Form and position measurement flexible clamp and form and position measurement method for columnar part

A technology of flexible fixtures and parts, applied in the field of shape and position measurement fixtures, can solve the problems of unusable clamping and failure to ensure the shape and position of parts, etc., and achieve the effect of improving clamping efficiency, increasing contact surface, and ensuring no occlusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

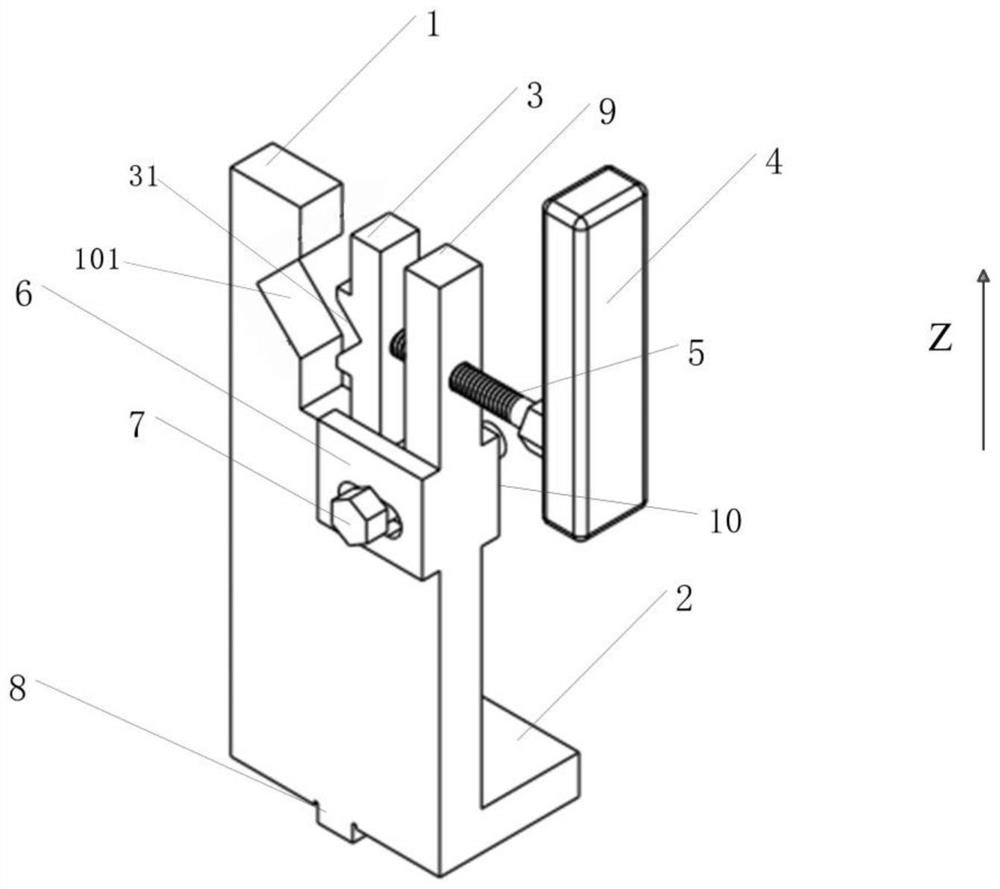

[0034] like figure 1 , 2 As shown in the figure, a flexible fixture for measuring the shape and position of a columnar part includes a fixed base 2, and at least one pair of splints is arranged on the fixed base 2. The pair of splints includes a fixed splint 1 and a corresponding movable splint 3. The fixed splint 1 A first V-shaped groove 101 is provided, and the movable splint 3 is provided with a second V-shaped groove 31 opposite to the first V-shaped groove 101 . The movable splint 3 is connected to a propulsion mechanism, and the propulsion mechanism drives the movable splint 3 to move. The clamping method is a unilateral movable adjustment method, that is, the fixed splint 1 is fixed on the fixed seat 2 as a fixed end, and the movable splint 3 can be adjusted according to the section size of the columnar part. The double-sided movable clamping can reduce the repeated positioning of precision measuring equipment and improve the clamping efficiency.

[0035] In a prefer...

Embodiment 3

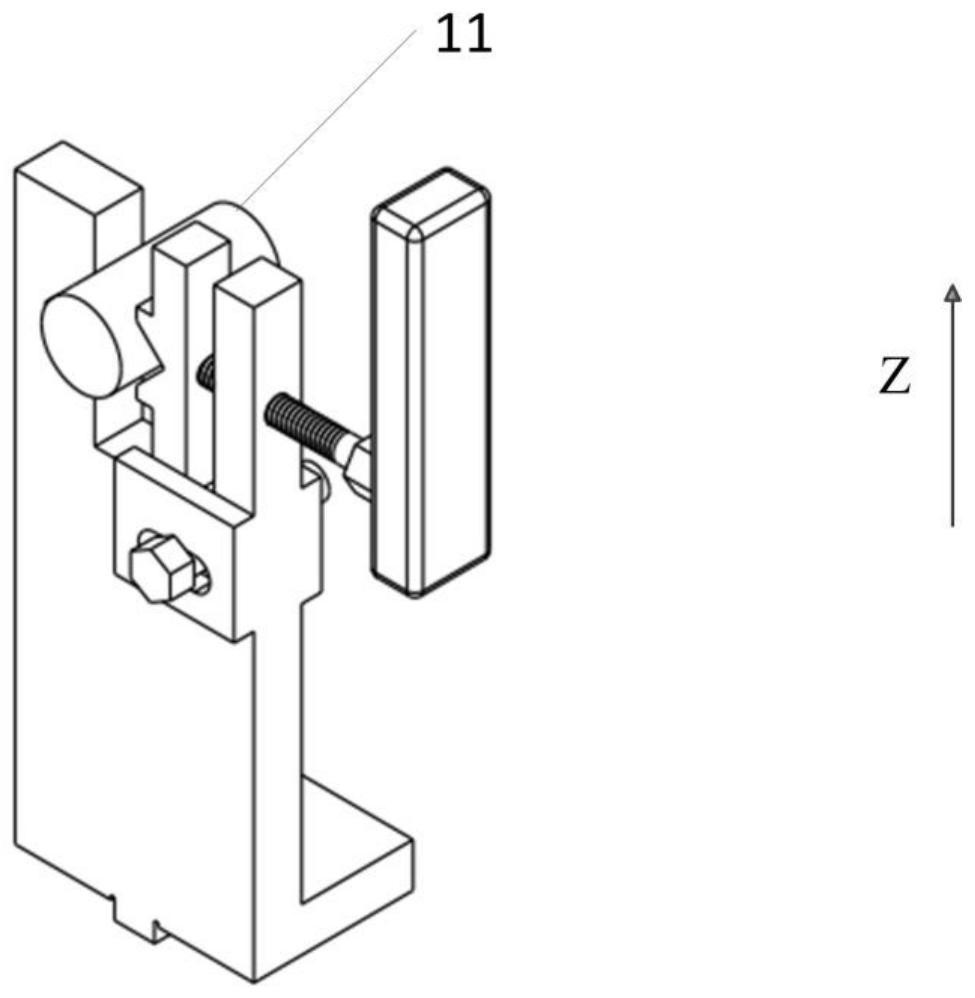

[0049] Specifically, when the part to be measured 11 needs to be fixed, firstly, the part is matched with the groove of the fixed splint 1 to constrain the degree of freedom of rotation and movement of the part to be measured 11 along the X axis; at the same time, the handle 24 is rotated to fix it on The No. 1 screw 5 on the handle 24 passes through the thread of the fixed push block 9, and pushes the movable splint 2 to move along the track between the limit block 6 and the limit block 10 until the part 11 is fixed and clamped, which further constrains the part to be tested 11 Degree of freedom of rotation and movement along the Y axis; at this time, the part to be tested 11 is in contact with the fixture on all four sides, that is, the upper surface, the lower surface of the fixed splint 1, the upper surface (or upper side) and the lower surface of the movable splint 3 (or the lower side) is in contact with the cylindrical part 11 to be measured, the movement degree of freed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com