Single-row self-propelled scallion combine harvester

A combine harvester and self-propelled technology, which is applied to excavator harvesters, harvesters, excavators, etc., can solve the problems of inability to meet the requirements of onion farmers, green onions are easily broken, and onion roots are entangled and blocked, so as to reduce manual work. Strength, easy bundling and collection, stable power output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to clearly illustrate the technical features of the solution, the solution will be described below through specific implementation modes.

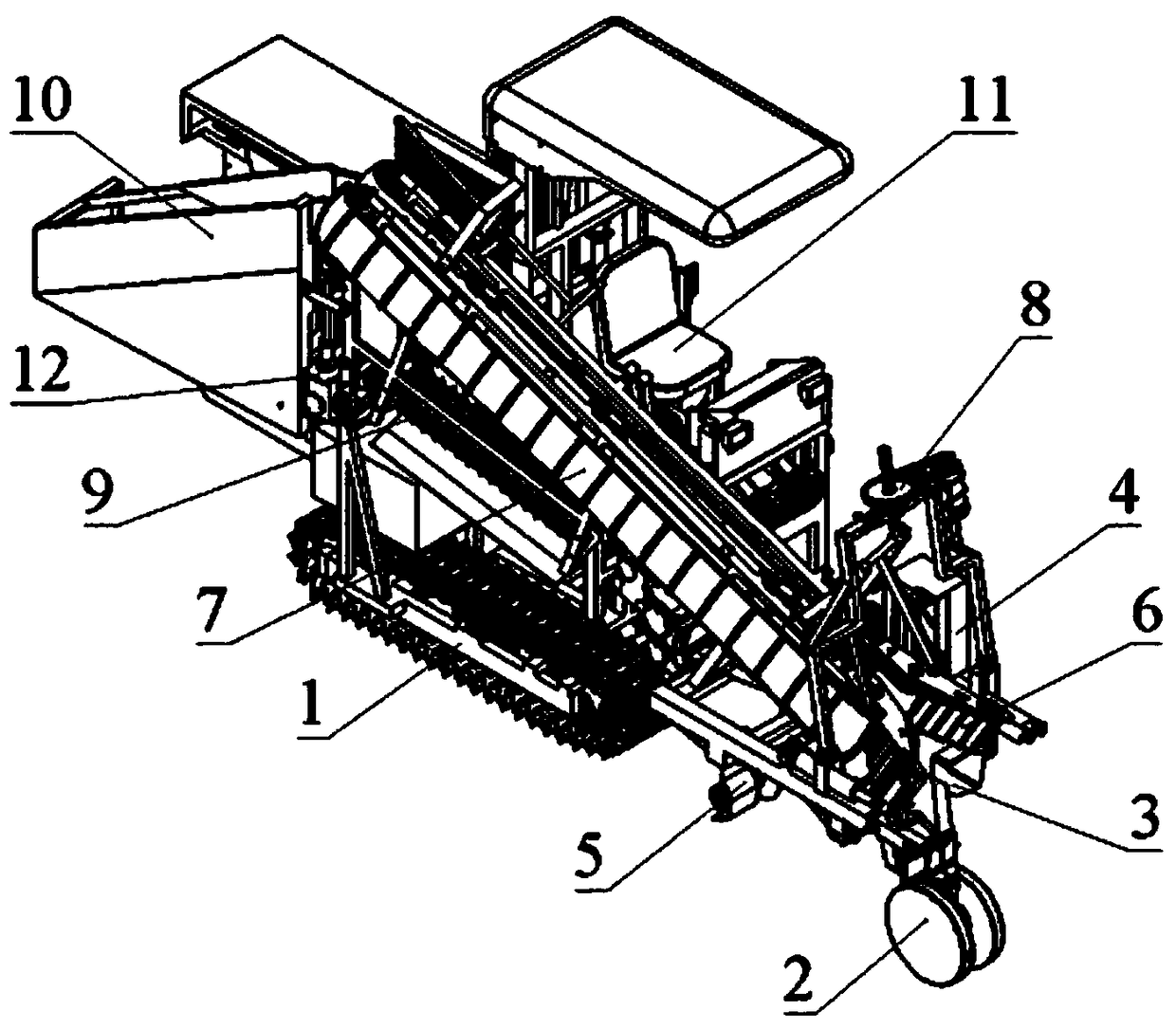

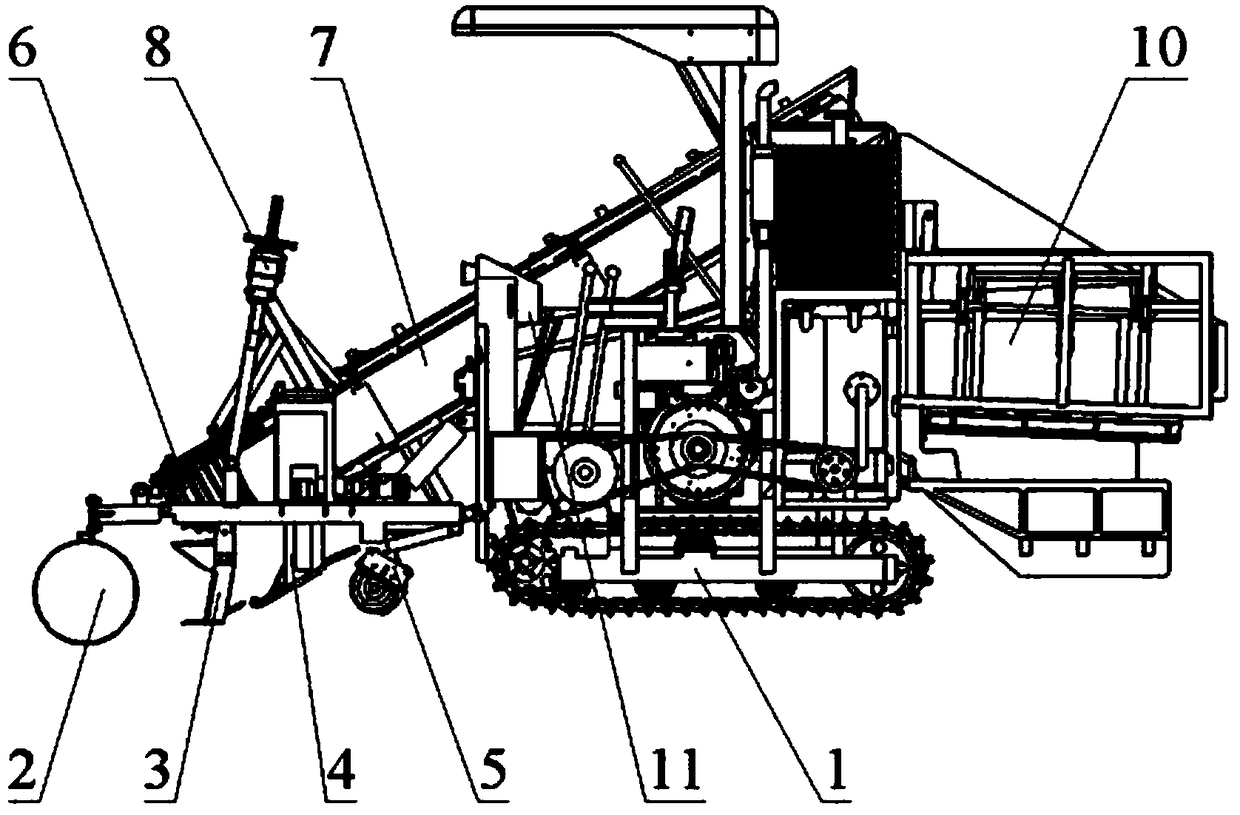

[0051] Such as figure 1 A single-row self-propelled green onion combine harvester is shown, including a chassis 1 equipped with a power system, and an excavating device 3 installed on the chassis general frame 101, a clamping conveying device 7 and a collector located at the discharge end of the clamping conveying device. Unloading device 10.

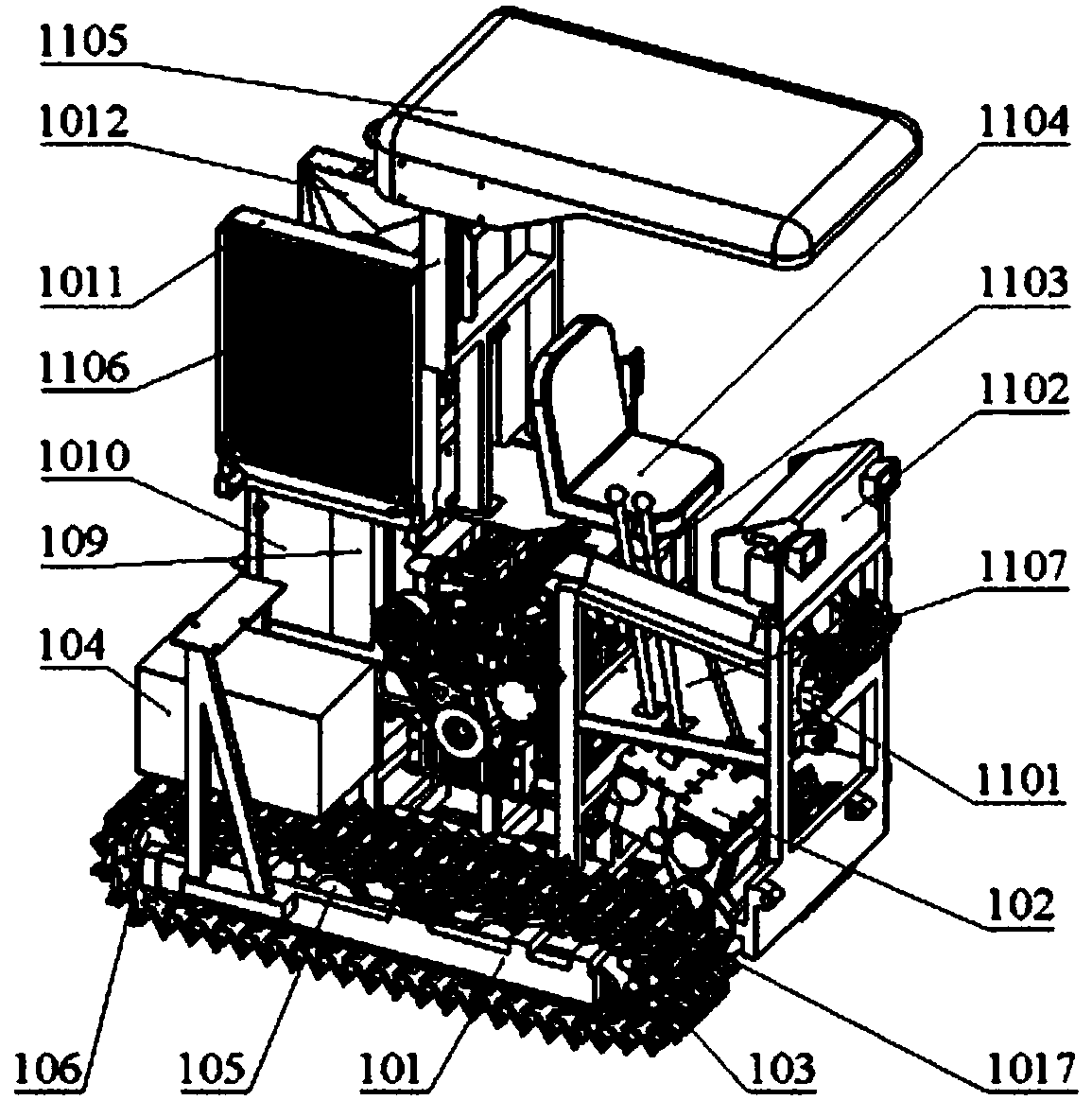

[0052] Chassis 1 includes general frame 101, gearbox 102, driving wheels 103, supporting wheels 104, guide wheels 105, diesel engine 106, gear pump 107, hydraulic oil pipe 108, diesel tank 109, hydraulic oil tank 1010, exhaust fan 1011, heat dissipation Device 1012, battery 1013, air filter 1014, exhaust pipe 1015, counterweight box 1016, crawler belt 1017. The main frame 101 is the structural frame of the whole machine to support each component; the gearbox 102 is a special gearbo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com