooperation of the expansion support device and the telescopic clamping device, thereby realizing multi-point positioning and installation of the dentures, and has the advantages of convenient positioning operation and control It has the advantages of low difficulty and high positioning accuracy; the expansion support device supports the denture, avoiding the deformation of the overall shape due to force when the denture is clamped; the use of mechanical devices for clamping also makes the denture fixed better.

Owner:NORTHEASTERN UNIV LIAONING

Clamping jaw based on gel driver

Owner:ZHEJIANG UNIV OF TECH

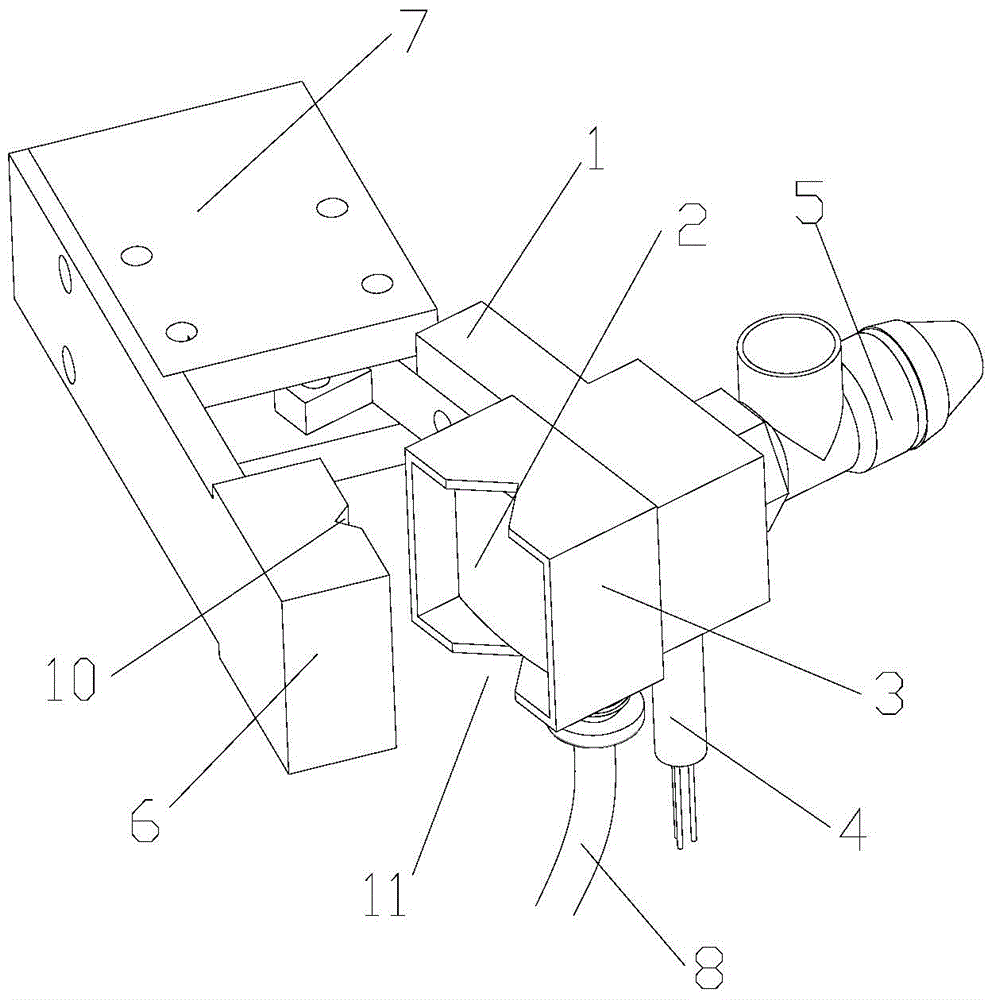

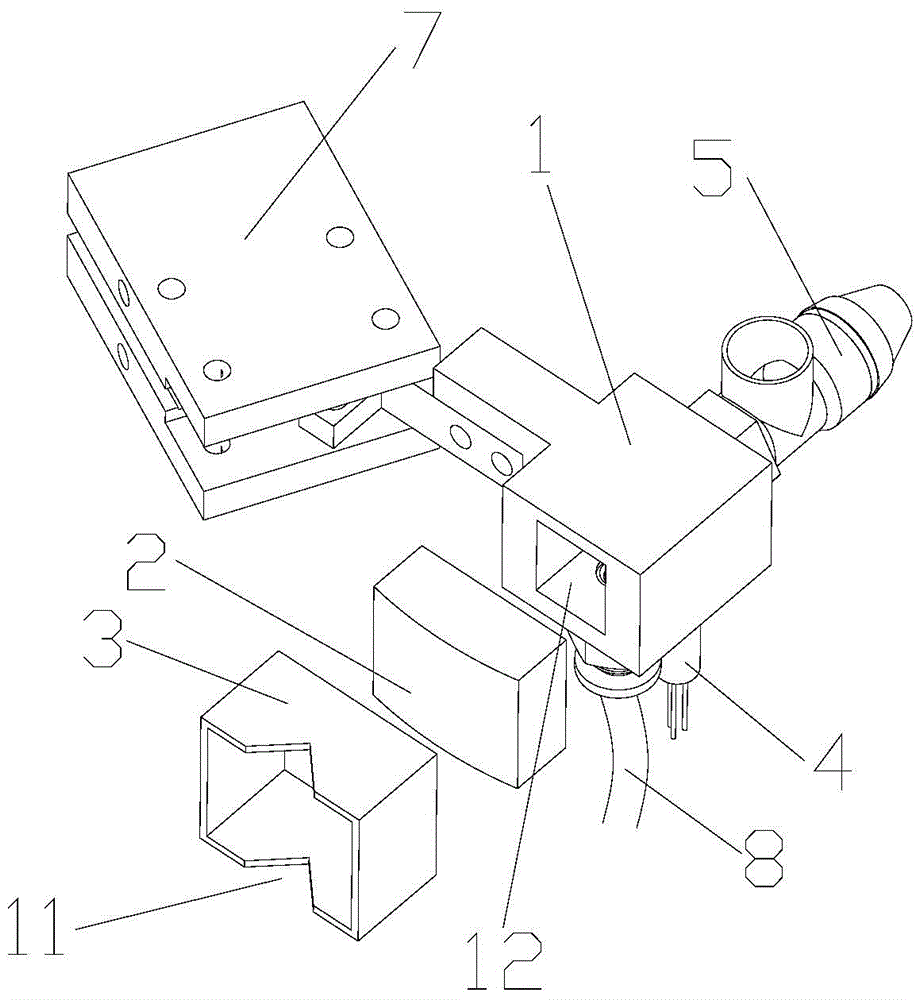

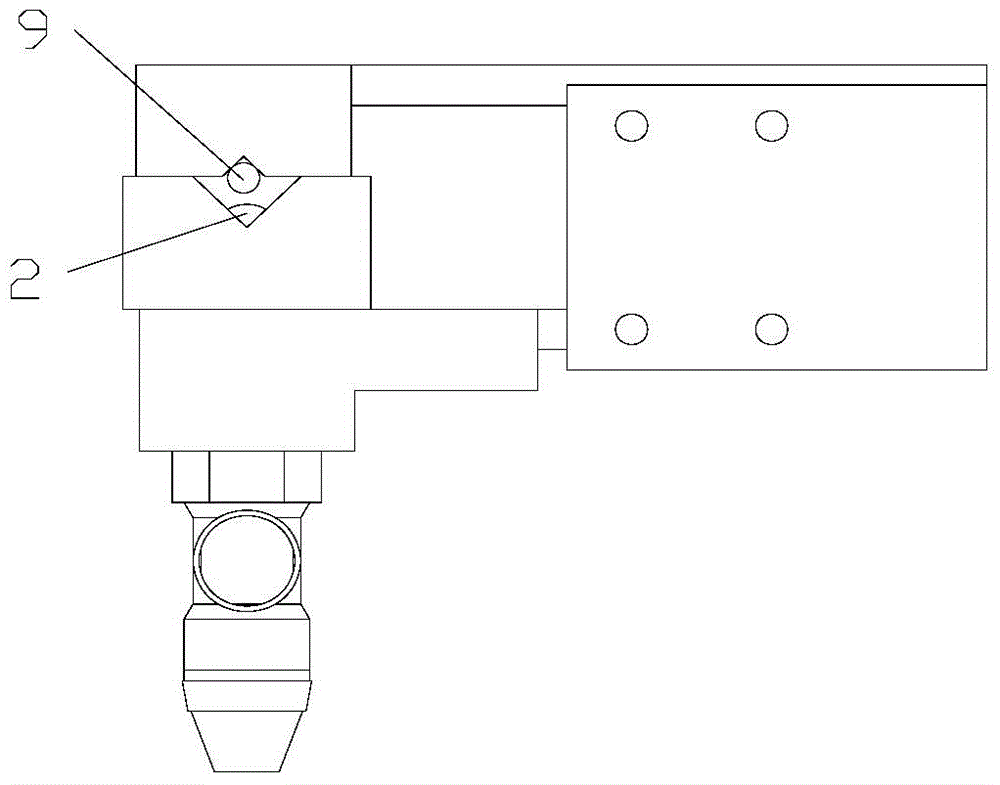

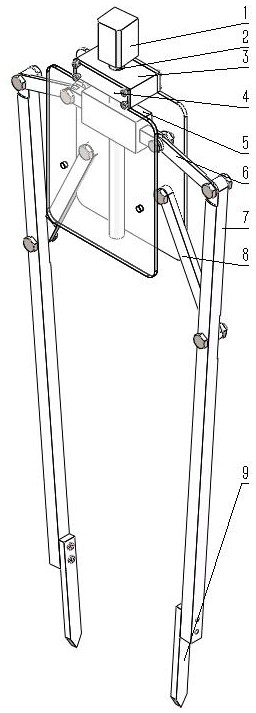

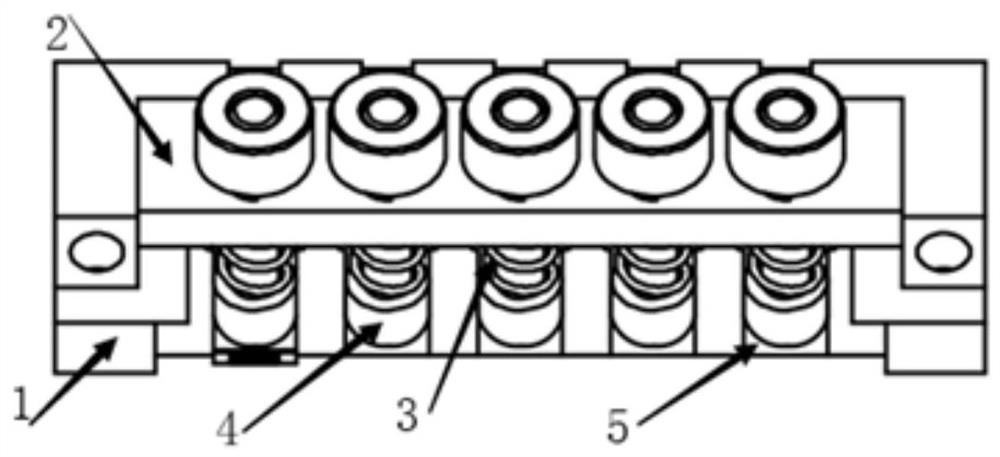

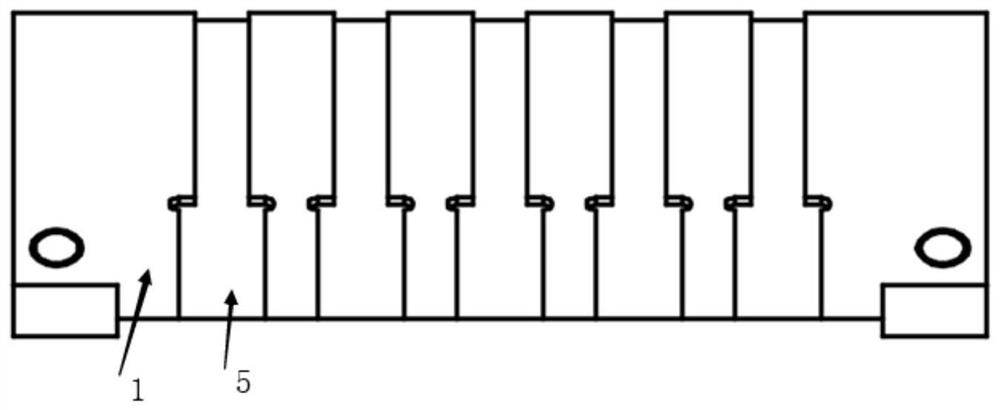

FA optical fiber end face coating clamp and using method thereof

ActiveCN112676062APrecise positioningEnsure consistencySpraying apparatusEngineeringStructural engineering

The invention discloses an FA optical fiber end face coating clamp which comprises a clamp base, a spring support, compression springs and pull rods. A plurality of positioning grooves are formed in the clamp base, the bottom of the spring support is fixed to the clamp base, a plurality of through holes are formed in the spring support, the pull rods penetrate through the through holes, the front ends of the pull rods are matched with the positioning grooves, and the compression springs sleeve the pull rods. The invention further discloses a using method of the FA optical fiber end face coating clamp. The FA optical fiber end face coating clamp replaces an existing outdated coating mode, the coating quality is improved, and the efficiency is improved.

Owner:UNION OPTIC

Network communication chip machining clamping device

InactiveCN108972415AThe overall structure is novelImprove clamping stabilityWork holdersPistonEngineering

The invention provides a network communication chip machining clamping device. The network communication chip machining clamping device comprises a lifting air cylinder, the lifting air cylinder comprises a cylinder body and a piston, a supporting rod is connected to the lower end of the cylinder body, and clamping assemblies are symmetrically arranged at the two ends of the supporting rod; a guide rod is arranged in the middle of the lower end of the piston, a transmission sleeve sleeves the guide rod, a limiting disc is arranged at the lower end of the guide rod, a spring is arranged betweenthe transmission sleeve and the limiting disc, and two horizontally-arranged transmission rods are symmetrically arranged on the outer side of the transmission sleeve; and the clamping assembly comprises a supporting shell, the upper end of the supporting shell is fixedly connected with the end part of the supporting rod, a sliding rod is arranged in the supporting shell, the upper end of the sliding rod is connected with the end of the transmission rod, the front side of the lower end of the sliding rod is provided with an adjusting protrusion, the front side of the supporting shell is rotationally connected with an adjusting plate, and an arc-shaped adjusting hole is formed in the lower end of the adjusting plate. The network communication chip machining clamping device has the beneficial effects that the overall structure is novel, the clamping stability of a communication chip is improved, moreover, flexible clamping of the communication chip can also be realized, and the possibility of damage in the clamping process of the chip is reduced.

Owner:江苏又一城智能科技有限公司

Vacuum adsorption clamp and adsorption method for clamping thin-wall spherical shell type micro component

ActiveCN113695937ASolve the deformationSolve the clamping problemWork clamping meansMilling equipment detailsSuction forceEngineering

The invention provides a vacuum adsorption clamp and an adsorption method for clamping a thin-wall spherical shell type micro component, and relates to the technical field of clamping of thin-wall spherical shell type micro components. The vacuum adsorption clamp and the adsorption method are provided for solving the problems that in the machining process of uniformly distributing micro pit structures on the whole surface of the thin-wall spherical shell type micro component, an existing clamping mode is difficult to operate, a control part is complex, consequently, spherical shell deformation is large, and the repeated positioning precision is low. According to the technical key points, a vacuum suction head is detachably connected with the adsorption end of a vacuum adsorption clamp body in a sealed mode, and the hole diameter of a vacuum cavity in the vacuum adsorption clamp body in the axial direction of the vacuum adsorption clamp body is decreased from the connecting end to the adsorption end; and the vacuum cavity serves as a main air source channel, and an auxiliary air source connector communicating with the vacuum cavity is formed in the vacuum adsorption clamp body. When the vacuum adsorption clamp is adopted to adsorb the thin-wall spherical shell type micro component, the specific structure shape of the suction head and the vacuum negative pressure are calculated and checked. A clamp chuck is suitable for flexibly adjusting the vacuum degree according to the deformation condition of a thin-wall spherical shell, that is, the suction force of the clamp chuck is adjusted, clamping deformation is reduced, and the machining precision is guaranteed.

Owner:HARBIN INST OF TECH

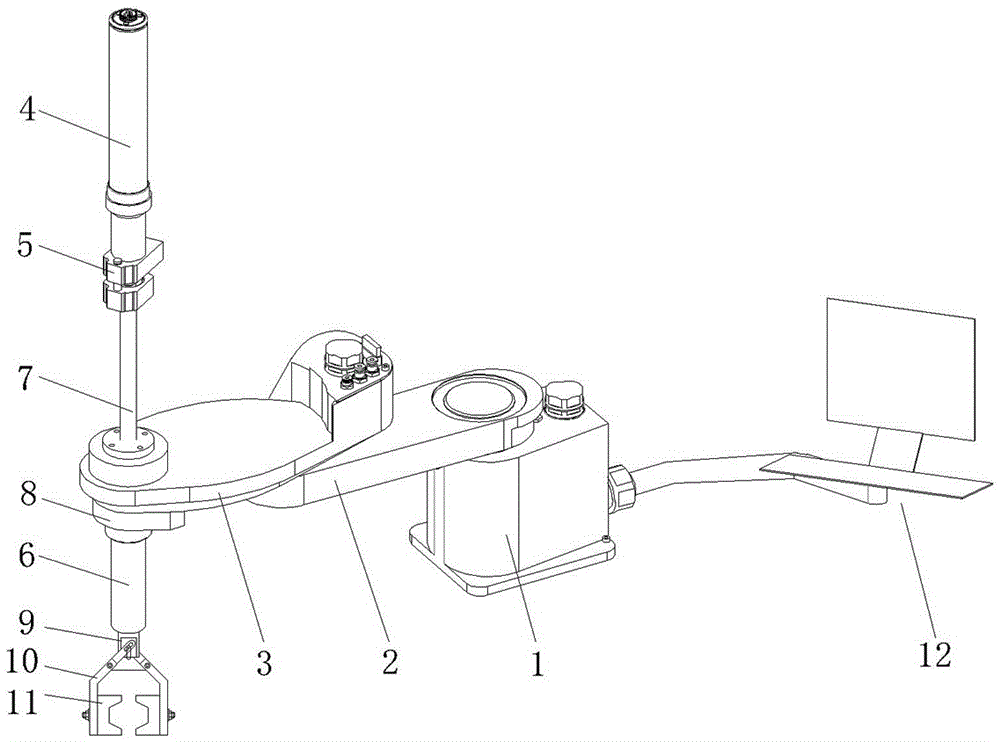

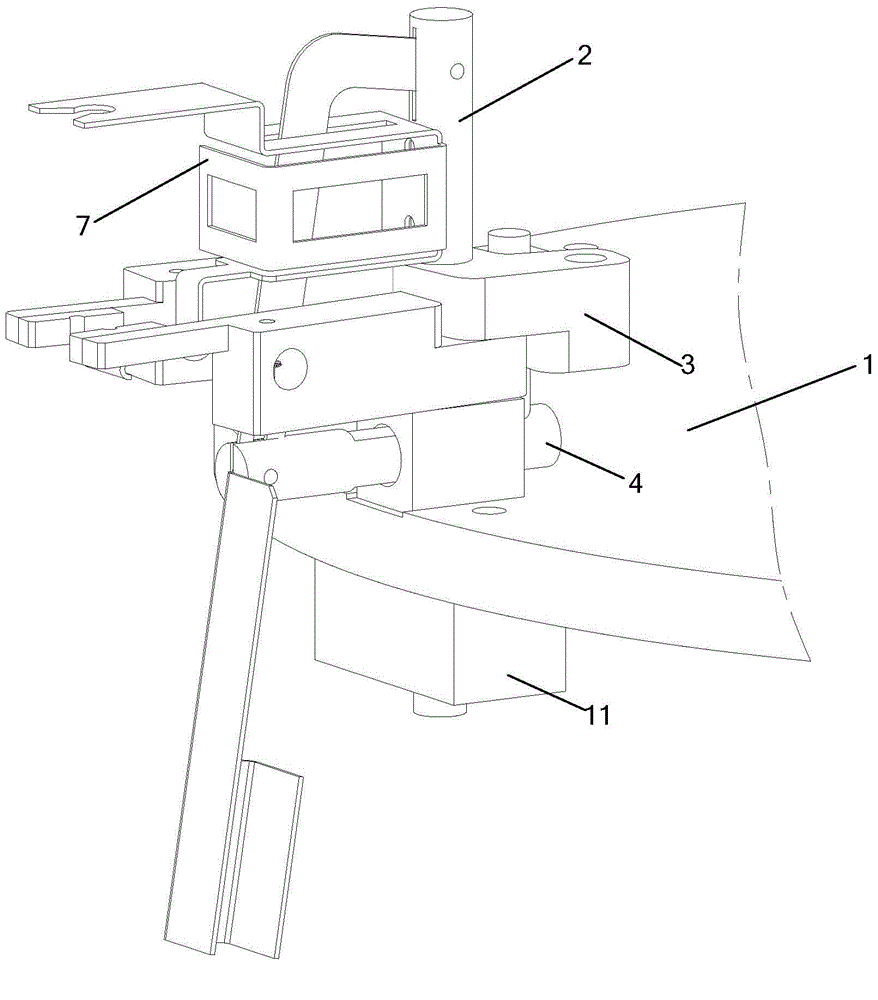

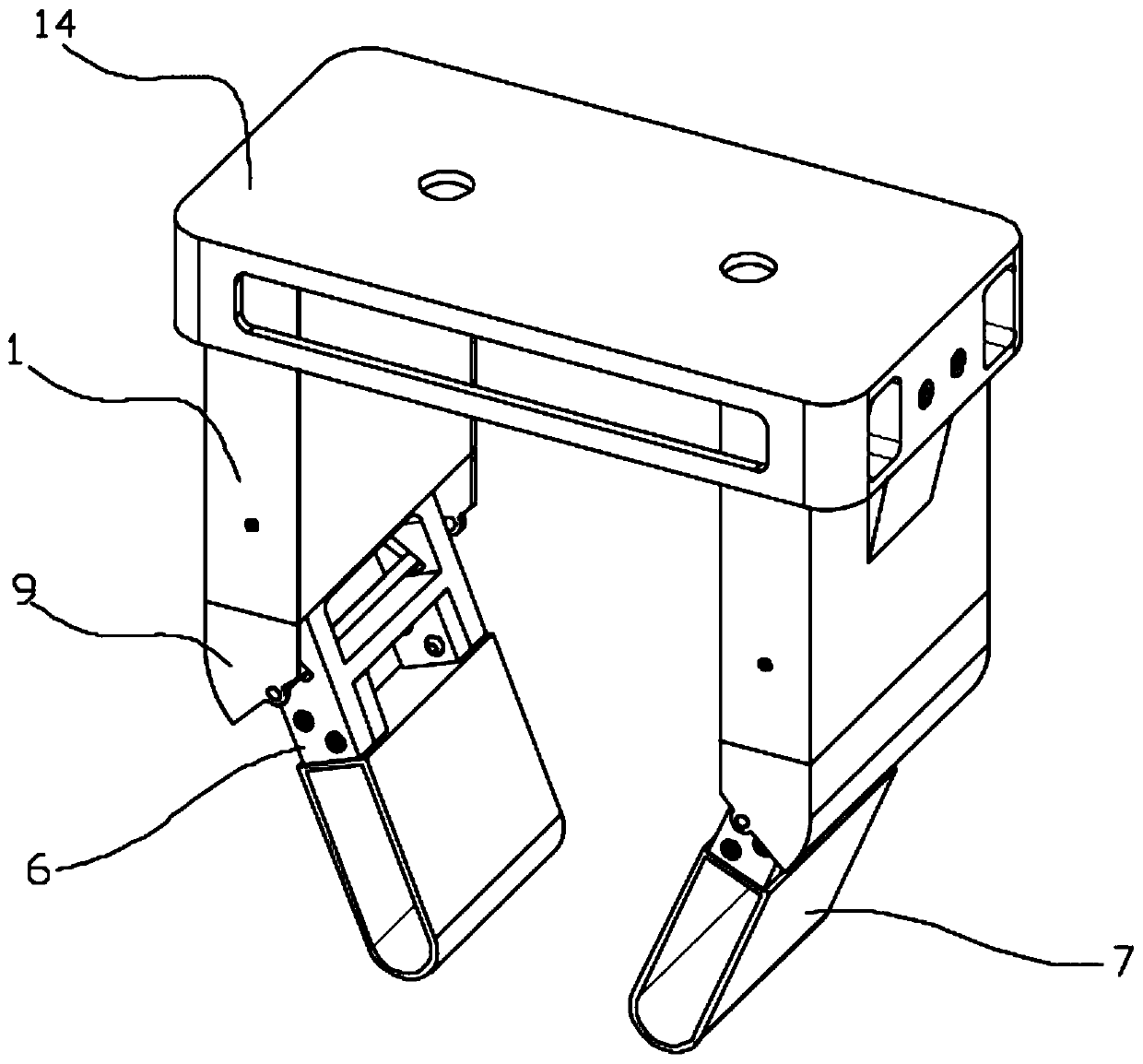

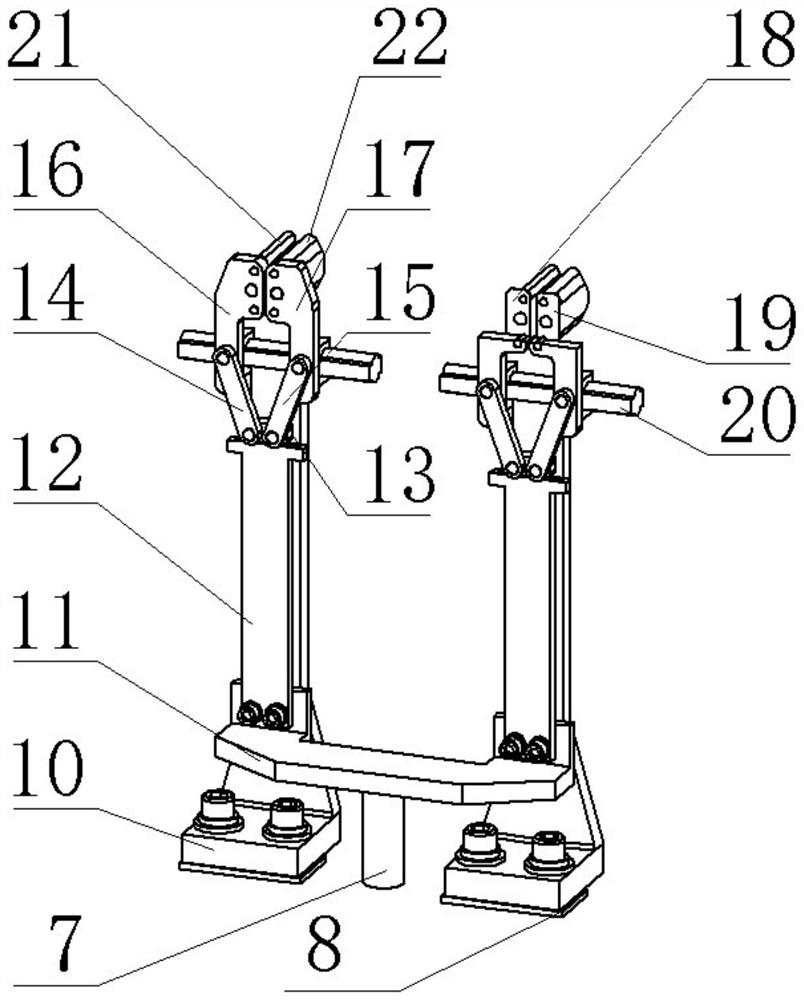

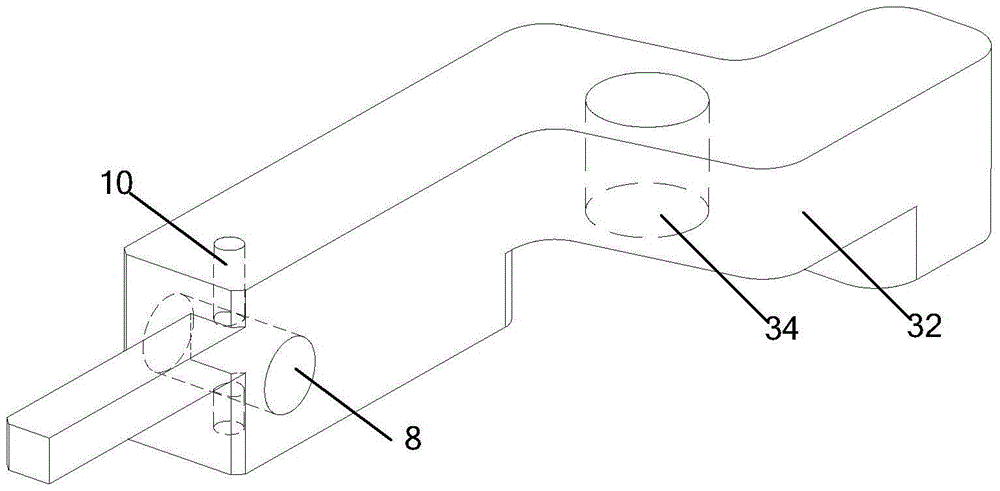

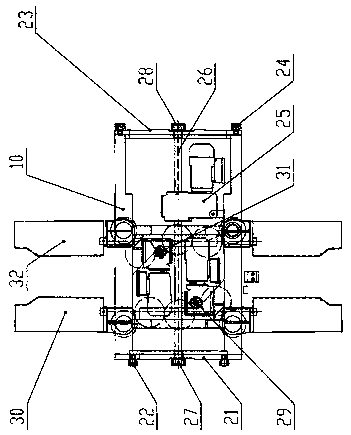

Degenerate-rank connecting rod end tooling of forging robot

The invention discloses degenerate-rank connecting rod end tooling of a forging robot The tooling is composed of a connecting flange frame, a driving mechanism, transmission mechanisms and clamping mechanisms, wherein the transmission mechanisms are completely the same and are symmetrically installed, and the clamping mechanisms are completely the same and are symmetrically installed. Supporting arms are symmetrically installed on the two sides of a piston rod of the driving mechanism, fixedly connected with an air cylinder body and used for supporting and fixing the transmission mechanisms and the clamping mechanisms. High-temperature heat insulation gaskets are clamped between the supporting arms and the air cylinder body and are made of composite heat insulation materials, and a wave-shaped heat insulation interlayer is arranged in the middle of each high-temperature heat insulation gasket. Finger sliding rails are installed at the tail ends of the supporting arms, clamping slidingrods do axial movement on the finger sliding rails under the force transmission action of the transmission structures and drive clamping fingers to make contact with and clamp connecting rod forge pieces, and the forge piece clamping work is completed. The degenerate-rank connecting rod end tooling of the forging robot is simple in structure, connecting rod forge pieces can be clamped in a double-piece mode at the same time, and the working efficiency is improved; and according to the internal expanding type clamping mode adopted based on the under-rank principle, clamping of connecting rod forge pieces of different sizes can be achieved, automatic centering can be achieved, and therefore the working stability of the tooling is improved, and the utilization rate of the tooling is increased.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

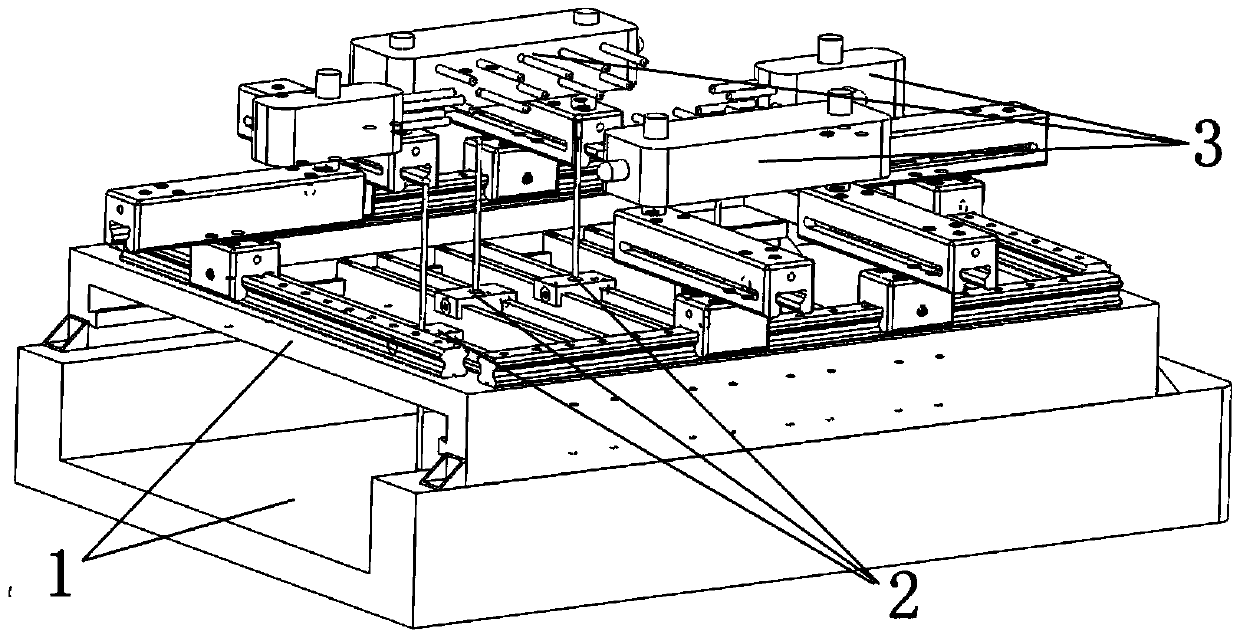

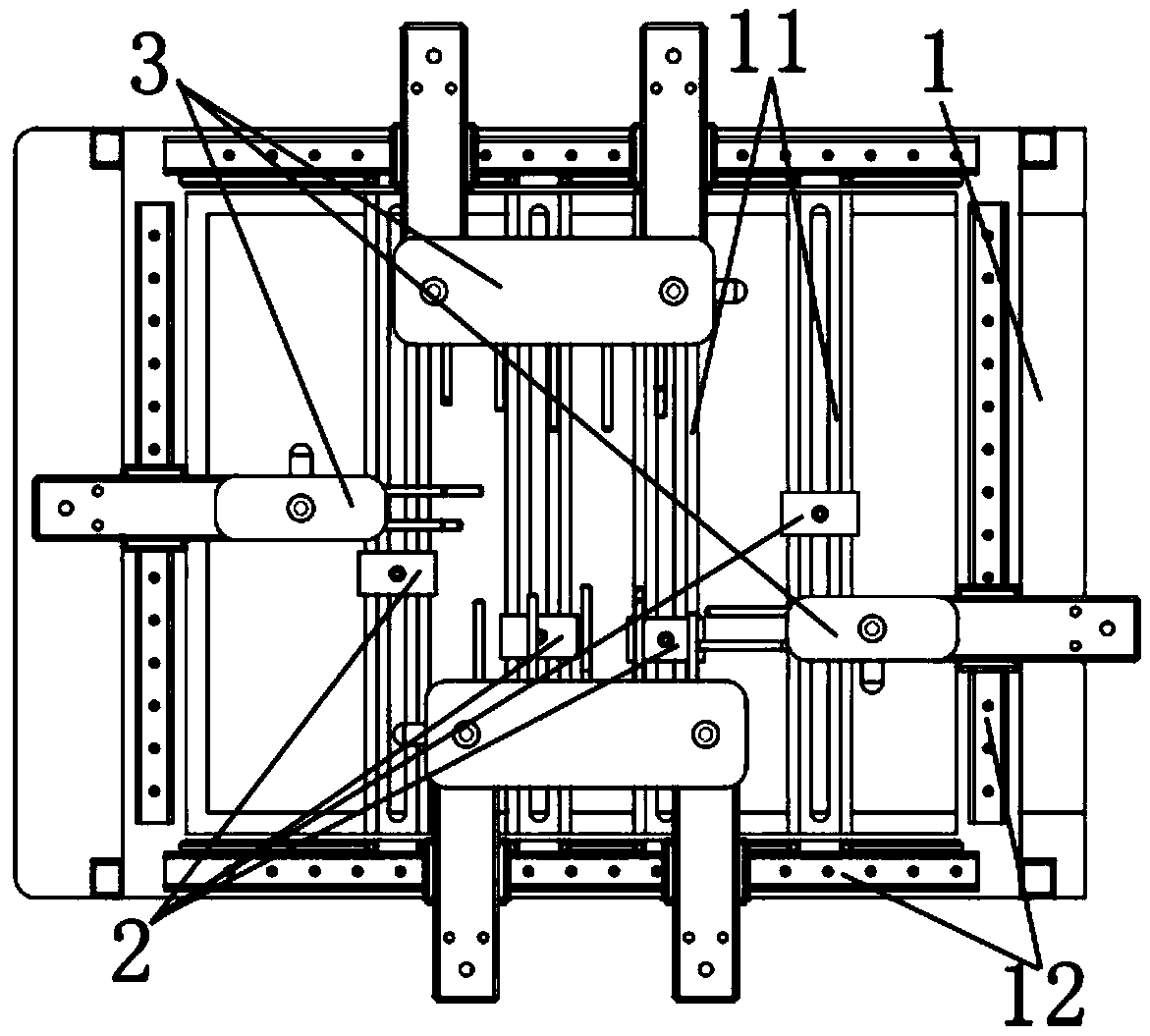

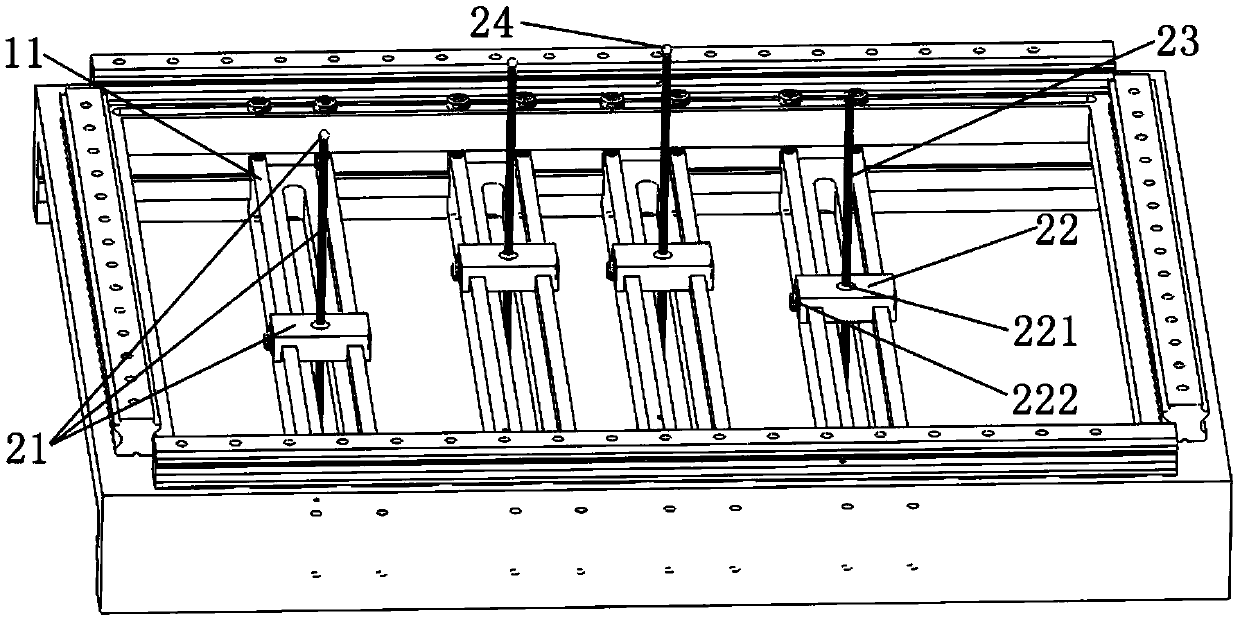

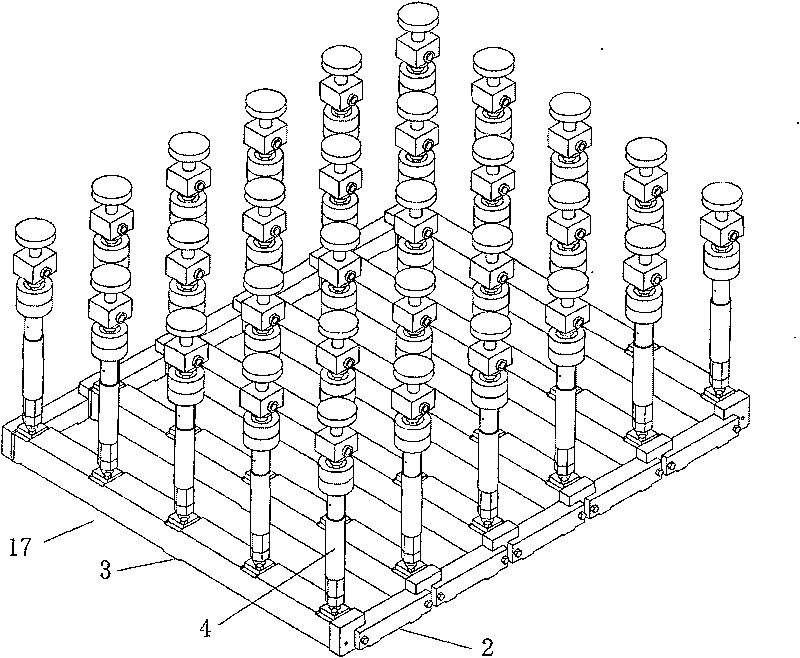

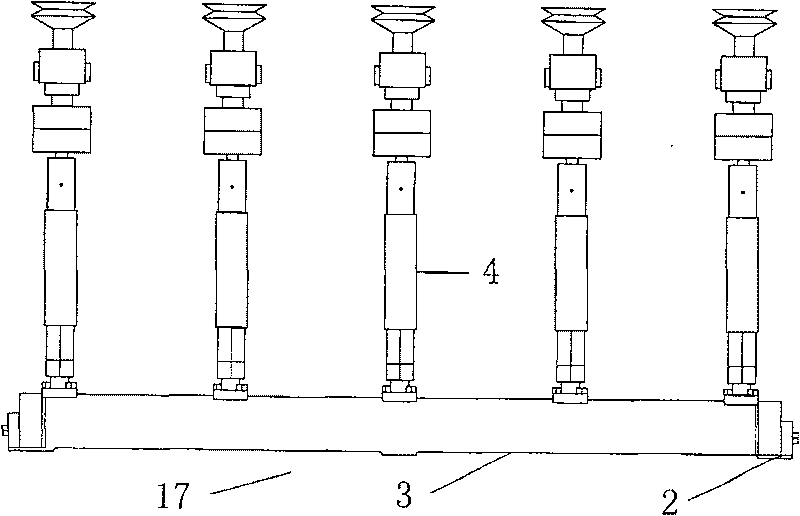

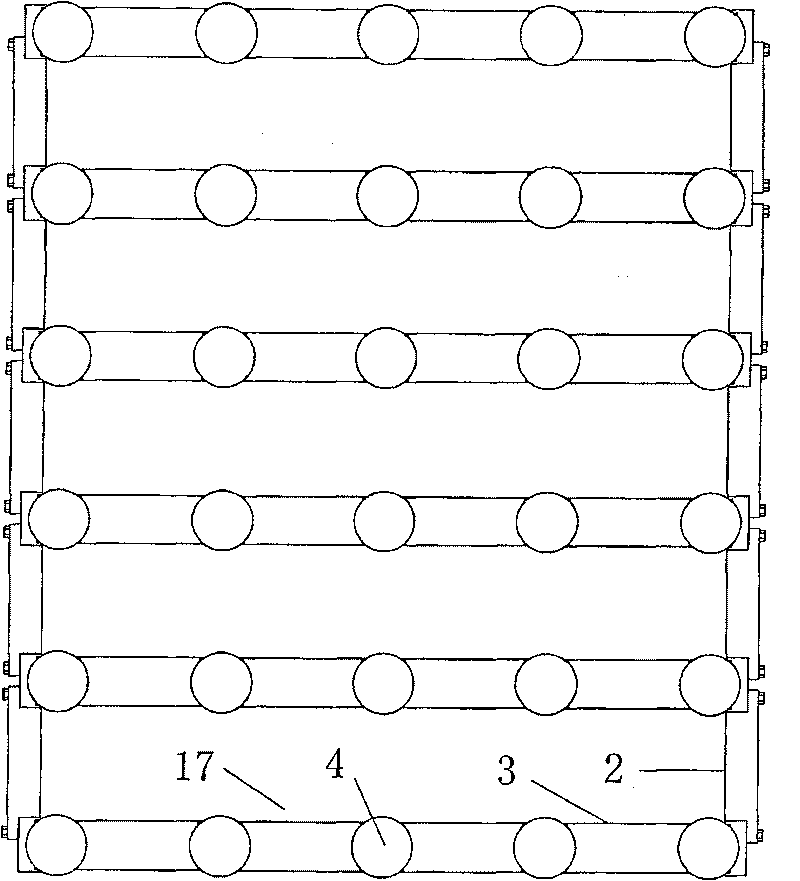

Combined type skin type surface trimming cut flexible multi-supporting equipment

InactiveCN101229598BReduce in quantityEasy to assembleWelding/cutting auxillary devicesWork holdersEngineeringMechanical engineering

The invention relates to a combination flexible multipoint support device with skin and trimming, which consists of a plurality of positioning plates and a plurality of adjusting components; the positioning plates is flat T-shape and a threaded hole and a matching surface are arranged on the positioning plates; the adjusting components consist of a basioccipital and a nail height adjusting unit; the adjusting components are put in parallel in an X direction and the interval between centers is fixed; the positioning plates are divided into two symmetrical rows in a Y direction; each positioningplate is connected with the same end of two adjacent adjusting components; the basioccipital shapes like a rectangular and locating holes, a threaded hole and a matching surface are arranged on the basioccipital; the locating holes are evenly distributed in a line on the basioccipital and the nail height adjusting unit is fixed in the locating holes; the nail height adjusting unit consists of a large double-screw bolt, a bolt, a locknut, a rotary nail, a replaceable nail sleeve, a joint cylinder, a universal device, a vacuum generator and a vacuum chuck. The device of the invention realizes flexible holding, reduces special clamping devices and frocks and has remarkable economic and time benefits.

Owner:BEIHANG UNIV

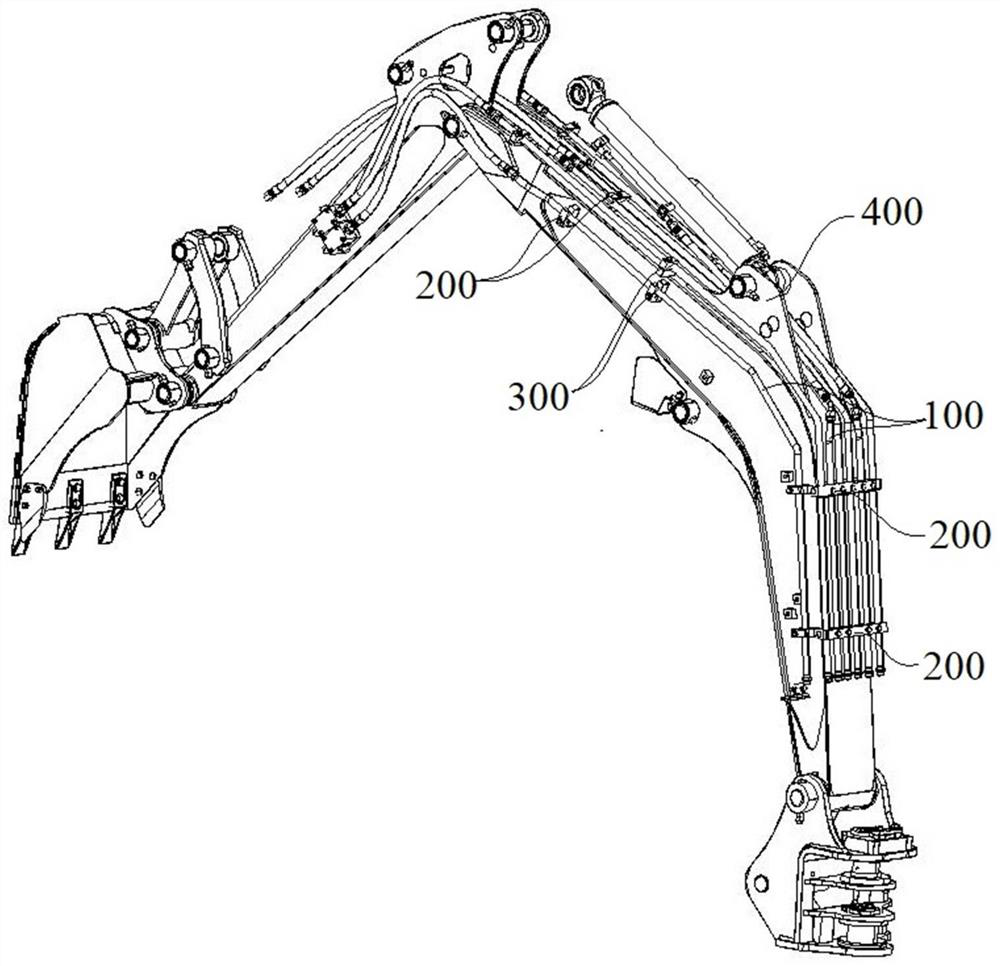

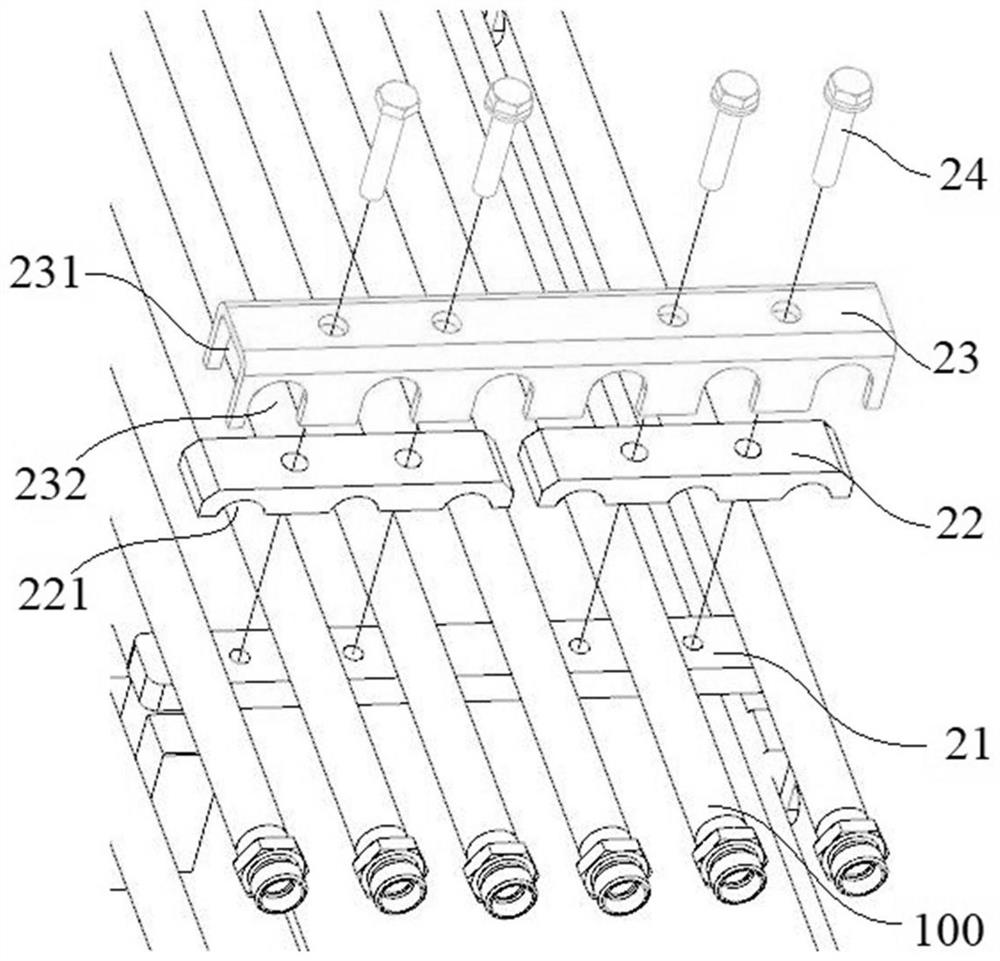

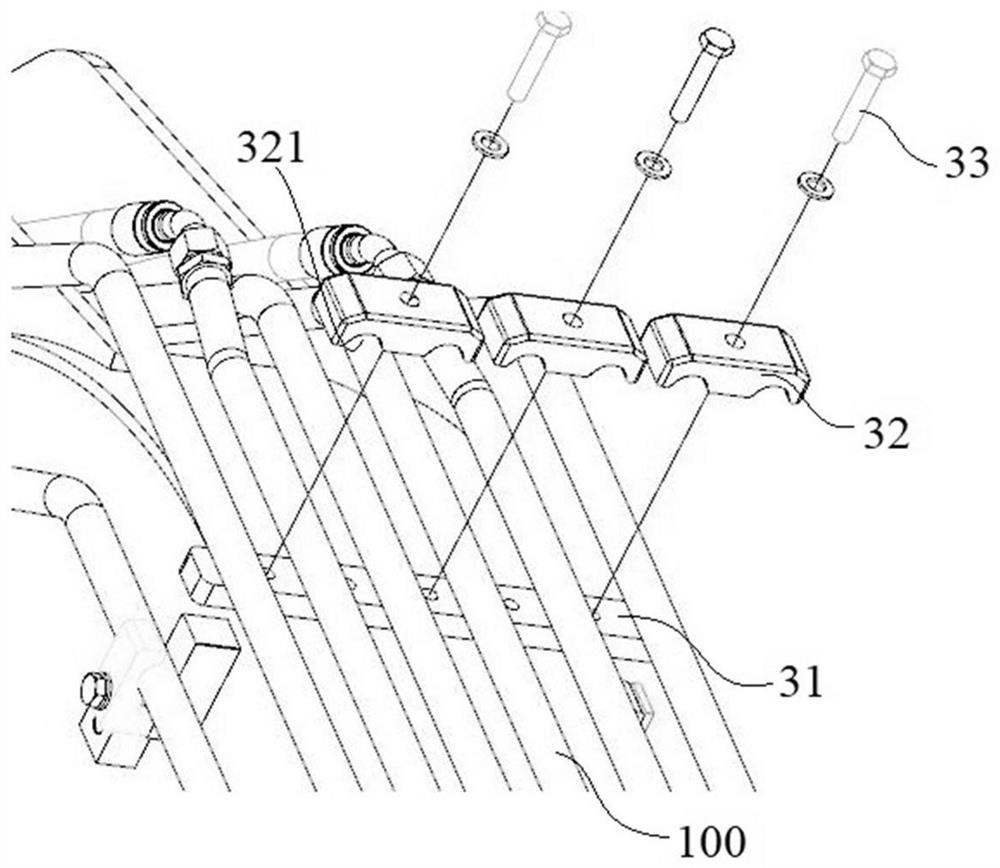

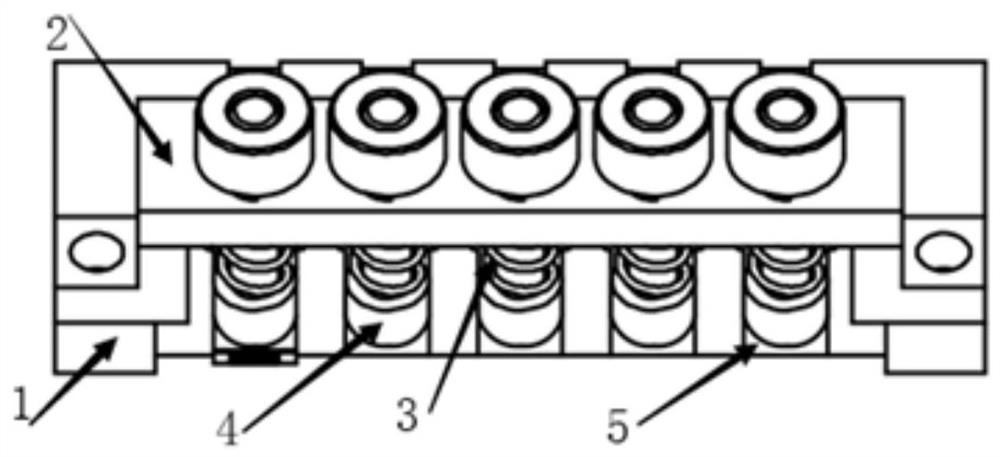

Cantilever crane, method for fixing hydraulic pipe on cantilever crane and operation machine

ActiveCN114809178AEffectively fixedReduce wearGeneral water supply conservationMechanical machines/dredgersControl engineeringMachine

The invention provides an arm support, a method for fixing a hydraulic pipe on the arm support and an operation machine. The arm support comprises at least one knuckle arm, a hard hydraulic pipe, a soft clamping assembly and a hard clamping assembly. The hard hydraulic pipe is arranged in the extending direction of the knuckle arm, and the soft clamping assembly is clamped to at least one of the first end and the second end of the hard hydraulic pipe. The hard clamping assembly is clamped between the first end and the second end of the hard hydraulic pipe; and the soft clamping assembly and the hard clamping assembly are respectively connected with the knuckle arm. According to the hydraulic pipe fixing device, the hydraulic pipe is effectively fixed on the basis of the soft clamping assembly and the hard clamping assembly, the problem that the hydraulic pipe is abraded and moves at the same time in the using process can be avoided to a certain degree, the fixing reliability of the hydraulic pipe is ensured, and the service life of the hydraulic pipe is prolonged.

Owner:SANY HEAVY MACHINERY

A kind of FA optical fiber end face coating fixture and using method thereof

ActiveCN112676062BPrecise positioningEnsure consistencySpraying apparatusStructural engineeringMechanical engineering

The invention discloses a FA optical fiber end surface coating fixture, which comprises a fixture base, a spring bracket, a compression spring and a pull rod. The fixture base is provided with a number of positioning grooves, and the bottom of the spring bracket is fixed on the fixture base. The spring bracket A plurality of through holes are arranged on the top, the pull rod passes through the through holes and the front end of the pull rod matches the positioning groove, and the compression spring is sleeved on the pull rod. The invention also discloses a method for using the FA optical fiber end surface coating fixture. The invention replaces the existing outdated coating method, improves the coating quality and improves the efficiency.

Owner:UNION OPTIC

A flexible drive fixture for rotating workpieces

ActiveCN110052871BRealize flexible clampingHigh structural precisionPositioning apparatusMetal-working holdersMachined surfaceEngineering

Owner:廊坊市钦纵机电产品制造有限公司

Flexible Gripper

ActiveCN104786230BRealize flexible clampingAvoid Rigid Clamping DamageGripping headsHorticultureEngineeringMechanical engineering

The invention provides a flexible clamping claw which comprises a base, a perpendicular fixed shaft penetrating through the base, a clamping device arranged on the fixed shaft in a sleeving mode, and a push device for opening and closing the clamping device. The clamping device comprises a left clamping body, a right clamping body and a tension spring, wherein the tail portion of the left clamping body and the tail portion of the right clamping body are arranged on the fixed shaft in a crossed and sleeving mode and rotate in the axial direction of the fixed shaft, and the two ends of the tension spring are fixedly connected with the arm portion of the left clamping body and the arm portion of the right clamping body respectively. The push device comprises a push rod and a limiting rod, wherein a slide groove which is through and extends in the length direction of the push rod is formed in the push rod, and the fixed shaft perpendicularly penetrates through the slide groove. The first end of the push rod is fixedly provided with the limiting rod which is parallel to the fixed shaft, the limiting rod is clamped in a space outside the crossed point of the tail portion of the left clamping body and the tail portion of the right clamping body, the slide groove is used for making the push rod reciprocate within the stroke range of the slide groove, the limiting rod is separated from or clamped in the crossed space of the tail portion of the left clamping body and the tail portion of the right clamping body, and therefore the left clamping body and the right clamping body can be opened and closed.

Owner:INTELLIGENT EQUIP TECH RES CENT OF BEIJING ACAD OF AGRI & FORESTRY

Flexible clamping and holding arm of intelligent transportation vehicle

PendingCN111485753ARealize flexible clampingAvoid damageParkingsStructural engineeringControl theory

Owner:SHANXI ORIENTAL MATERIAL HANDLING +1

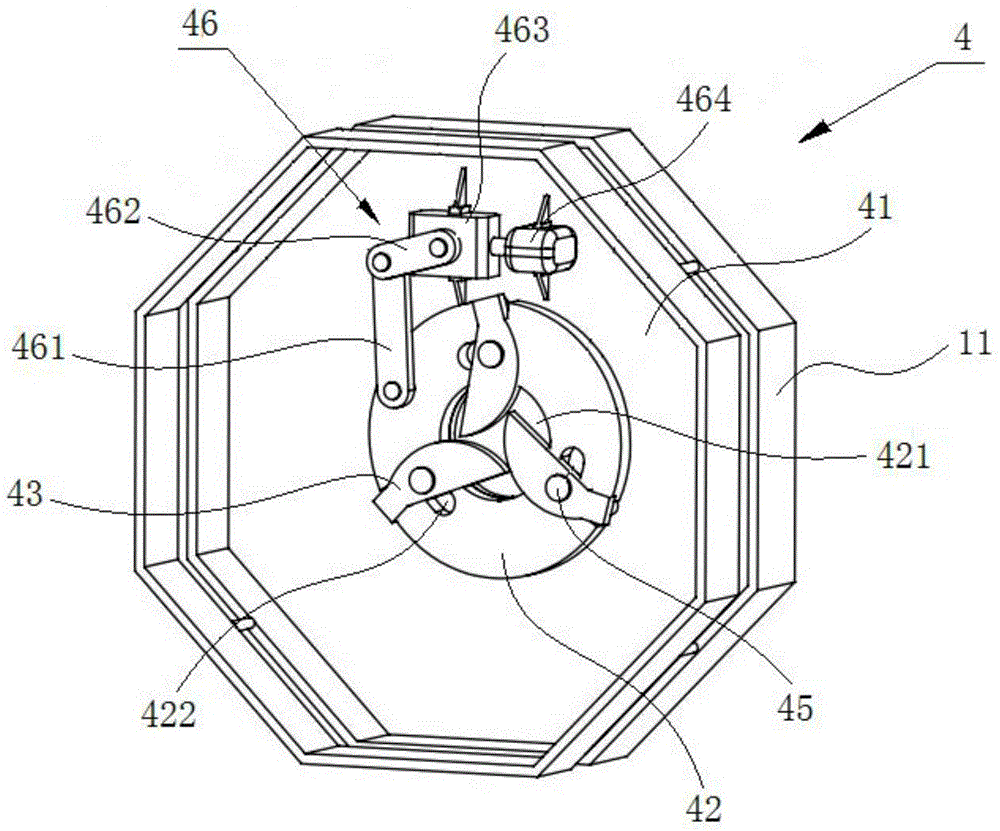

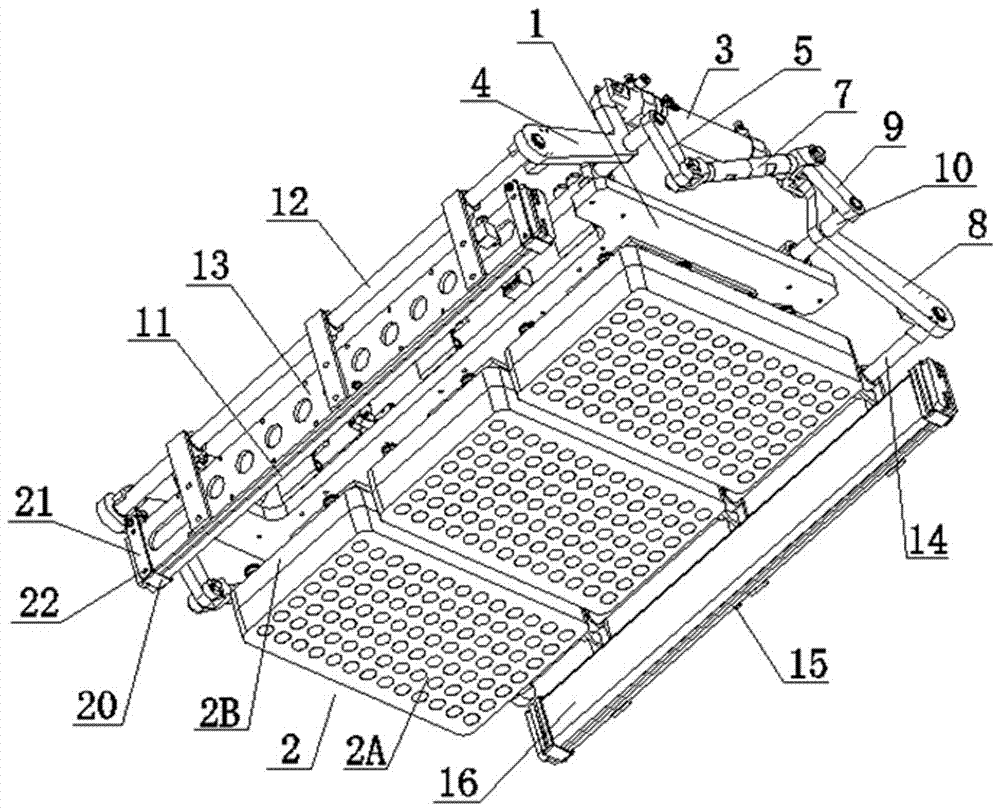

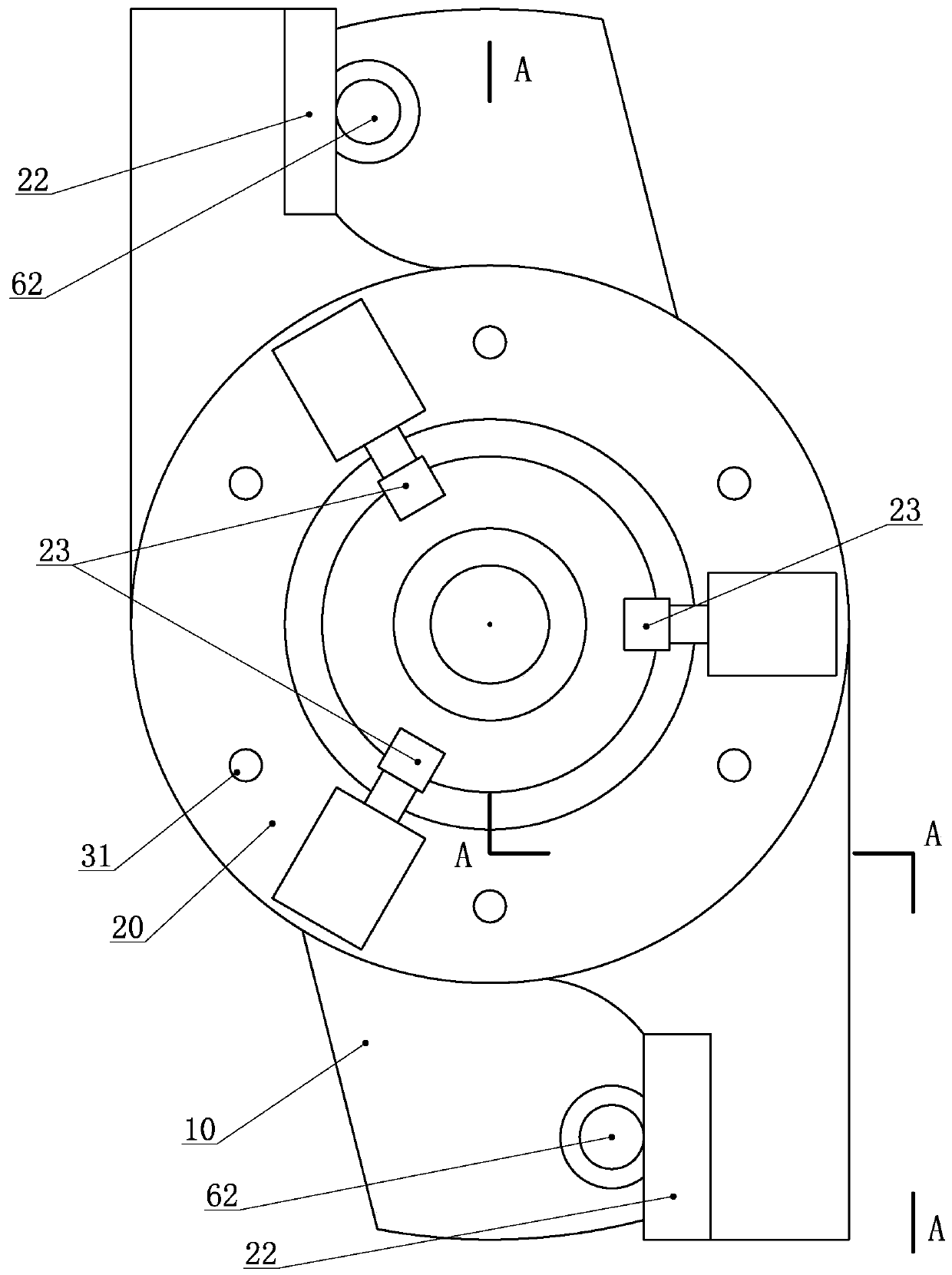

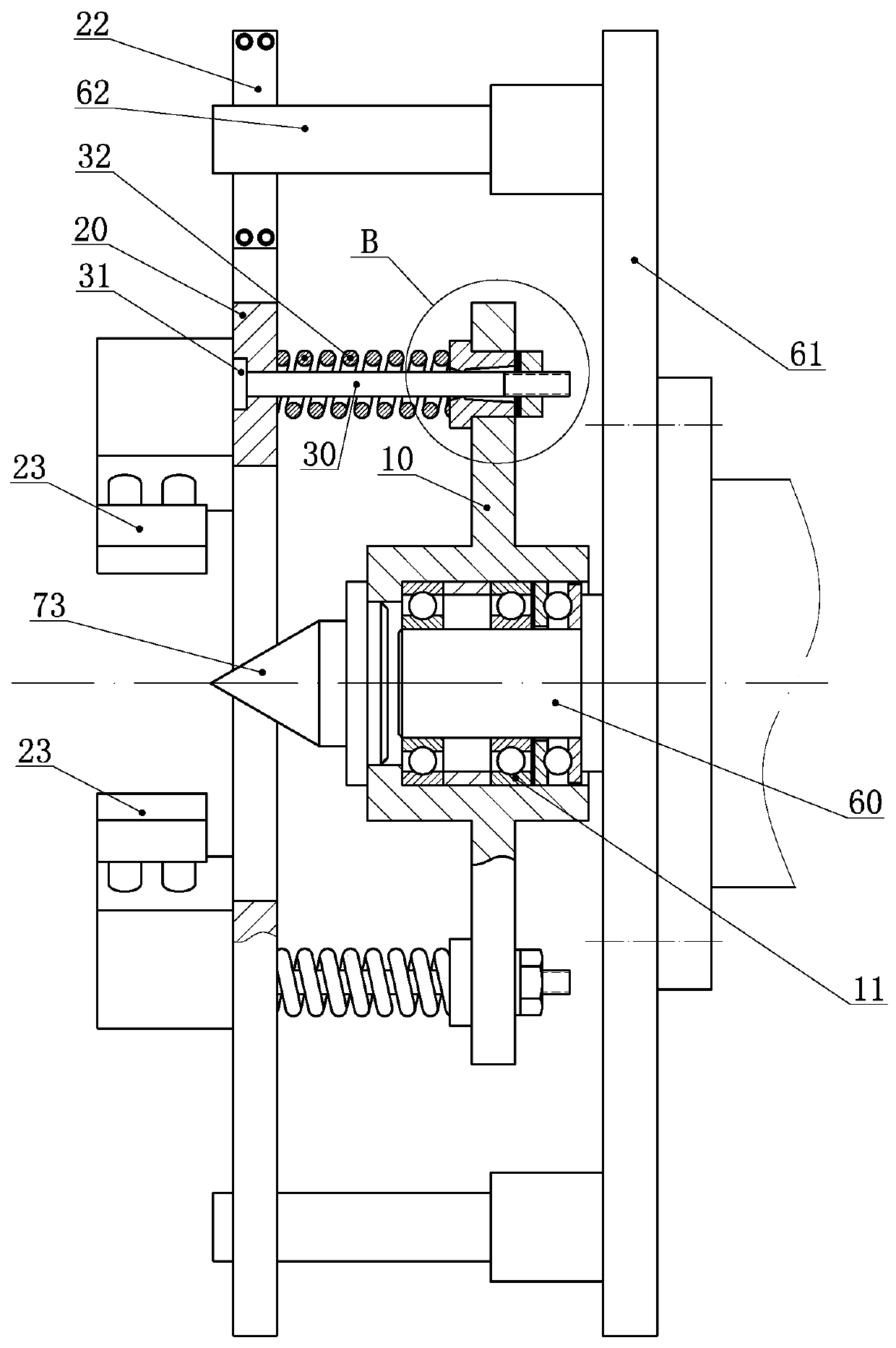

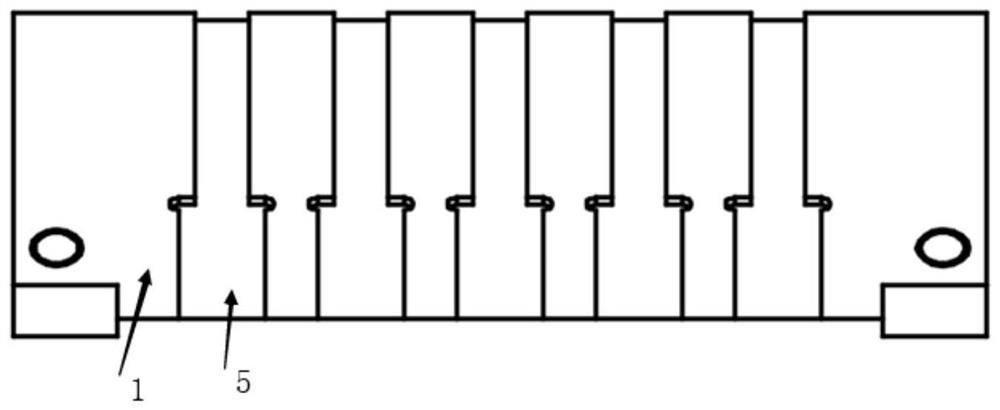

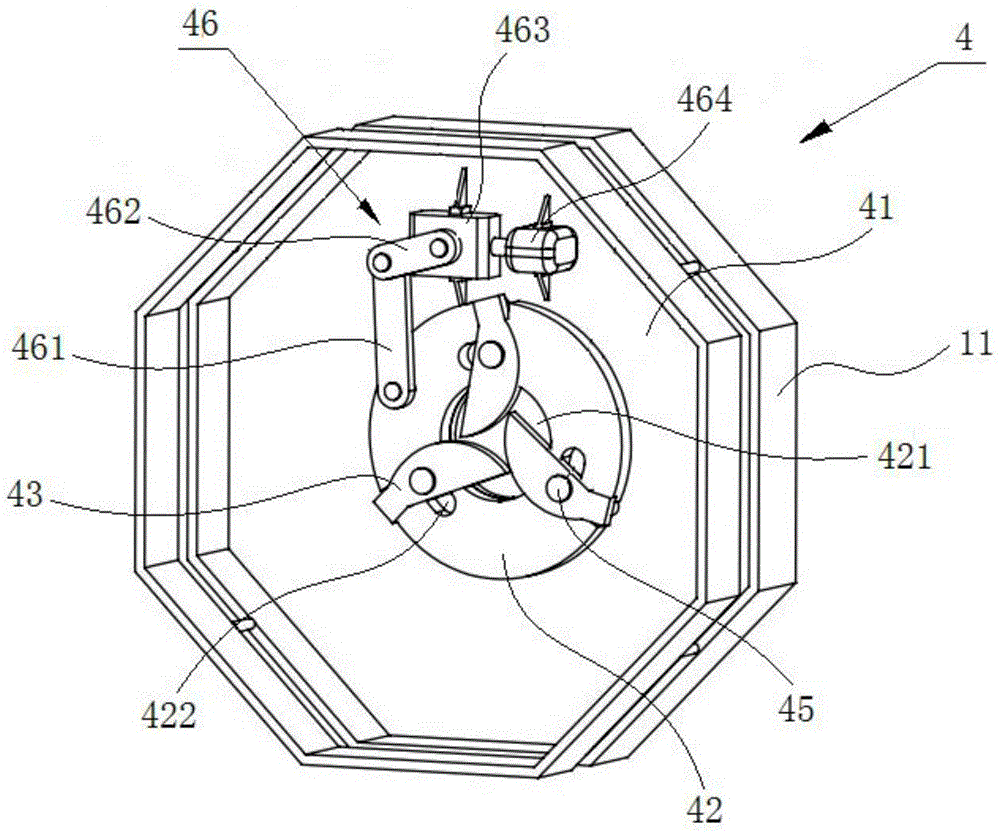

Disc Flexible Clamping Device

ActiveCN104798559BStable clampingThe clamping piece is stable for clamping rod-shaped cropsCuttersEngineeringTorsion spring

Owner:GUANGXI UNIV

Sugarcane cutting device based on seed bud image recognition

ActiveCN104798614BHigh degree of automationReduce labor intensityCuttersCutting implementsControl systemIdentification device

The invention discloses a sugarcane cutter device based on seed bud image identification. The device comprises a rack, a cutting device, a clamping device and an image identification device, wherein the rack is provided with a conveying device; a cutting box is arranged on the front end of the conveying device on the rack; the cutting device is arranged in the cutting box and is used for cutting off sugarcanes; the clamping device is arranged in the cutting box, is located behind the cutting device, and is used for clamping or releasing the sugarcanes; the image identification device is arranged in the cutting box and is capable of identifying seed buds on the sugarcanes through image forming; the number of the seed buds contained by the sugarcanes passing the cutting device is counted. According to the invention, the seed buds of the sugarcanes are counted by the image forming, a control system can control the cutting device to cut off the sugarcanes by virtue of the number of the seed buds, each section of sugarcanes can contain a proper number of seed buds, the degree of automation is high, the labor intensity is reduced, and the production efficiency is improved.

Owner:GUANGXI UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com