Self-propelled dried nut picking harvester

A self-propelled, harvester technology, used in harvesters, agricultural machinery and implements, applications, etc., can solve the problems of increased manual harvesting costs, high labor intensity, and low efficiency of harvesting methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

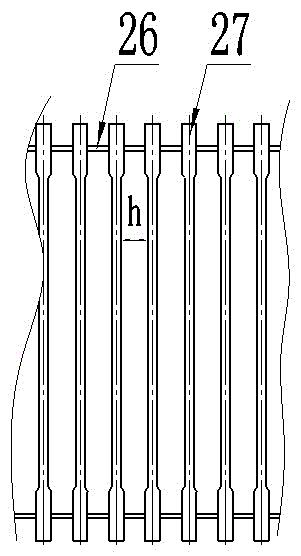

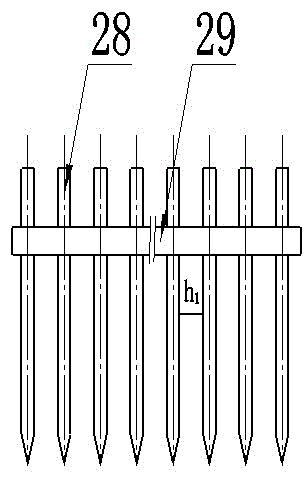

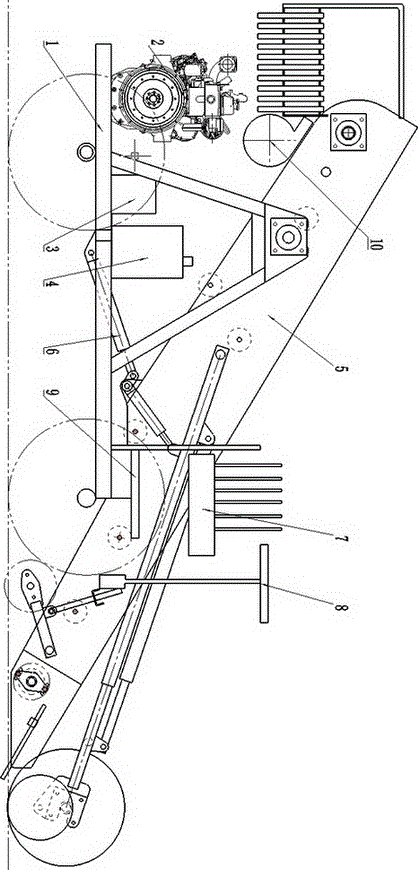

[0020] refer to Figure 1~4 , Self-propelled dry nut picking and harvesting machine, including 1 set of walking chassis, 1 set of engine and hydraulic pump, 1 set of 12V starting battery, 1 piece of hydraulic oil tank, 1 set of picking and conveying system, 1 pair of lifting cylinders for picking and conveying system, hydraulic valve 1 set of group, 1 set of steering wheel, 1 set of seat, 1 set of cleaning fan. The pick-up conveying system includes 1 piece of conveyor frame, 1 set of pick-up conveyor chain with driven sprocket set, 1 set of pick-up conveyor chain with driving sprocket set, 1 set of depth-limiting sticks, and 1 set of left and right depth-limiting stick adjustment mechanisms , 1 set of pick-up grating for front entry, 12 supporting sprockets, 1 set of pick-up and cleaning rollers, 1 pair of pick-up and sweep roller depth-limiting wheels, 1 set of pick-up and sweep roller telescopic rods on the left and right, 1 pair of pick-up and sweep roller telescopic oil cy...

Embodiment 2

[0022] Compared with Embodiment 1, the difference of this embodiment is that the gap between the two adjacent chain connecting rods of the self-propelled dry nut picking and harvesting machine is 30mm, and the angle between the picking and conveying chain belt and the ground is 30° when it is working. , the angle between the entry rod and the ground is 25°.

Embodiment 3

[0024] Compared with Embodiment 1, the difference of this embodiment is that the gap between two adjacent soil entry poles of the self-propelled dry nut picking and harvesting machine is 0, that is, it adopts the form of a whole board.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com